Salt water disposal is a large and often overlooked area of the oil and gas industry.

There are approximately 1 million producing oil and gas wells in United States, and altogether they produce 58 million barrels of water each day—twice the amount that flows over Niagara Falls in 24 hours. This is why the discussion about bringing a well online to produce oil and gas begins with water.

Where Do Oil and Gas Producers Get Water?

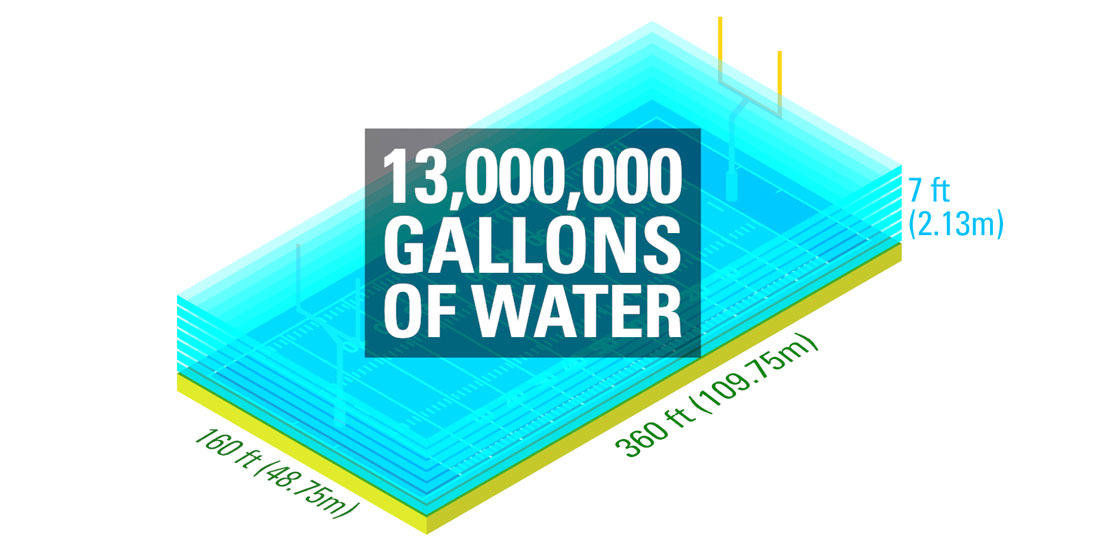

Altogether, it takes approximately 13 million gallons of water to drill and fracture a well. Producers must figure out where all this water will come from and how to get it to the wellhead.

Some companies use freshwater sources from a pond or river and pumped through flexible hoses to their well site.

Because of the large volumes needed in this process, more and more companies are using recycled water from previously drilled, nearby wells.

In this process, storage ponds are dug for the water, where it is treated, processed, and eventually sent back to the well pad to be re-used in the drilling and completion processes.

How is Water Used in Oil and Gas Production?

Drilling

In the drilling process, water is injected into the drill string and used to cool the drill bit as it bores into the earth. It is also used to bring rock cuttings and any other debris back up to the surface. This water is then referred to as drilling mud and can be reused over and over for the drilling process.

Fracturing

A second need for water in production is for fracturing a well. Water is an essential part of the completion process as it carries the proppant or sand down into the well and helps keep the fractures that are created open.

What is Water Management in Oil and Gas?

Water management in oil and gas is creating processes to handle and direct this water where you need it to go.

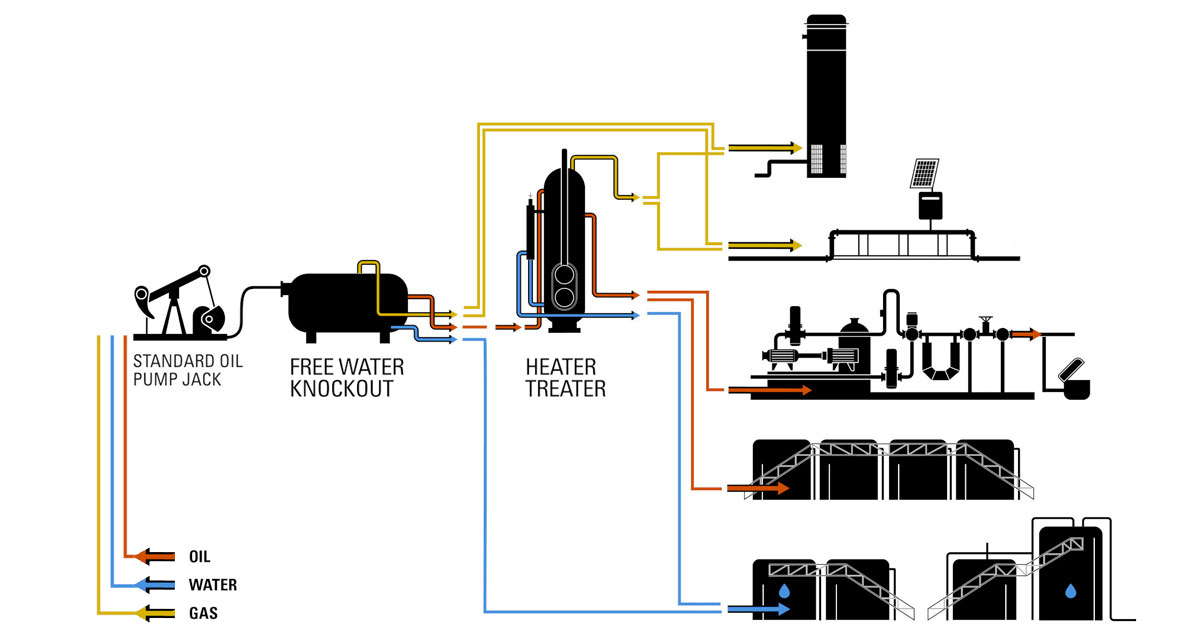

This illustration below shows the general process of oil, gas, and water separation.

Produced water is a byproduct during the extraction of oil and natural gas. It comes out of the wellhead and is mixed with oil and gas.

It then goes through various separation vessels where the water, oil and gas are separated from each other. The water leaves the vessel and travels to storage while the oil and gas goes through one or two more stages of separation.

Producers have two options for the produced water: dispose of it or treat it for re-use.

What is a Salt Water Disposal Well?

As the injected water comes up in the production fluid, commonly referred to as “flowback water” or "oil well water," companies must then figure out what to do with it: dispose of it or recycle it.

A salt water disposal well is a well used to inject the salt water from oil and gas wells back into the formation.

Drive down a road in the Permian Basin, STACK, or any other oil and gas producing area, and you’re sure to spot a disposal well, also referred to as a salt water injection well.

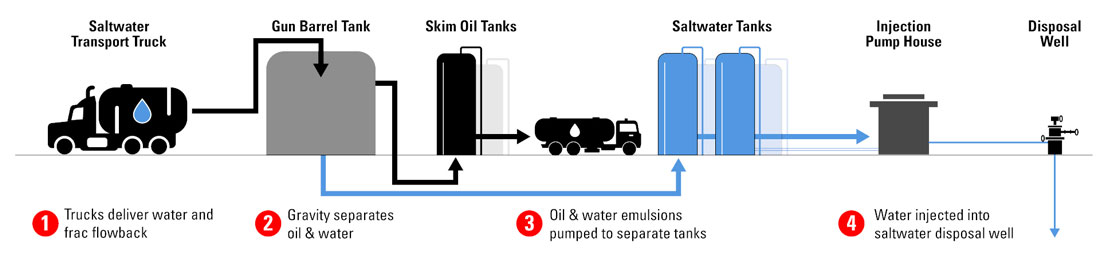

Trucks transport the salt water from a producing well to the unloading facility on these sites, where the water is pumped to a tank battery.

There, what oil remains in the water—referred to as “skim oil”—is separated into a holding tank. The water will settle in saltwater tanks, and eventually be pumped down the disposal well.

The oil will be sold and trucked away from the site, while the water will be injected into the formation. This process is also referred to as SWD in oil and gas.

Corrosion in Salt Water Injection Wells

Salt is a very corrosive element. You know this if you live near the ocean or in a region where the roads are regularly salted during winter.

While salt itself does not cause metal to rust, it accelerates the rusting process because electrons move more easily in salt water than they do in pure water.

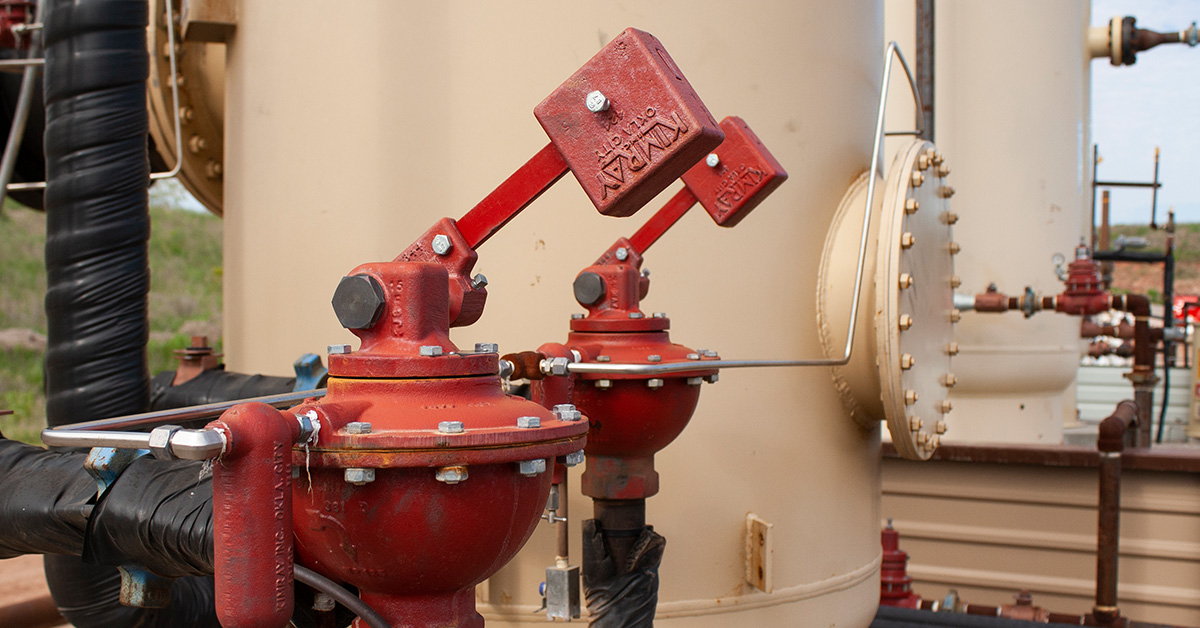

This means the material in your salt water injection valves, vessels and other equipment must be durable.

The Best Valve for Salt Water Disposal

A Weight Operated Dump Valve (previously called a treater valve) is a throttling valve that uses a weight to hold liquid level in saltwater disposal systems.

On a saltwater disposal well, the Weight Operated Dump Valve can regulate the fluid in both the oil tanks and water tanks.

It can be outfitted with a metals and elastomers designed specifically to handle corrosive salt water. We also offer a variety valve coatings to limit corrosion and erosion.