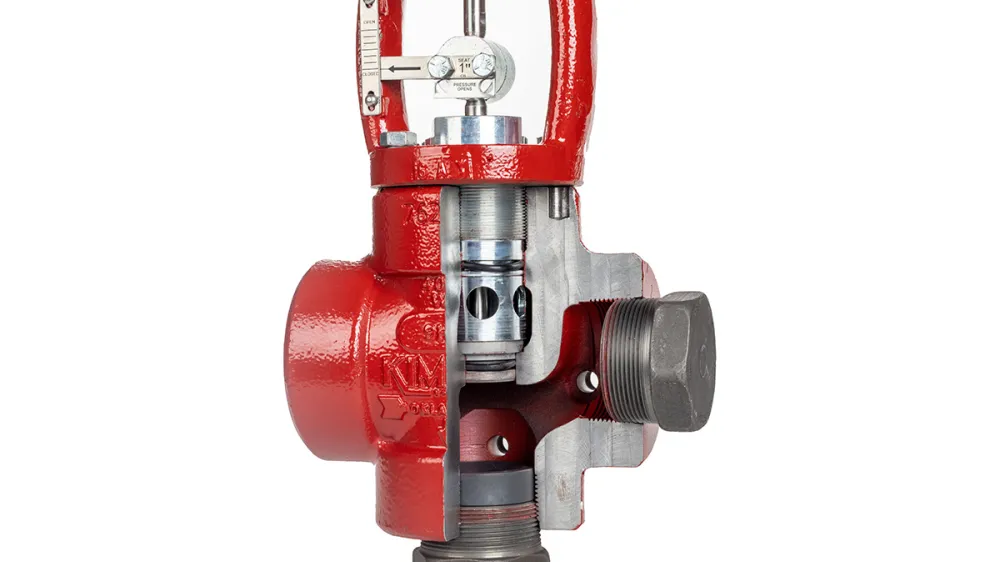

The T-Body High Pressure Control Valve provides long-lasting, robust control of high-pressure processes and allows you to extend production time in flowback and erosive applications.

Is your valve compromised by erosion?

With the increased use of proppant in well completions, control valve body replacement has become a regular requirement for oil and gas producers.

Erosive production fluid causes equipment damage and can lead to environmental and safety issues as well as costly downtime.

Prevent Control Valve Body Replacement with the T-Body High Pressure Control Valve

The T-Body High Pressure Control Valve is ideal for liquid dump, plunger lift, gas lift, flowback, or any other control application where erosive conditions exist.

With regular maintenance, the T-Body provides long-lasting control of high-pressure processes and allows you to minimize control valve body replacement.

There are 4 key features that make this valve effective:

Replaceable Wear Plug

Configurable Body

Field-Reversible Top Works

Electric or Pneumatic Actuation

Key Benefits for Oil & Gas Producers

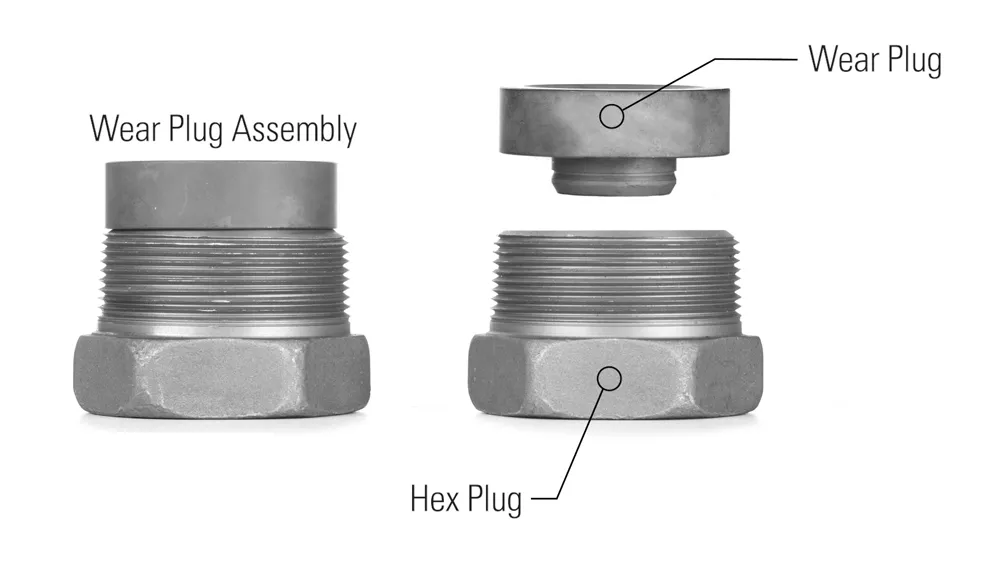

Replaceable Wear Plug Assembly

The key feature of the T-Body valve is the replaceable wear plug assembly. This plug assembly is designed to absorb the force of sand and other erosive materials that wear away and damage HPCVs.

You can easily examine this sacrificial piece and replace it without taking the valve out of line.

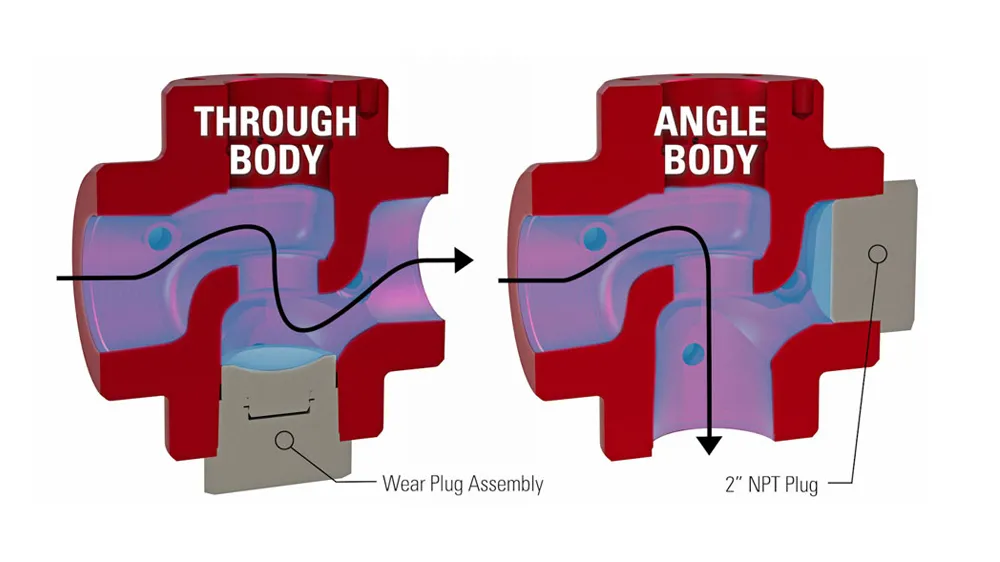

Configurable Body

The NPT end connection option can also be quickly converted from through-body to angle-body configuration.

This means you can easily repurpose your valves for different applications, and purchase one valve rather than two to reduce the overall amount of inventory needed for your operation.

Field-Reversible Top Works

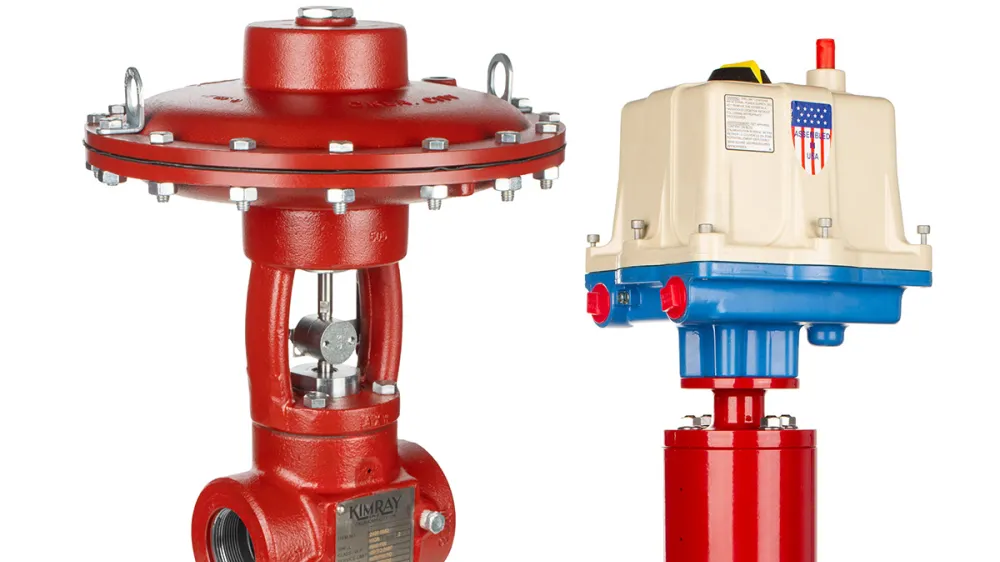

With the pneumatic version of the T-Body, you can convert the topworks in the field from fail-closed to fail-open operation.

This allows you to quickly pivot from one application to another using the same valve.

Electric or Pneumatic Actuation

The T-Body High Pressure Control Valve comes standard for pneumatic actuation.

You can also pair it with one of our electric actuators to reap benefits like zero-emission operation and remote control.

Full Line of T-Body High Pressure Control Valve Options

A Solution for Flowback Problems in East Texas

An oilfield services company was providing flowback services for wells in East Texas. A well’s flowback phase is known for being very volatile due to the presence of erosive materials in the production fluid, and they were experiencing rapid deterioration of their valve bodies.

On top of the equipment damage and replacement costs, the compromised valves were causing downtime, a loss of production, and environmental issues due to production fluid leaking out from the valves. They were very motivated to find a solution.

Other Field Studies

GPU Erosion in Pennsylvania

A producer in Pennsylvania was experiencing fires in their Gas Production Units (GPU). Upon analysis, they discovered that the erosive production fluid was boring a hole through their valve bodies.

As a result, gas was released from a hole in the compromised valve, and the burner on the GPU was causing the flammable gasses to ignite and fire to spread throughout the unit.

Sandy Conditions in Western Oklahoma

A producer was operating plunger lift wells in very sandy conditions in Western Oklahoma. On these particular wells, they had transitioned to plunger lift during initial production, directly after flowback.

After experiencing an increasing amount of sand downstream in their separator as well as inconsistent production from the wells, they decided to examine the valves and trim.

Find Kimray In Your Area

To see how the T-Body High Pressure Control Valve might fit into your operations, talk to an expert at our corporate office by calling (405) 525-4264, Mon - Fri, 7 AM - 5 PM CST.

We ship all products from our 10 Kimray Stores and have authorized Kimray distributors across the United States and around the world. Our distributors and stores are divided by region, with dedicated representatives specializing in their areas.

Visit our International section for information on non-domestic purchasing and certifications.