Flowback is the first stage of production after a well has been opened. In this guide, we’ll briefly explain the flowback process, the job of a flowback operator, and some unique challenges the flowback phase presents.

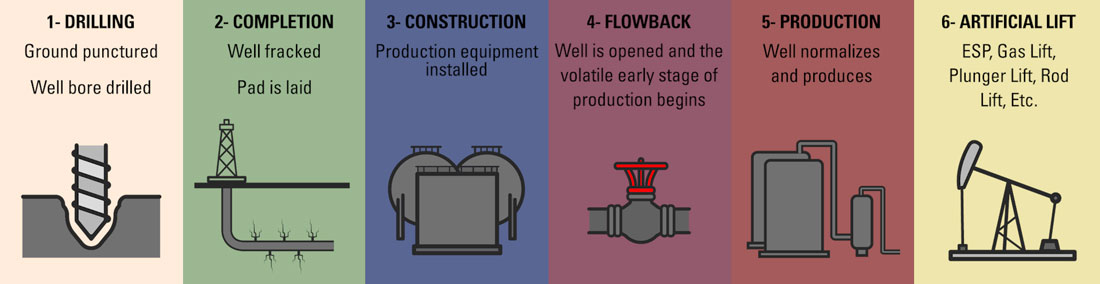

6 Stages of Oil Well Production

The process of producing a well follows six broad stages:

- Drilling: The ground is punctured and the well bore drilled.

- Completion: The well is fracked.

- Construction: All production equipment needed to flow the well is installed, including tanks, separators, and interconnecting piping.

- Flowback: The well is opened and the volatile early stage of production begins.

- Production: The well normalizes and produces consistently as long as downhole pressure remains.

- Artificial Lift: After production, as the reservoir pressure decreases, producers may choose from a variety of artificial lift options.

What is Flowback?

After a well has been drilled, the casing cemented, the shale fractured, the pad laid, and the piping and production equipment installed, the flowback phase begins.

Flowback typically lasts between 30 and 120 days. The fluid produced during this phase is a mixture of crude oil, natural gas, water, and sand.

A producer’s goal during this period is to manage the sandy flowback fluid and keep the well open and running so it can normalize and more freely flow oil and gas.

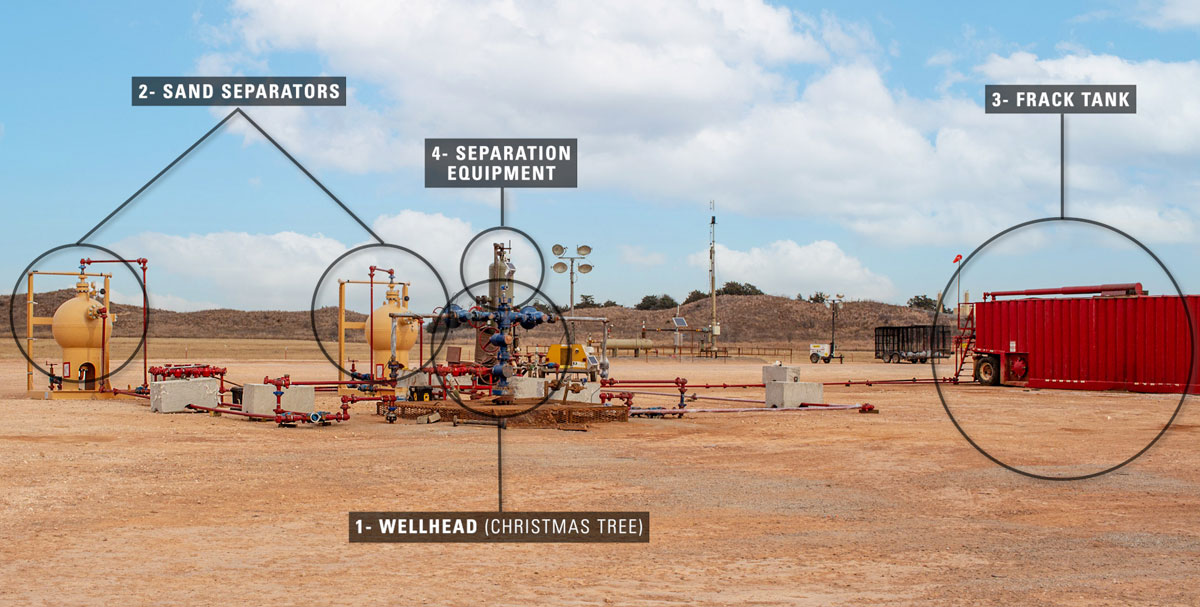

The fluid first flows up the well bore and through the wellhead, which is often referred to as the “Christmas tree.” From there it moves to sand separators.

Sand separators spin the production fluid, which creates centrifugal force. This is where the bulk of the sand is processed out of the fluid. It is then piped to on-site frac tanks, which trucks will retrieve throughout the process.

Producers then flow the fluid through a variety of separators. These include two- and three-phase separators, free-water knockouts, and heater treaters.

These vessels separate the fluid into its three primary elements—gas, oil, and water. What sand remains sinks to the bottom of the vessels and gets processed out with the water.

What Does a Flowback Operator Do?

Flowback is a very volatile period of production. The pressure is high and sand is ever-present. The key people during this phase are the flowback operators.

A flowback operator is a field professional who specializes in troubleshooting equipment during the flowback phase. His job is to manage this period and keep the well flowing, come what may.

A flowback operator lives in a trailer on site and works twelve hours a day, seven days a week. His primary duties include recording hourly flow rates, troubleshooting equipment, and coordinating transport trucks and equipment techs on site.

We recently had the opportunity to interview a flowback operator on site in the Woodford Shale, and we were able to gather some insight from the challenges he encounters every day.

We’ve been working with flowback operators and oil producers to solve some of the unique challenges flowback production presents. We have found success in three key areas:

- Premature Damage to Dump Valves

- Premature Damage to High Pressure Control Valve Trim

- Erratic Liquid Level Control

Flowback Challenge: Dump Valve Damage

The same thing that gives sand its value downhole—its abrasiveness, which is crucial to stimulating shale—presents problems when it comes to the surface during flowback.

Sand flowing at high pressures is destructive. If not managed correctly, it can quickly erode pipes, vessels, and valves.

Due to their tight flow paths, valves are susceptible to damage and must be repaired or replaced regularly during flowback. We’ve seen significant damage done to dump valves in particular.

Solution One: PBT Dump Valve

This led us to test some different solutions to offset this damage. One product that has performed well during flowback is our Piston-Balanced Throttling (PBT) Dump Valve.

With other dump valve options, the trim of the valve sits in the flow path whether the valve is open or closed. During flowback, high-pressure sand is constantly hitting these elements, leading to rapid deterioration.

The PBT Dump Valve pulls the seat, trim, and stem out of the flow path. This means that when the valve opens, the abrasive flowback fluid can dump downstream while causing less damage to the internal valve parts.

Solution Two: Dual Dump Valves

Another method some producers have started using is setting up Dual Dump Valves.

This dual set up provides redundancy when maintenance and repairs need to be done. If the trim on one valve fails, you can isolate it and divert the flow to the second valve.

This practice also allows for greater variability in production volume. You can install two smaller valves rather than one large valve.

You can then flow both dump valves in flowback and early high-volume production, and then as the production rate declines move down to one valve and repurpose the other in a different application.

Challenges to Flowback

Damage to High Pressure Control Valve Trim

In High Pressure Control Valves, the valve trim is susceptible to damage from abrasive flowback.

While no trim is indestructible, we have two options designed specifically to stand up better to sandy conditions.

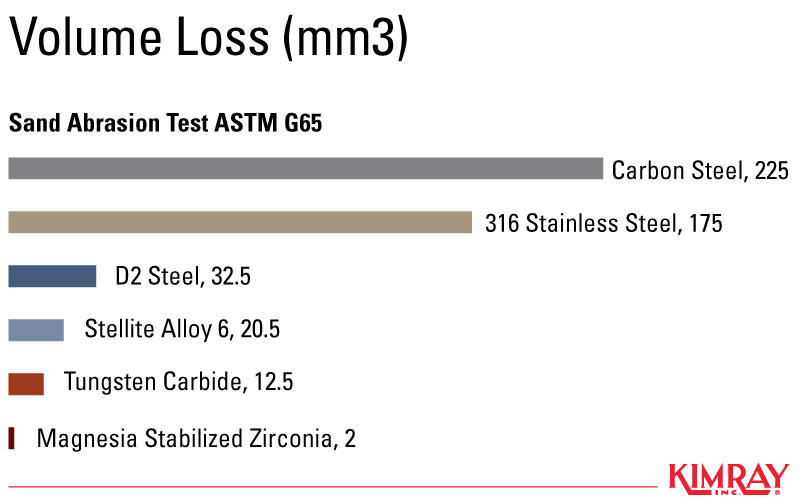

- Carbide is a hard metal we recommend using for valve trim during flowback. In an ASTM G65 test of material loss, Carbide trim performed 2.5x better than standard D2 Steel trim.

- Zirconia is a hard ceramic we recommend for valve trim in extremely abrasive flowback conditions. In the same test of material loss, Zirconia trim performed 16x better than standard D2 steel trim.

Erratic Liquid Level Control

During flowback, the composition of a well’s production fluid often changes rapidly. This makes it extremely difficult to maintain accurate liquid level control inside your separator.

The float sitting in the fluid often has a tough time responding to the varying conditions of the fluid. As a result, flowback operators may have to shut-in the vessel and re-weight the float multiple times. This is costly downtime.

To adjust for this, some operators use random items around their site to keep the float up. Adding this weight on the arm can make the float more buoyant to deal with the changing fluid densities.

After noticing this practice, we worked to standardized a solution to help with this issue.

Kimray threaded weights, like those used on our Weight Operated Dump Valves, can be bolted to the trunnion lever bar of the liquid level float. You can quickly adjust or remove these weights as the density of the fluid changes without shutting in the vessel.

Now rather hunting around site for something to weight the float you have a standard, simple solution available to deal with this problem.

What Happens After Flowback?

Once the well has “cleaned up”—meaning the amount of sand produced has tapered off and production is relatively steady and predictable—the flowback operator turns the well over to the production lease operator.