Finding a solution for oil and gas producers to meet environmental commitments is challenging.

There are many options for meeting both voluntary and mandatory emissions targets. Deciding on the best one for your operation is crucial for long-term success, operational performance and cost.

Kimray offers several solutions to achieve your emissions goals efficiently. This includes electric products, non-venting options, and outside supply configurations.

In this video, we’re going to look at the operation and best practices for using an outside source of supply to power your existing pneumatic control equipment.

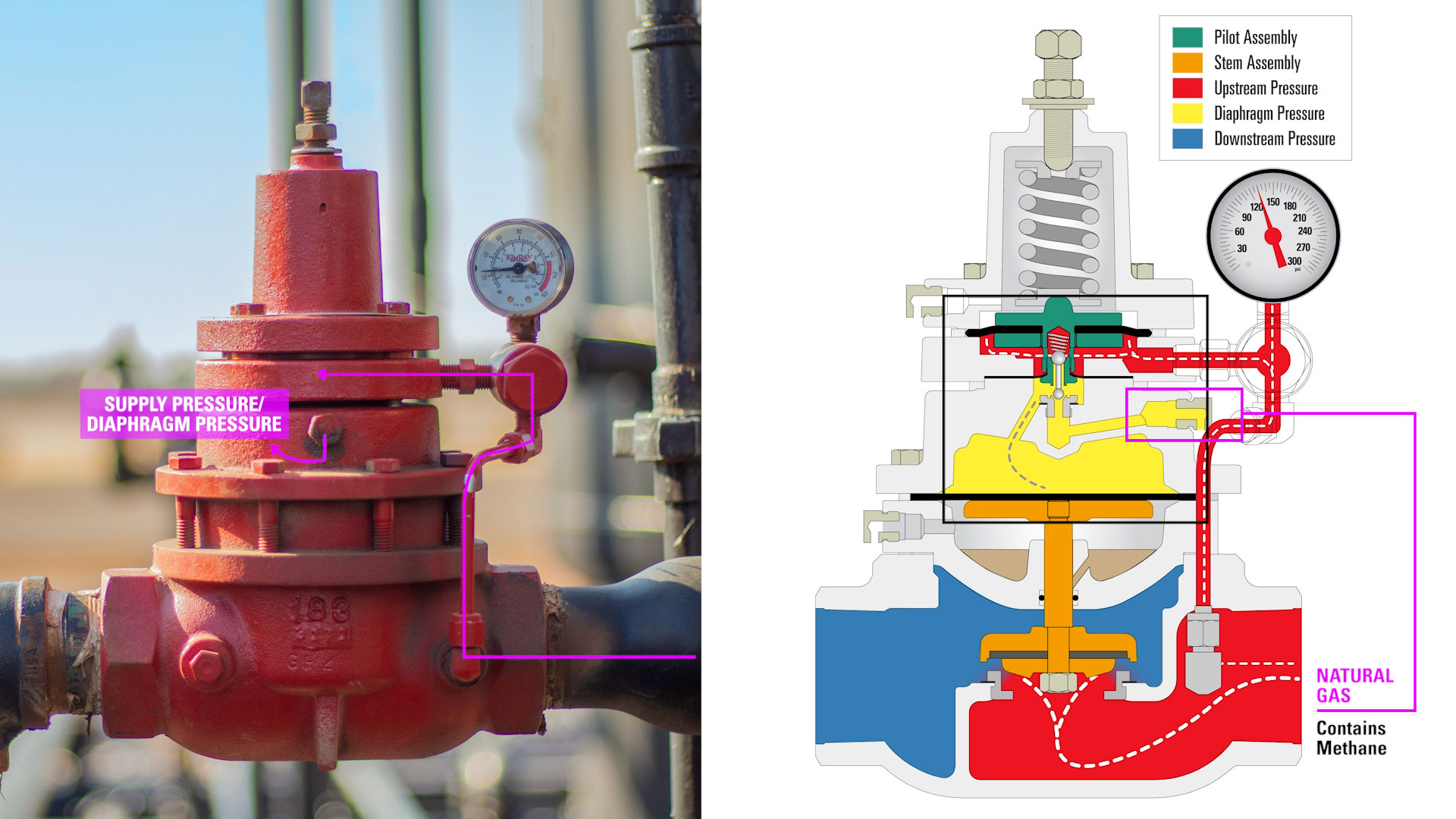

Pneumatic Control Valves

Pneumatic control devices require a source of supply pressure to operate. This is traditionally provided by natural gas produced on site.

Unfortunately, this same supply pressure, which contains greenhouse-intensive methane, must also exit a control valve and enter the atmosphere.

Rather than capturing or rerouting process emissions, which may be a limited option for many sites, many producer choose to change the source of supply pressure to a non-polluting gas.

Compressed air is one option, but there may be more advantages to using compressed nitrogen, including reliability, lower cost of ownership, and data collection.

why Nitrogen?

Since nitrogen is an inert, odorless gas which makes up 78% of our air, this solution completely eliminates methane emissions by replacing your existing gas supply with a clean, dry, inert nitrogen supply.

There are 3 primary benefits to using nitrogen as the motive gas for your valves:

Zero Emissions

Venting nitrogen into the atmosphere has no ill effects on the environment, making nitrogen a great solution to eliminating greenhouse gas emissions. If the venting of hazardous gases like H2S is a concern for personnel on your location, using nitrogen for the pneumatic supply is an excellent solution as it poses no health risks.

No Corrosion

Because nitrogen is free from corrosive elements and hydrocarbons, it eliminates corrosion damage and liquid accumulation in regulators and pilots, extending their lifespan and preventing malfunctions.

Safe

Because it is an inert gas, it is non-combustible and therefore does not pose the same risk of ignition that compressed air does, making it inherently safer.

Kathairos tank management

Kimray has partnered with Kathairos to support United States oil and gas producers in eliminating methane emissions on hundreds of thousands of well sites.

The Kathairos solution is simple. It works regardless of region and weather conditions. The nitrogen tanks utilize thermodynamics to supply ample gas pressure, requiring no moving parts, no maintenance, and no external energy sources.

In its liquid form, nitrogen has an expansion ratio of 700:1, making it an excellent replacement for instrument gas in powering pneumatics. Compared to gaseous nitrogen, you can store much larger volumes of nitrogen in liquid form extending available working supply.

Learn more about Kathairos Methane Elimination System

Kathairos handles all tank management through data driven operations, identifying the correct time and volume to resupply liquid nitrogen at site.

Under normal operation, data such as liquid level, tank pressure, and telemetry unit battery charge are typically collected every hour and uploaded every 12 hours. They also monitor all consumption data 24/7 and provide monthly reports on the system’s nitrogen usage, cost, methane abated, and overall operational performance.

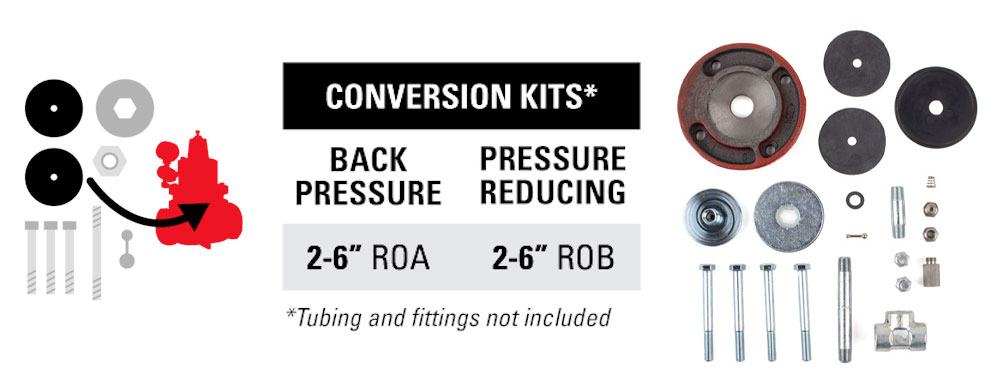

Product Conversion for Outside Supply

Kimray regulators can be easily converted to accept outside supply like nitrogen. Conversion kits are available for all sizes and step-by-step guides and videos for back pressure and pressure reducing regulators are on our website.

Watch: How to Convert a Back Pressure Regulator to Outside Supply

Watch: How to Convert a Pressure Reducing Regulator to Outside Supply

Watch: How to Convert a Low Pressure Back Pressure Regulator to Outside Supply

When you’re prepping your site for outside supply with nitrogen, we also recommend installing a repair kit. It is important to replace existing elastomers where hydrocarbons have been present in the working gas supply which may have caused swelling on the elastomers. Switching to nitrogen may cause these hydrocarbon-exposed elastomers to shrink or crack.

All new installations or conversions of Kimray products can be taken care of on-site by your team, or by Kimray Field Services’ experienced technicians.

Contact your local Kimray store to find out how easy it is for you to convert your well sites to use nitrogen as a clean supply source for your pneumatic devices.