Gas lift is an artificial lift system where gas is injected into a produced well casing to help lift liquids up to the surface through the production tubing.

In this video, Kyle explains why a producer may choose to use gas lift, walks through the two types of gas lift, highlights the components of the system and explains how it operates.

Benefits of gas lift

Why might a producer choose to use gas lift?

The short answer is cost. In most cases, gas lift will be the most cost-effective form of artificial lift. There are a few key reasons for this:

- Low operating costs. Operating costs are low for the entire system because natural gas is used as compressor fuel

- No additional downhole equipment. It does not require additional downhole equipment for maintenance and installation as opposed to other artificial lift systems.

- Easier to maintain. With few moving parts, repairs are quick and economical.

- Easier to replace. When there is a change in the flow conditions, producers can inexpensively remove and replace the gas lift valve without a workover rig.

Producers use one of two types of gas lift, depending on the makeup of the well: continuous or intermittent.

What is Continuous gas lift?

Continuous gas lift can be adapted to a large range of production conditions in gas wells such as large incline angle wells, high gas-oil-ratio wells and wells that have sand, wax or scale.

However, it is not suitable for heavy oil or emulsion oil wells.

What is intermittent gas lift?

Intermittent gas lift systems can operate efficiently in low-pressure, low-productivity wells.

Intermittent gas lift is when gas injection is done at a predetermined interval and fluids are produced in an intermittent cycle.

How a Gas Lift system Works

Now let's look at how a standard continuous gas lift system works and identify each component.

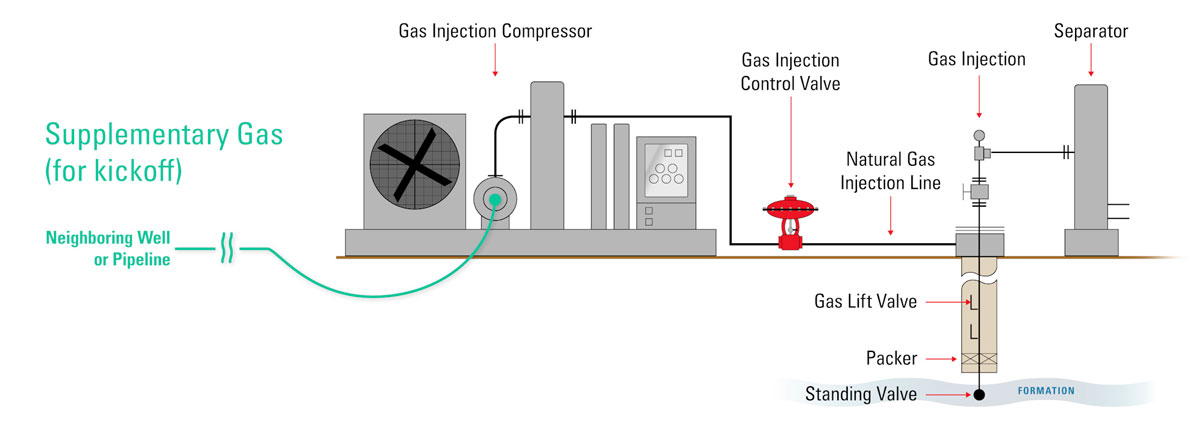

After initial startup or “kickoff”, the well must produce enough gas volume to operate the gas lift system. In many gas lift wells, supplementary gas is taken from nearby wells or pipelines to “kickoff” the artificial lift process.

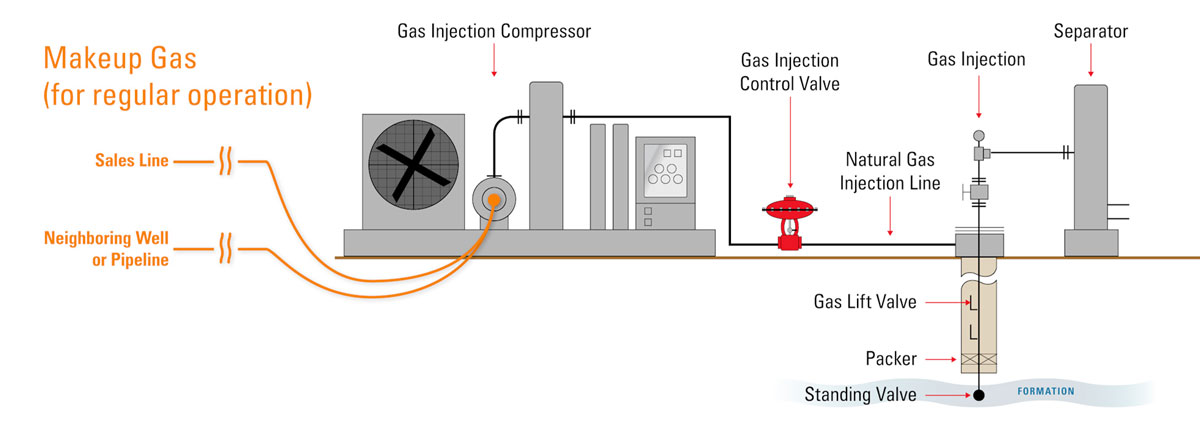

If the well is not making enough gas to meet the volume needs of the gas lift system, makeup gas can be brought in from the sales line or a neighboring well.

Compressor

Low pressure natural gas is compressed and will travel into the injection line or be re-routed through the bypass valve if pressure and volume requirements have been met in the well bore.

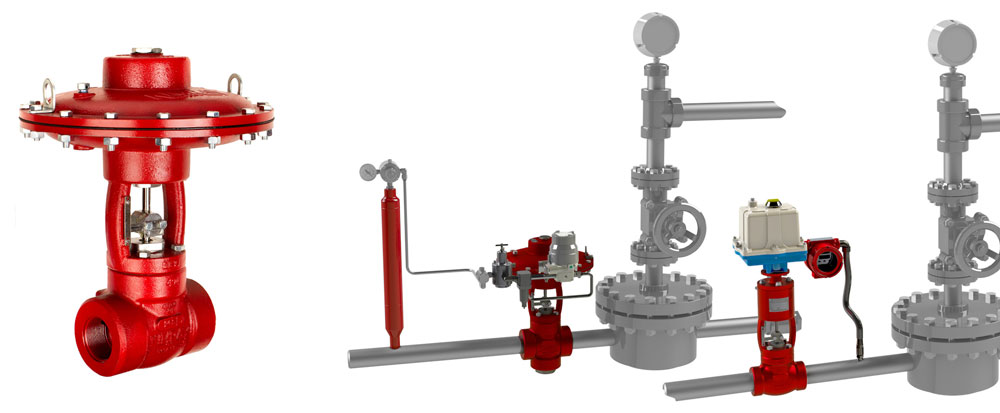

Gas Injection Valve (Control Valve)

The gas injection valve helps control the flow of natural gas into the well. Kimray’s high pressure control valves are used in this application because they offer flexibility in trim sizes, and they can be controlled pneumatically or electrically.

what are Gas Lift Valves?

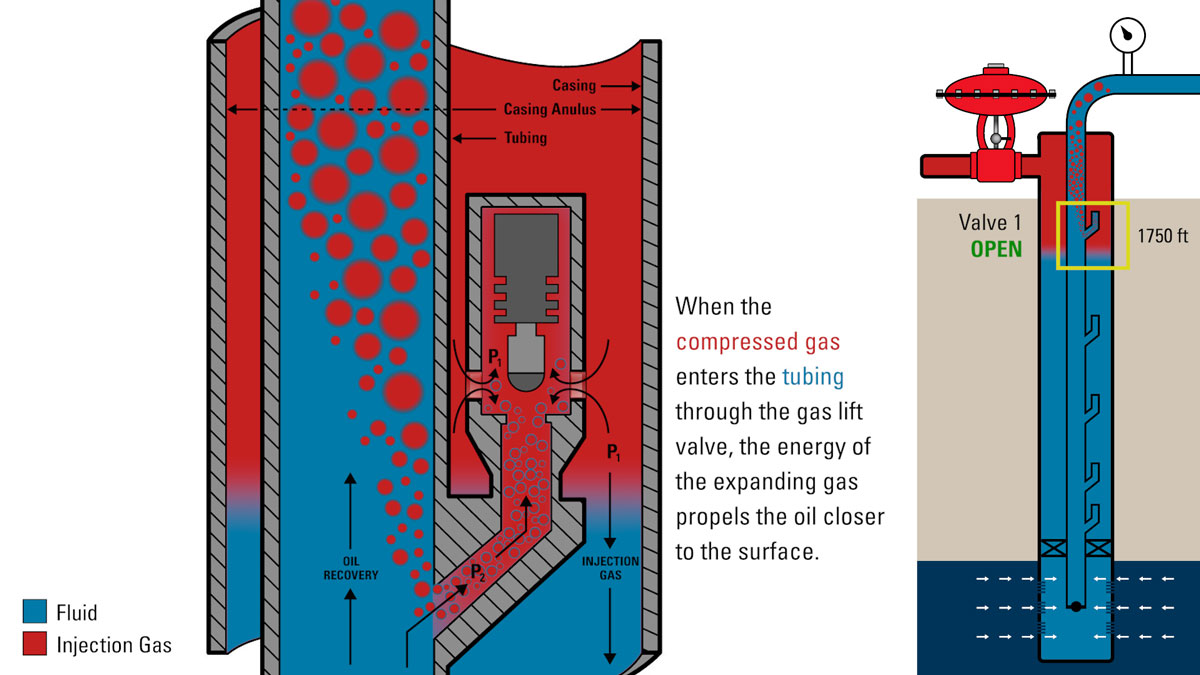

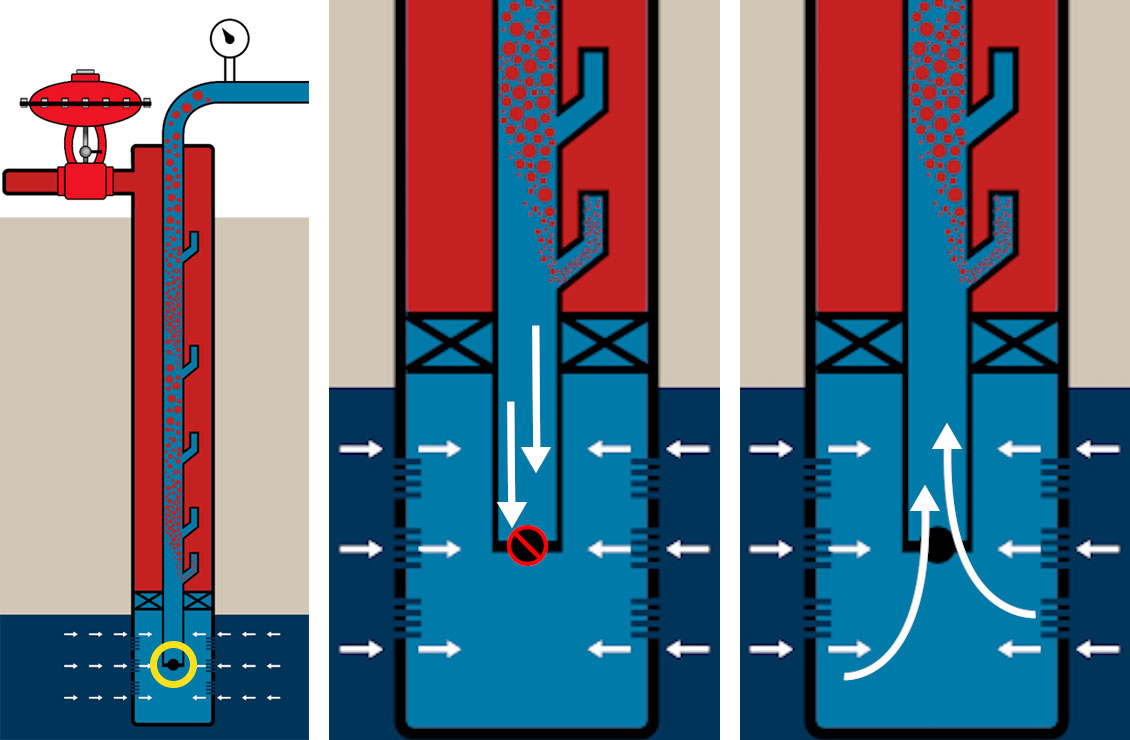

Gas enters the casing and travels down to the gas lift valves.

Most gas lift valves open in reaction to a specified gas pressure in the casing. The casing pressure (P1) compresses a bellows inside the valve and raises the stem to open the valve.

When the compressed gas enters the tubing through the gas lift valve, the energy of the expanding gas propels the oil closer to the surface. The gas also aerates the fluid column, lowering its density and allowing it to flow more easily with less pressure.

There are additional gas lift valves installed at intervals below the surface. At the beginning of production, these “unloading” valves are used to reduce the density of the fluid column that has risen above the primary gas lift valve.

This “operating valve” is injecting gas at the deepest point in the well bore. This process is referred to as well kickoff or well unloading.

Standing Valve

The standing valve ensures all fluids remain in the tubing rather than allowing fluid to exit into the formation. However, like a check valve, the standing valve allows gas and fluids to enter the tubing from the reservoir.

Packer

A packer is a device that forms a seal between the two chambers of the well—the tubing and the casing. This seal keeps injected gas from traveling into the formation or into the end of the production tubing.

final stages of well life

For the final stages of production at the end of a well's life, operators can replace other artificial lift systems with intermittent gas lift until the reservoir pressure becomes too low to lift the target fluid volumes.

When it’s not economical to operate gas lift or bottom-hole pressure is too low, operators typically switch to rod pump or electrical submersible pump systems.

Next up: How Natural Gas Compressors Work