Artificial lift describes a variety of methods oil and gas producers use to increase downhole pressure and push resources up to the surface.

Why is Artificial Lift Used?

When a well is first opened, there is typically plenty of existing pressure and volume to get oil and gas to the surface. However, after time that initial boost dwindles. In some areas like the DJ Basin in Colorado, many producers even start new wells with artificial lift to get production flowing strong from the beginning.

Artificial lift is used for two primary reasons:

- To enhance production

- To extend life of a well

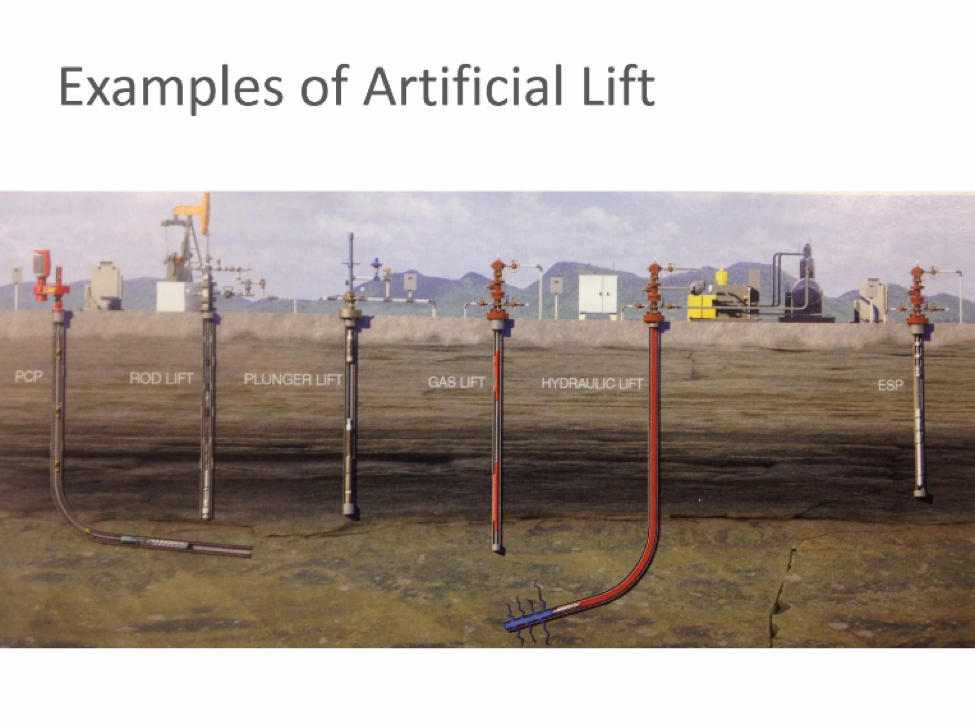

Some of the most common types of artificial lift are Progressive Cavity Pump (PCP), Rod Lift, Plunger Lift, Gas Lift, Hydraulic Lift, and Electric Submersible Pump (ESP).

1. Progressive Cavity Pump (PCP)

The red piece on top is electric motor attached to a gear reduction. A string of rods rotate all the way to where the pump is located. At that point a large screw turns and essentially augers fluid out of the well.

In the picture you can see that the progressive cavity pump is laying horizontally in the well. This is one of the best types of artificial lift for horizontal wells. This is important because all shale plays have horizontal activity.

One challenge for PCP is that has to have electricity to operate. A lot of newer shale plays are in areas that do not have grid power available yet, so they may have to rely on rented generators to power their pump.

2. Rod Lift via Pump Jack

The most common example and recognizable method of artificial lift is rod lift.

Rod lift is done using a pump jack at the surface. A pump jack goes by many different terms, including sucker rod pump (SRP), horse head, dinosaur, and nodding donkey.

The pump jack uses sucker rod string and pump to pressurize the well downhole and bring resources up to the surface piping and equipment. The rods don't rotate. They go inside the tubing, which is inside casing. At the bottom of the rod string is a pump and two check valves.

A pump jack may be powered by electricity or gas.

One challenge with rod lift is the volume limitations. If you are operating with increased volumes, you may have to change out the pump, which requires downtime and access to a portable rig.

3. Plunger Lift

Plunger lift can be used to create a pressure differential and draw liquid up the casing to production equipment.

This type of artificial lift is done using a timer control, which is typically connected to a High Pressure Control Valve.

There are several different types of plungers, including a solid plunger, pad plunger, brush plunger, and flow through or continuous flow plunger. They all perform a similar function.

As the tubing is shut in, the flow of the well stops. The plunger then falls down to bottom of well, and liquid accumulates on top of it.

The timer tells the control valve to open, and the plunger lifts the column of fluid out, through the valve, then to the production equipment.

Plunger lift is a great option for artificial lift. It's often the first form of artificial lift producers use because they can install it without the large expense of a work-over rig. It's more cost effective than PCP and rod lift, can be set up in a day, requires few people, and doesn't change a lot on location.

An electric actuator is ideal in this situation because pneumatics tend to fail as moisture in the gas causes damage to the elastomers.

4. Gas Lift

Gas lift is another way to lighten the load on the reservoir, which can push the product to the surface.

To employ gas lift, a producer sends low-pressure gas from the well through a compressor. They then send it back down the well. This pressurizes the well and forces liquids back up to the surface piping and equipment.

Gas lift valves sit at calculated depths to inject the high pressure gas into the tubing, which lifts the liquids from that zone.

Gas lift can production ranges widely, from hundreds to several thousand barrels of fluid per day.

5. Electric Submersible Pump

Producers also use electric submersible pumps (ESPs) to push production out of the well.

If you live in a rural area and have your own water well, it's more than likely using an ESP.

An ESP sits below the reservoir fluids at the bottom of the tubing string and connects to a long electric motor.

The pump has blades that move the fluids in the well. It is powered electrically, with a cable running from the surface downhole to the pump.

ESPs are designed to move large large volumes of fluid.

They feature a control box (on the right of the ESP in the picture), which can sense when pump needs to be sped up to move more liquids or slowed down as volumes decrease.

One advantage of ESPs is the heat they add.

The friction caused by the pump creates heat. This pre-heats the production fluid and aids in separation even before the fluid gets to the first production vessels. If your fluid is going to a heater treater, you may even be able to lower the burner temperature.

Producers often use a Kimray High Pressure Control Valve package to hold back pressure on the tubing out of the well head. This prevents the pump from causing cavitation.

An ESP can produce over twenty-thousand barrels of fluid per day.