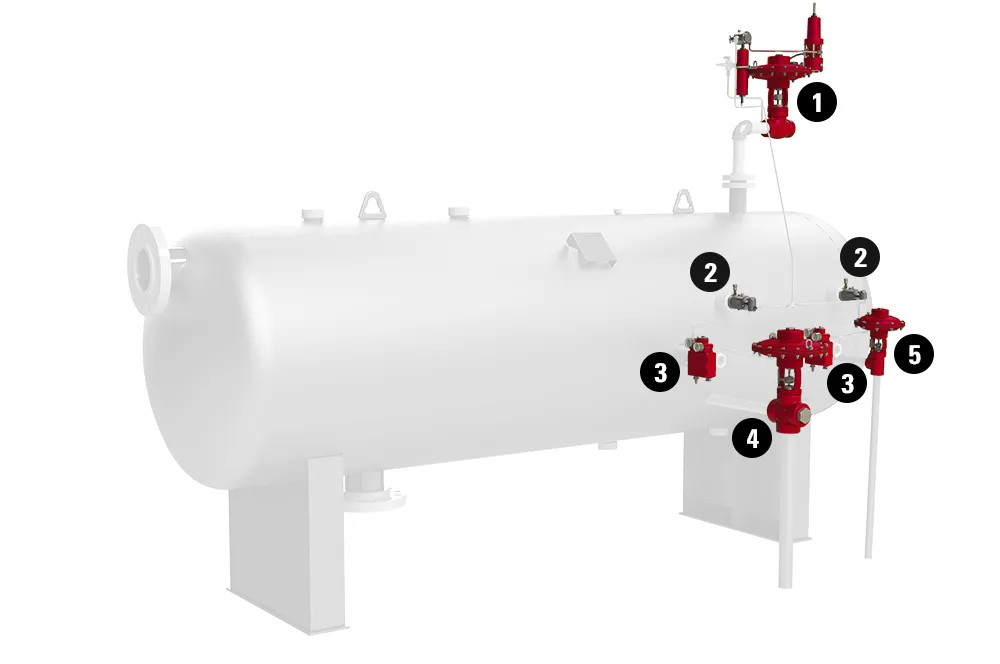

In a horizontal three-phase separator, fluid enters the vessel through an inlet, and immediately hits an inlet diverter. This sudden impact provides the initial separation of liquid and vapor.

In the liquid section of the vessel, the emulsion separates and the oil starts forming a layer (or “pad”) above the water. The oil spills over the top of the weir, and then a level controller, which operates the oil dump valve, controls its level.

An interface level controller also senses the height of the oil-water interface. This controller signals another dump valve to release as much water from the vessel as is needed to maintain the oil-water interface at the pre-determined height.

Meanwhile, gas rises to the top of the separator. It flows horizontally and exits thru a mist extractor to a back pressure valve, which maintains constant vessel pressure.

Related Trainings & Demos

Training that Makes These Diagrams Come to Life

We do in-person trainings at our facilities or in your field to help you make these applications work in the real world.

Learn easy installation techniques

Discover maintenance and preventative care plans to preserve the life of all your equipment

Connect with Kimray engineers and technicians

Find more products to improve your entire system

Domestic and international trainings - Kimray covers the globe

Contact your business development representative to visit us at our OKC campus or have someone come to you. We can't wait to see you.

Monthly Videos, Tips, & Insights

The Kimray Chronicle is your source for news within the Kimray community.

Each monthly newsletter includes information on product improvements, tips on how to better optimize your site, videos and articles on how to complete your own repairs, as well as news about training and events.

© 2026 Kimray, Inc. All Rights Reserved.