In upstream oil and gas, accurate liquid level control is vital to the separation process.

If you don’t have it, you can experience serious problems like dumping oil into your water line or water in your oil line. These issues can result in operational downtime, environmental hazards, and the loss of valuable resources.

In this blog, we're going to explain one root cause of inaccurate liquid level control, and show you a solution designed to address it.

A Root cause of inaccurate Liquid Level Control

In a lever-operated mechanical system, a root cause of erratic liquid level is rotational play.

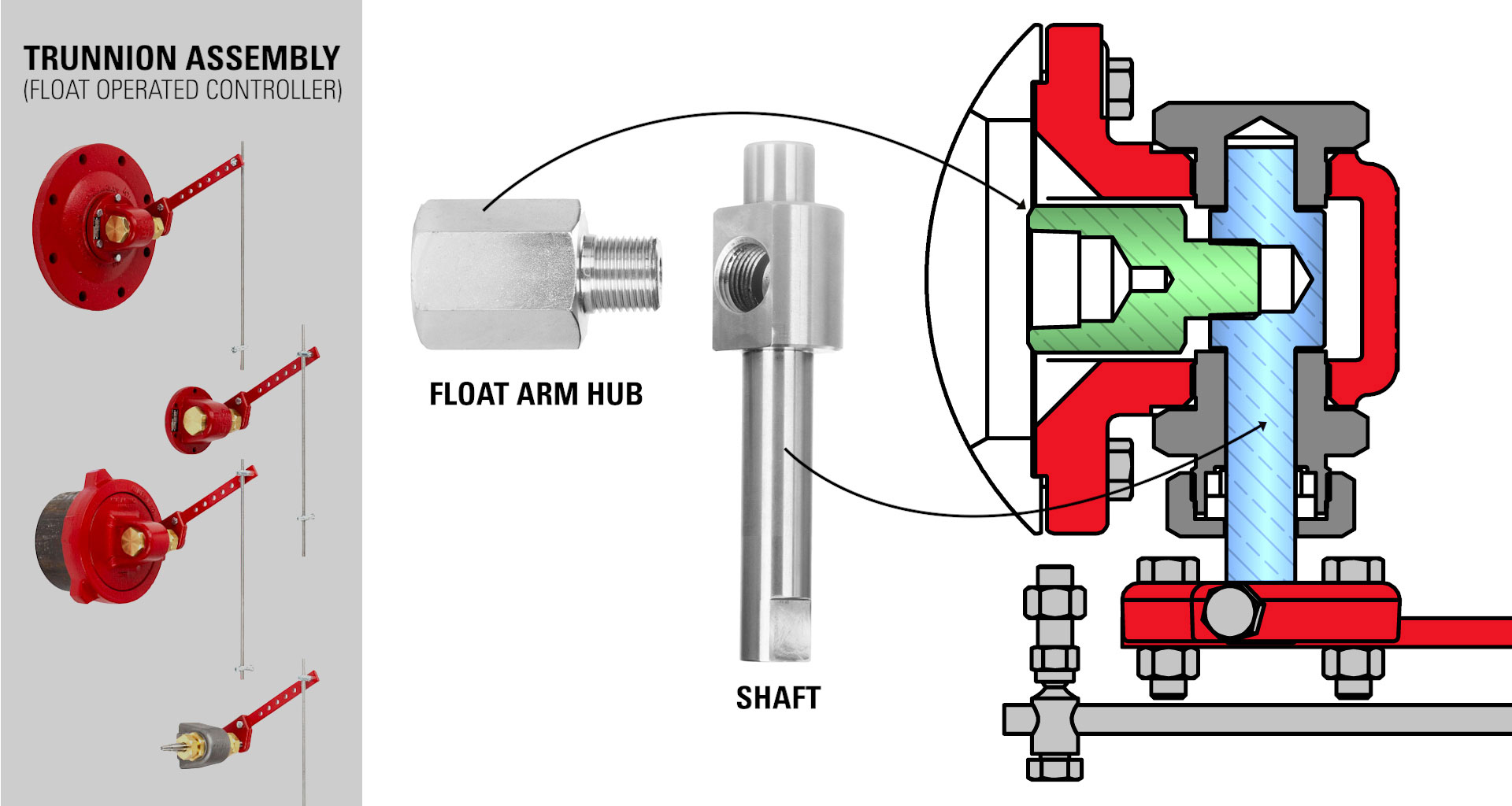

Rotational play occurs when the connection between the hub and shaft is not fixed in place. This is typically caused by a difference between the hub inner diameter (ID) and shaft outer diameter (OD) at a few crucial spots in your system.

In a system with no rotational play, as the liquid level rises and lowers, the float simultaneously starts to move, engaging the lever arm which actuates the valve trim immediately.

If the hub and shaft are not fixed in place, allowing rotational play, there will be a delay in the response of the valve trim.

The more rotational play you have, the longer it will take to engage the valve trim to open and close. This can lead to the valve not opening fully, meaning the valve won’t reach its full Cv capacity, or not closing fully, which can allow unintended loss of liquid from the vessel.

3 Key improvements in Liquid Level Control

Minimizing this rotational play can eliminate these issues. Recently, Kimray’s product and engineering teams have worked to develop 3 key solutions in our lever-operated mechanical liquid level control system:

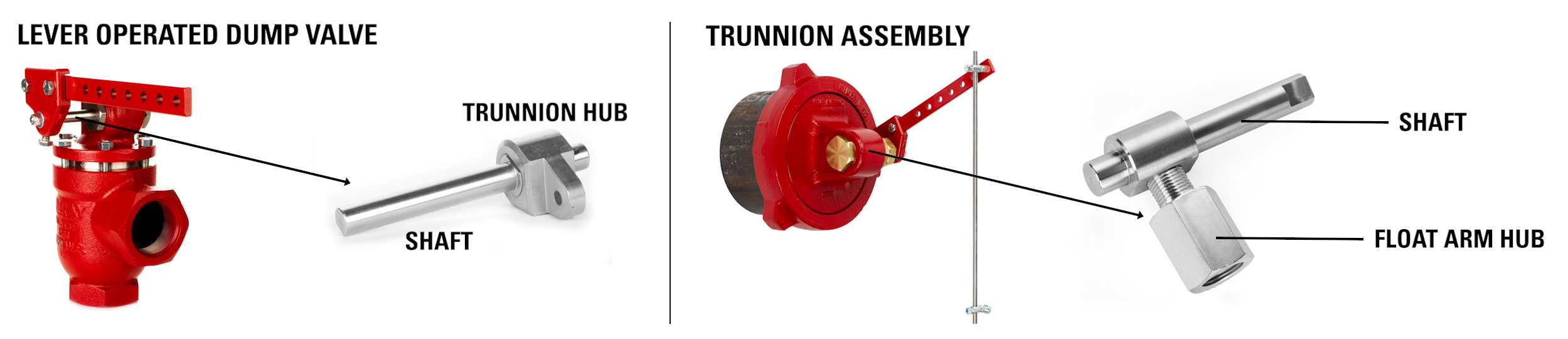

1. Fixed the float arm hub to shaft connection.

The trunnion assembly now has a threaded design on the float arm hub, which yields no rotational play at that connection.

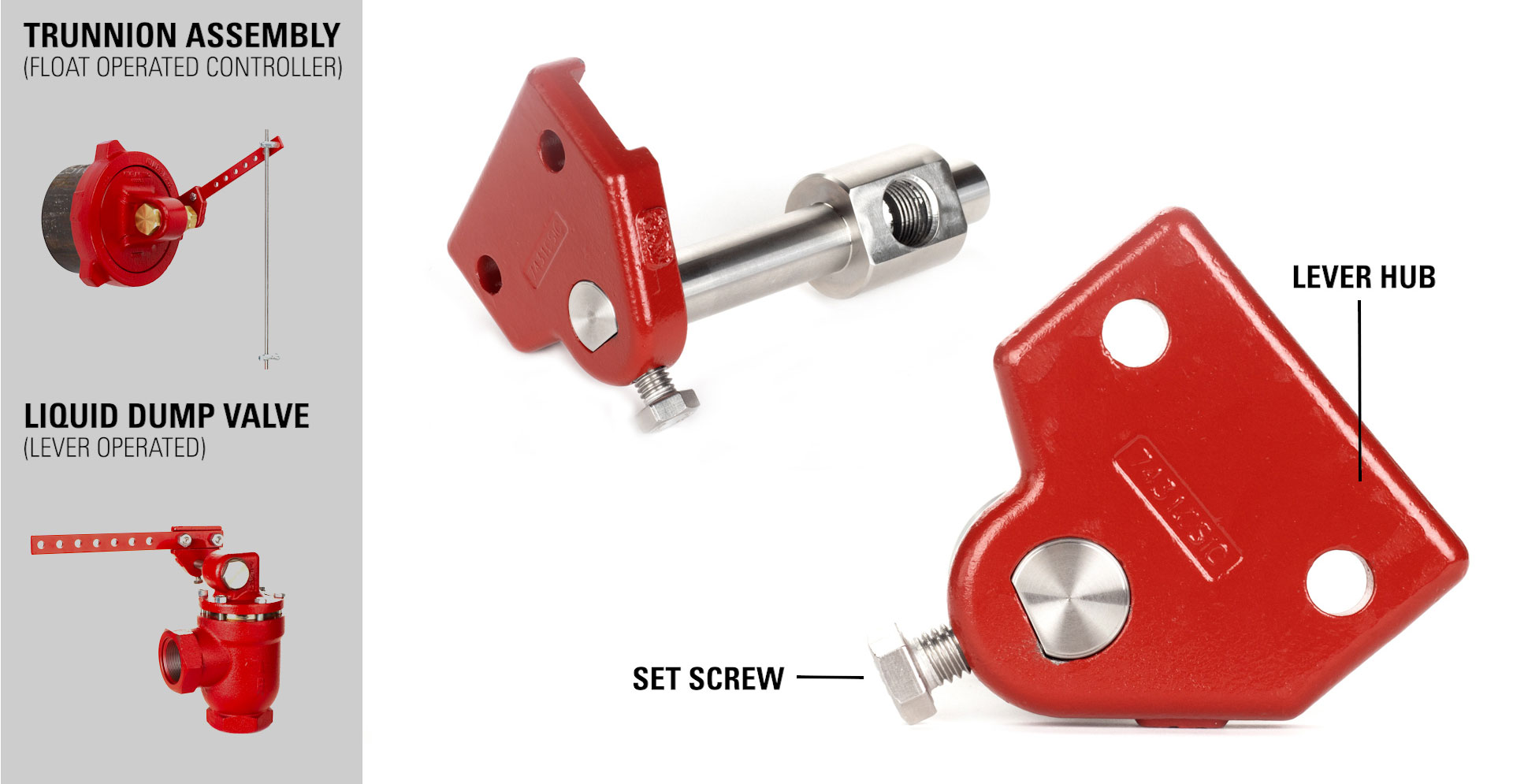

2. Added lever hub set screws.

There are now set screws in the lever hubs in both the trunnion assembly and the valve, which eliminates rotational play at those connections.

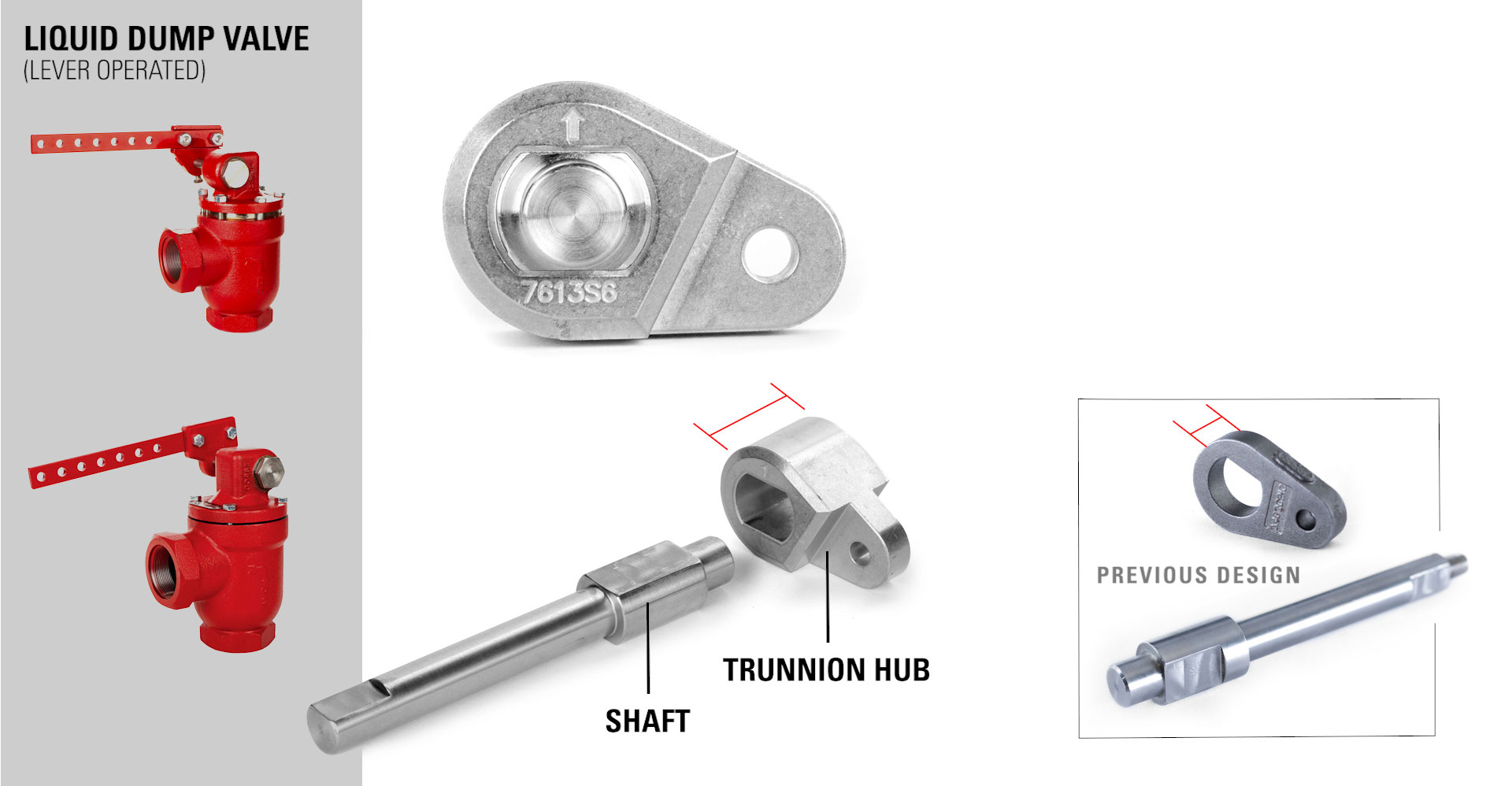

3. Improved hub and shaft designs in the dump valve.

The most recent improvement is in the lever-operated dump valve trunnion hub and shaft. This new shape and thicker hub cross-section, combined with tight-tolerance precision manufacturing, has minimized the rotational play in this connection to the least amount of any other solution.

Together, these combined solutions in the Kimray trunnion and lever-operated dump valve have proven to yield the least amount of rotational play of any fluid level control system on the market.

To speak with an expert about how we can help optimize your liquid level control, contact your local Kimray store or authorized distributor.