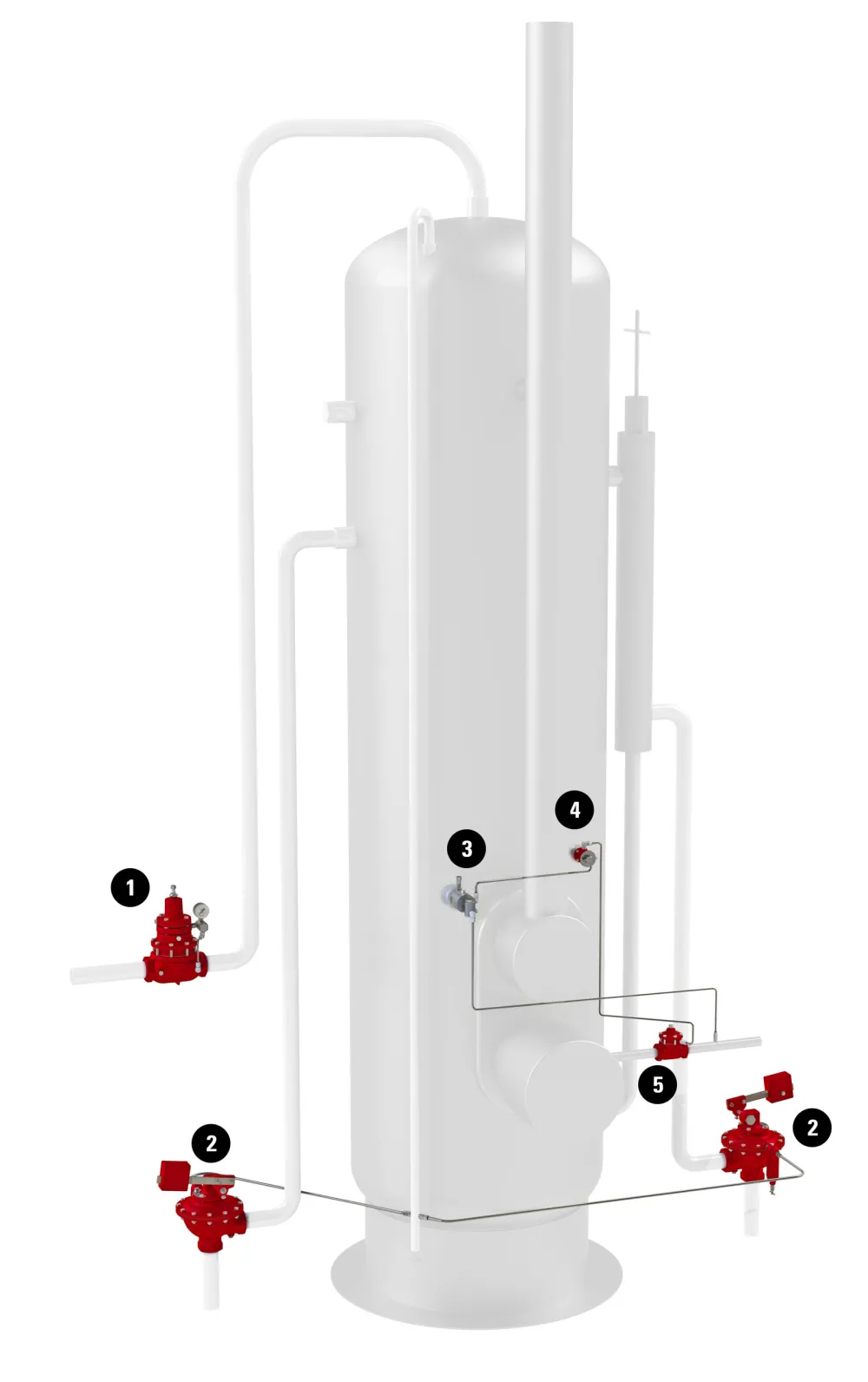

Oil and gas producers use heater treaters to separate emulsion into three phases. These are typically installed at tank batteries and come in horizontal or vertical orientations. Heater Treaters have a fire tube, which loops through the inside of the heater treater and comes into contact with the emulsion. The burner uses supply gas to create fire & heat the fluid inside the vessel. Fluid enters the treater inlet and absorbs heat from the fire tube. Gas released from the incoming well stream moves to the top of the vessel and exits through a back pressure valve. Water—the heaviest of the three elements—collects at the bottom of the treater and is eventually dumped out of the vessel to be stored or disposed. Meanwhile, the oil separates into the middle and then is dump out to storage or sales.

Related Trainings & Demos

Training that Makes These Diagrams Come to Life

We do in-person trainings at our facilities or in your field to help you make these applications work in the real world.

Learn easy installation techniques

Discover maintenance and preventative care plans to preserve the life of all your equipment

Connect with Kimray engineers and technicians

Find more products to improve your entire system

Domestic and international trainings - Kimray covers the globe

Contact your business development representative to visit us at our OKC campus or have someone come to you. We can't wait to see you.

Monthly Videos, Tips, & Insights

The Kimray Chronicle is your source for news within the Kimray community.

Each monthly newsletter includes information on product improvements, tips on how to better optimize your site, videos and articles on how to complete your own repairs, as well as news about training and events.

© 2026 Kimray, Inc. All Rights Reserved.