Kimray has three primary categories of dump valves: pneumatically operated, lever operated, and weight operated. Each performs the same general function of regulating the flow of liquid in vessels and pipelines on a production site.

In this video, we look at lever and weight operated dump valves, their benefits and different options available.

Lever Operated Liquid Dump Valves

Lever operated dump valves are mechanical, meaning they use a linkage arm connected to a trunnion assembly and float to actuate the valve and regulate the flow of liquid.

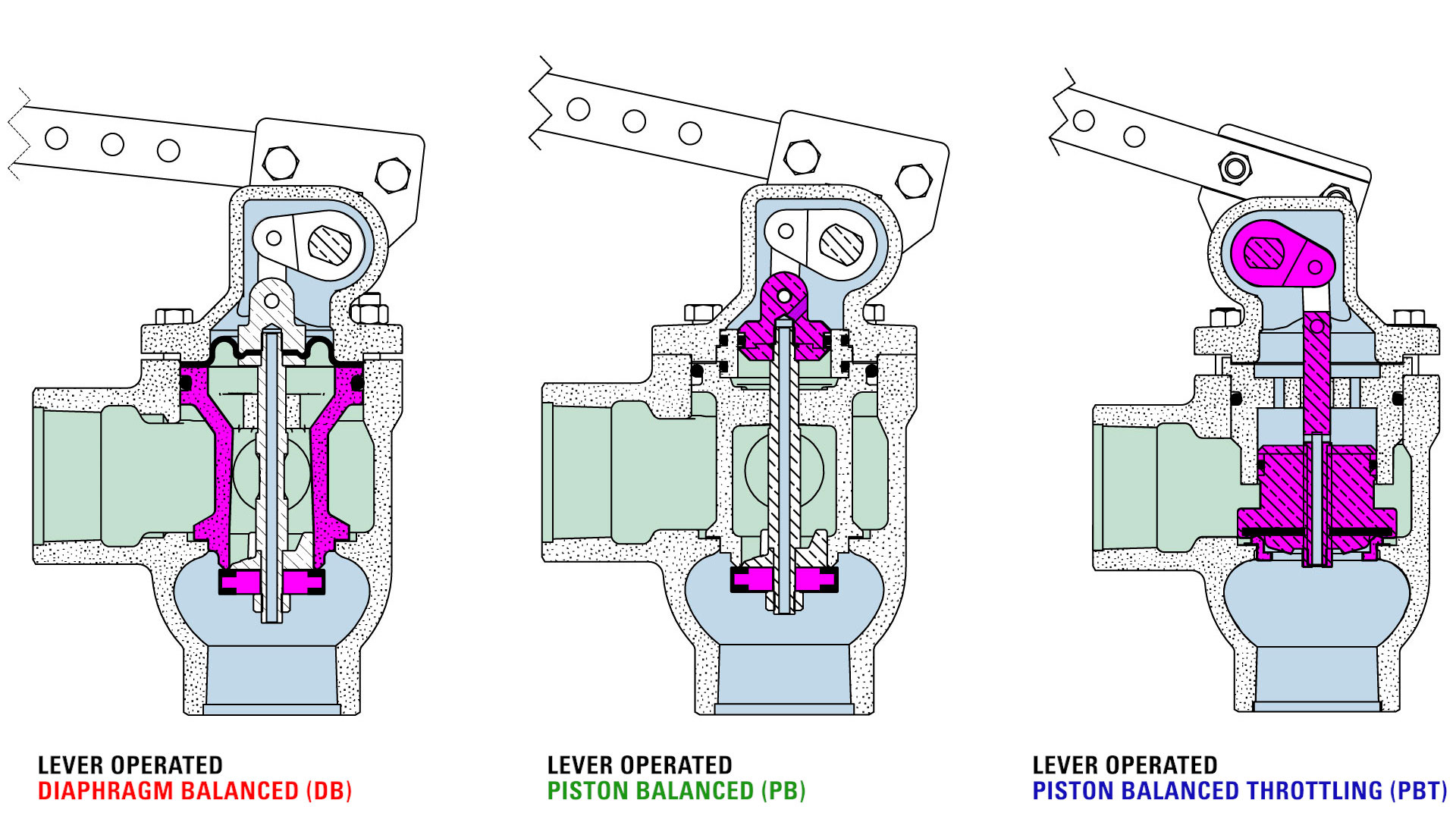

There are three different designs, all of which are “balanced.” This means the upstream and downstream pressures are used to equalize the forces on the trim. Because of this balance, the valve can more easily open and close, regardless of the pressure differential of the valve.

- Lever Operated Diaphragm Balanced (DB) models communicate downstream pressure through the stem to the top side of the balancing diaphragm.

- Lever Operated Piston Balanced (PB) models communicate downstream pressure through the stem to the top side of the balancing piston, allowing it to operate at higher pressures than the diaphragm balanced models.

- Lever Operated Piston Balanced Throttling (PBT) dump valves are designed for higher volumes and erosive production conditions. The trim lifts out of the flow path when it opens, limiting contact with the process fluid, preventing wear on the trim.

Weight Operated Dump Valves

Weight operated dump valves also use a lever to operate, but do not require a linkage arm, and trunnion assembly with a float to control liquid level.

Instead, the upstream pressure and liquid head pressure push on the main diaphragm in the valve, working against the weight attached to the arm.

They are used on free water knockouts, saltwater disposal units, and heater treaters for both the oil and water dump lines.

Lever Bars, Weights, and Liquid Head Height

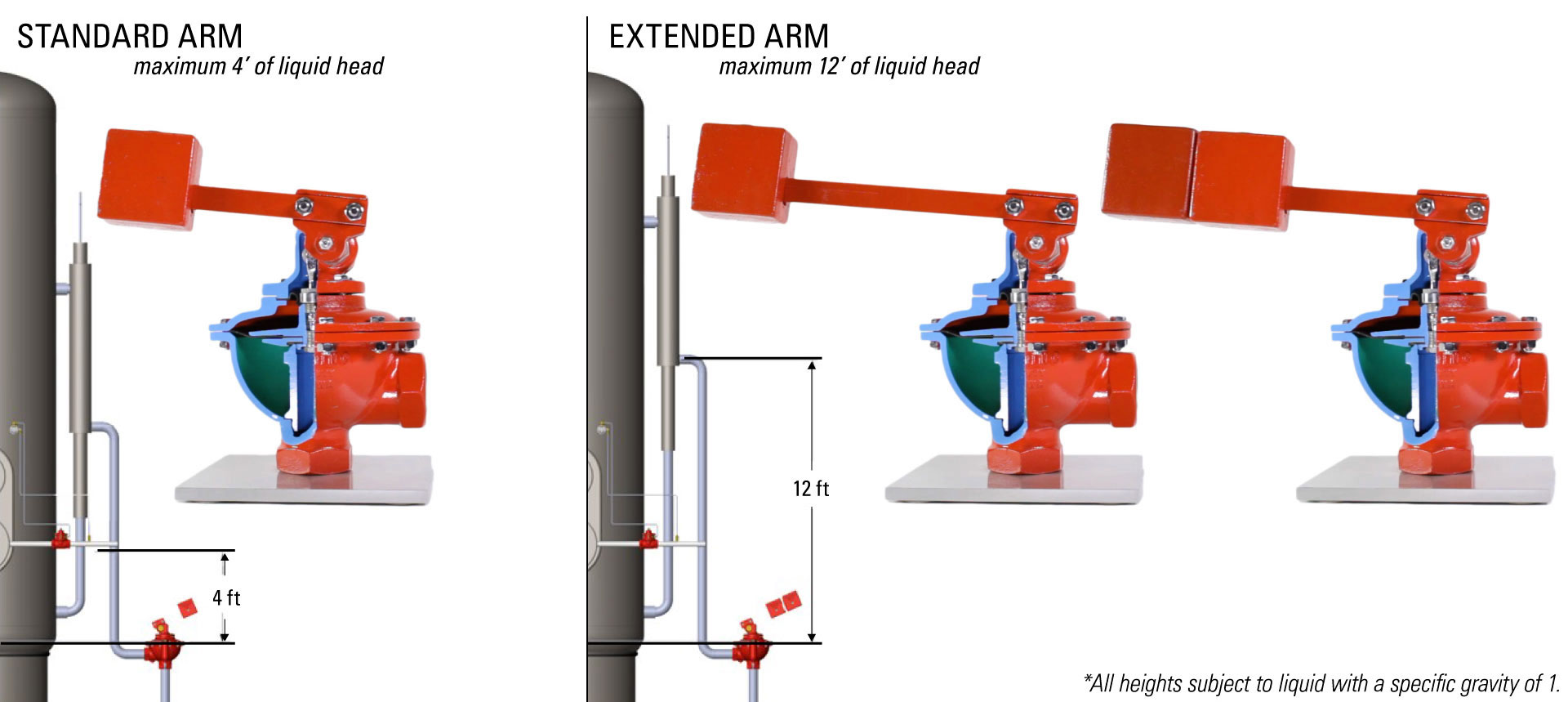

The position of the weight on the lever determines the height of liquid being held inside the vessel or downcomer. That liquid head pressure builds and adds to the operating pressure of the vessel to open the valve.

Adding weights and/or longer levers increases the maximum liquid head height. A single weight and standard arm can hold up to 4 feet. Two weights and an extended arm can hold up to 12 feet.

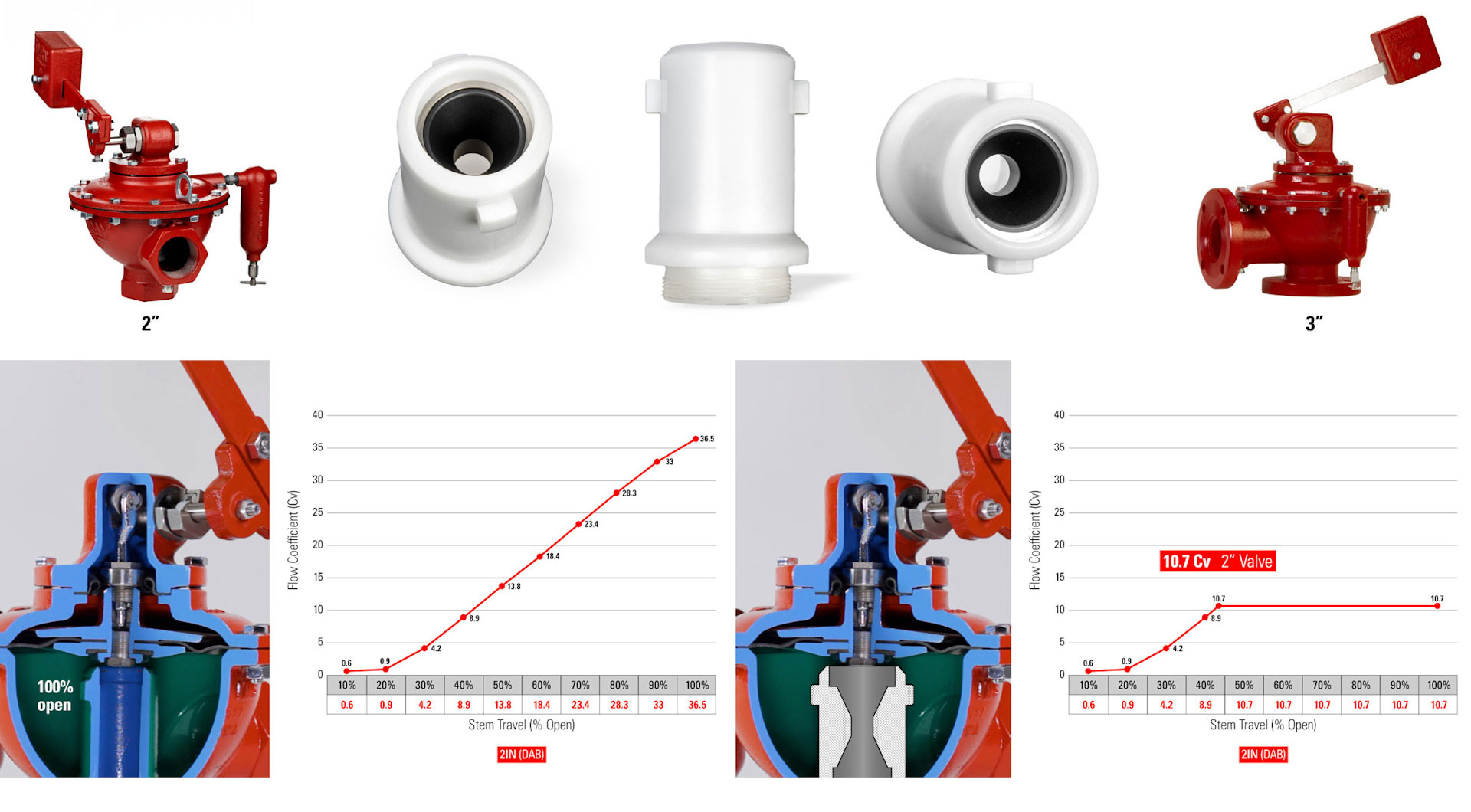

Orifice Reducer Assembly

2” and 3” weight operated dump valves can be fitted with an orifice reducer assembly that effectively changes the high end of the Cv by restricting the flow downstream of the trim. This can be useful for valves that have become oversized after reduced production volumes.

additional Dump Valve features for Lever and Weight Operated Models

Here are additional features of Kimray dump valves that are for both weight operated, and lever operated models.

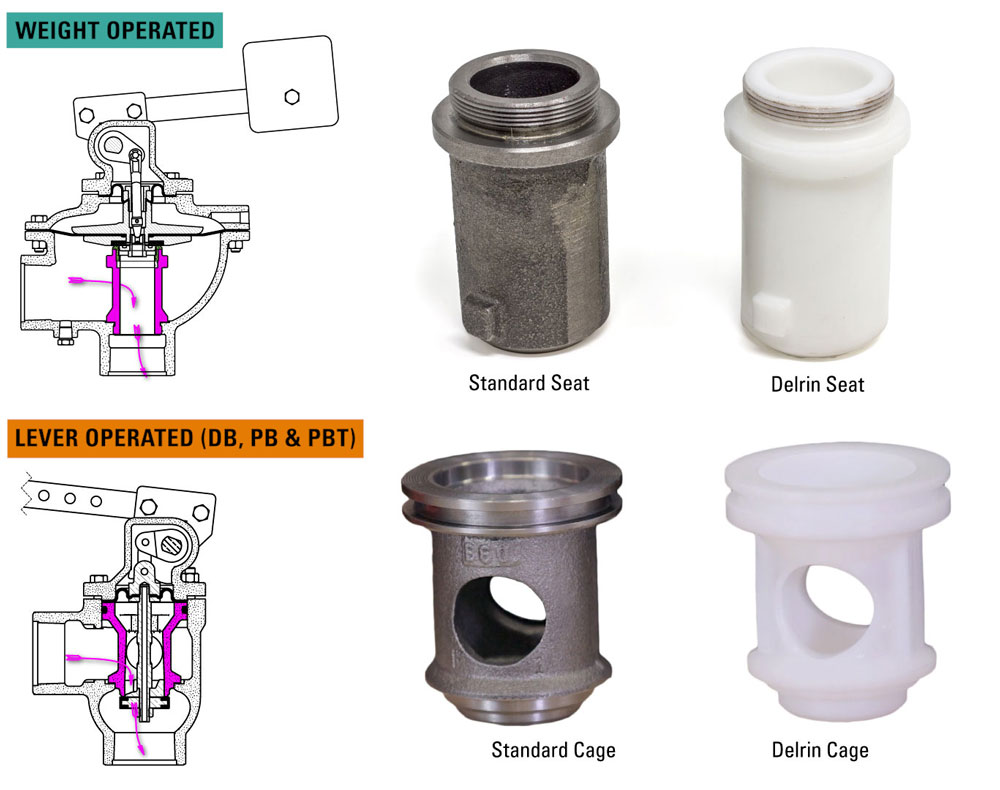

Material Options

316 stainless steel parts are available for corrosive applications such as where H2S, CO2, or saltwater are present. Delrin is available for some internal components for erosive applications.

Emissions-Free

Both the Lever operated and Weight operated dump valves do not use pneumatics to operate. This means under normal operating conditions there will be no gas emitted to the atmosphere.

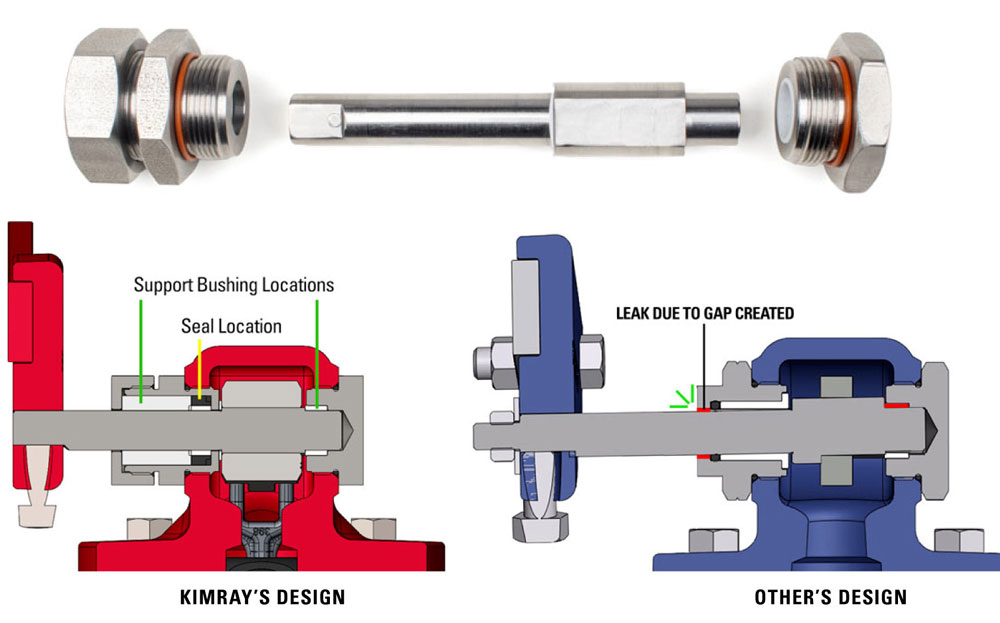

Hub & Shaft design for Reduced Rotational Play

Kimray’s specially engineered hub and shaft design has minimized the rotational play in this connection to the least amount of any other solution.

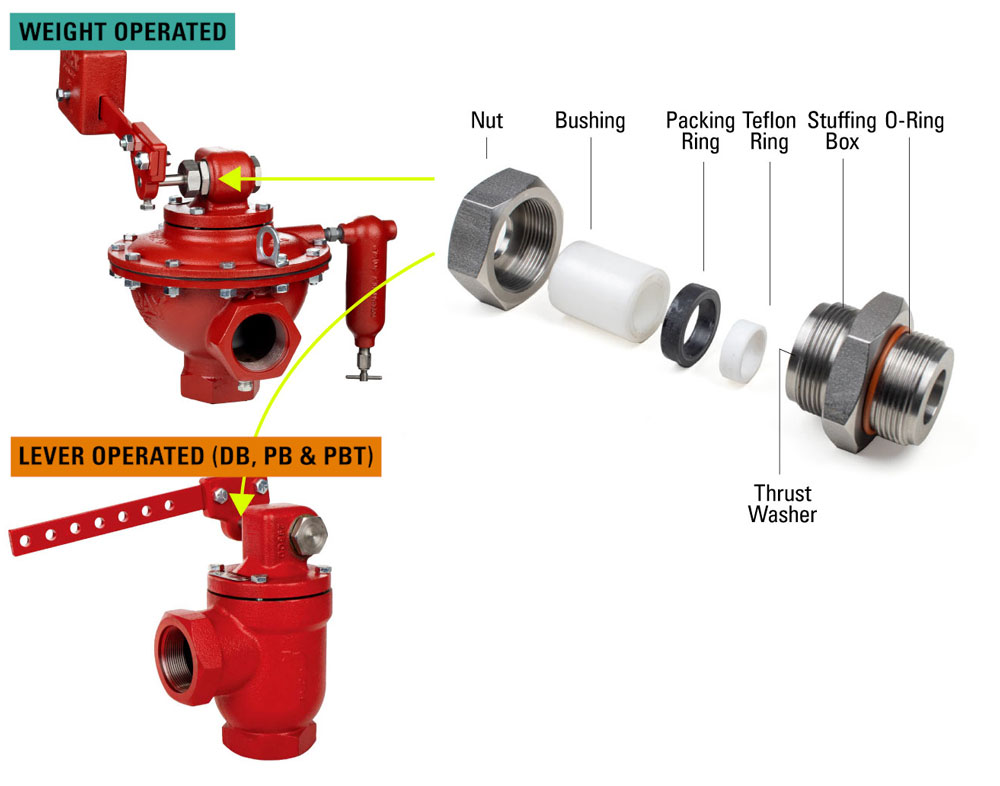

Adjustable Packing

The adjustable packing in the weight operated valve provides an easy way to prevent leaks and make your valve last longer before maintenance is required.

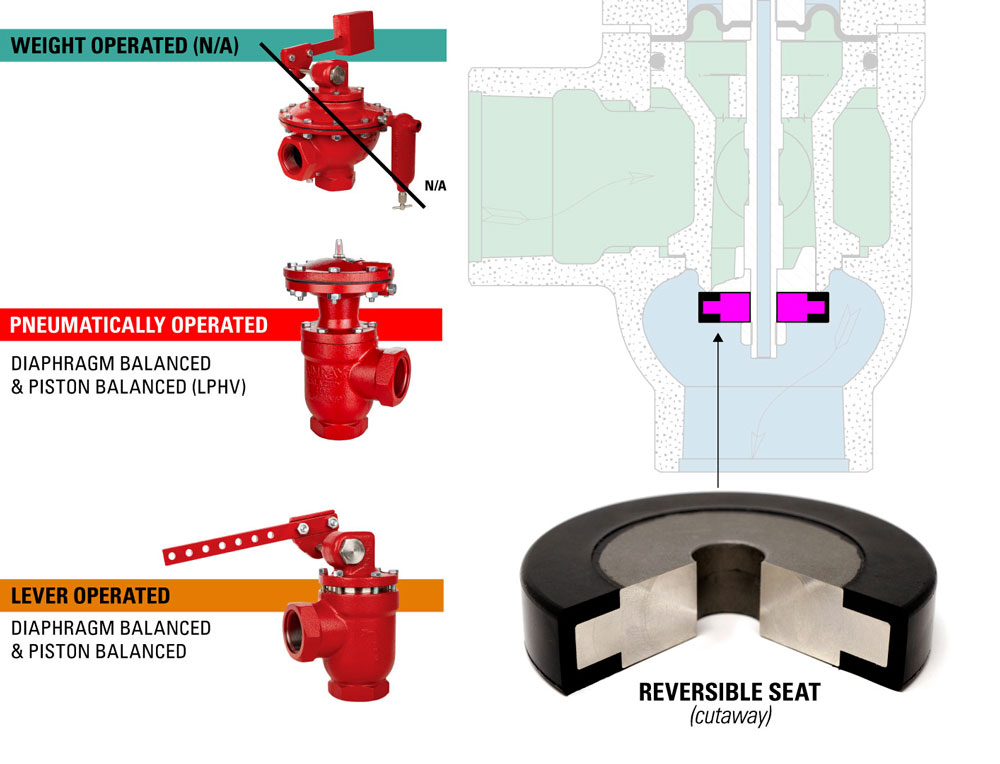

Reversible Seat (lever & pneumatic; not weight operated)

The valve seat is the component that seals the valve closed. This seat is reversible, meaning that when one side of the seat is compromised it can be flipped 180° and used again, doubling its lifespan.

Certifications

Manufactured and assembled in the USA, our liquid dump valves are certified for use in North and South America and most areas around the world.

Hydrostatic testing, Materials Test Reports (MTR) and NACE compliant documentation are available upon request.

We have 25 distribution centers in the U.S. and international distribution partners globally. Kimray is also an ISO 9001-certified manufacturer.

Reach out to your local Kimray representative today to explore how we can help solve your control challenges.