Flowback in Woodford Shale Production

Woodford Shale production can be challenging due to erosive sand in the production fluid.

Recently, we met a with Kimray customer who had operations in the Woodford Shale. This well had been online for a few months, and they were still getting a large amount of sand in their production. This resulted in three time-consuming and costly issues:

- The customer was having to empty their sand separators at least twice daily.

- All of their 90-degree pipe turns from the wellhead to their inlet separator were being subjected to premature wear due to the sand in their fluid and erosional velocity. In order to remedy this, they had to install swoop 90-degree turns to decrease the wear on their piping.

- They were experiencing rapid trim washout on their Kimray 2200 High Pressure Control Valves that they were using as dump valves on their inlet separator.

Valve Trim Washout

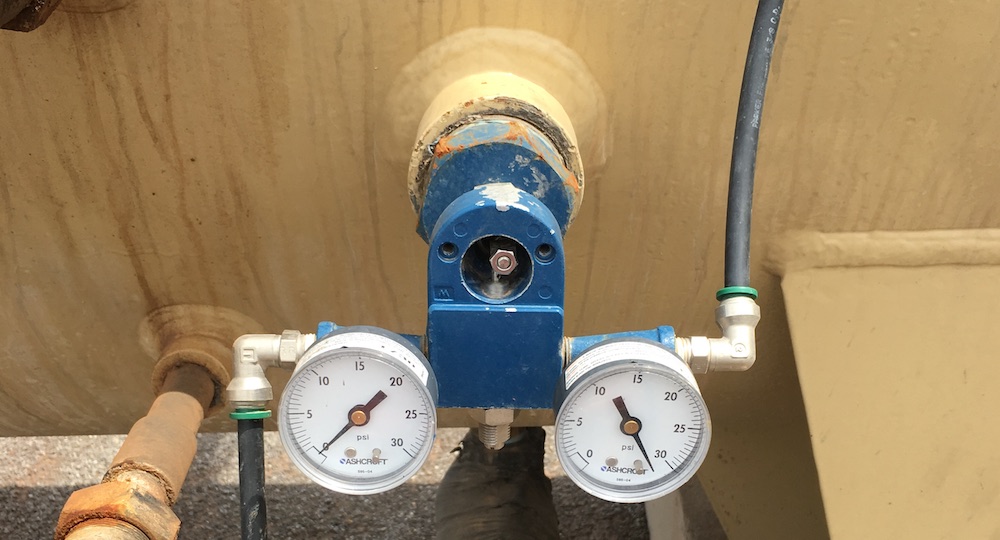

I subsequently met them in the field to troubleshoot the issue with the valve trim.

After investigating, we discovered that the liquid level controllers they were using on their separator were malfunctioning. Specifically, they were not venting off all of the supply gas from the dump valves. As a result, the High Pressure Control Valves were not fully closing.

The dump valves were constantly barely cracked open and continuously bleeding downstream. Because of this, the sand still present in the fluid was washing the trim out very quickly.

Solution for woodford shale production

Our recommendation was twofold:

- Switch the High Pressure Dump Valve trim material from standard D2 steel to our more erosion-resistant carbide trim.

- Use Gen II Liquid Level Controllers on their separator to provide the appropriate amount of supply gas to allow the dump valves to operate correctly.

Currently using a Gen II? Upgrade to the new Gen 3 - our all-new liquid level controller that's even easier for operators to install and adjust in the field.

Result

These changes allowed the dump valves to close completely, eliminating the issue of constant erosion. The customer had been replacing the valve trim once a week. After these changes, valves have been operating for over five weeks without failure.

To speak with an expert about solutions for erosive production, contact your local Kimray store or authorized distributor.