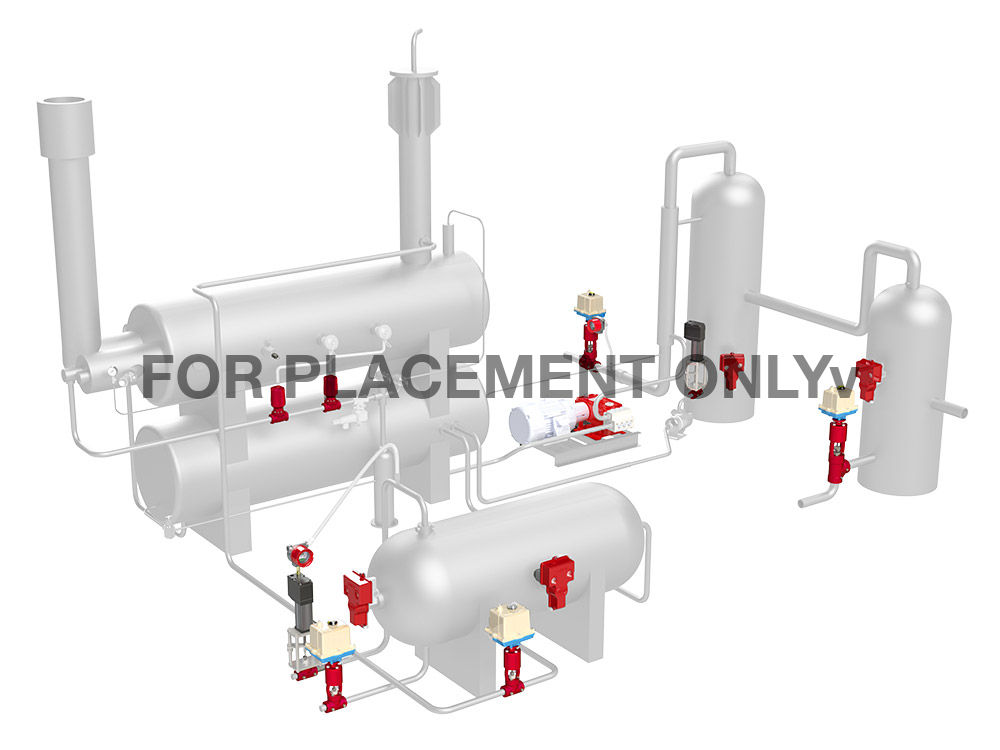

Product Applications

ACY

Build & Save a Quote

We'll get you options, pricing, and anything else you need.

Anything we can do to help?

Talk to a specialist at (405) 525-4264 or fill out a quick product message form.

Product Charts

Tech Specs

| Type | Value |

|---|---|

| Connection Size: | 3 " |

| Connection Type: | 150 RF |

| Body Style: | Through Body |

| Body Material: | Cast Ductile |

| NACE MR0175: | Option Available for NACE MR0175 compliance or certification |

| Trim Size: | 3 " |

| Trim Type: | Equal Percentage |

| Leakage Class: | Class VI |

| Process Fluid: | Gas |

| Pilot Type: | Vent |

| Max Working Pressure: | 250 psig |

| Min Set Point Pressure: | 10 psig |

| Max Set Point Pressure: | 250 psig |

| Operation: | Pneumatic |

| Catalog Page: | 06:80.1 |

| Face-to-Face Length: | 12.188 " |

| Max Cv: | 117 |

| Cf: | 0.75 |

| Weight: | 90 lbs |

Product Videos

Compatible Kits and Tools

| Type | Product Code | |

|---|---|---|

| Repair Kit: | RYK |

Downloads & Updates

Frequently Asked Questions

Differential Pressure Regulators function like a back pressure regulator but sense an auxiliary pressure source in addition to upstream pressure. The differential is maintained in accordance with the adjustment screw setpoint, so flow is consistent and metered appropriately.

Common applications include use in meter runs and gas injection in gas lift applications to help control flow.

The regulator is designed to control a set difference between upstream pressure and downstream OR auxiliary pressure from a downstream process/vessel. The differential (upstream pressure – downstream/auxiliary pressure) must be greater than the bonnet spring force to allow for the regulator to open. When at setpoint, any downstream/auxiliary pressure increases will require a corresponding increase in upstream pressure to allow for the same positioning of the inner valve.

Connection Types and Sizes

- 1”: NPT only

- 2-4”: NPT and 150RF

- 6”: 150RF

Elastomer Options

- Buna

- HSN

- Viton

- AFLAS

Stainless Steel Component and Trim Options

Refer to the product's technical specifications as this is dependent on end connection type and shell material.

Refer to the product's technical specifications as this is dependent on end connection type and shell material.

- Ductile, NPT end connection: 300 psi

- Ductile, 150RF end connection: 250 psi

- Steel, 150RF end connection: 285 psi

No, typical applications for these regulators only deal with metering gas flow based on differential pressure from two different gas sources

Repair Kits are available for all regulators. Maintenance is recommended to be performed at least once a year. However, this frequency can increase depending on the application and potential changes in operation conditions.

Still have a question? Send us a quick product message to get help from our team.

Quick Links

Kimray has a team of experts that can help you identify the right products to meet your product and emissions goals.

Talk to a specialist Mon - Fri, 7 AM - 5 PM CST at (405) 525-4264.