A burner management system (BMS) is used on heated vessels in the oil and gas industry where precise temperature control is needed. This system includes a combination of products that:

- Control and monitor the temperature in a heated vessel

- Control safety systems used to ensure safe startup and shutdown process burners

- Operate fuel trains

You’ll find a BMS anywhere that heat is being controlled within a vessel, such as Heater Treaters, Line Heaters, and some horizontal separators.

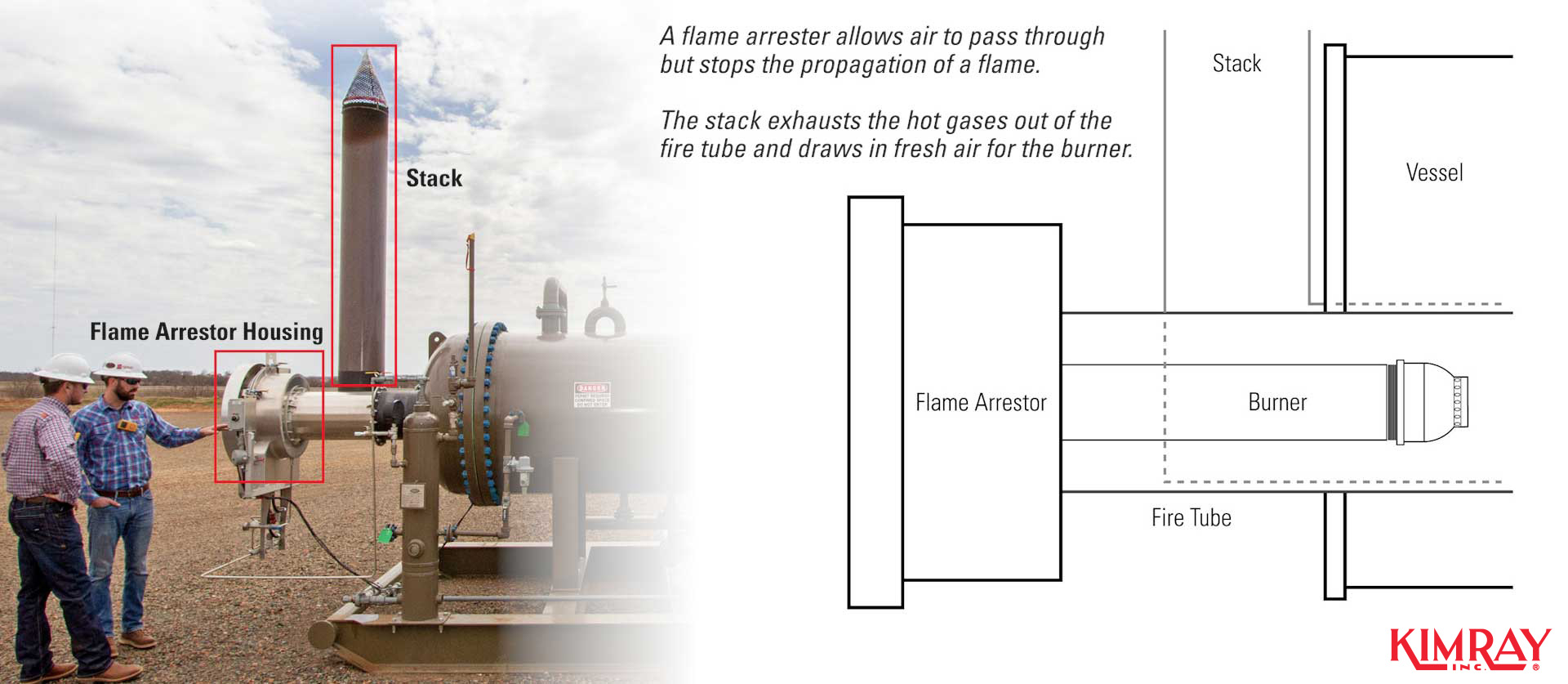

The easiest way to identify a BMS is to look for a flame arrestor and stack. These are easily recognized pieces of equipment that signify the use of a BMS on a heated vessel.

A flame arrester allows gas to pass through but stops the propagation of a flame. The stack exhausts gases.

Without a burner management system, if a pilot flame is extinguished, the burner gas will continue to flow even without proper temperature control. This creates a dangerous situation and increases the chance of fire and accidents from burner gas venting.

BMS Heating: Direct vs Indirect Fired

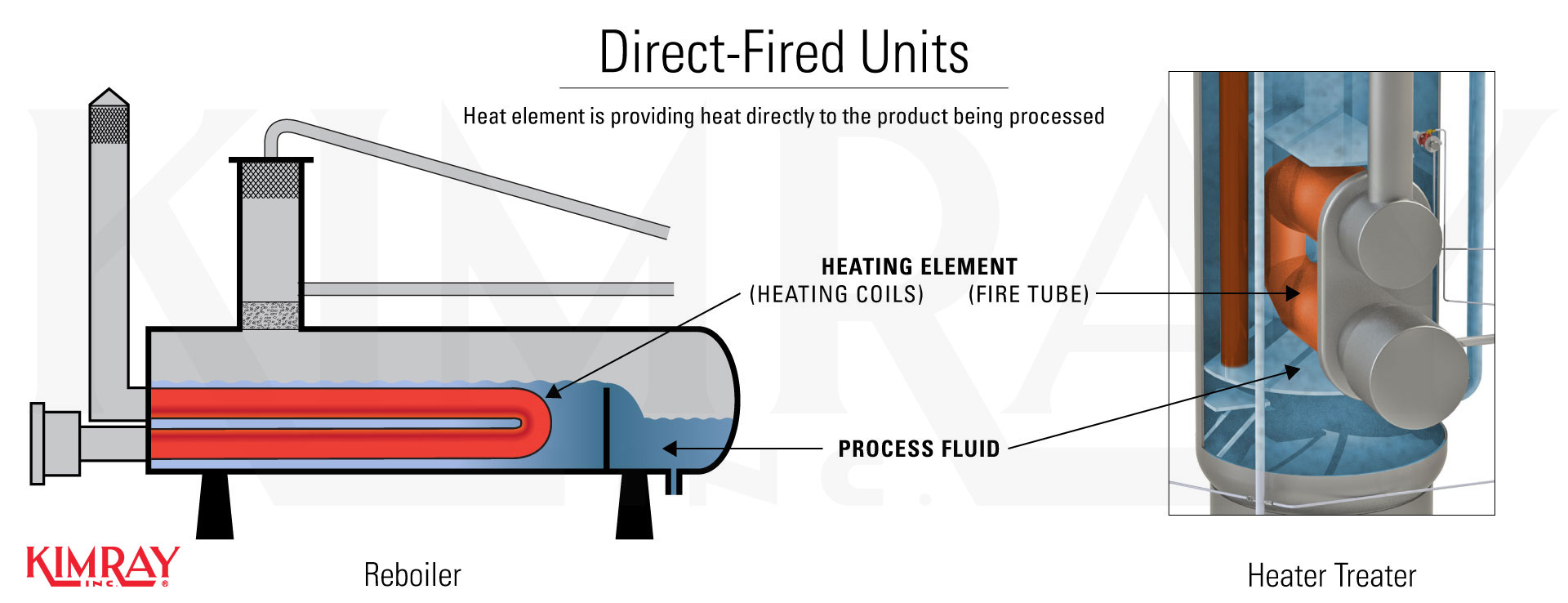

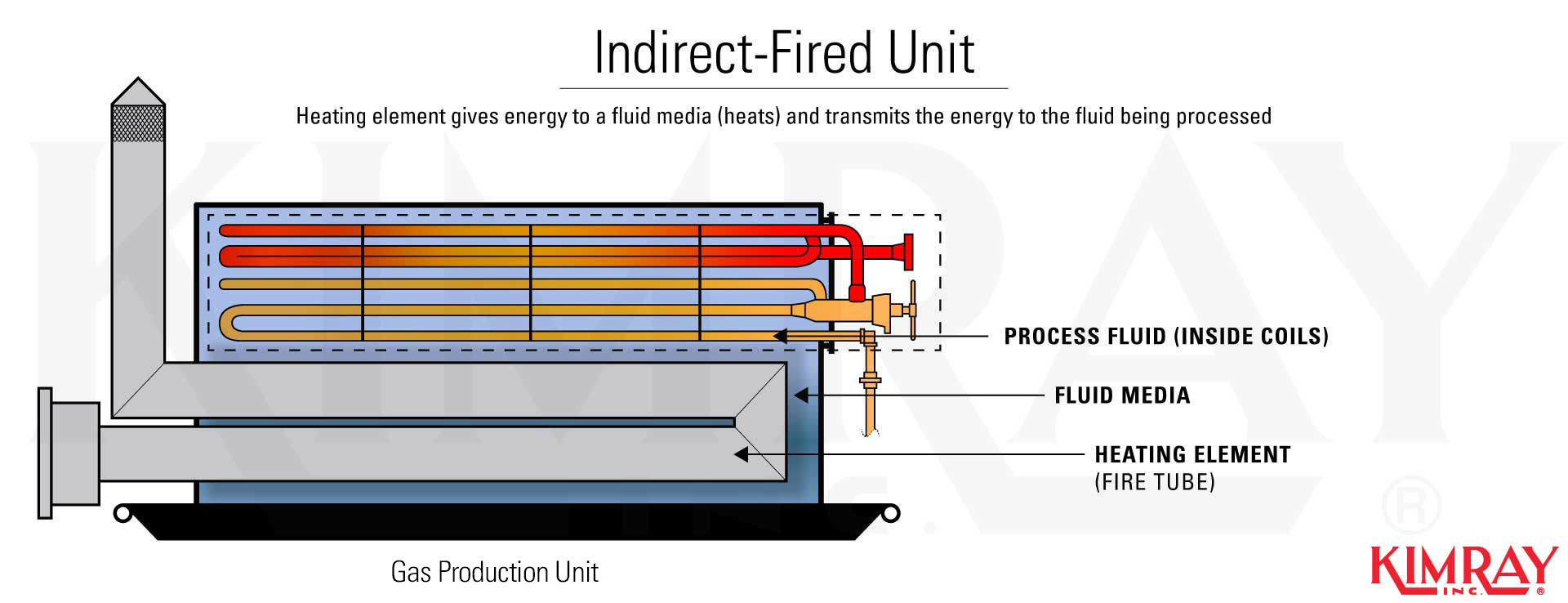

There are two kinds of heated vessels producers use: direct fired and indirect fired.

The term direct fired means the heat element is providing heat directly to the product being processed. Examples of these types of units are glycol reboilers and heater treaters.

The term indirect fired means the heating element gives energy to a fluid media, often called a water bath, that then heats the well stream. Examples of these types of units are line heaters and gas production units.

Manual Burner Management Systems

Manual BMS Working Principle

A manual BMS has controls that must be manually adjusted or started. These systems can use a pilot light to ignite the main burner and are referred to as a free-standing pilot burner.

The pilot light needs to be manually ignited in the start-up process. The T-12 Temperature Controller is used to operate a pneumatic low pressure control valve when the temperature needs to be adjusted.

While manual BMS's have historically been the standard, they can put the operator in a potentially dangerous situation during the start-up process.

Manual BMS Equipment

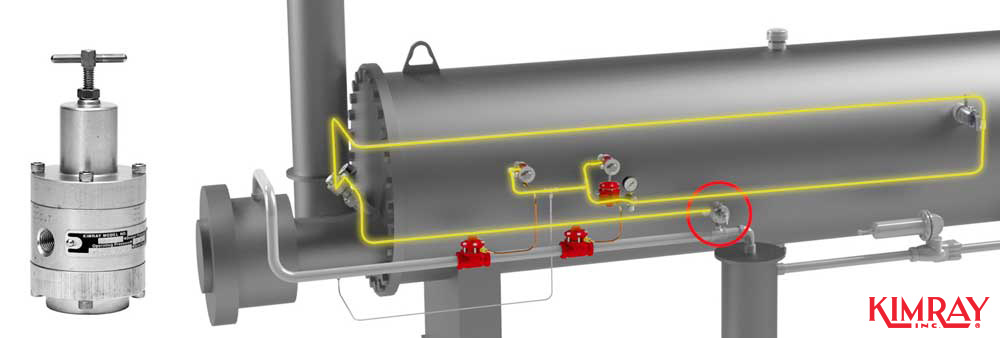

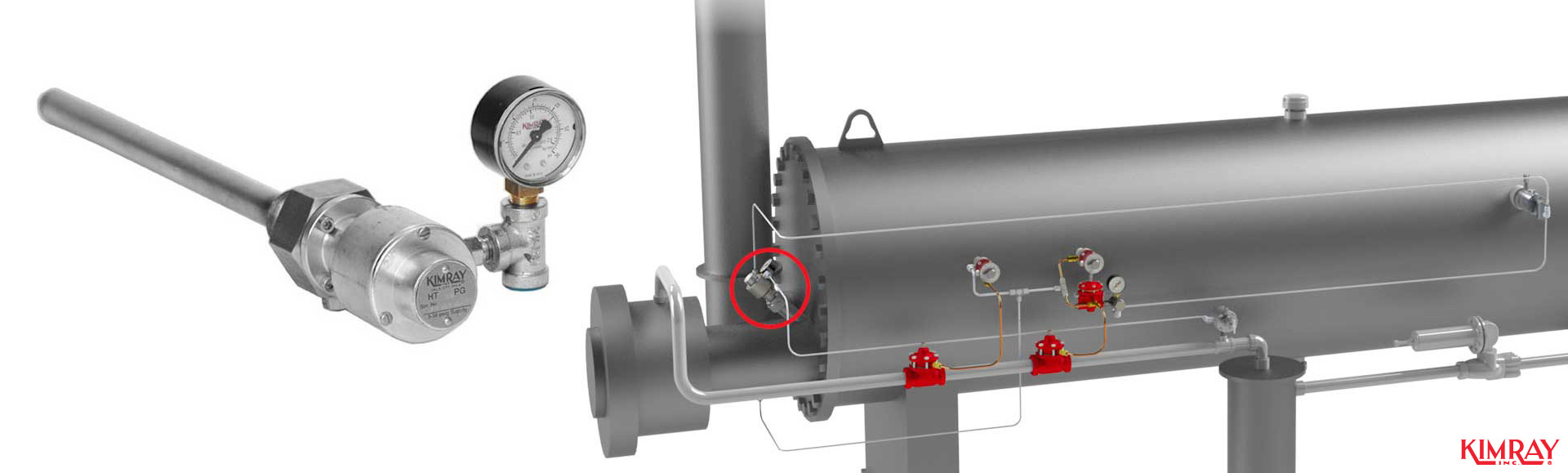

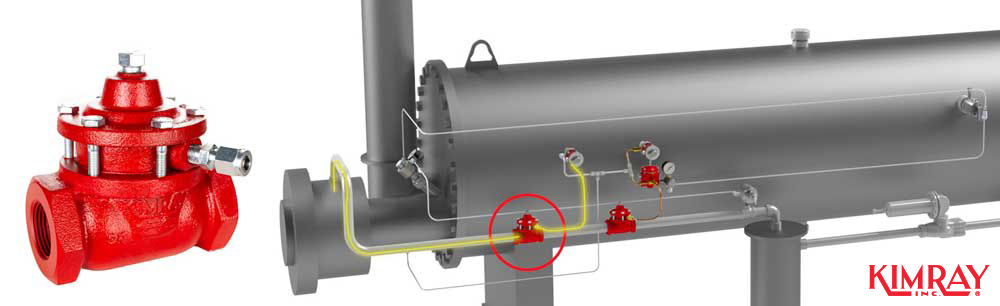

Using a standard line heater as an example, we’ll start by looking at the Supply Gas Regulator. This regulates supply gas to all the pneumatic controls in the BMS.

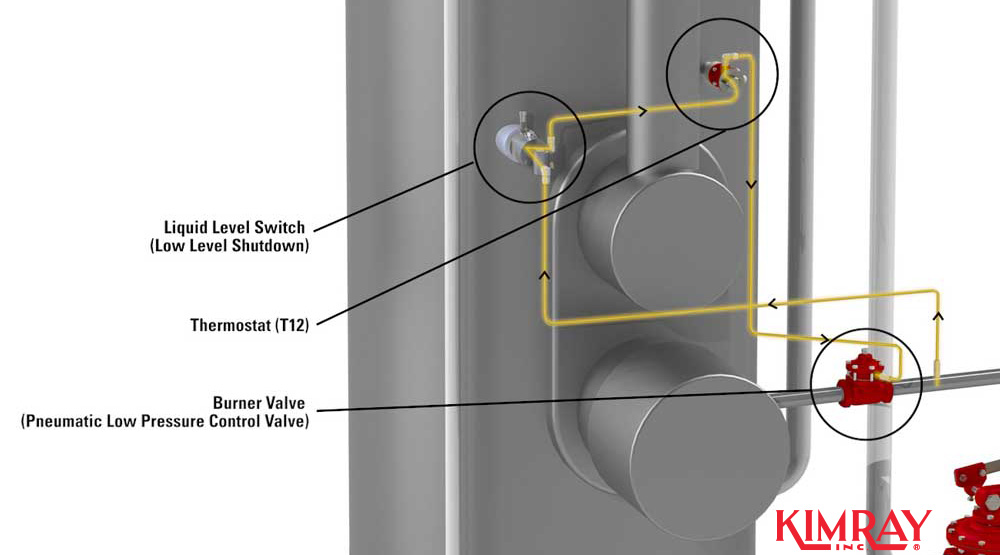

It initially leads to the pilot guard, which then feeds the level switch, followed by the high-temperature shutdown and thermostat.

The Pilot Guard is directly in the pilot flame, monitoring the free-standing pilot burner. If the flame goes out for any reason, it shuts supply gas off to the rest of the system. This prevents natural gas from going into the burner without a pilot flame and being emitted into the atmosphere. It makes sure that the pilot light is lit, and the gas is being consumed.

For safety measures, when there's a BMS, there’s also a Liquid Level Switch used as a low-level shutdown. When the heat transfer media drops below a certain level, it could expose the fire tube, in turn creating hot spots and compromising the fire tube.

If the level switch is tripped, it cuts off all supply gas to the BMS, removing all fire until the liquid level is increased above that point.

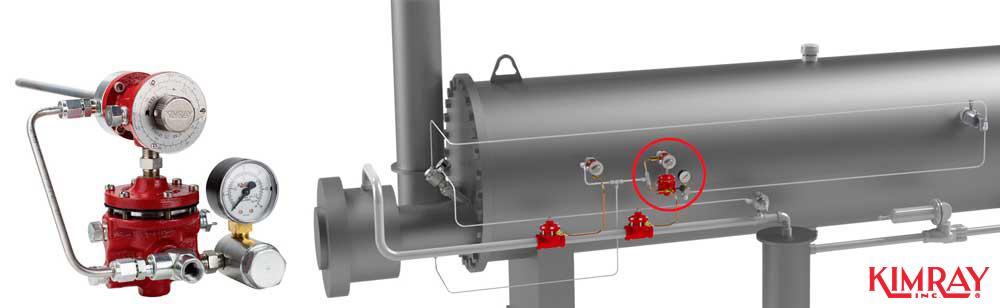

The Indirect Shut-In (also known as High Temperature Shutdown) controller monitors the temperature as a safety backup in case the Temperature Controller fails and temperature rises. Once the fluid gets to a predetermined temperature, the High Temperature Shutdown removes all supply gas to the burner by closing a valve upstream of the primary burner valve, so it can no longer heat the vessel.

The High Temperature Shutdown is made up of a temperature controller and a manual reset pilot.

Once the BMS setpoint is reached, the High Temperature Shutdown must be manually reset to supply the burner with fuel. This ensures that an operator must go to the location to inspect the equipment and fix the issues that caused the overheating before they reset the High Temperature Shutdown.

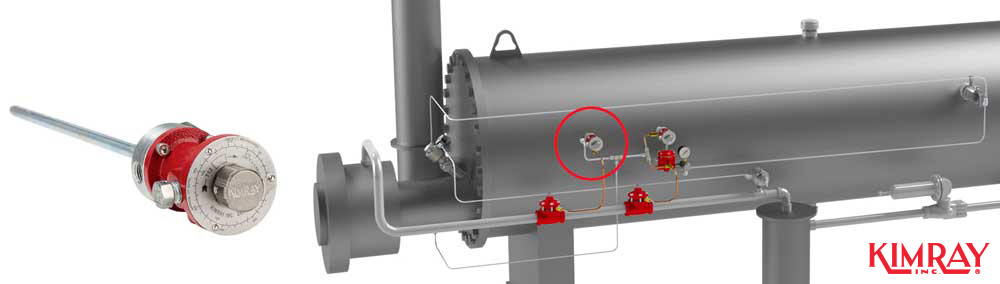

The Temperature Controller (also known as T-12 Thermostat) is installed where it will be immersed in the liquid to be heated. The thermostat monitors the liquid temperature and expands and contracts with the temperature change of that fluid. This positions the pilot plug to either vent or output a pneumatic signal to control how much fuel the burner is receiving via a pneumatic low pressure control valve.

An optional separable socket, or thermowell, allows you to remove the thermostat from the vessel without having to depressurize the vessel.

This pneumatic signal from the T12 is sent to the Low Pressure Control Valve (used as a Burner Valve).

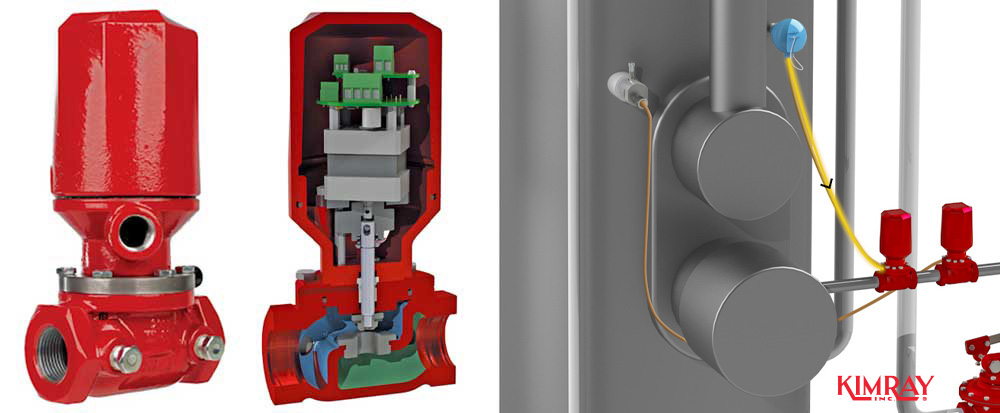

The Low Pressure Control Valve opens to let the appropriate amount of gas through to the burner to increase the temperature.

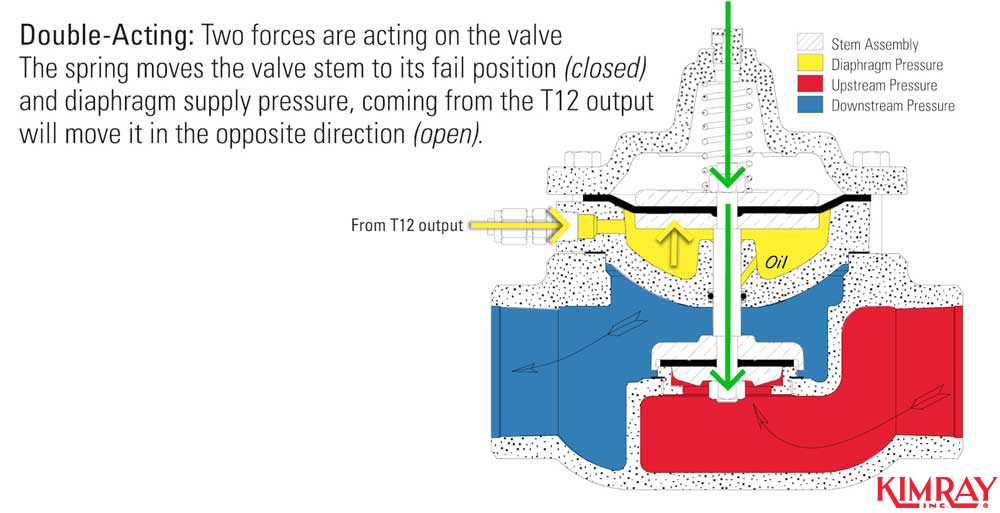

The valves used in this application are double acting, meaning there are two forces acting on the valve. The spring moves the valve stem to its fail position (closed) and diaphragm supply pressure, coming from the T12 output will move it in the opposite direction (open).

These systems are not exactly the same, but they use the same principles that the supply gas is always fed through the safety systems before it gets to the low pressure control valve, ensuring that if any safety systems are tripped, the low pressure control valve is shut down completely.

Automated Burner Management Systems

Automated BMS Working Principle

While a manual BMS uses supply gas to control its pneumatic components, an automated BMS requires low-voltage electrical power to control its electronic components.

An automated BMS can sense when the burner needs to be extinguished or relit and can complete that task automatically. These systems communicate with low pressure control valves, such as the Kimray E-LO.

These automated valves provide electric burner temperature control by releasing the appropriate amount of gas into the burner in order to maintain the desired temperature.

Automated BMS’s will have an electronic ignition system that keeps the operator out of harm's way. These systems eliminate the possibility of a constant pilot being blown out and minimize fuel consumption and atmospheric emissions.

Electronic ignition systems are also much safer for the operator in the event of a back flash or equipment fire.

Automated BMS Equipment

.jpg)

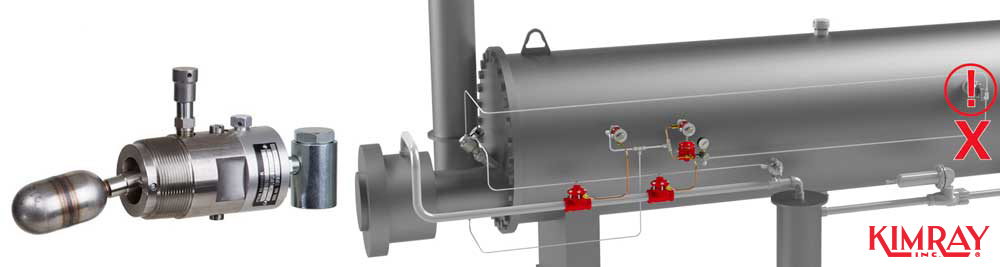

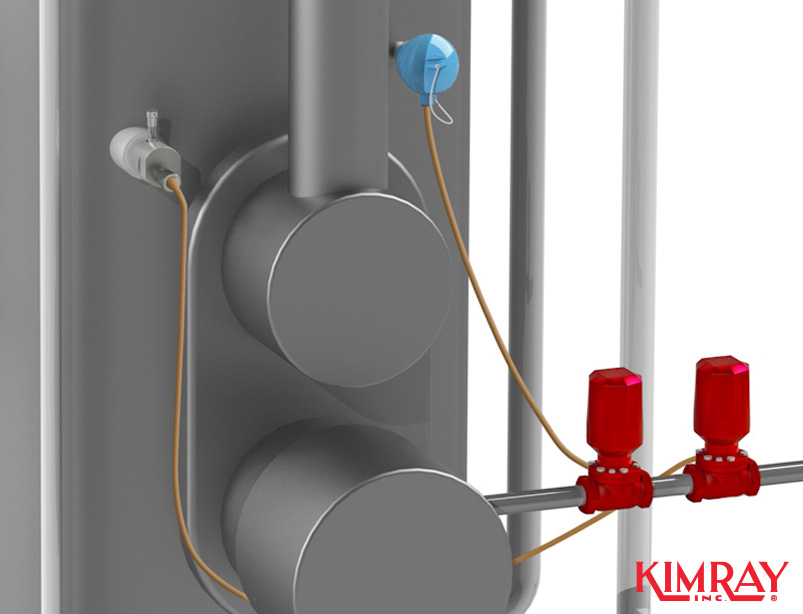

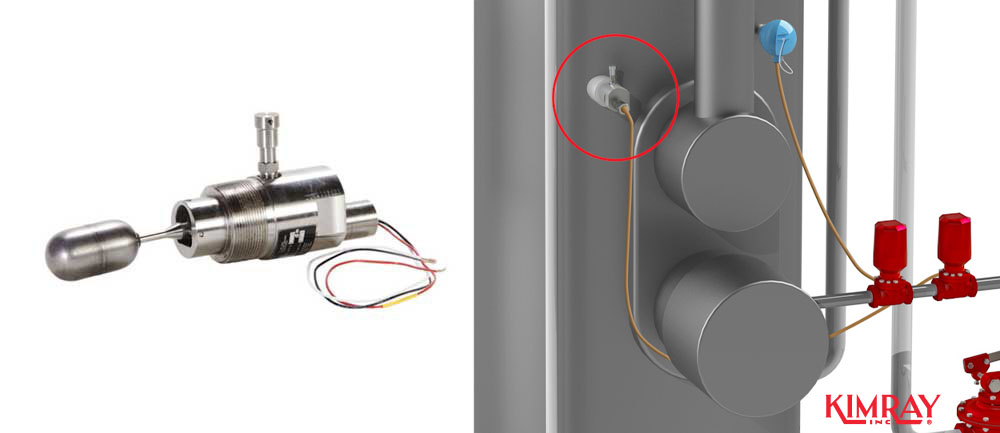

Using a Heater Treater as an example, we'll start by looking at the Resistance Temperature Detector or RTD. An RTD senses the temperature of the production fluid and sends an appropriate electric signal to a burner valve to adjust the amount of fuel it is providing the burner to maintain a temperature set point.

RTDs have high accuracy and repeatability, which is key to any BMS.

The E-LO Low Pressure Control Valve is a low-power controller designed to control flow in applications less than 45 psi. Producers use it often as a burner control valve within an automated BMS.

In this scenario, the E-LO will receive an electronic signal from an RTD and move to the appropriate position to control the amount of fuel it's providing the burner.

In an automated BMS, an Electric Liquid Level Switch is used as a low level shutdown. The switch stops fuel from traveling to the burner in case of the liquid level being too low, exposing the firetube.

Benefits of Using a Burner Management System

The primary benefits of using a Burner Management System include limiting gas emissions and safer working conditions.

- Limiting Excess Gas Emissions: using a BMS enables producers to be more in control of emissions. The BMS automatically shuts off and relights the burner based on what temperature it senses. This resulting in releasing less gas into the atmosphere.

- Safer Working Conditions: because gas is not continuously being released, operators are working in a safer environment, reducing the risk of injury.