Ever been confused about valve trim, seat, and springs? You're not alone!

We recently received a contact on our LinkedIn page from a lease operator asking if we could do a video on these items.

In this video, we explain what valve trim is in regulators and high pressure control valves. We cover the different terms, types and materials for valve trim and springs so you understand exactly what you need to get the job done right.

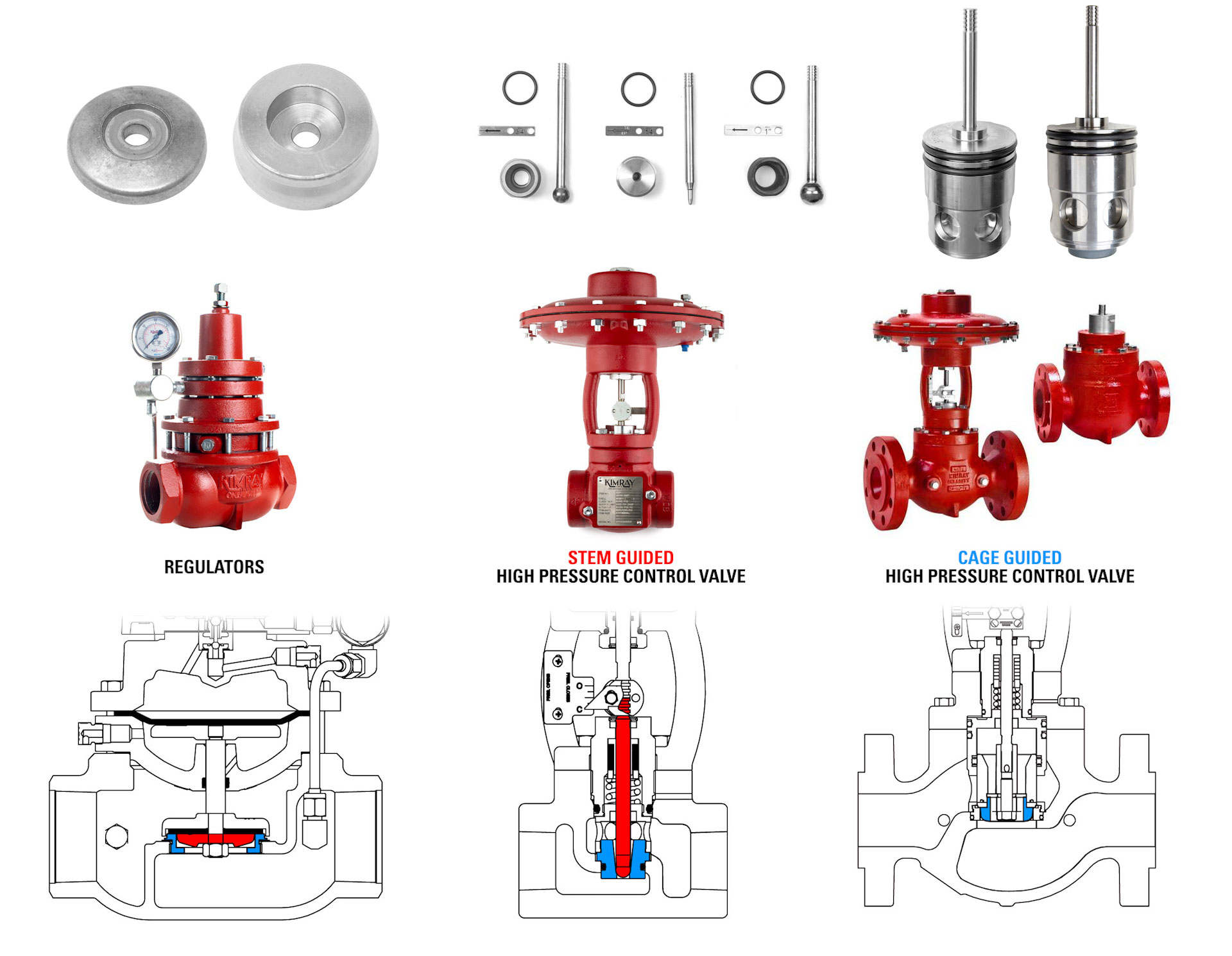

Valve Trim in Regulators & High Pressure Control Valves

Valve trim–sometimes called a “trim set” or just “trim”–is a collection of critical components that control the flow of liquid and gas through a valve or regulator.

Valve trim can be found in both regulators and high pressure control valves, but it comes in a variety of options that each look and behave differently. It’s crucial to understand these options to ensure you’re using the right tool for the job.

REGULATORS

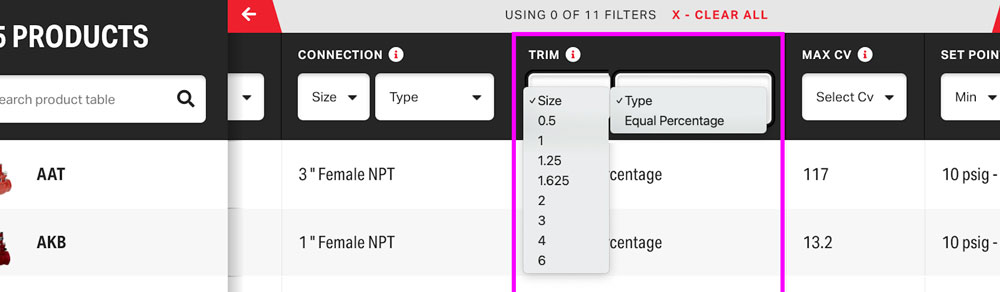

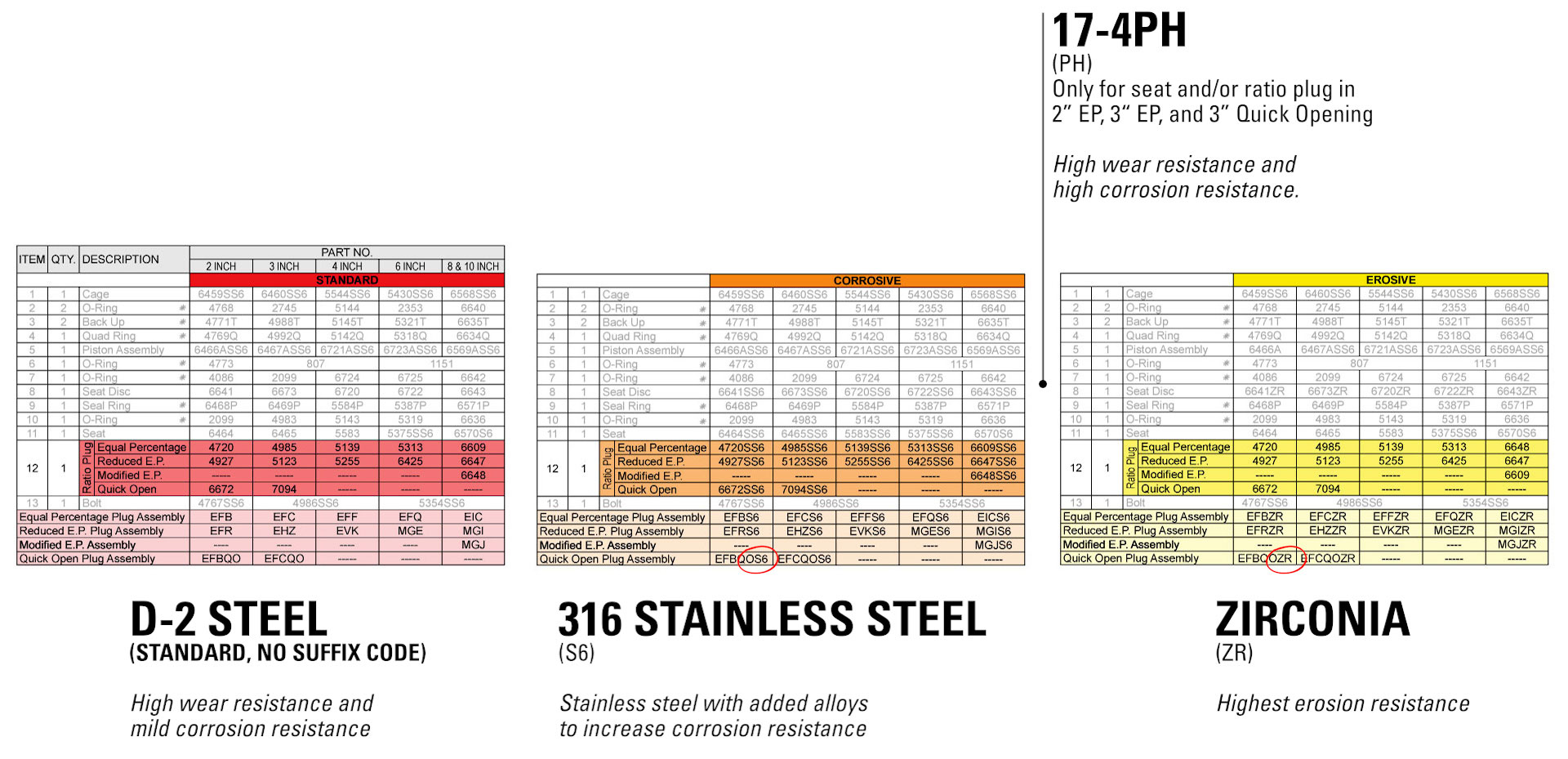

You’ll see the trim options for Kimray Regulators labeled a few different ways, but they’re all referring to the same components. For example, on the website product search, trim is listed as a “size and type.” Note that all regulator trim is equal percentage. We’ll see more options here when we look at high pressure control valves.

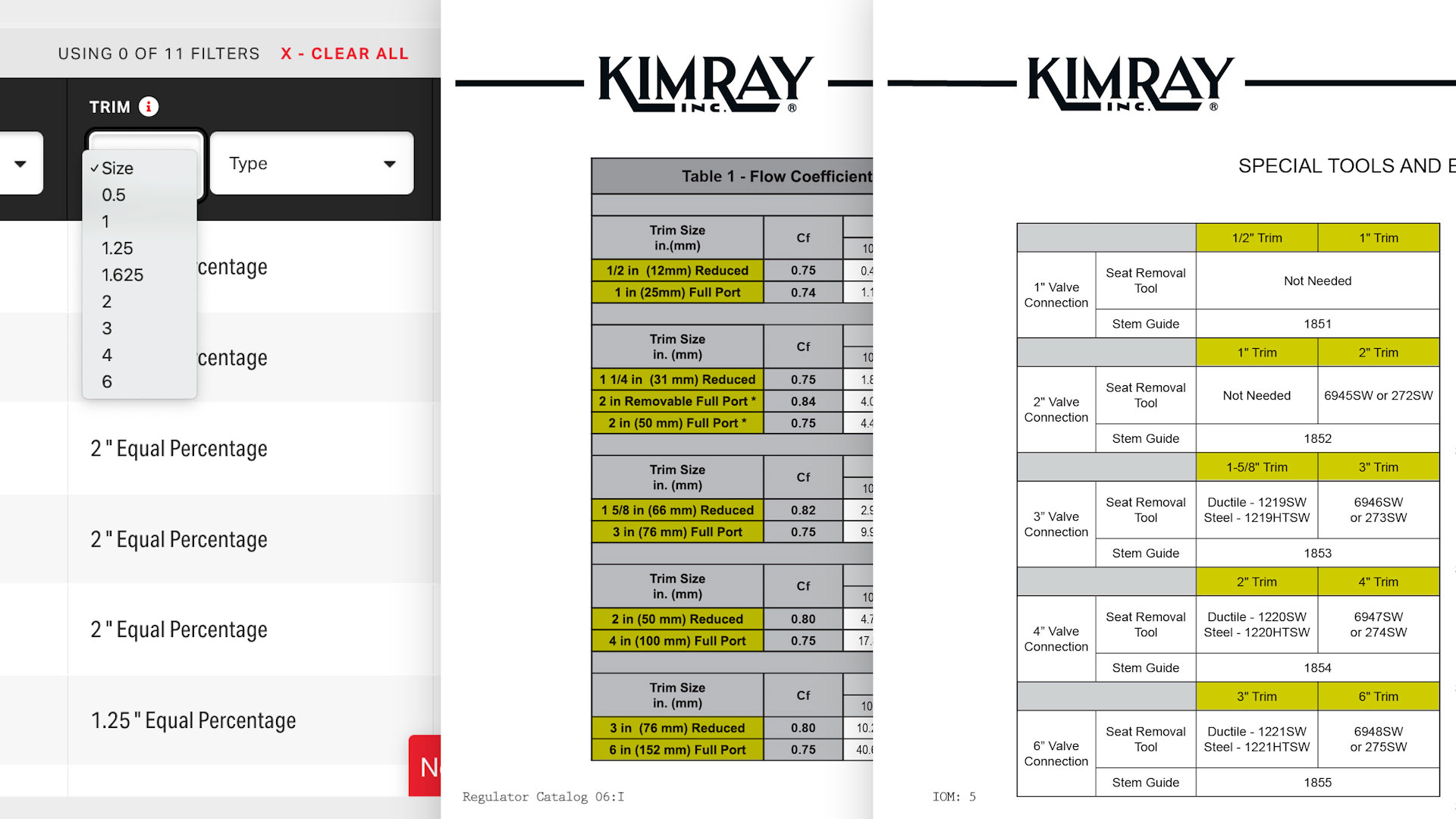

The trim sizes are written in decimals on the website, but you may see the same options written as fractions on catalog pages and in the Installation and Operation Manual.

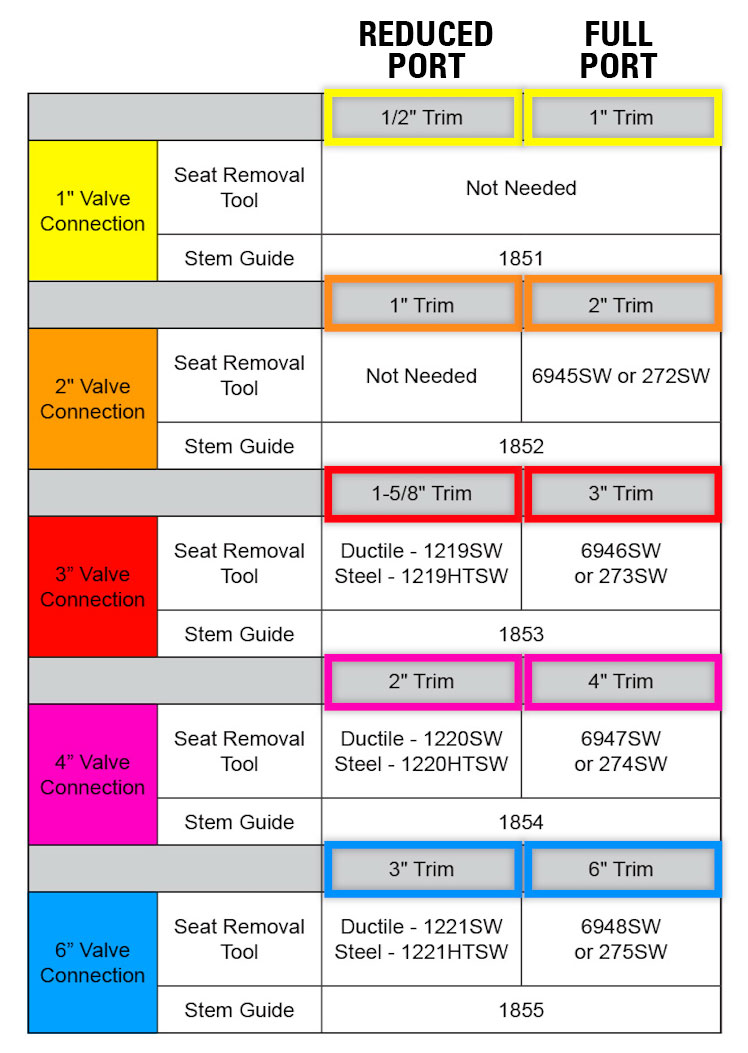

It may seem like a lot of choices, but each connection size only has two trim size options. These two trim sizes are commonly called full-port or reduced-port. By using these names, you don’t need to remember numerical values.

On the Code Builder, you’ll see this option called the “Inner Valve Size” and will be either F or R. On the product code, this is identified with a 5 after the letters, such as an AAR5.

These can also be swapped out to adapt to changing production volumes without the need to purchase a new regulator.

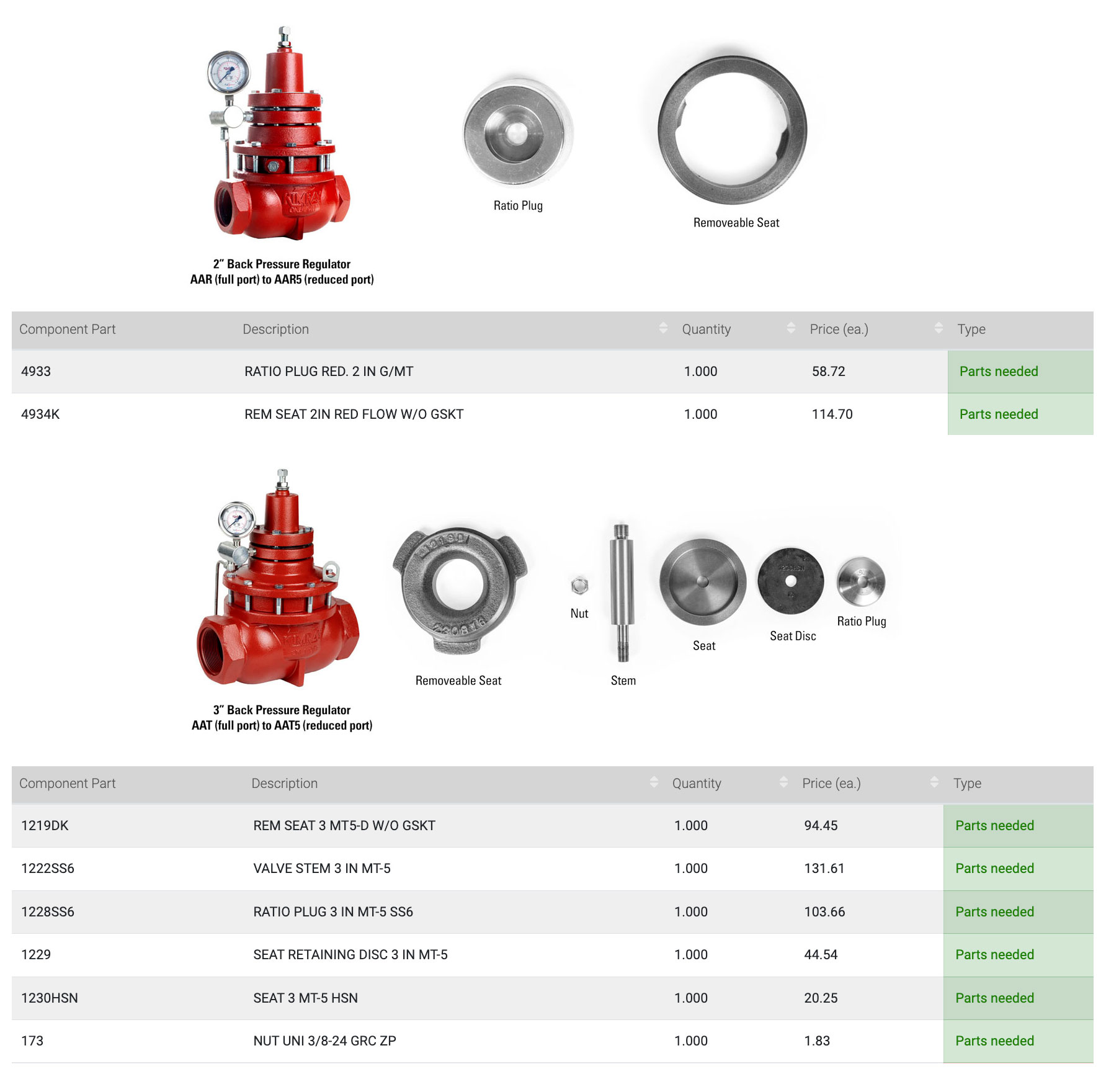

The components that are swapped out vary per regulator size. For example, a 2” AAR trim includes the removeable seat and ratio plug. However, a 3” AAT includes the removeable seat, valve stem, seat, seat disc, and ratio plug.

We have a video and blog outlining how to complete this conversion process from full port to reduced port should you need to adjust your regulators for changing conditions.

Material Options

When ordering, you can specify your regulator for either standard or corrosive production. In the corrosive configuration, all wetted parts are made from corrosion-resistant stainless steel.

CAGE GUIDED HIGH PRESSURE CONTROL VALVES

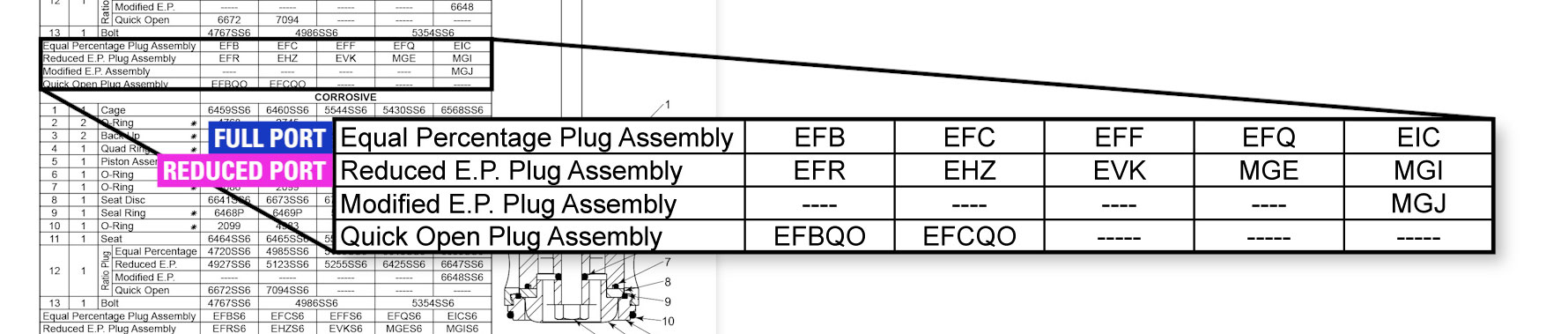

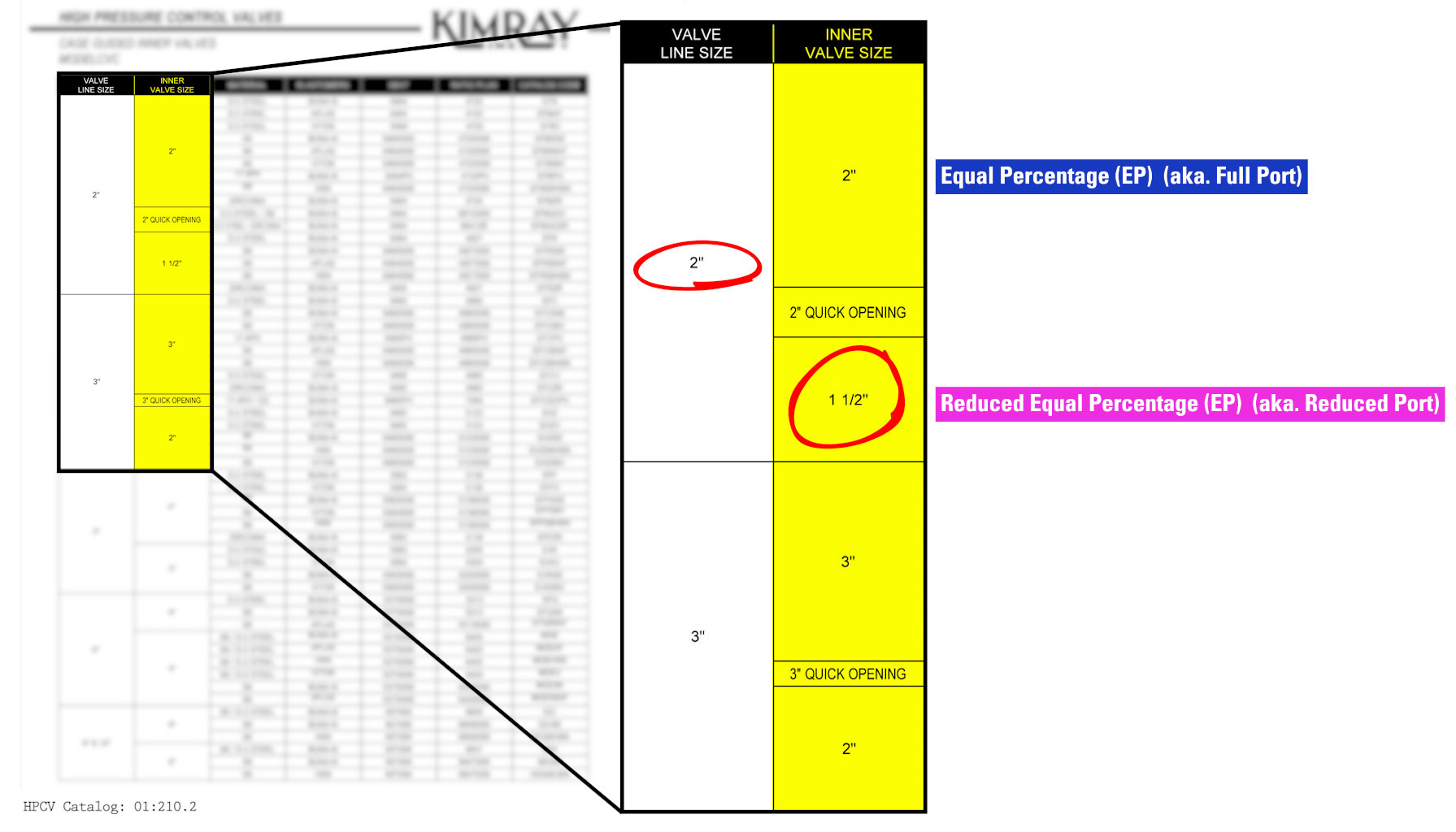

Cage Guided High Pressure Control Valve trim options are a little different from regulators. There are 3 types of trim for each connection size: Equal Percentage, also called Full-Port; Reduced Equal Percentage, also called Reduced-Port; and Quick Opening (available only in 2” & 3”).

Full-Port (Equal Percentage)

Full port trim is designed so that an increment of change in stem position will produce an equal percentage of change in Cv.

This is the standard trim for cage guided valves. You may also see this on catalog pages written as an inch size. For example, a 2” line size with a 2” inner valve size is Equal Percentage trim; a 2” line size with a 1-½" inner valve size is reduced equal percentage.

Reduced-Port

Reduced trim can be used to reduce the flow area while maintaining the line size connection. This may be something you install initially or retroactively as conditions change.

Quick Opening

Quick Opening trim is used in dump applications to move fluid the moment the trim opens. It is only available in 2”-3” valves, because there is only a marginal gain from quick opening trim in large 4-10” valves.

Modified EP

The 8” & 10" Cage Guided model also has an option for Modified EP, or “Modified Percentage Trim.” This trim is designed to achieve max flow at full open and precise control at the lower end. This may be useful for large suction control applications. Contact our Technical Sales Support Team if you think this might apply to your operation.

Conversions

Cage guided trim sets can be swapped as site conditions change. Kimray has complete plug assemblies listed on the tech specs page for equal percentage, reduced equal percentage, quick opening and modified EP which can be easily retrofitted as needed.

Materials

There are also 4 material options available for cage guided inner valve components for standard, corrosive or erosive applications. These materials include D-2 Steel, S6, 17-4PH, and Zirconia.

STEM GUIDED HIGH PRESSURE CONTROL VALVES

In a stem guided high pressure control valve, the trim set includes three components: the ball, stem, and seat.

The ball and stem are connected as one piece. The stem is always the same diameter regardless of the diameter of the ball.

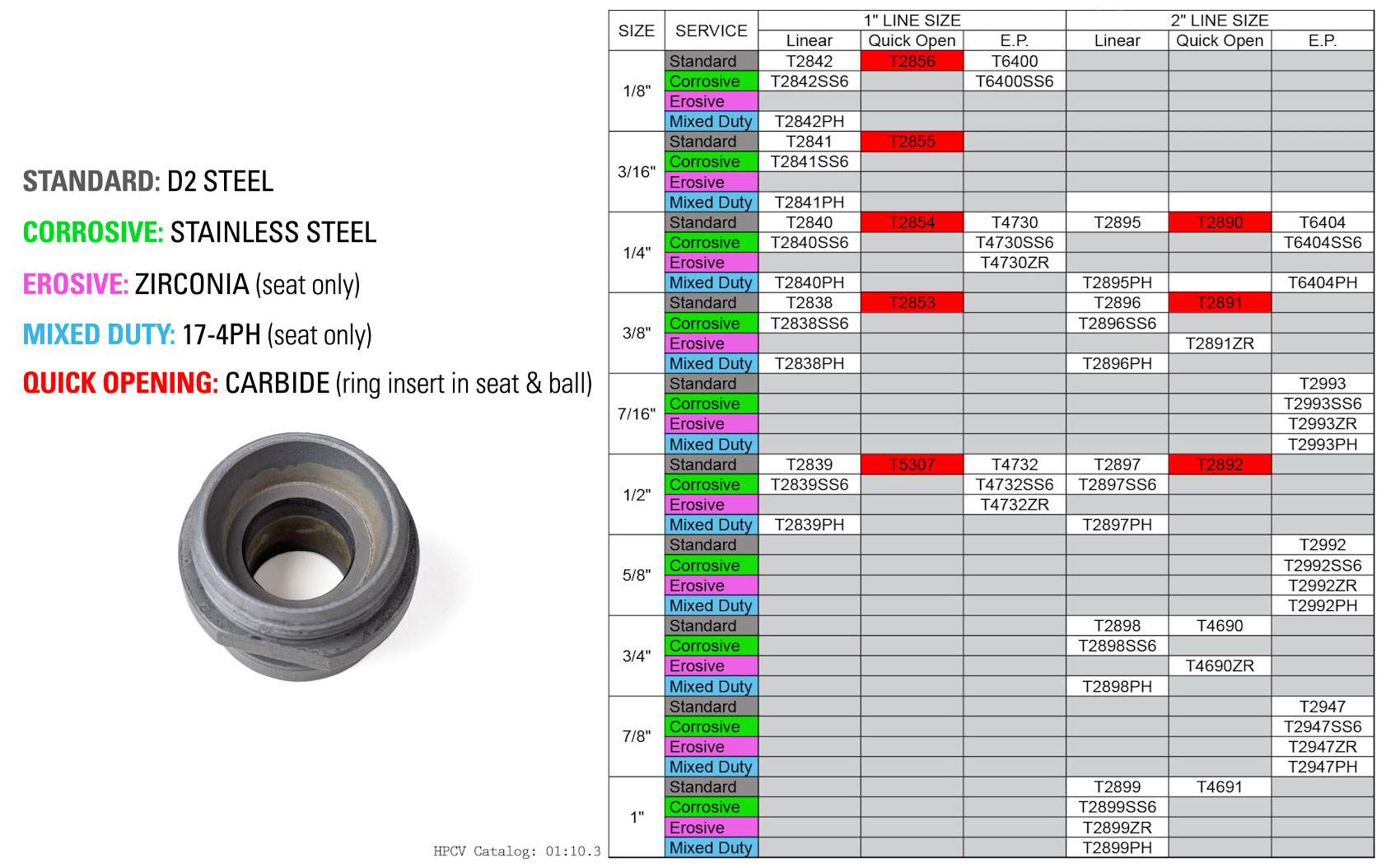

Trim options are listed by the size and type of trim. There is a wide range of sizes, 3 different types and 5 different materials. That can look like a lot of options to figure out, but let’s break it down so you understand the differences.

Trim Sizes

The size of trim is selected primarily by using our sizing calculator to calculate flow rates and volumes.

Each trim size has a different Cv value. See our sizing calculator video and Cv video for more information on both of those topics.

Trim Types

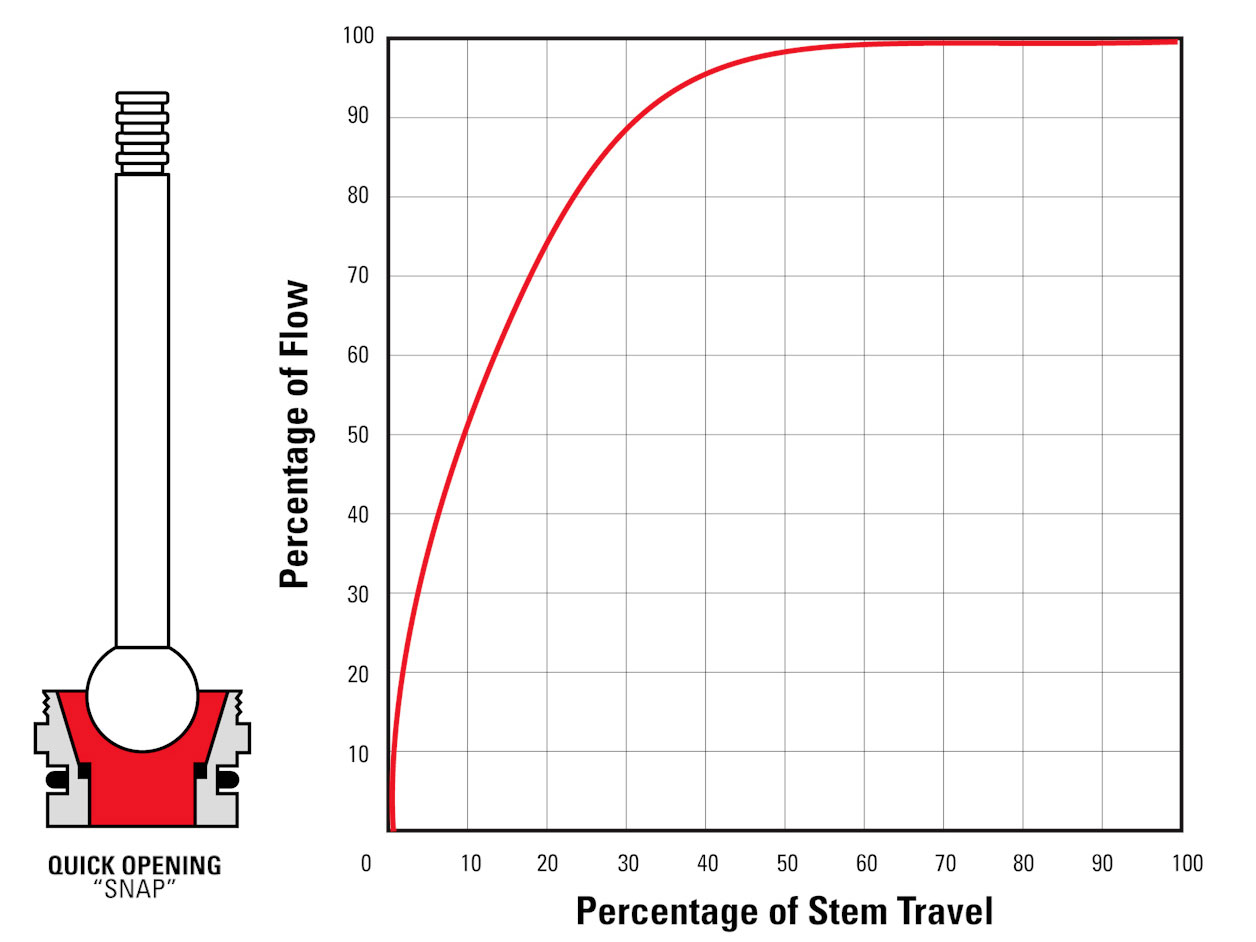

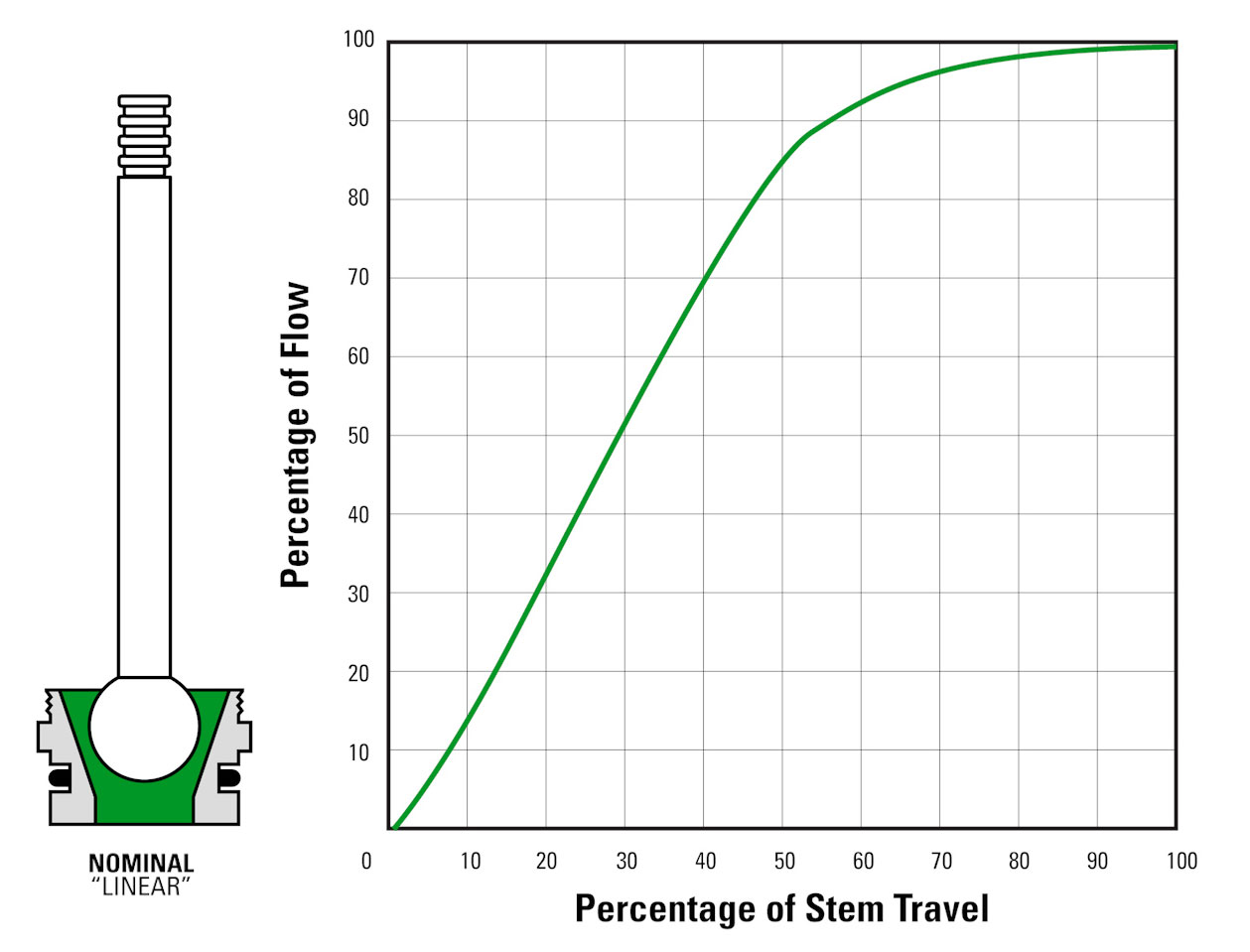

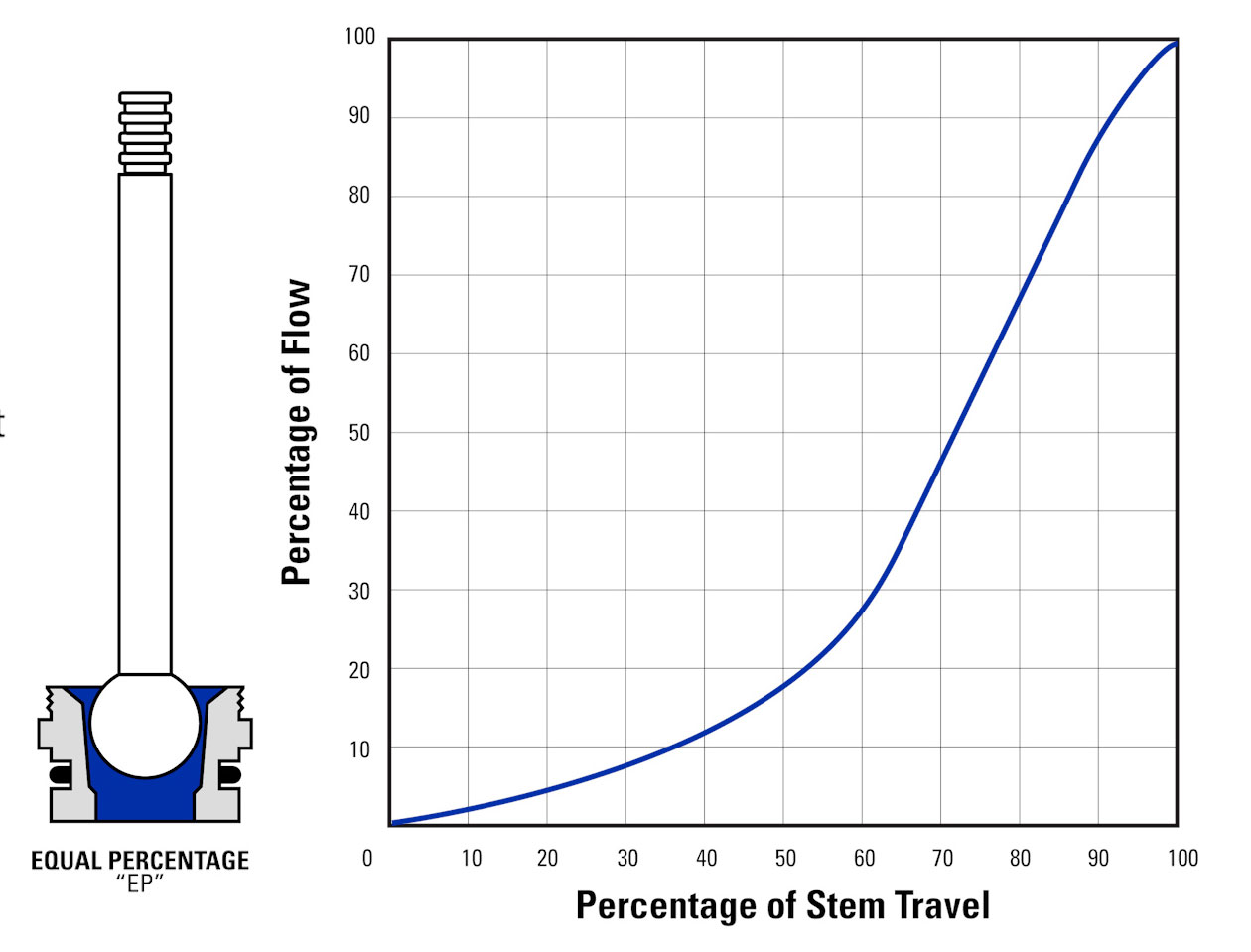

Each type of valve trim is characterized by the relationship between the percentage of flow and the percentage of valve stem travel. The differences here are not in the size of the ball, but the design of the seat.

Snap Trim

Snap, also called "Quick Opening" opens quickly and is used for on/off service. That is, the system goes from open to closed or vice versa instantly. Primary applications include liquid dump, metering, and highly abrasive service. This trim has a carbide ring insert in the seat portion that provides excellent erosion protection but also allows it to achieve full flow with very little stem travel.

Nominal Trim

Nominal, also called "Linear," is used for throttling liquids, liquid level control, and in applications where water hammering has been an issue and where abrasive material is not present in the stream.

Equal Percentage Trim

Equal percentage is used to control pressure or flow of liquids and gases in throttling applications. It allows for precise control at high pressure drops throughout the valve’s range of positions.

Trim Materials

In addition to the size and type of trim, there are also options for the trim material, depending on the type of service it will be in—standard (tool steel), corrosive (316SS), erosive (Zirconia), and mixed duty (17-4PH) which is for applications with both corrosive and erosive flow.

Sometimes the ball, stem, and seat are all the same materials, but other times the ball and stem may differ from the seat, such as with the carbide option.

Snap trim is only available in carbide. Carbide cannot be machined in a complex form like that of the seat. Instead, there is a single carbide ring on the seat and the rest of the seat is made of D-2 steel. The ball is also made of carbide allowing the two materials to meet.

Springs

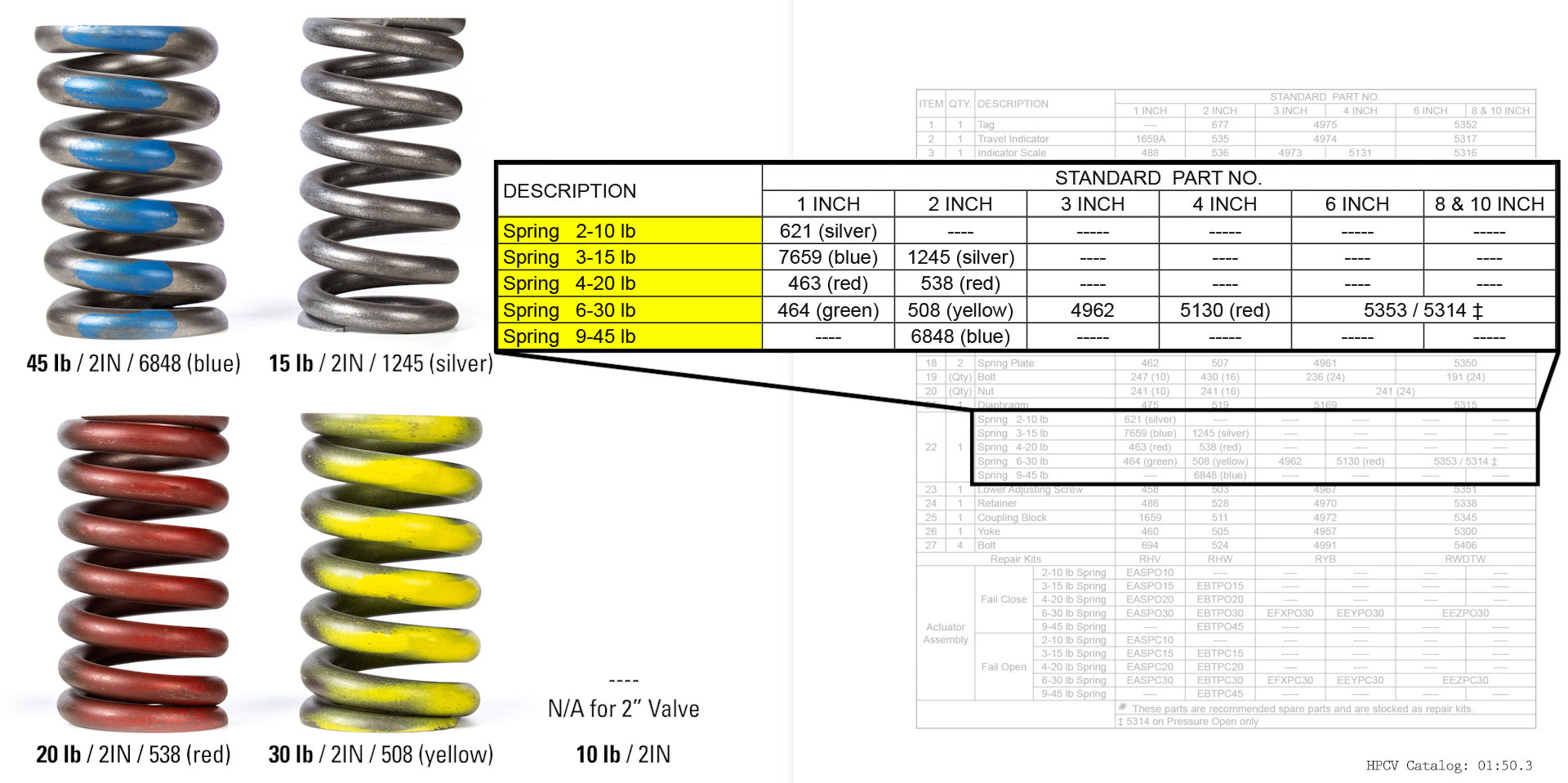

Another important option for High Pressure Control Valves is the actuator spring. This comes in 5 different pressure ratings, depending on your needs.

The 30 lbs. spring comes standard in our 3”-10" control valves and 20 lbs. spring is standard in 1”-2". Other springs can be requested for the 1”-2” control valves when ordering or retrofitting alternative springs.

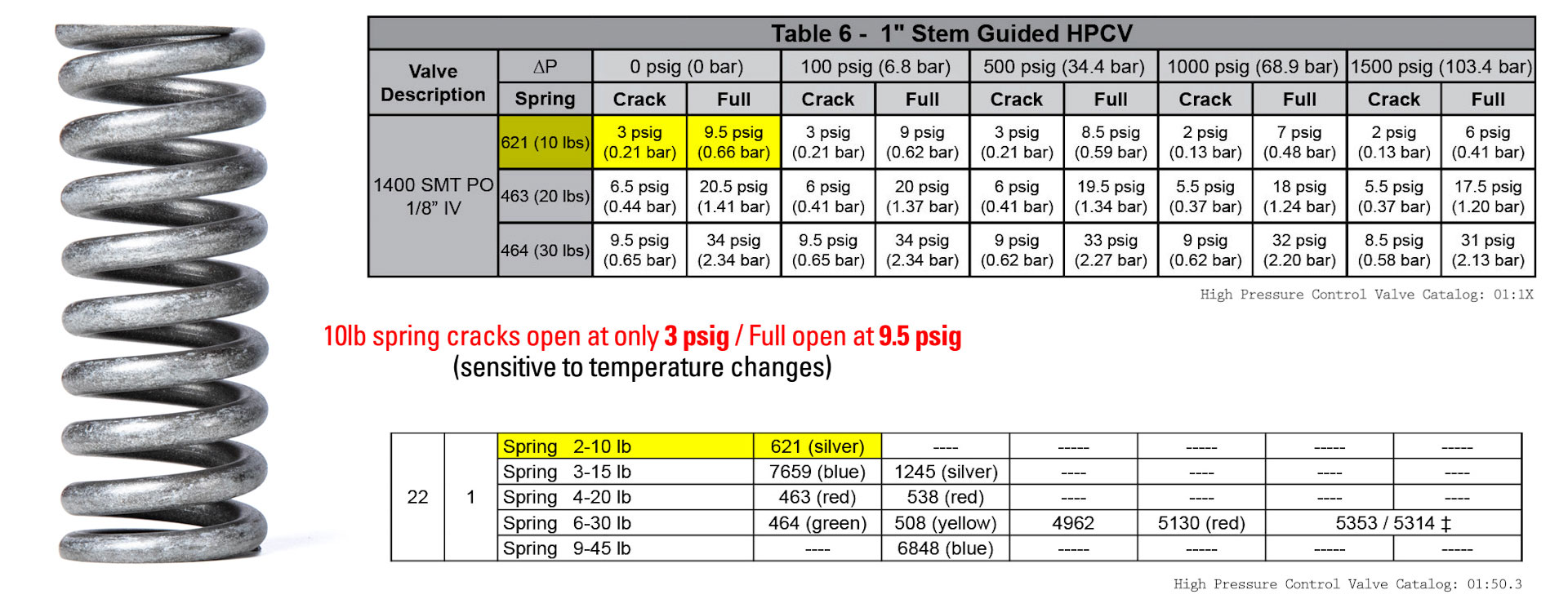

The actuator springs have a crack pressure, or the pressure where they will begin to open the valve, and a full open pressure.

The spring determines how much supply pressure is required to open or close the control valve and what pressure it can open or close against when supply pressure is removed.

Higher Spring Ranges

Higher spring ranges are used for applications where high-pressure drops are present. An example would be a 2” back pressure control valve package with 7/8" trim, which is fail-open, controlling 1,200 psi upstream and has only 200 psi downstream.

That’s a 1000 PSI Delta P and depending on the trim size installed in the control valve, the force created can keep the valve from returning to its fail position (open). A heavier, stiffer spring is required to operate in these conditions. The 45 lbs. spring would be a good option for this application.

Lower Spring Ranges

Lower spring ranges are used for low pressure applications or where the high pressure control valve needs to be more sensitive to changes in supply pressure.

A 1” high pressure control valve being used in a burner application is a good example of this. You want the burner valve to be sensitive to changes in the temperature and the 10 lbs. spring cracks open at 3 psi and fully opens the control valve at 9.5 psi.

Using the 10 lbs spring also allows you to use lower supply pressures in applications where 30 psi may not be available to fully actuate the control valve.

If you have questions about selecting or using any valve trim in your Kimray regulator or high pressure control valve, reach out to our Technical Sales Support team by phone, email or chat today.