There are four main types of oil and gas reservoirs in the United States today:

- Standard Oil Reservoirs: Mostly crude oil with some water and gas

- Volatile Oil Reservoirs: High amounts of corrosive gas in addition to oil and water

- Dry Gas Reservoirs: Mostly natural gas with some water vapor

- Gas Condensate Reservoirs: Full of heavy hydrocarbons that turn into NGL’s once brought to the surface

Below, we take a high-level trip through the flow path of each of these types to explore the commonly used vessels and equipment.

How is a Standard Crude Oil Reservoir Produced?

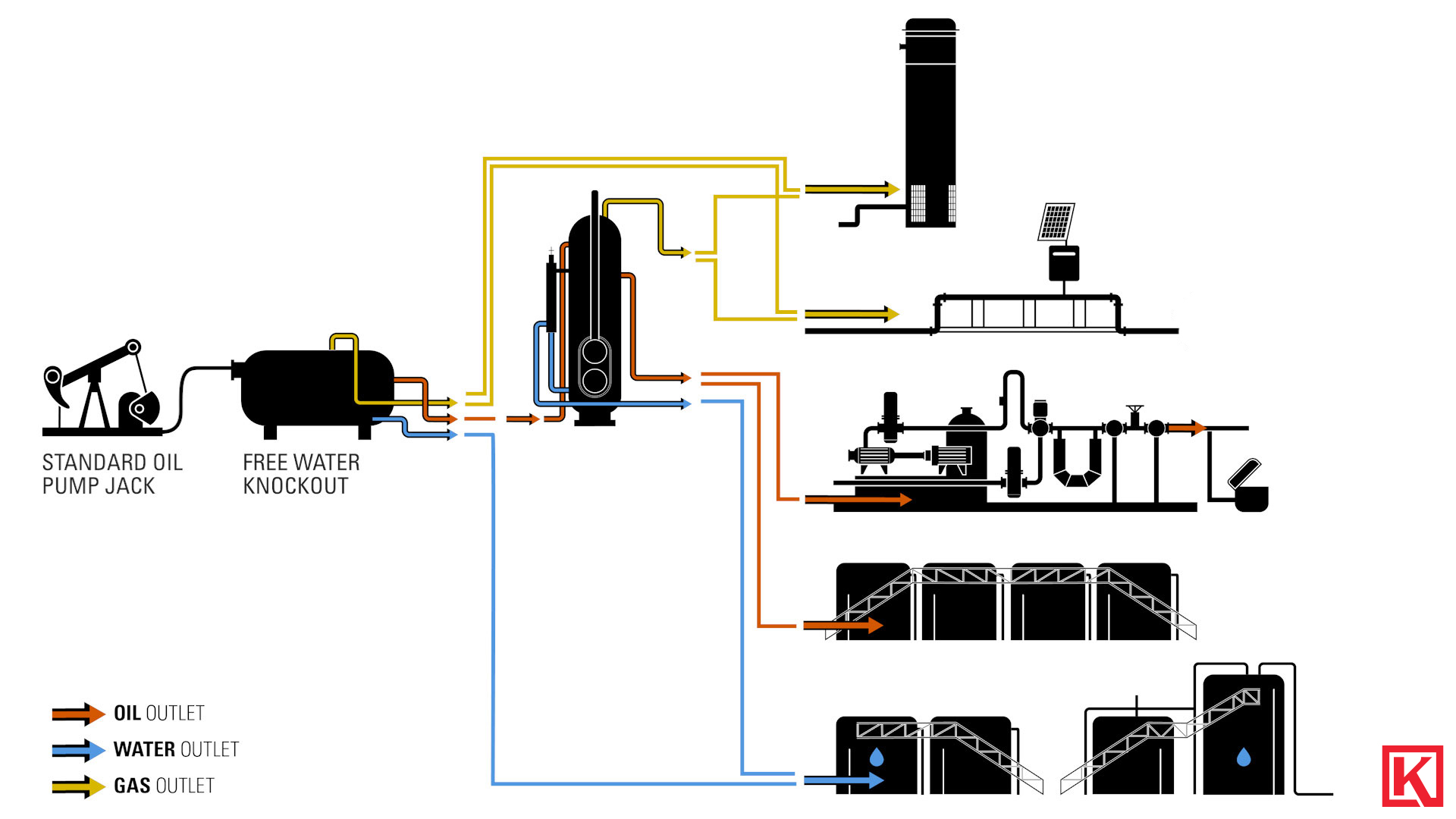

Standard crude oil reservoirs contain mostly crude oil with minimal amounts of water and gas. Standard oil reservoir will generally have two stages of separation.

The first stage will happen in a Free Water Knockout. In this vessel, retention time will allow the natural specific gravities to start separating the oil, water and gas from each other.

As they exit the vessel:

- The water is piped to storage, where it will eventually be disposed of.

- The gas is piped to either a sales line, via a meter run, or combustion line

- The oil emulsion will move on to the second stage of separation.

The second stage separation for an oil reservoir will typically happen in a heater treater. In this vessel, heat is used to accelerate the separation process and continue refining the produced emulsion into its three components.

As they exit the heater treater:

- the water is again piped to storage.

- The gas will either travel to a sales line through a meter run or is destroyed in a combustor if quality parameters are not being met by the producer.

- The oil will continue to either a Lease Automatic Custody Transfer (LACT) unit or storage to await midstream transportation.

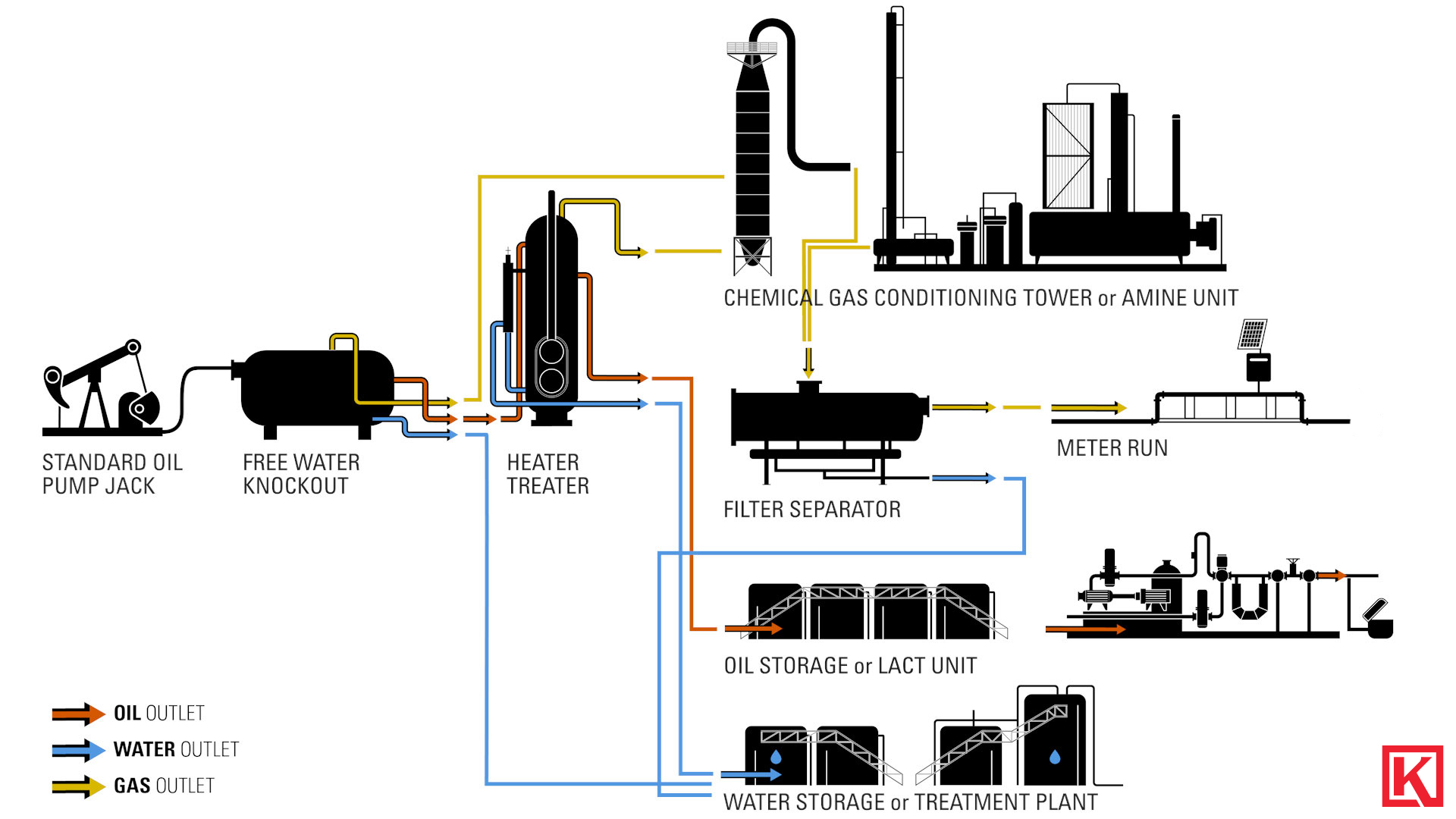

How is a Volatile Oil Reservoir Produced?

Volatile oil reservoirs contain high amounts of corrosive gas, in addition to oil and water.

This type of reservoir will follow the same path as a standard oil reservoir, except for the gas.

The gas in volatile oil well streams is highly corrosive. Because of this, it must be sent through an additional gas treatment process in a chemical gas conditioning tower or amine unit.

These vessels are designed to absorb unwanted elements from acidic gas. From there, the gas will go to a filter separator to remove any chemical carryover and then go back to the gas sales line.

An important consideration for producers operating volatile oil reservoirs is the materials in their vessels, piping and valves. It is recommended to specify corrosive-resistant materials to prevent premature wear due to the corrosive gas present in this type of well stream.

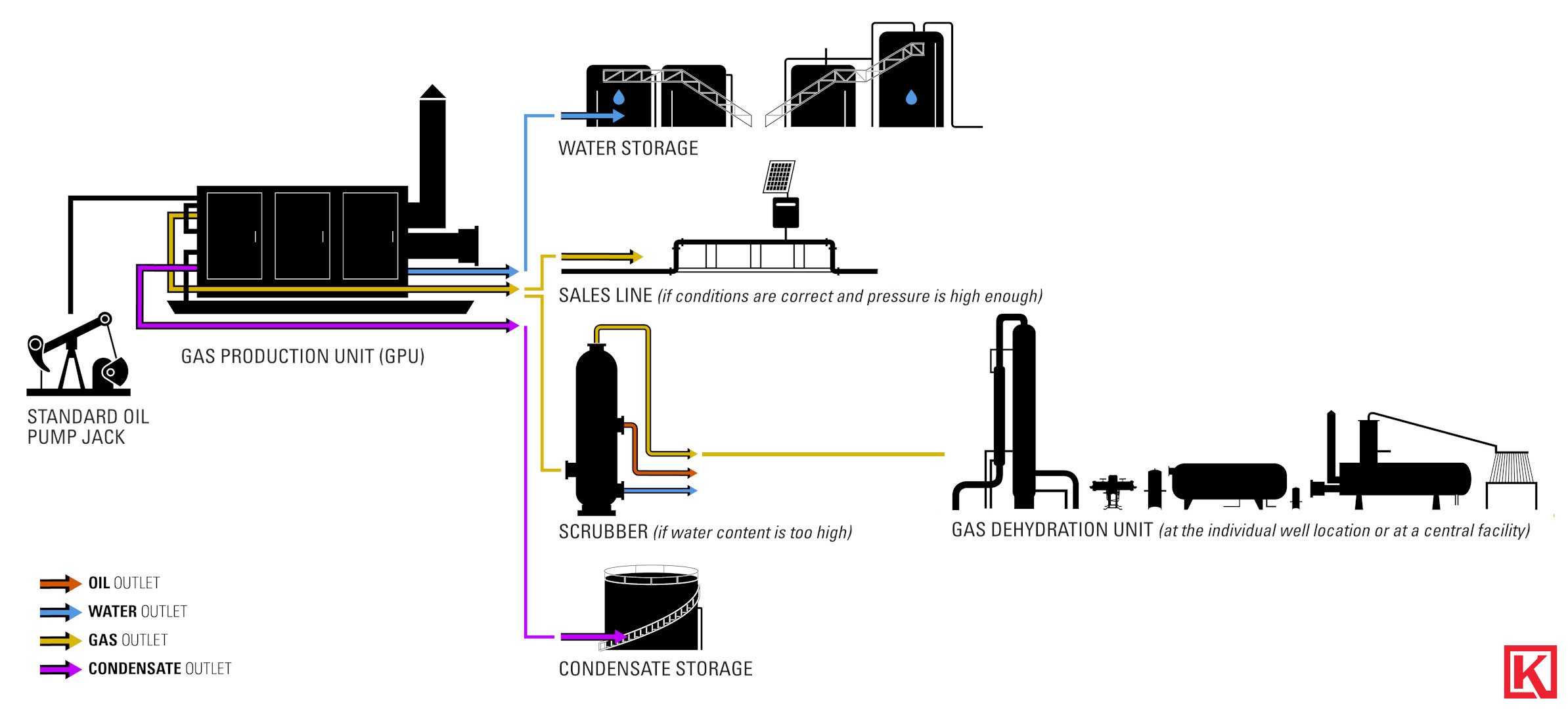

How is a Dry Gas Reservoir Produced?

Dry gas reservoirs produce mostly natural gas with some water vapor.

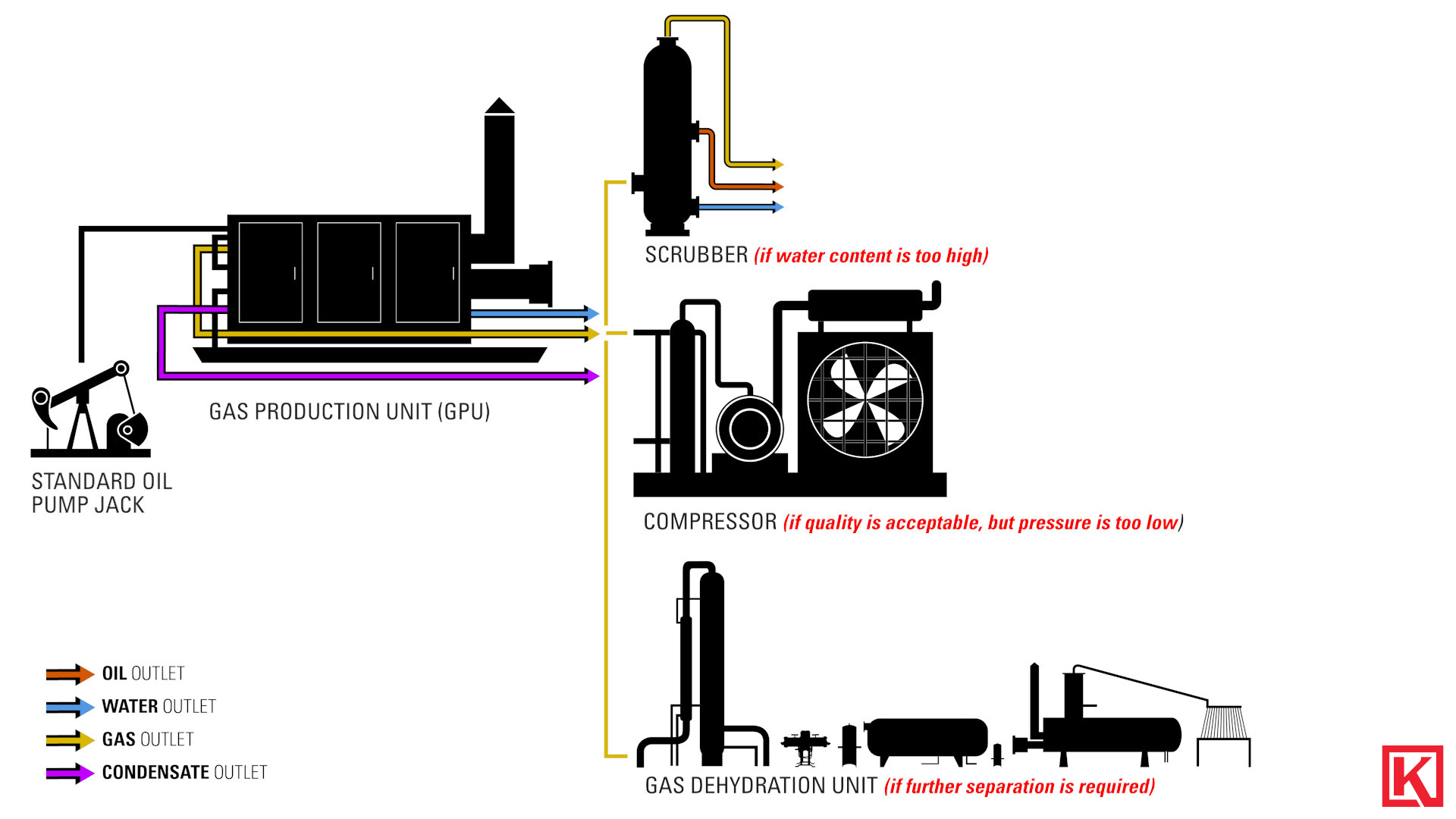

This type of reservoir will first go through a Gas Production Unit or GPU. This vessel incorporates a line heater and separator in one unit to separate the gas from the liquid.

When leaving the GPU:

- The water will go to storage for later transportation and disposal

- The condensate, which is a very light, valuable liquid hydrocarbon, will go to storage to be sold to a midstream company

- The gas will exit the GPU, and if conditions are correct and the pressure is already high enough, it will continue directly into a sales line

If the water content of the gas is too high, a large scrubber is used to remove additional liquid and further clean the gas before traveling into the sales line;

If further separation is needed, it will flow to a gas dehydration unit either at the individual well location or at a central facility before returning to the sales line.

If the quality of the gas is acceptable, but the pressure is too low, a compressor will be used to increase the pressure before it is sent downstream into a sales line.

How is a Gas Condensate Reservoir Produced?

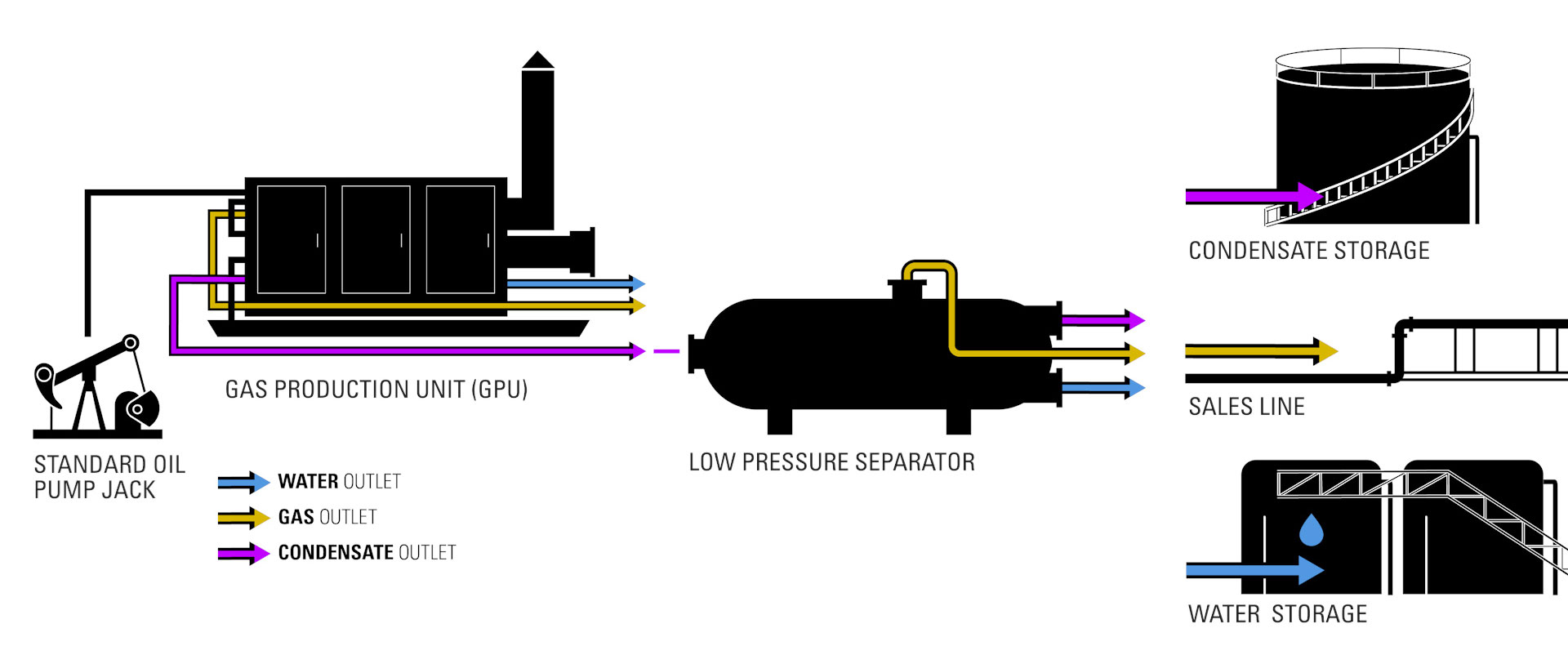

Gas condensate reservoirs will follow the same path as a dry gas reservoir, except for condensate. Because of the large amounts of condensate these reservoirs produce, additional separation equipment is needed.

After the GPU, the liquid condensate will go to a low-pressure separator to further separate it from the gas.

After that, the condensate will go to storage and the gas will go into a sales line.