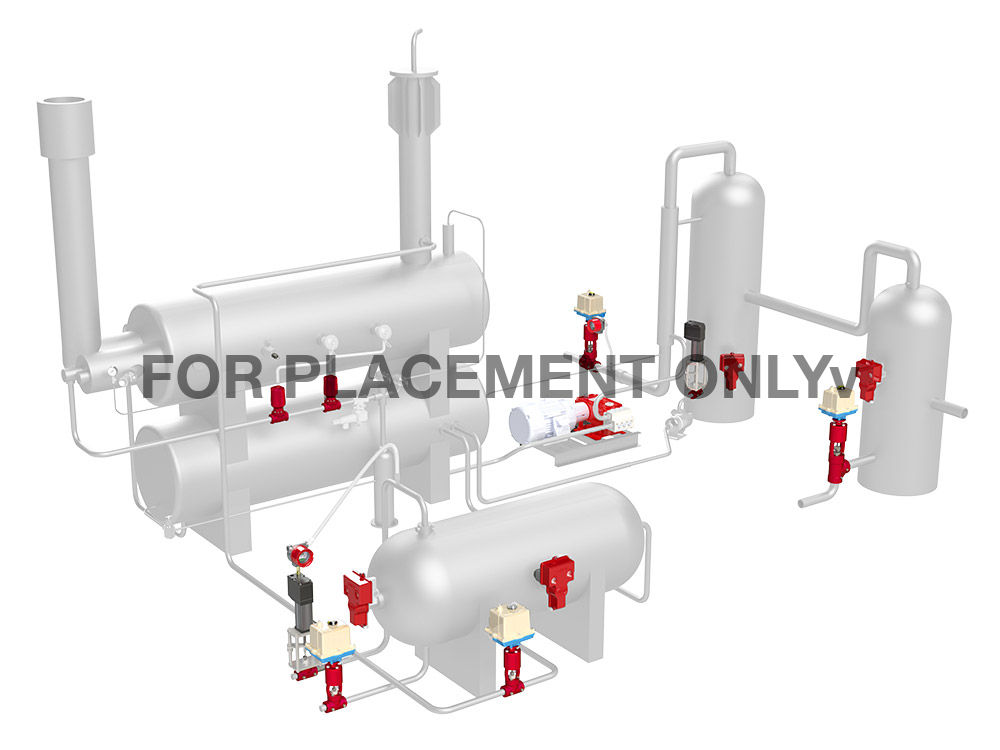

Product Applications

AMW5

Build & Save a Quote

We'll get you options, pricing, and anything else you need.

Anything we can do to help?

Talk to a specialist at (405) 525-4264 or fill out a quick product message form.

Product Charts

Tech Specs

| Type | Value |

|---|---|

| Connection Size: | 2 " |

| Connection Type: | 150 RF |

| Body Style: | Through Body |

| Body Material: | Cast Ductile |

| NACE MR0175: | Option Available for NACE MR0175 compliance or certification |

| Trim Size: | 2 " |

| Trim Type: | Equal Percentage |

| Leakage Class: | Class VI |

| Process Fluid: | Liquid and Gas |

| Pilot Type: | Non Vent |

| Max Working Pressure: | 250 psig |

| Min Set Point Pressure: | 25 psig |

| Max Set Point Pressure: | 50 psig |

| Operation: | Spring Operated |

| Catalog Page: | 06:100.1 |

| Face-to-Face Length: | 9 " |

| Max Cv: | 47 |

| Cf: | 0.75 |

| Weight: | 48 lbs |

Product Videos

Compatible Kits and Tools

| Type | Product Code | |

|---|---|---|

| Repair Kit: | RYJ |

Frequently Asked Questions

Common applications for back pressure regulators include gas sales lines, separators, heater treaters, free water knockouts, and flare lines.

Different options are available to accommodate corrosive or erosive environments. This includes different elastomer options as well as stainless steel component and trim options.

MWP depends on multiple factors such as end connection type, shell material type, and if the regulator is a standard pressure or low pressure regulator. Similarly, temperature ranges will be dependent on the elastomer option that is used on the soft goods in the assembly.

Typically, the standard process media is natural gas. However, certain back pressure models can accommodate wet gas and mixed liquid/gas process media.

The Back Pressure Outside Supply (BPOS) Regulators can function in wet gas conditions.

The Spring Loaded Back Pressure Regulator can maintain a setpoint on liquid or gas systems where 0 to 125 psig adjustable pressure is desired.

Master Repair Kits are available for all regulators. Maintenance is recommended to be performed at least once a year. However, this frequency can increase depending on the application and potential changes in operation conditions.

Still have a question? Send us a quick product message to get help from our team.

Quick Links

Kimray has a team of experts that can help you identify the right products to meet your product and emissions goals.

Talk to a specialist Mon - Fri, 7 AM - 5 PM CST at (405) 525-4264.