Pressure regulators are critical components in oil and gas operations, ensuring safe, reliable, and efficient flow control.

Two of the most common types are back pressure (BP) regulators and pressure reducing (PR) regulators. Though they operate on similar principles, they serve very different functions.

In this article, we’ll break down how they work, their applications, and go over some of the many variations Kimray offers.

Pressure Regulators at a Glance

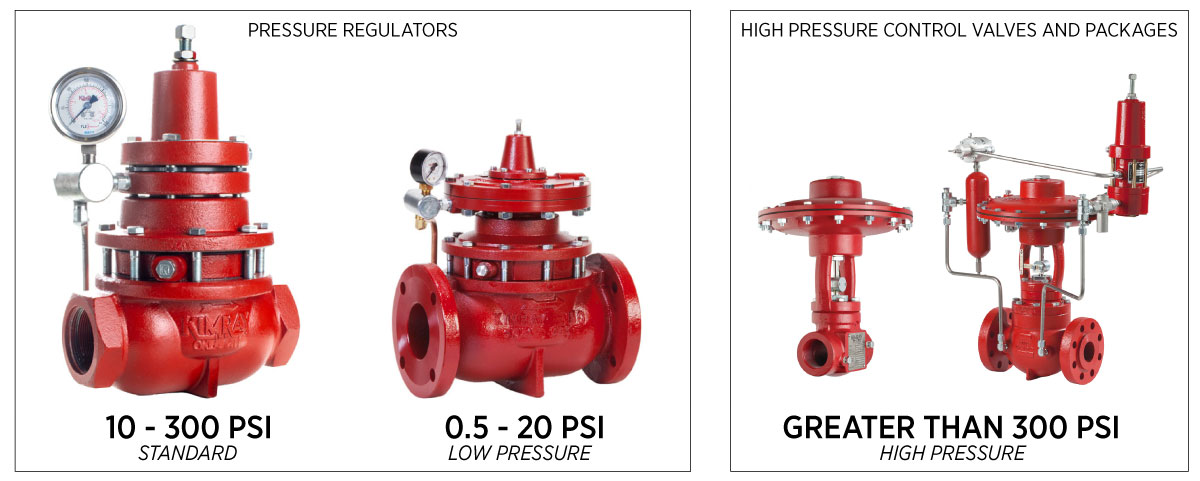

Regulators are designed to control pressure ranges from 10 to 300 PSI, though low-pressure variants can operate below 10 PSI. Anything above 300 PSI requires a high-pressure control valve package.

The two primary categories are:

Back Pressure Regulators (BP): Control upstream pressure.

Pressure Reducing Regulators (PR): Control downstream pressure.

Both types come in sizes from 1 inch to 6 inches, accommodating a wide range of flow rates and applications.

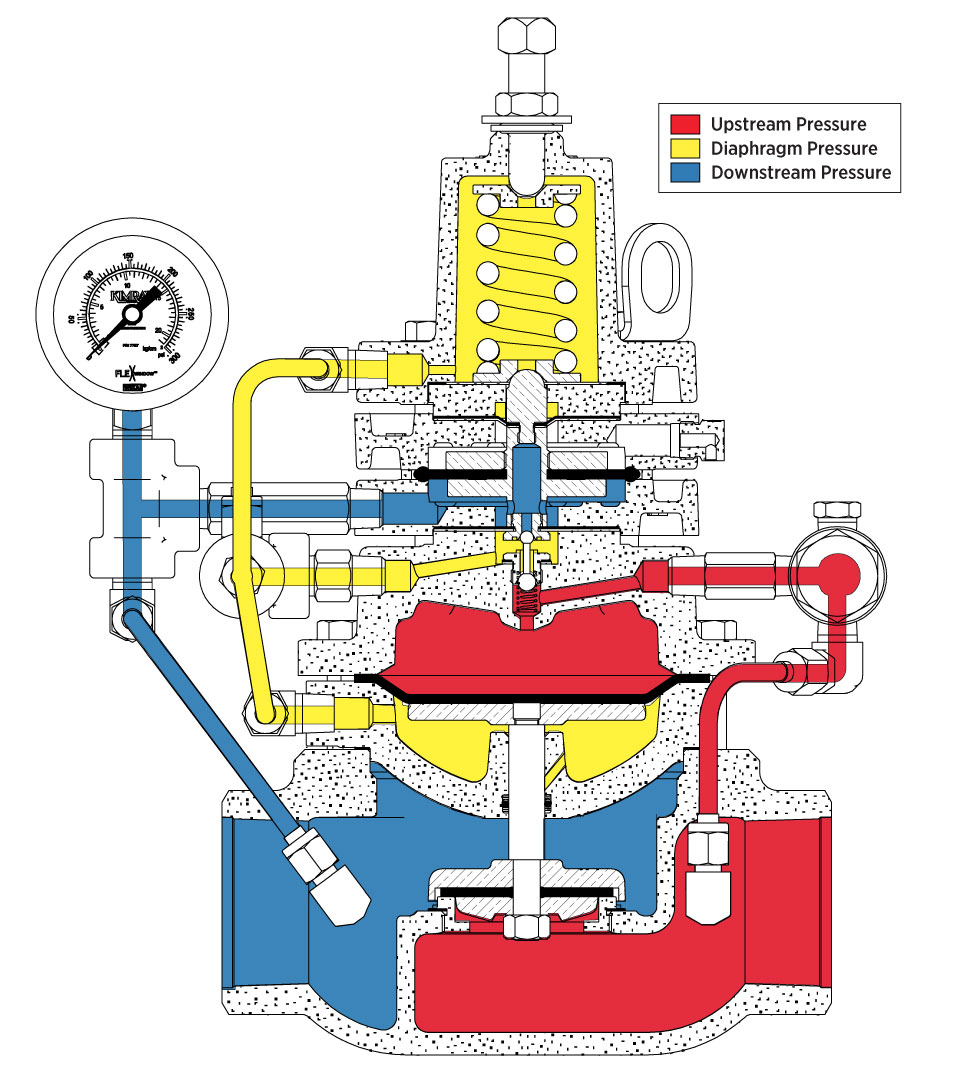

Back Pressure Regulators (BP)

How They Work

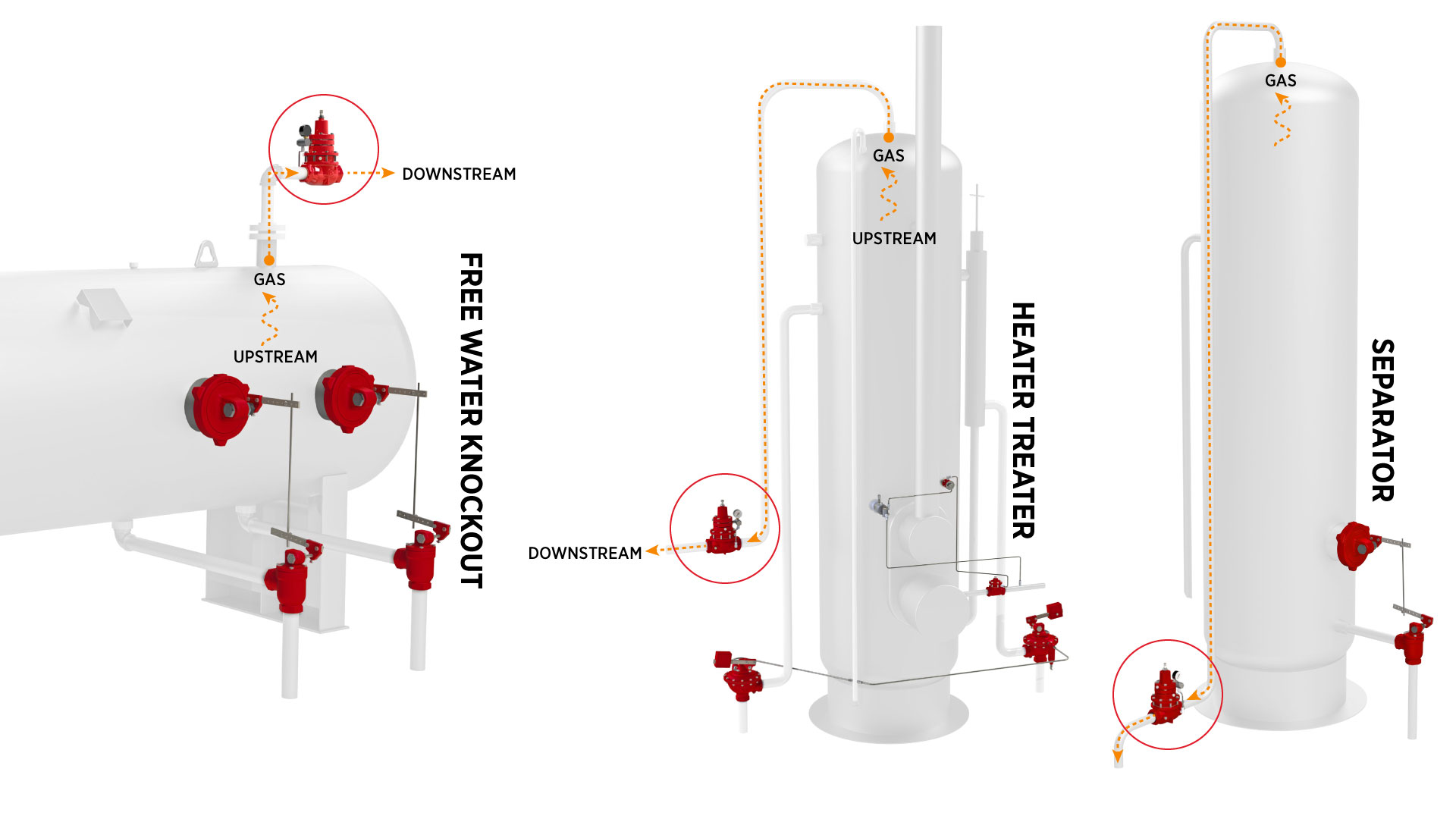

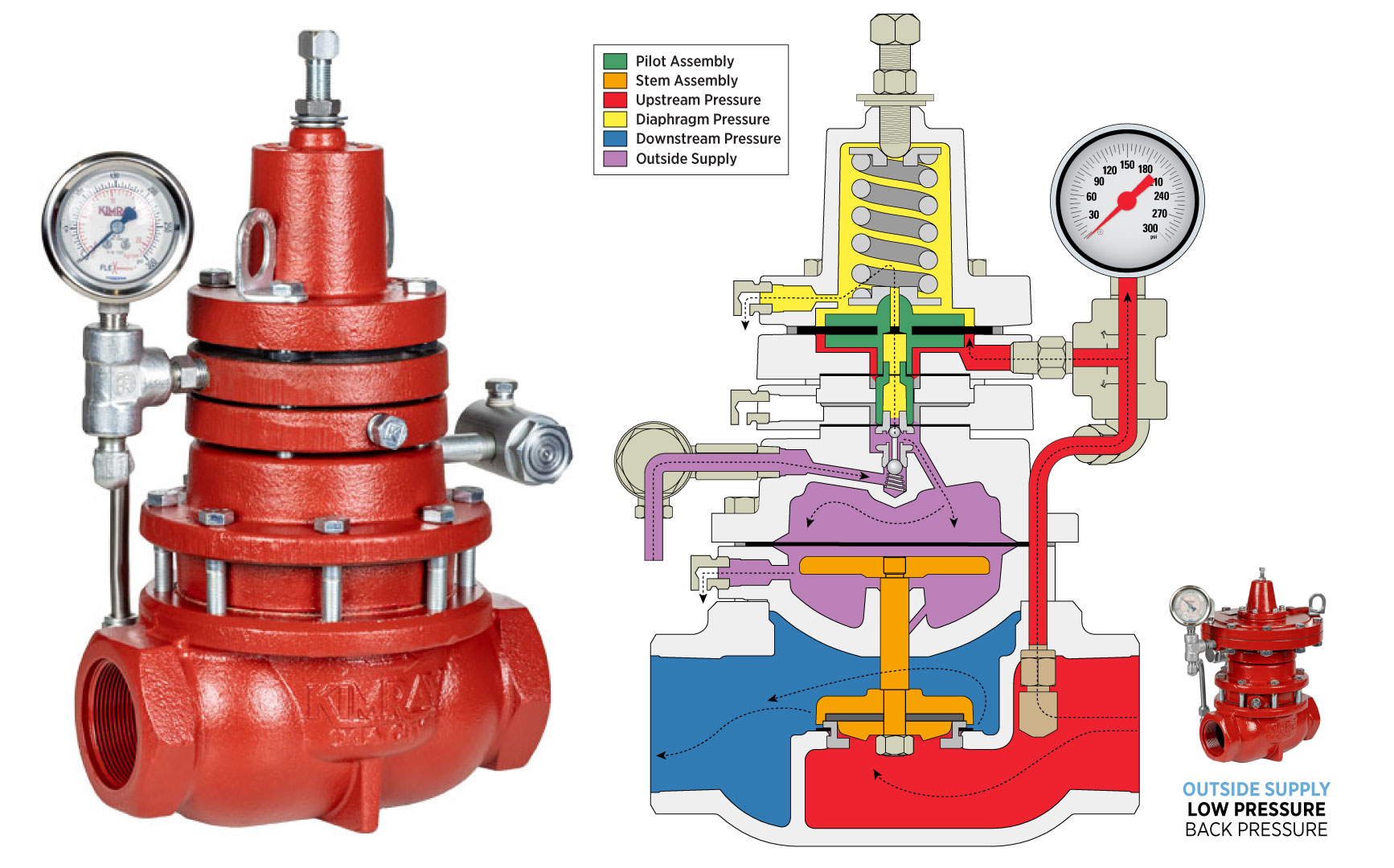

A back pressure regulator maintains pressure on the upstream side of the valve—often a separator or similar vessel. By holding pressure in the vessel, liquids and gases can be efficiently moved from one stage of the process to the next.

Think of it like a water gun: before water can spray, the vessel has to pressurize. A back pressure regulator ensures that pressurization happens so fluids can move downstream as intended.

Set Point Control: A spring sets the desired pressure. Increasing spring tension raises the set point.

Pressure Relief: When upstream pressure exceeds the set point, the regulator vents, allowing the valve to open and relieve pressure.

Surface Area: The diaphragm has twice the area of the valve seat, creating the force needed to keep the regulator sealed until the set point is reached.

Watch: Back Pressure Operation Animation

Back Pressure Regulators

Back Pressure to Vacuum: For applications with downstream vacuum, for example, vapor recovery units (VRUs).

Low-Pressure BP Regulators: Handle pressures from 0.5 oz to 20 PSI, available in several spring ranges.

Non-Vent Models: Capture vented gas and redirect it downstream, preventing emissions.

Watch: Back Pressure to Non-Vent Animation

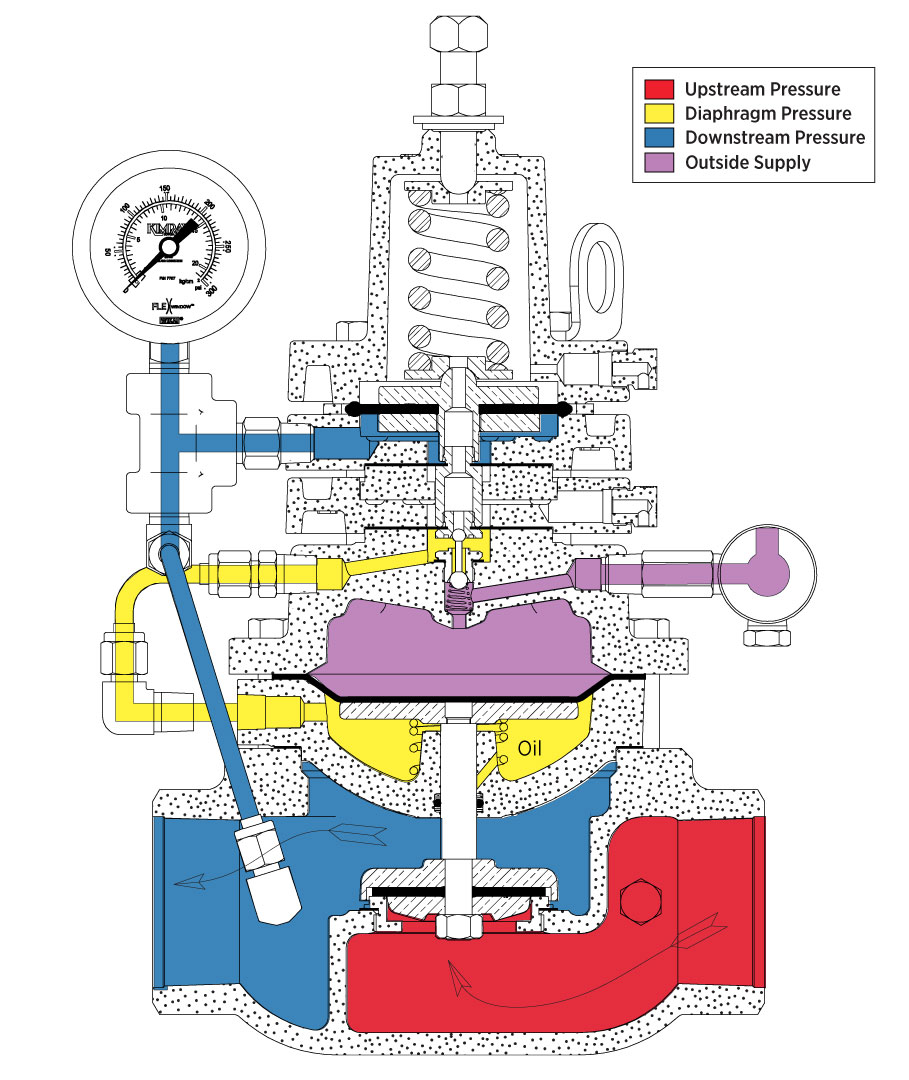

Outside Supply Models: Use compressed air or compressed nitrogen instead of process gas for emissions-free operation. Requires at least 60% of upstream pressure as supply.

Watch: Back Pressure to Outside Supply Animation

Spring Loaded Back Pressure Regulators

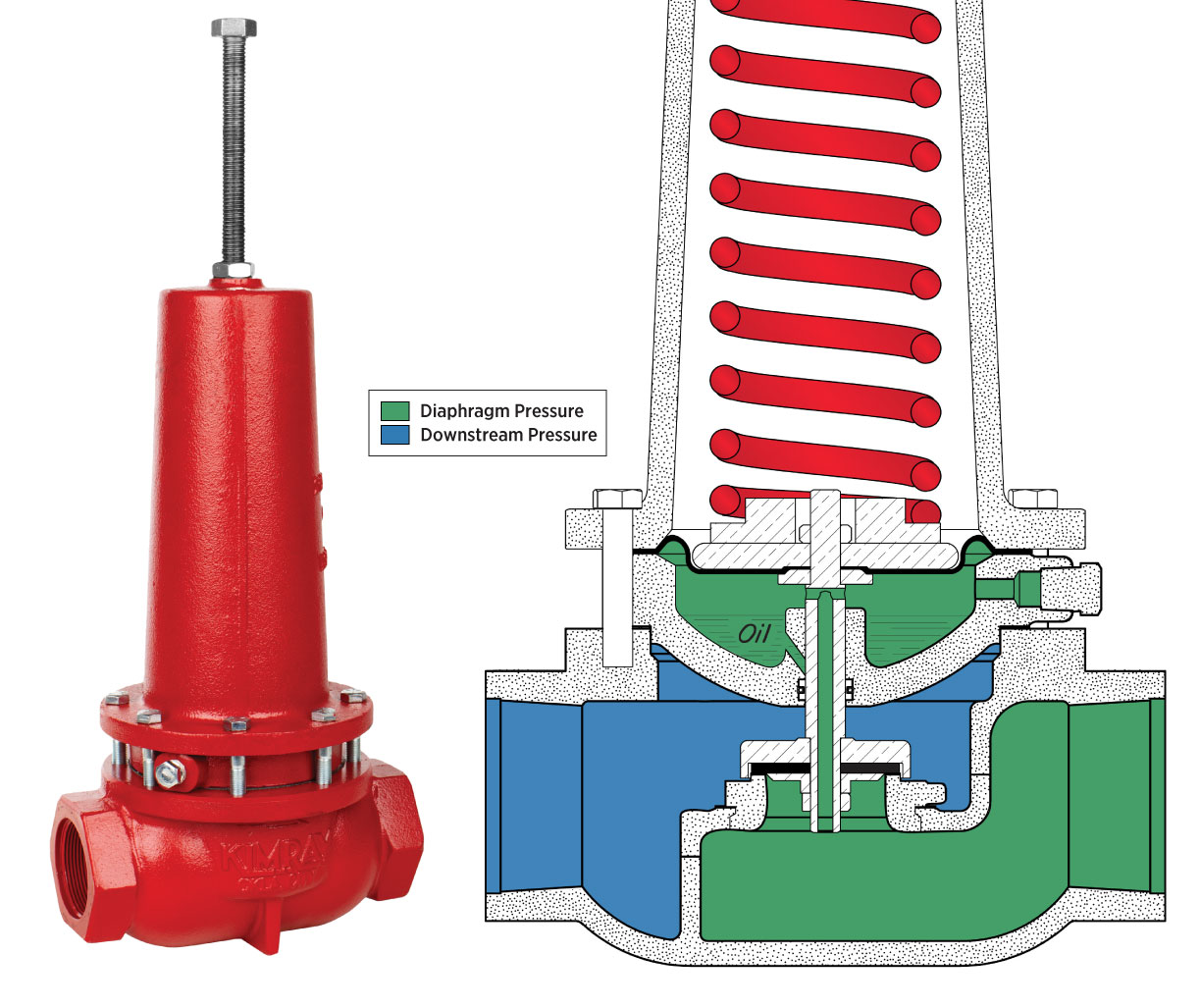

Unlike pilot-operated models, spring loaded back pressure regulators use a simpler design that makes them a great fit for certain applications.

How They Work

Upstream pressure is communicated directly underneath the diaphragm and diaphragm plate.

As pressure increases, it pushes against the diaphragm until it overcomes the spring tension. When that happens, the stem assembly lifts, unseating the valve and allowing excess pressure to flow through.

As pressure drops back below the set point, the spring pushes the assembly back into place, closing the valve.

Watch: Spring Loaded Animation

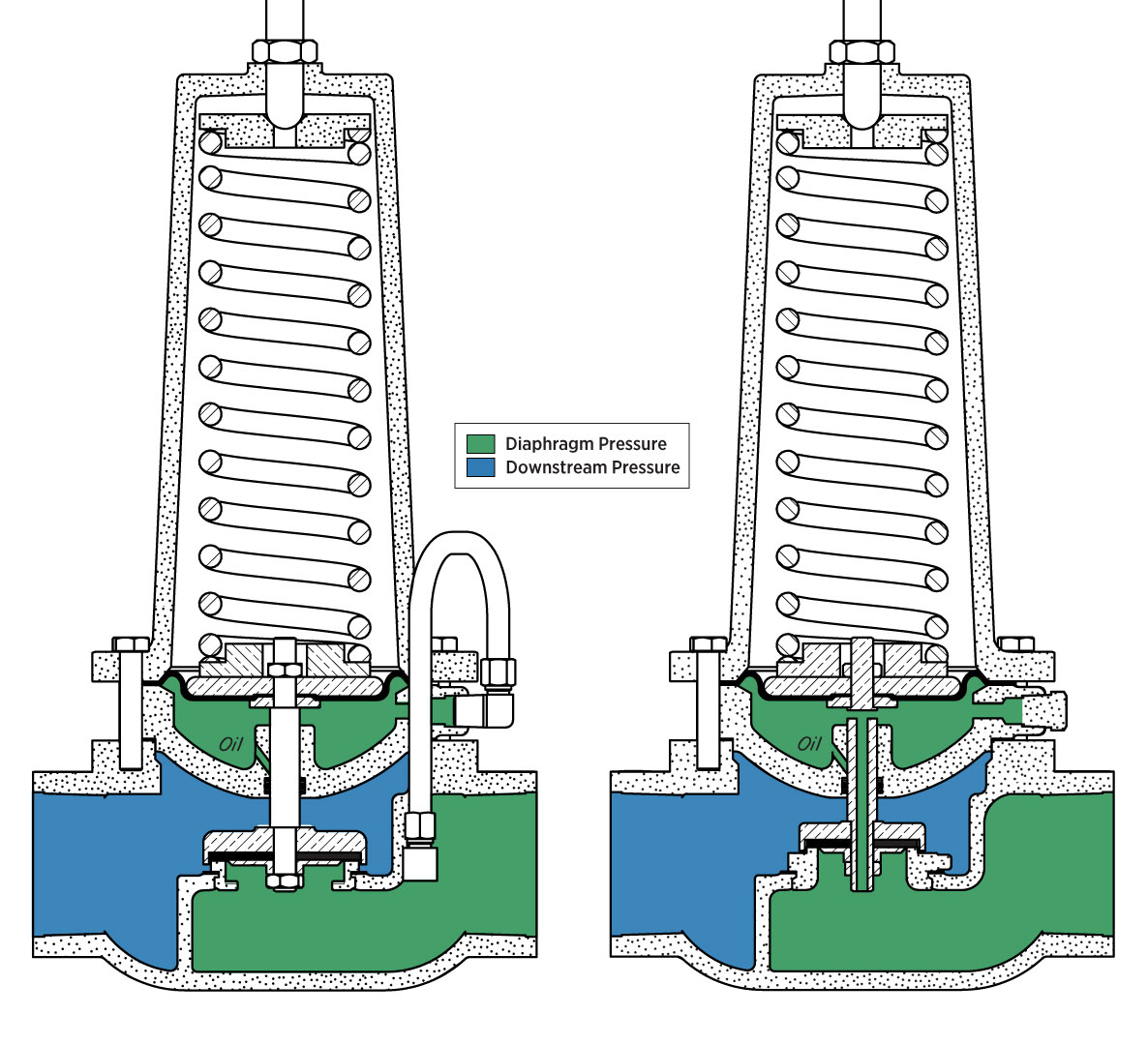

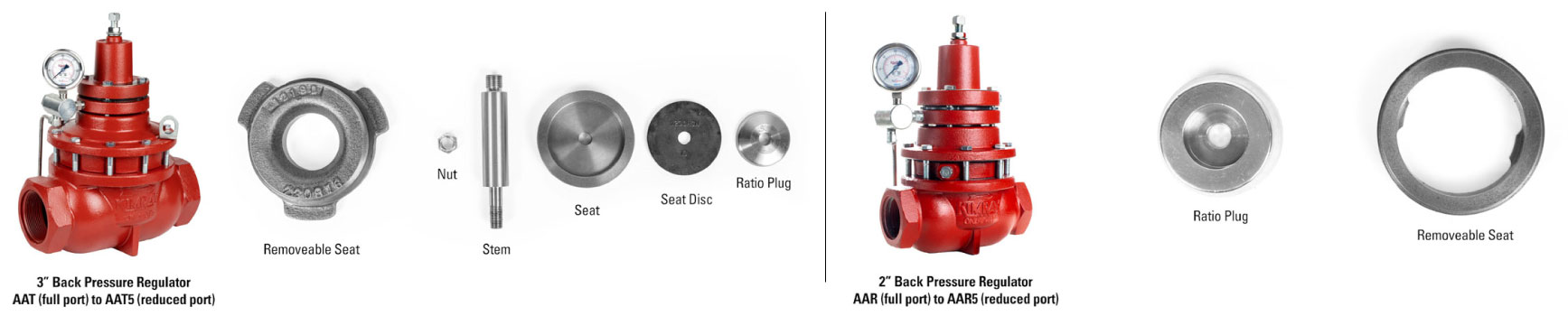

Full Port vs. Reduced Port in Spring-Loaded Models

Full Port vs. Reduced Port in Spring-Loaded Models

Full Port Versions: Use external tubing to route upstream pressure beneath the spring.

Reduced Port Versions: Do not require external tubing. Instead, pressure communicates internally through a hollow stem. This provides a quick visual indicator — if you see a spring-loaded BP regulator without tubing, it’s most likely a reduced port model.

Where They’re Used

Gas & Liquid Applications: Unlike most pilot-operated regulators, spring-loaded BPs are suitable for both liquid and gas service.

Liquid Back Pressure Control: Especially effective when paired with applications like liquid transfer systems. Alternatively, an outside-supply BP regulator can be used for similar liquid service.

Spring Ranges

Spring-loaded models are available in multiple ranges from 1 PSI up to 125 PSI. Each spring covers a smaller span (about 30–40 PSI), so selecting the right spring is critical to accurate control.

Advantages

Simpler, more rugged design.

Fewer components than pilot-operated regulators, reducing maintenance.

Reliable option when dealing with liquids or when a compact regulator is preferred.

Pressure Reducing Regulators (PR)

How They Work

How They Work

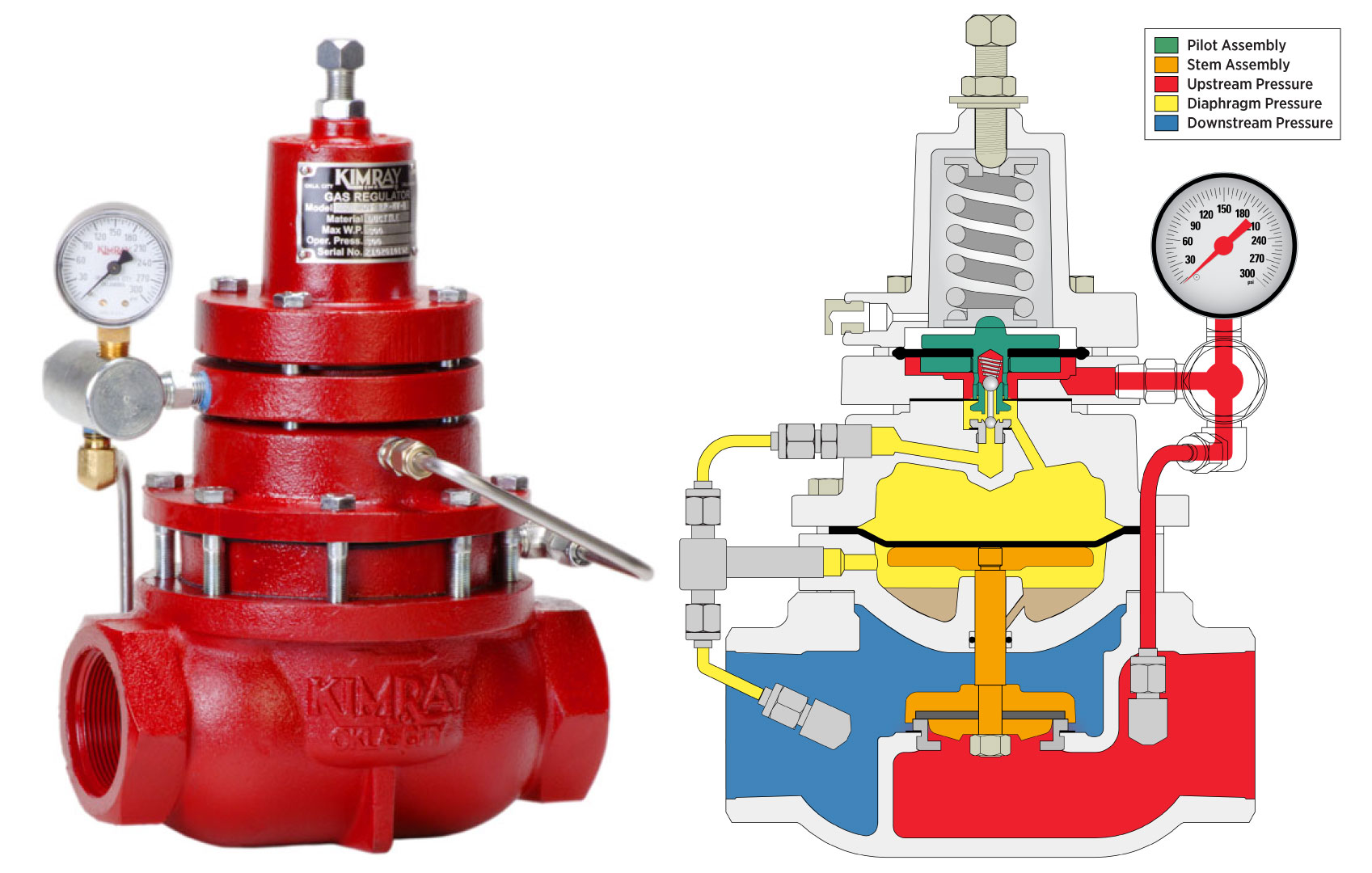

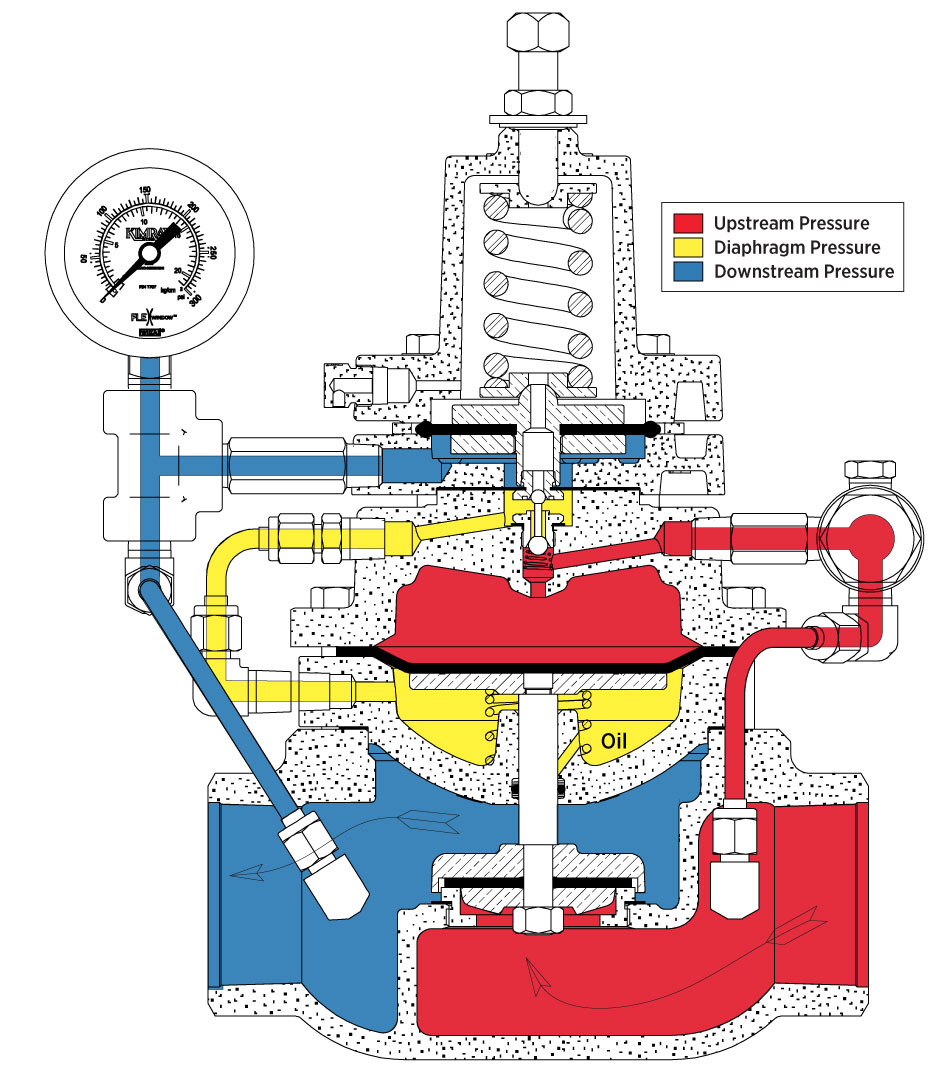

While BP regulators control upstream pressure, PR regulators control the downstream side of the system. Common applications include suction control on compressors or processes where reducing pressure is essential.

The gauge is monitoring downstream pressure.

Upstream supply pressure keeps the valve closed until downstream pressure falls below the set point.

When downstream pressure drops, the valve opens to maintain steady outlet pressure.

Watch: Pressure Reducing Operation Animation

Pressure Reducing Regulator Series

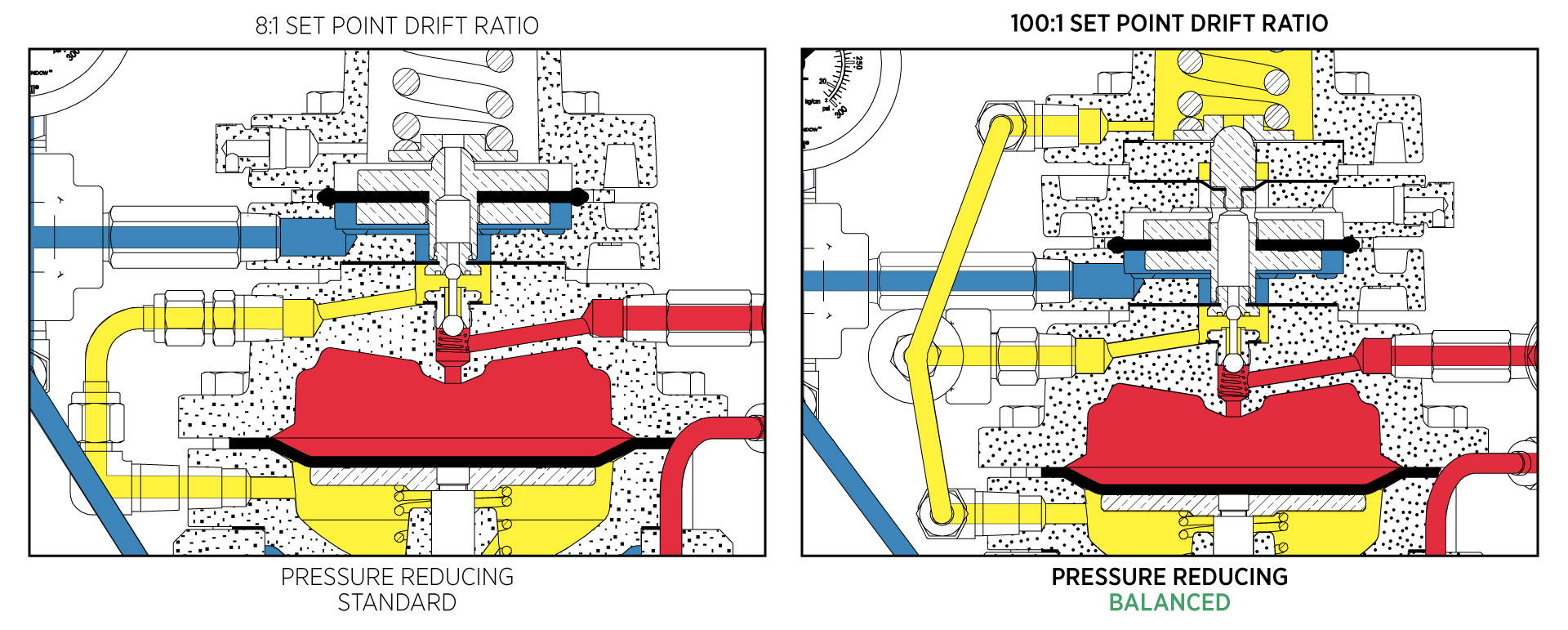

Balanced PR Regulators: One of the key performance differences between standard and balanced pressure reducing regulators (PRs) is how they handle set point drift.

What is Set Point Drift?

Set point drift describes how much the downstream pressure “set point” changes when upstream pressure fluctuates. Since PR regulators rely on upstream pressure to operate, variations in supply pressure can cause the downstream set point to shift.Standard PR Regulators:

These have a drift ratio of about 8:1. That means for every 8 PSI change in upstream pressure, the downstream set point can shift by 1 PSI. In systems where supply pressure is stable, this ratio may be sufficient. However, if supply pressure swings widely, drift can become a serious issue.Balanced PR Regulators:

Balanced models greatly improve this ratio to 100:1. In practice, that means upstream pressure would need to change by 100 PSI before the downstream set point shifts by just 1 PSI. This makes them especially valuable in applications like compressor suction control, where pressure fluctuations are common.

Non-Vent Models: Capture and redirect vented gas downstream.

Watch: Pressure Reducing to Non-Vent Animation

Outside Supply Models: Allow emissions-free operation with compressed air or nitrogen.

Watch: Pressure Reducing to Outside Supply Animation

Low Pressure Pressure Reducing Models: Control pressures as low as 0.03125 PSI to 20 PSI.

Maintenance & Troubleshooting Tips

Common Issues

Oversized Regulators: Cause rapid cycling (open/close repeatedly) instead of smooth throttling.

Undersized Regulators: Stay open constantly and may restrict flow, causing set point pressure to rise.

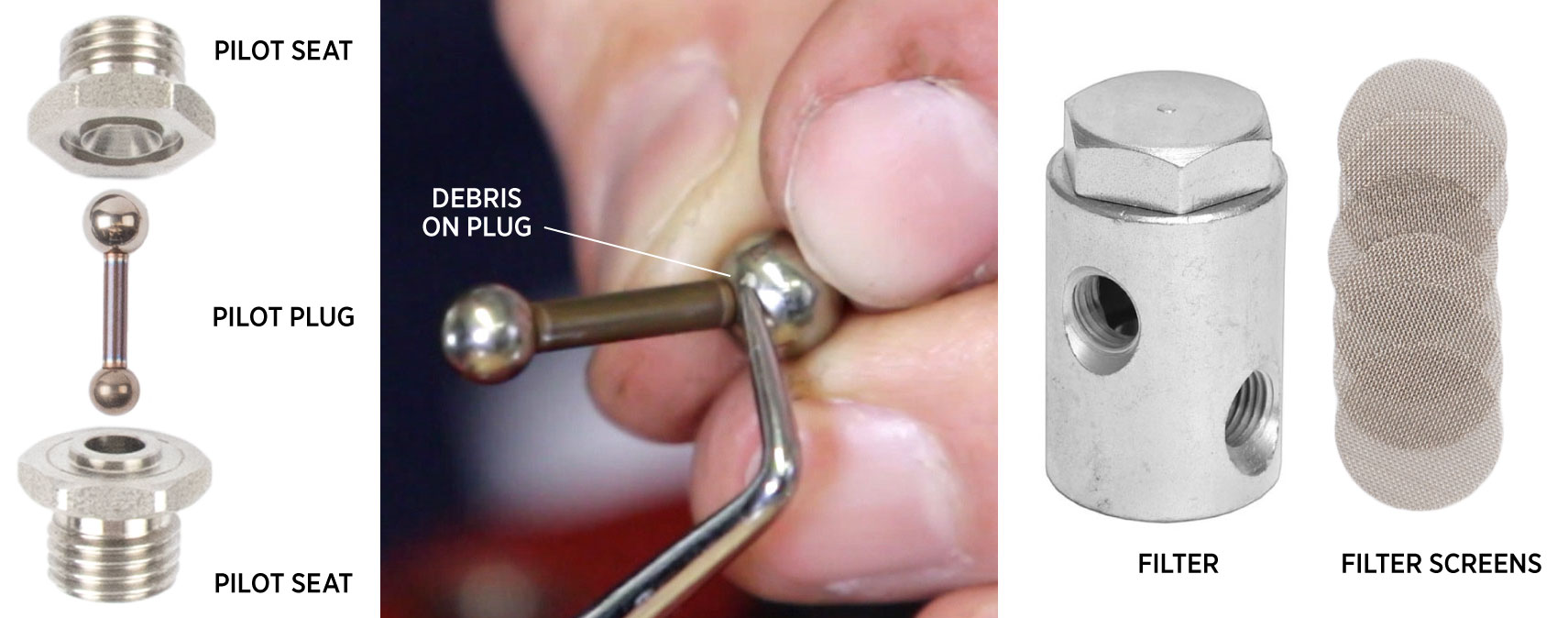

Dirty or Wet Gas: Debris and liquids can interfere with the pilot plug, causing venting issues or poor pressure control.

Tips

Vent Plug Removal: New regulators ship with a vent port plug to prevent oil leakage during transport. Remove this plug during installation to ensure proper operation.

Quick Fix for Debris: Rapidly adjusting the set point can help blow out trash or liquids stuck in the pilot plug.

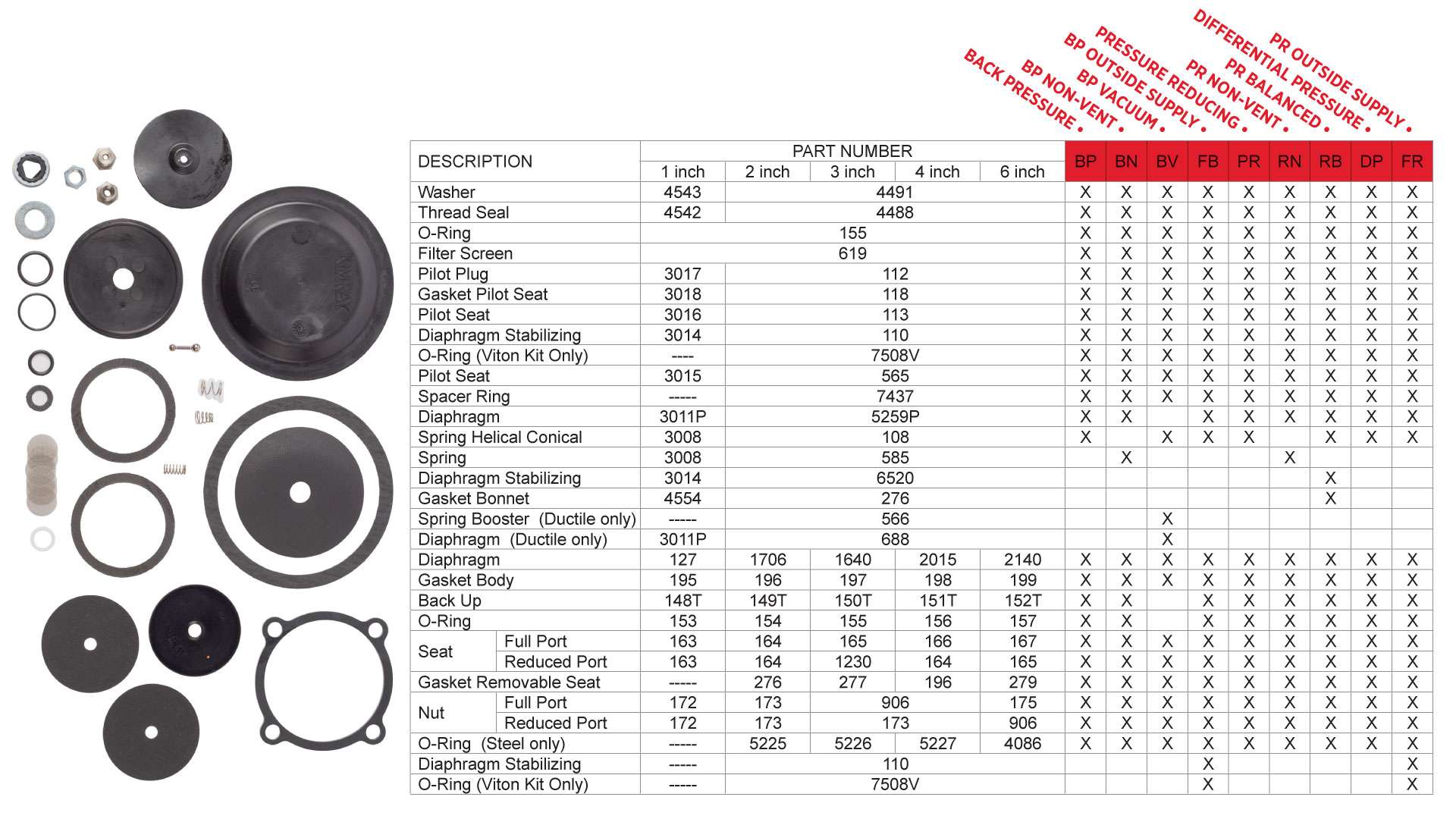

Repair Kits: Regulators can be repaired in-line using master repair kits. These kits cover multiple model variations, resulting in extra parts remain after the repair, depending on which model you're working on.

Material & Port Options

Material Choices

Regulators often operate in harsh environments where gas composition, pressure, and corrosive elements vary widely. To handle these conditions, regulators are available in different material and elastomer combinations:

Standard Service: Durable options for general gas and liquid service.

Sour Gas Service (H₂S): Elastomers rated for sour environments to prevent rapid wear and corrosion.

Stainless Steel Internals: Ideal for wet gas or corrosive applications, offering extended lifespan and reliability.

These material options allow you to match the regulator’s construction to your specific process conditions, improving both safety and performance.

Watch: 3 Keys to Selecting the Right Valve Elastomers

Full Port vs. Reduced Port

Each regulator size can be configured as either:

Full Port: The internal seat matches the inlet size (e.g., a 4" regulator has a 4" port). Best for high flow capacity.

Reduced Port: Cuts the seat size in half (e.g., a 6" regulator has a 3" port). This option is useful in lower-flow applications or when production decreases, allowing you to maintain control without replacing the entire valve body.

Since trim sizes can be swapped without replacing the full regulator, retrofitting is quick and cost-effective, making it easier to adapt to changing flow requirements.

Watch: Control Valve Trim, Seats, & Springs

Watch: How to Convert from Full Port to Reduced Port

More training

For in-person training and hands-on learning, visit the Kimray training page for more information.