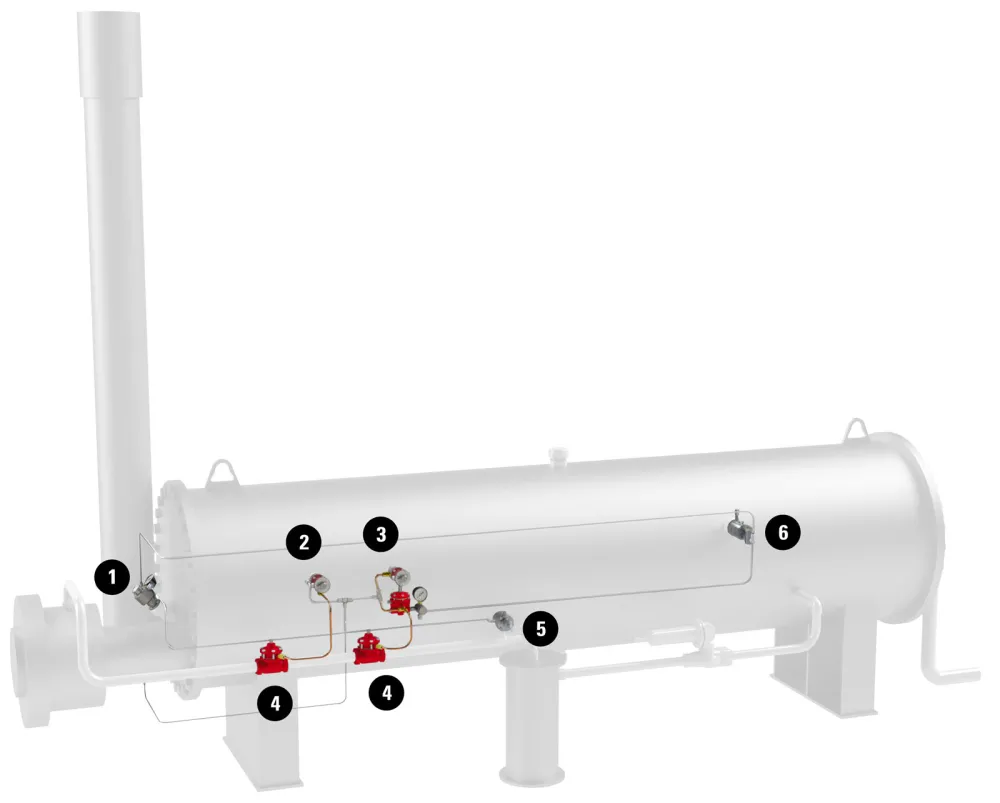

As the pressure of process fluid is cut from high to lower pressure, the Joule-Thomson effect (also referred to as the “JT effect”) can cause an extreme drop in the fluid’s temperature. This can quickly result in hydrates freezing in the line, blocking flow and shutting in the pipeline until the frozen hydrates are thawed or removed. A line heater is used in order to prevent this freezing. A line heater is a horizontal vessel used to heat up the well stream. The heater uses supply gas to run the burner fire and heat the fire tube. The fire tube runs along the bottom of the vessel and heats the surrounding liquid, often referred to as a “water bath.” Meanwhile, the process fluid runs through a series of coils above the fire tube. The coils are also submerged, allowing the process fluid inside to absorb heat from the vessels water bath. This raises the temperature of the well stream to prevent freezing.

Related Trainings & Demos

Training that Makes These Diagrams Come to Life

We do in-person trainings at our facilities or in your field to help you make these applications work in the real world.

Learn easy installation techniques

Discover maintenance and preventative care plans to preserve the life of all your equipment

Connect with Kimray engineers and technicians

Find more products to improve your entire system

Domestic and international trainings - Kimray covers the globe

Contact your business development representative to visit us at our OKC campus or have someone come to you. We can't wait to see you.

Monthly Videos, Tips, & Insights

The Kimray Chronicle is your source for news within the Kimray community.

Each monthly newsletter includes information on product improvements, tips on how to better optimize your site, videos and articles on how to complete your own repairs, as well as news about training and events.

© 2026 Kimray, Inc. All Rights Reserved.