Energy producers use a burner management system to control the temperature inside separation equipment.

One of the challenges with these systems is the GHG emissions that result from their operation.

In this blog, I'll show you a key change you can make to reduce emissions from your burner management system, and one very important recommendation.

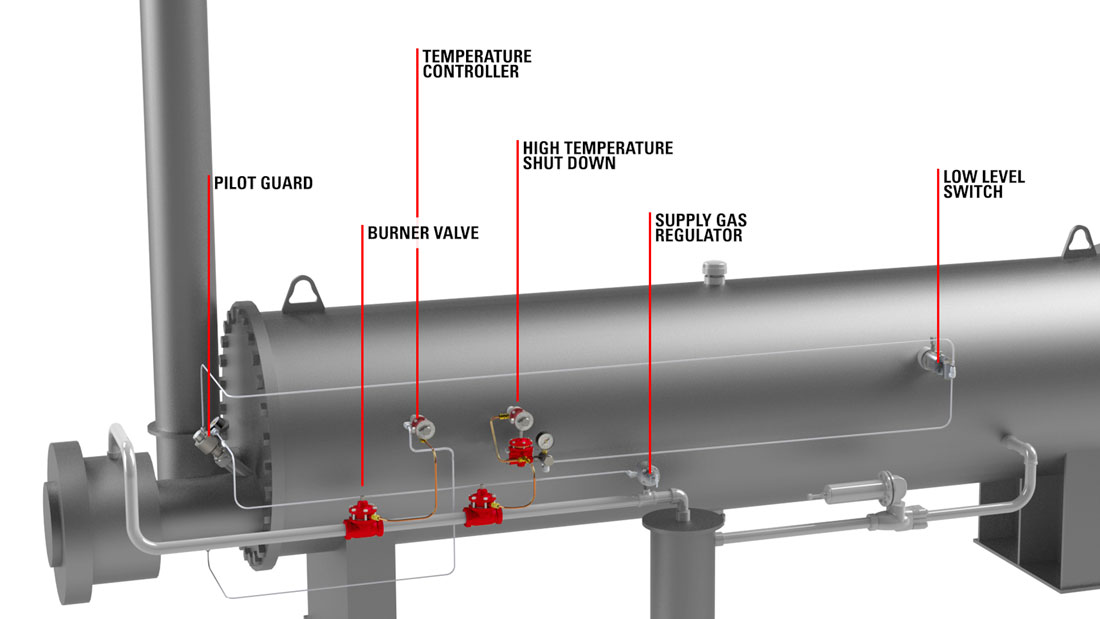

what are the key Components of a Burner Management System?

The key components of a BMS include:

- Standard temperature controller (T12)

- High Temperature Shut down (HT12)

- Control valve (Burner valve)

- Supply gas regulator

- Pilot guard

how to reduce Emissions in your BMS

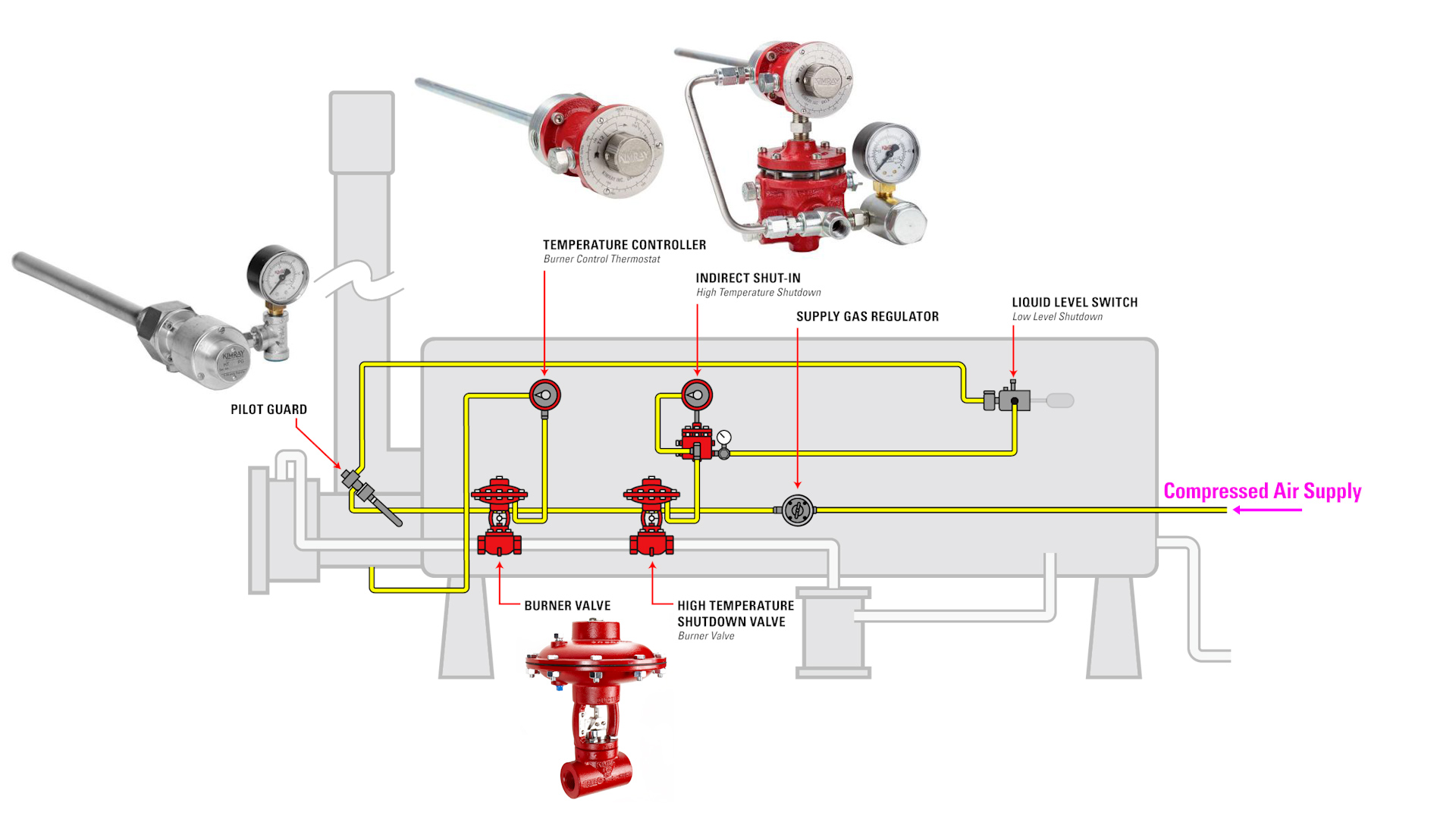

Reducing emissions has become a priority for most energy producers. One way they achieve this is by using compressed air to power their pneumatic devices.

This alternative eliminates the emissions released when using natural gas to supply pneumatic controllers.

A burner management system can take advantage of this method. As a pneumatic device, the T-12 and burner control valve can be powered with compressed air as well to eliminate emissions.

However, it's critical to use the right components to prevent potential safety hazards.

Why you should Use a High Pressure Control Valve in Your Burner Valve Application

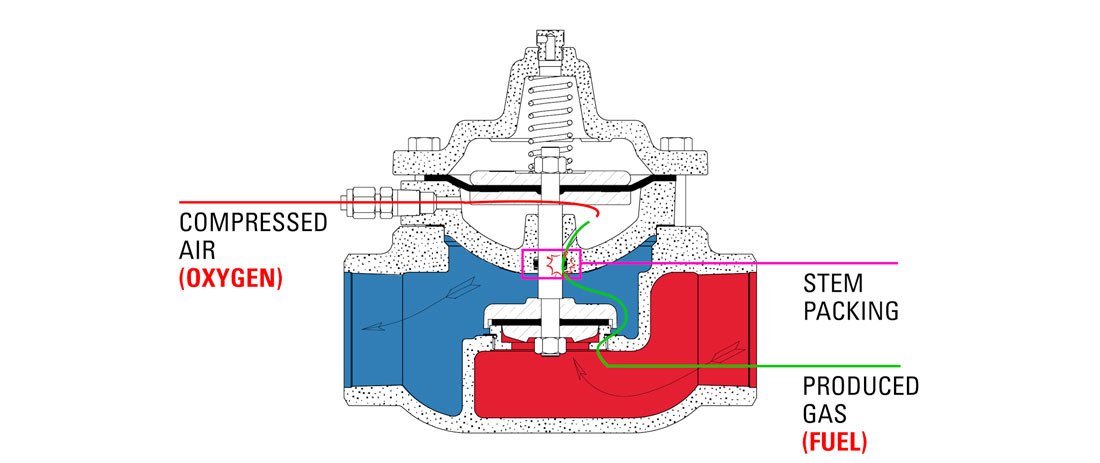

In a burner management system, because the pressures are typically low, many producers use a low-pressure control valve in this application.

However, if you do make the change to compressed air, we require using a High Pressure Control Valve in this burner management application.

Here’s why:

When the air and gas work their way through the low pressure control valve, there is only one point of potential failure in between them—the stem packing. If the packing is cracked or compromised in any way, the gas and air can mix, creating the potential for fire.

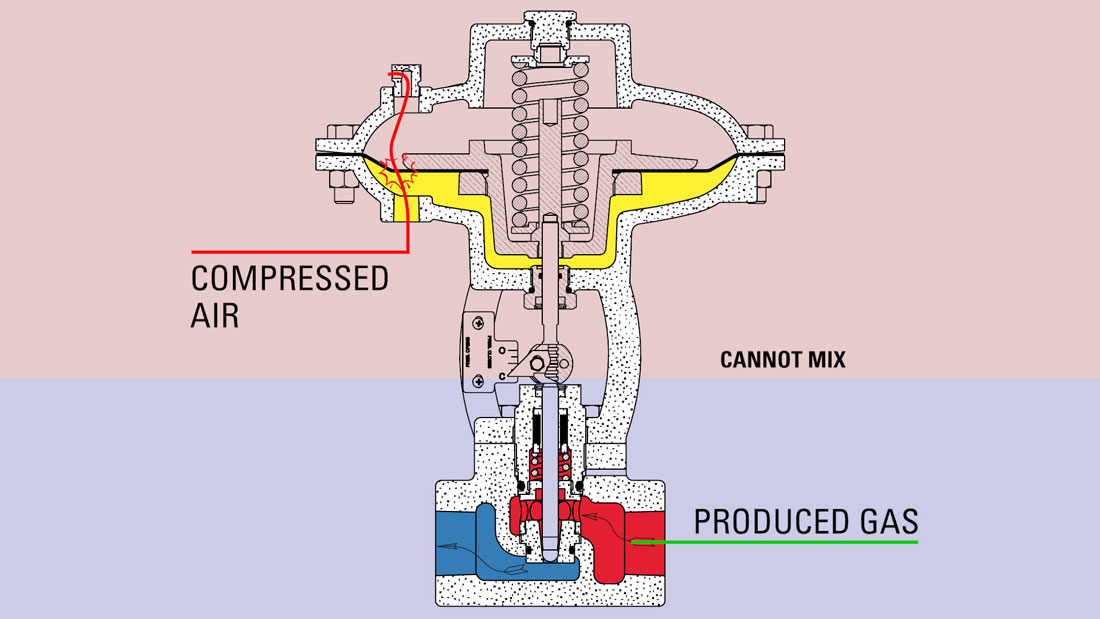

To mitigate this risk, we recommend using a High Pressure Control Valve. This valve has an open-yoke design, so if there is an issue with the diaphragm, the compressed air is vented out of the topworks rather than mixing with the produced gas in the flow-path of the valve.

And while it's named "High Pressure" Control Valve, it can also handle pressures well below 300 PSI.

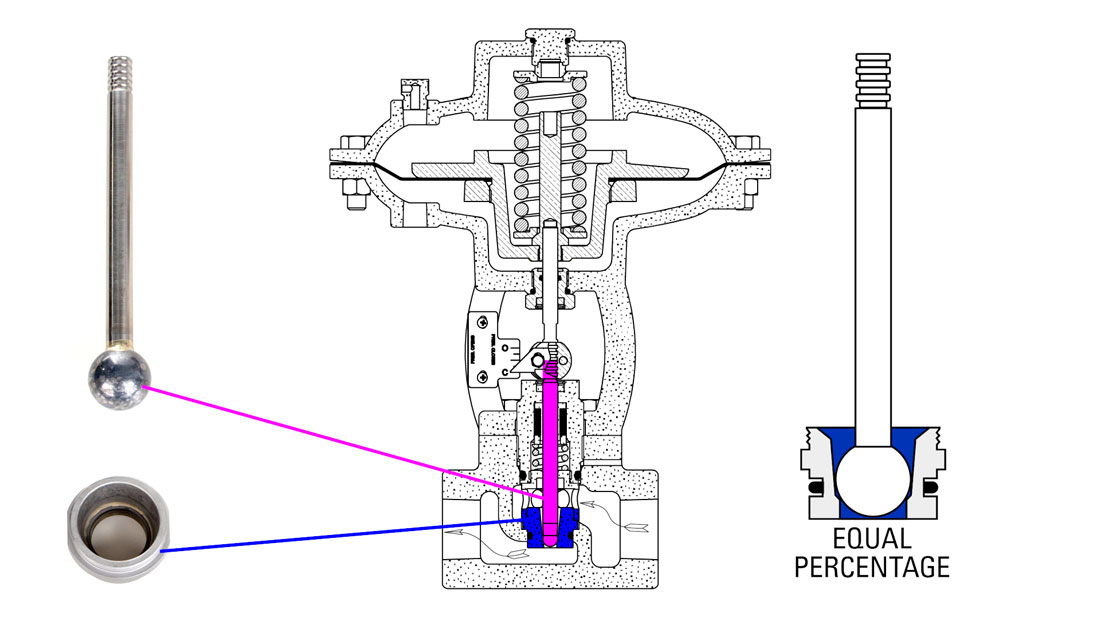

Which Control Valve Trim Should I Use?

Throttling is key in Burner Management applications to keep temperature control consistent, so you for your High Pressure Control Valve, you will want to specify an equal percentage trim because it throttles better than quick-opening and nominal.

See also:

Can I Use Electric Controls in my BMS?

Yes! Another way to eliminate emissions in your Burner Management System is to use electric controls, like the Electric Low Pressure Valve. To learn more about this set up, check out our blog on Manual and Automated Burner Management Systems.

To speak with an expert about your burner management system, contact our product applications team.