Where to listen online:

Plunger lift is an increasingly popular form of artificial lift that energy producers use to help lift oil and gas from their wells.

In this video, we explain how plunger lift works using this demonstration model.

What is Plunger Lift?

Plunger lift is a well-established artificial lift system that has been in use since the 1950s.

In the early life of a liquid-producing gas well, flow rates and velocities usually are high enough to keep the wellbore clear of liquids. As reservoir pressures decrease and liquids begin to accumulate in the wellbore, there can be a large amount of hydrostatic head pressure that builds. The reservoir gas can bubble up through this liquid column but cannot lift it completely out of the wellbore. If liquid loading is not addressed, it can effectively plug the well, stopping all production.

This is a cost-effective solution for removing liquids and allowing the natural reservoir pressure to produce the well. This system is cost effective because it uses the well’s natural pressure and does not need any external input of pressure.

Since the 1980s the primary application for plunger lift systems has been liquid loaded gas wells. However, plunger lift can be used in tandem with gas lift to effectively produce oil wells in what is known as gas assisted plunger lift.

Plunger lift systems are most effective in wells that have low bottomhole pressures and high gas/liquid ratios (GLRs). Wells with a shut-in wellhead pressure that is 1.5 times the surface flowline pressure are also good candidates for plunger lift systems.

Other methods can be utilized to remove the liquid column from the wellbore.

For example, soap sticks or surfactants, once introduced to the liquids in the well, begin to create a foam that is more easily lifted to the surface by the natural well pressure. With this method, there are costly chemicals that must be maintained and possible downhole injectors that must be installed. This method is also not effective if there are large amounts of liquid hydrocarbons present that can neutralize the surfactants.

Why is plunger lift considered one of the simplest form of artificial lifts?

Plunger lift is often the first form of artificial lift producers use because they can employ it without the large expense of a work-over rig.

It's more cost effective than PCP and rod lift and can typically be installed in about a day.

Plunger lift equipment

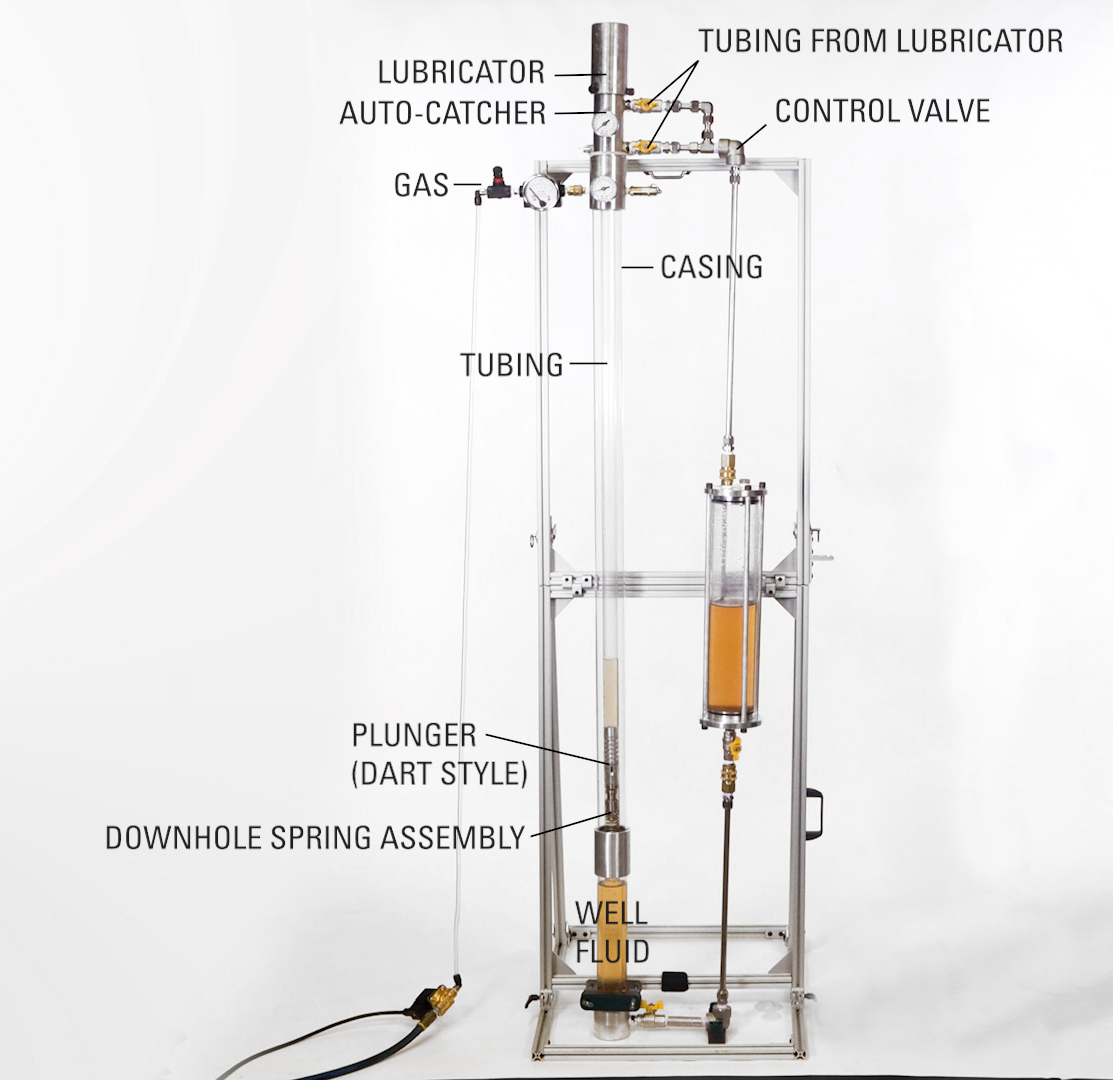

The model in the video is simulating gas-assisted plunger lift. Here's a typical list of plunger lift equipment:

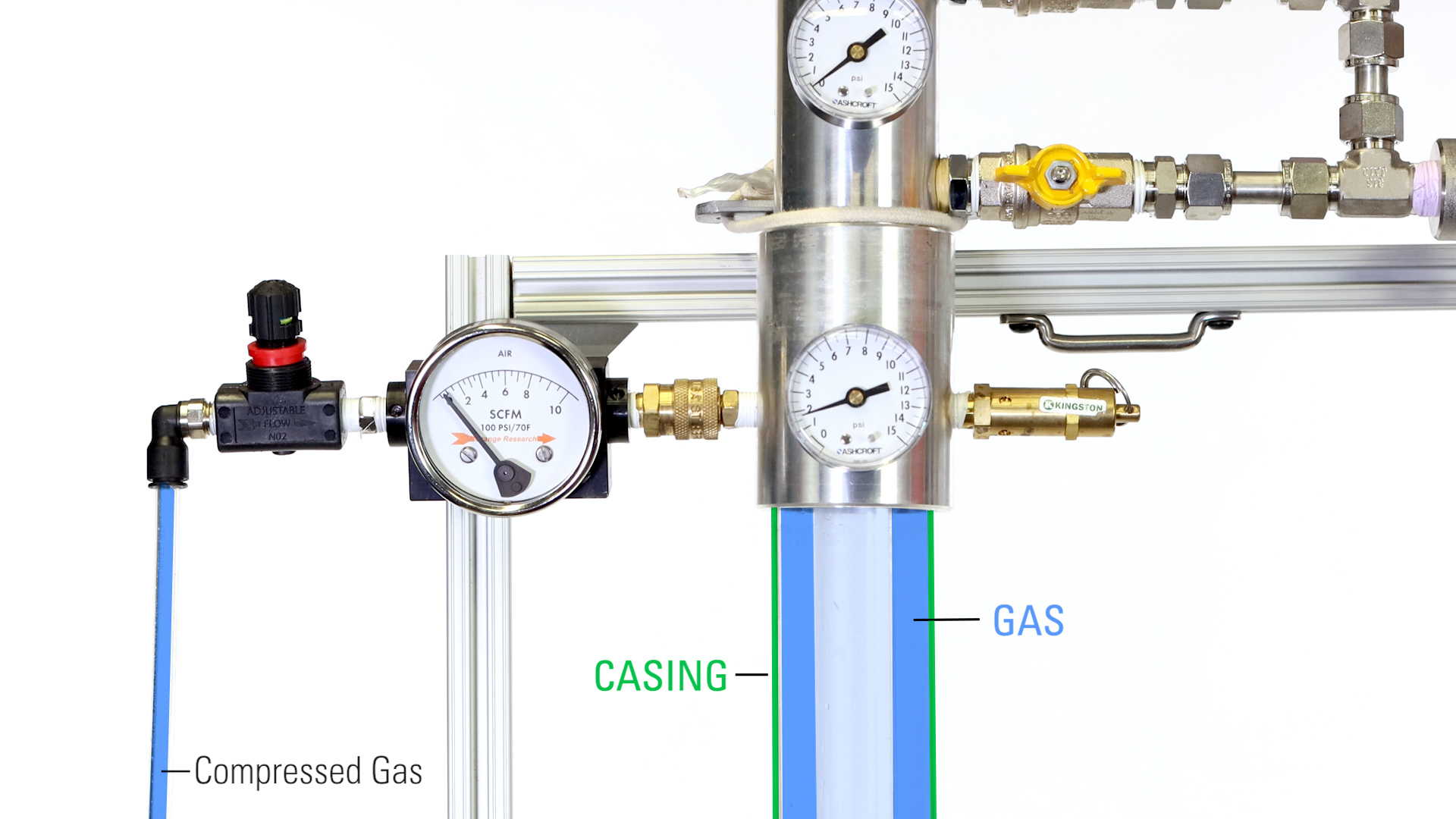

- “Gas” is coming from a gas compressor is being injected into the well casing.

- The plunger is at the bottom of the well. This is a dart-style plunger, which is used with high flow rates or in the bypass phase of the well.

- Well fluid is on top of the plunger.

- The larger diameter outer piping is called the casing.

- The smaller diameter inner piping is called the tubing.

- Above the surface (and not pictured in the video) would be the Christmas tree, flow line and control valve.

- Lubricator

- An auto-catcher inside the lubricator

How does a plunger lift work?

In gas-assisted plunger lift, the producer is injecting gas in order to pressurize the well. As gas travels down the casing, it eventually enters the tubing through perforations beneath where the plunger and downhole spring assembly are located.

The downhole spring assembly has a check ball that only allows gas and fluids to pass up through it. This keeps any fluid or gas from passing back down below the downhole spring assembly which prevents dry runs from occurring.

Because the valve at the surface is closed, pressure will continue to build until the valve opens. There is a column of fluid in the tubing that will be brought to the surface with the plunger when the control valve opens.

What causes the valve to open?

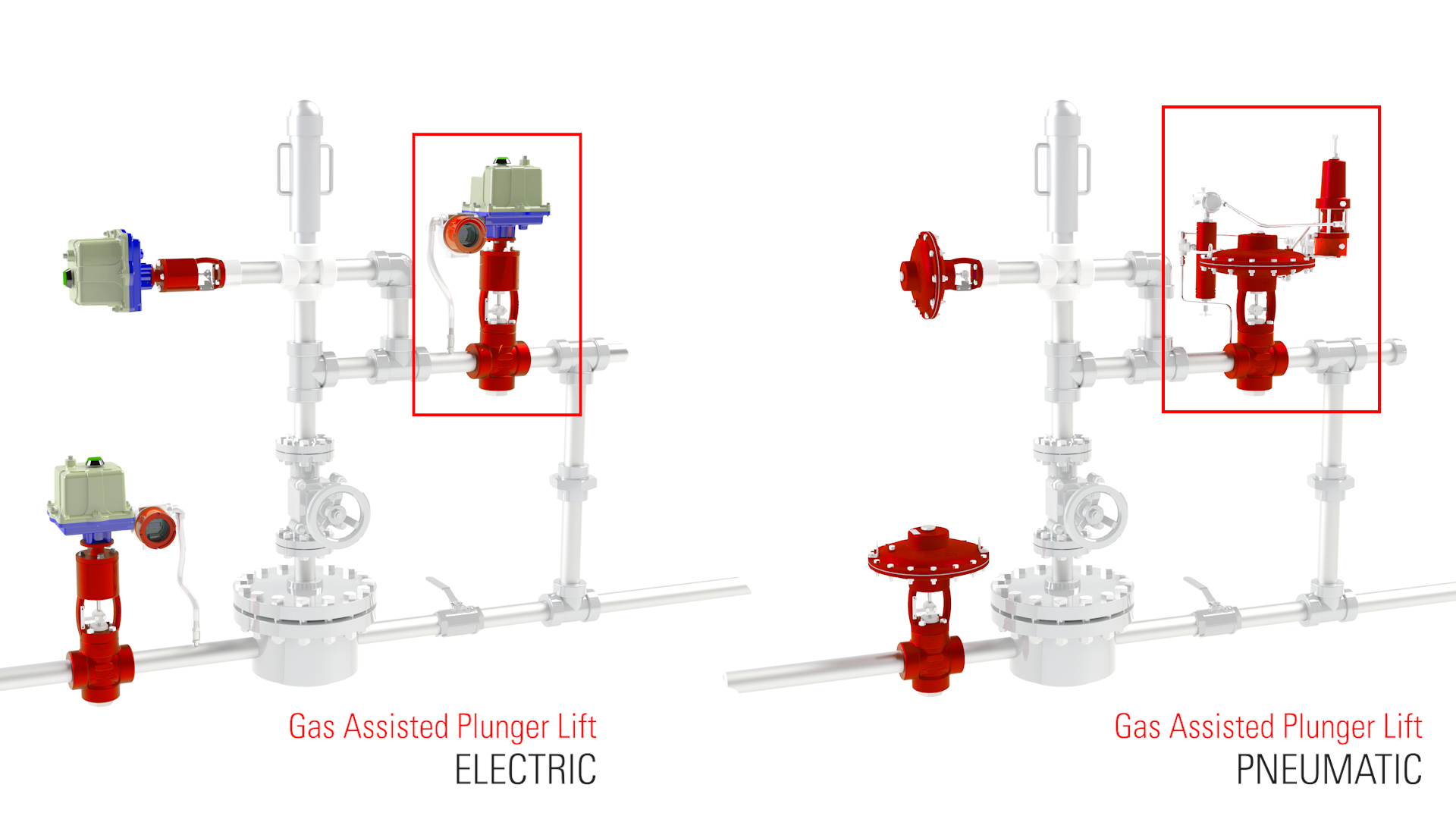

The valve will be actuated by either a pneumatic signal to a pilot or a discreet electric signal if an electric actuator is being used. When the valve opens, and how long it stays open will be determined by the producer and is based on either time or well pressures.

As the plunger enters the lubricator it passes the arrival sensor positioned at the bottom of the lubricator. This sensor alerts the well controller of the plunger position.

If the plunger needs to be changed or have maintenance performed, an internal auto-catcher can be activated to keep the plunger in the lubricator even after the control valve is closed. There is a pin inside the auto-catcher designed to catch the plunger and not allow it to fall downhole.

Once either the timer is ready or the casing pressure drops to below the set point, the valve closes.

The plunger then falls through any remaining fluid that’s in the tubing and down to the downhole spring. Then the process will start again.