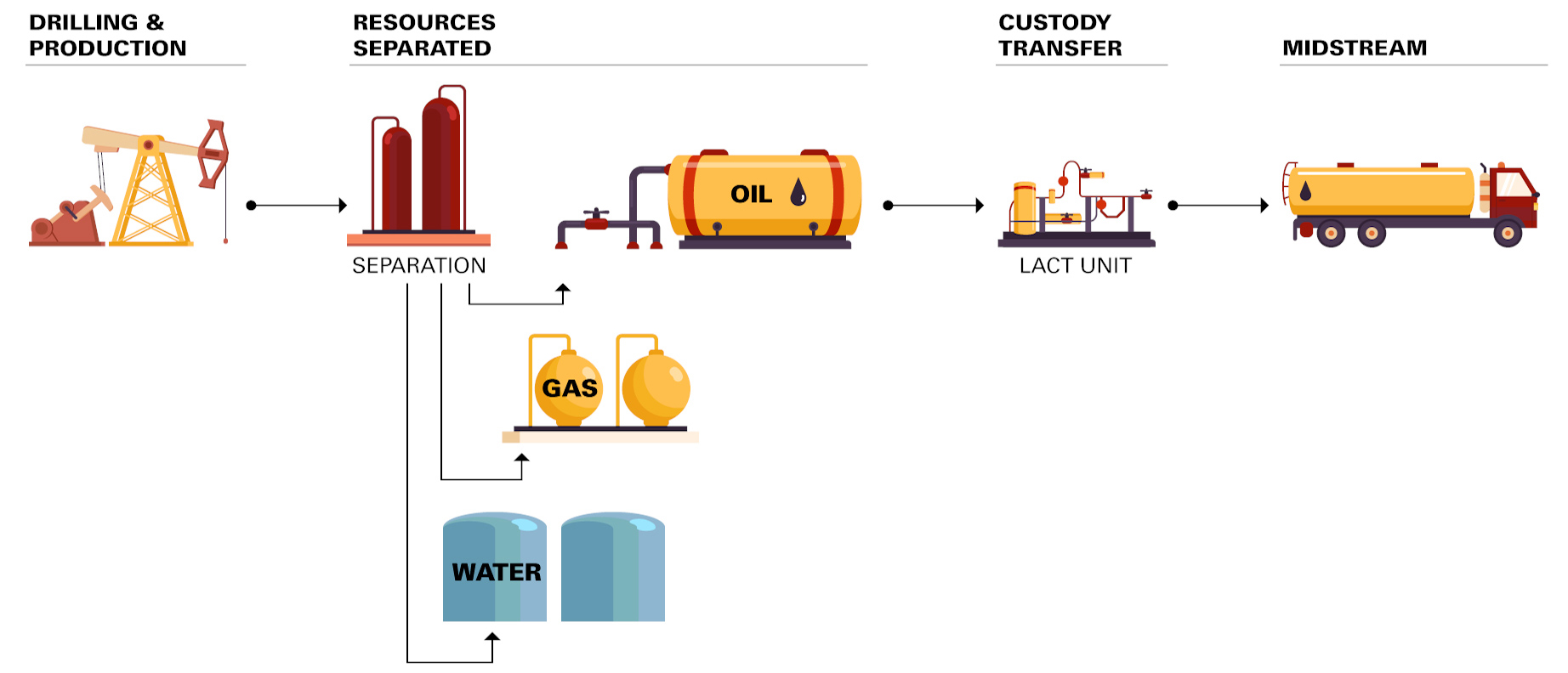

After initial drilling and production, the resources are separated, and custody or ownership of oil is typically transferred from an upstream producer to a midstream oil and gas company for storage or transportation.

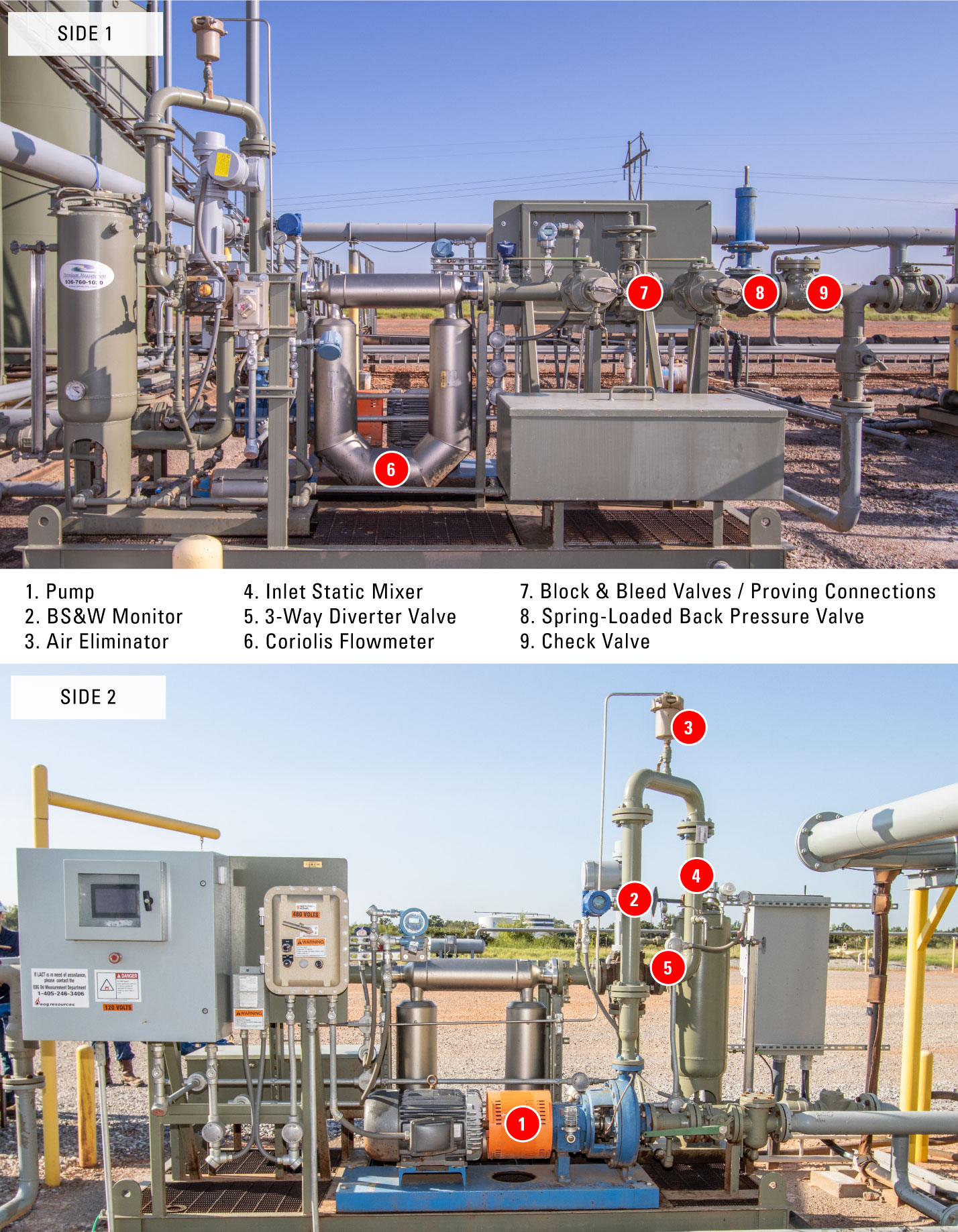

LACT stands for Lease Automatic Custody Transfer. A LACT Unit is a piece of oil and gas equipment used to sample and measure oil so it can be transferred from one company to another.

How Does a LACT Unit Work?

Pump

The pump draws oil from a storage tank into the unit.

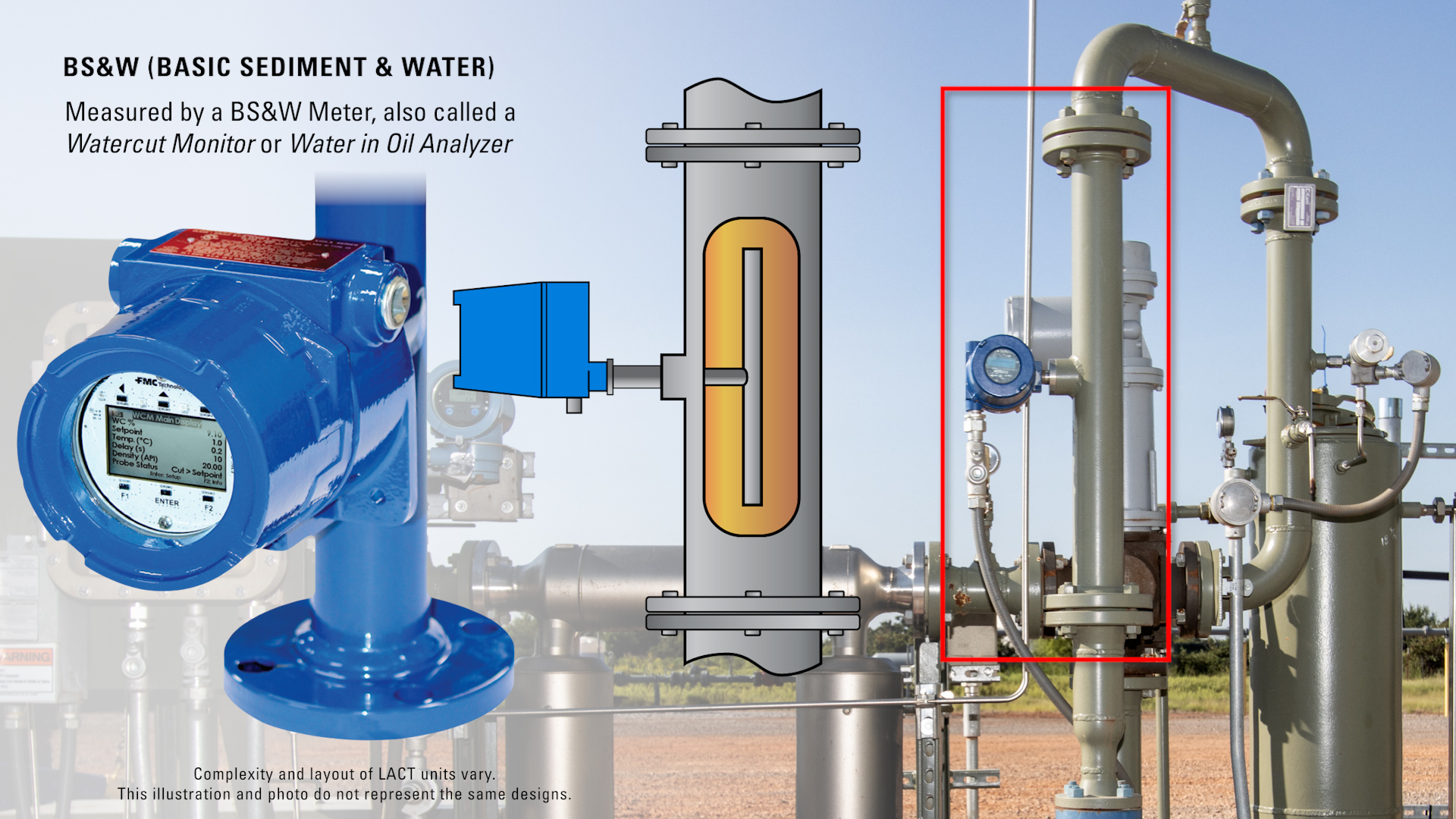

BS&W

The levels of BS&W - Basic Sediment and Water - is read by a sensor and probe in the flow stream which is then communicated to a control panel. The BS&W Monitor records representative samples of the oil and the percentage of water.

Often these monitors will also read the temperature of the oil, which can affect the measurements.

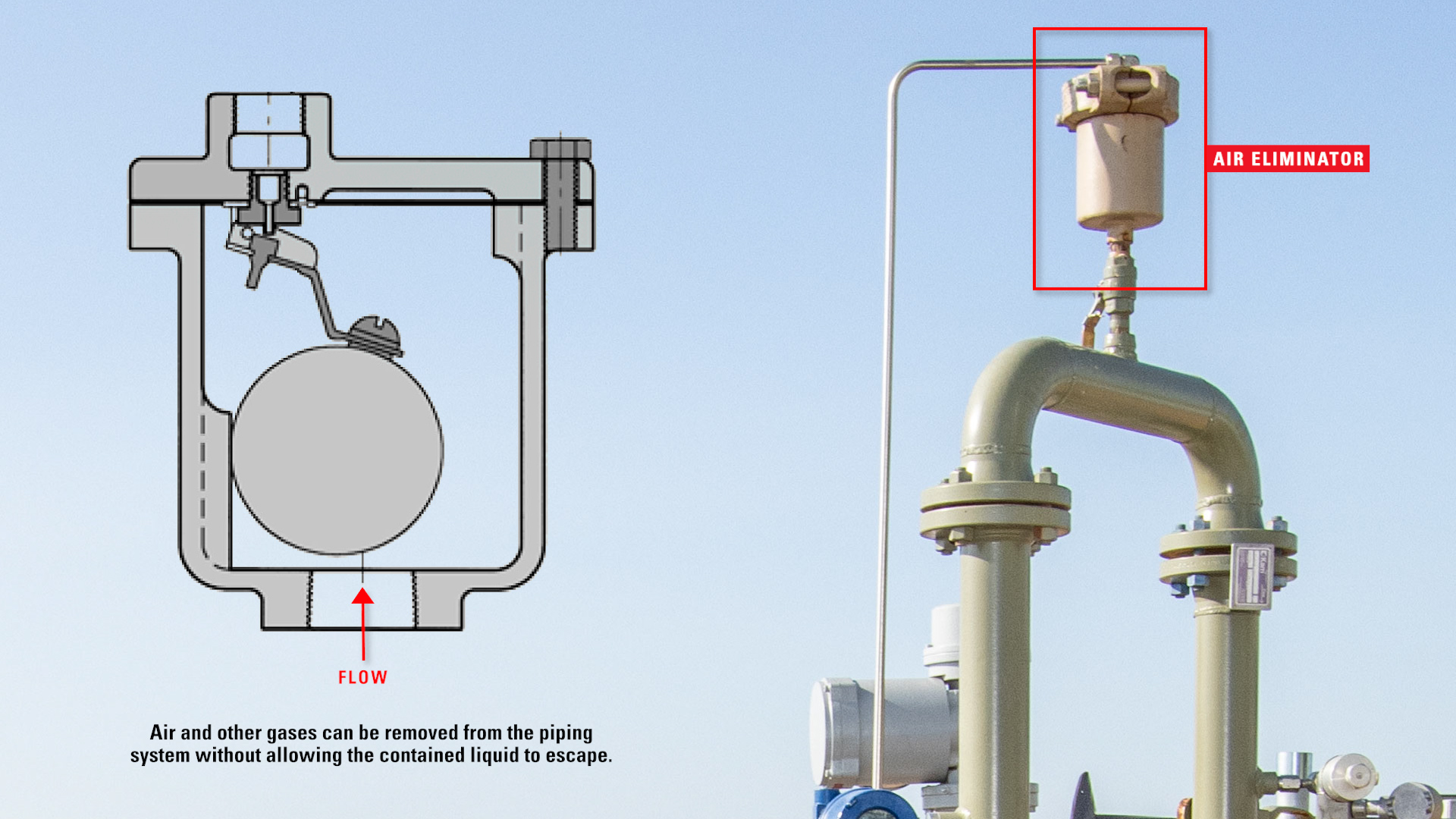

Air Eliminator

The oil travels through an air eliminator, which removes gas or air in the pipe without allowing the liquid to escape. This air can cause inaccurate metering if not removed.

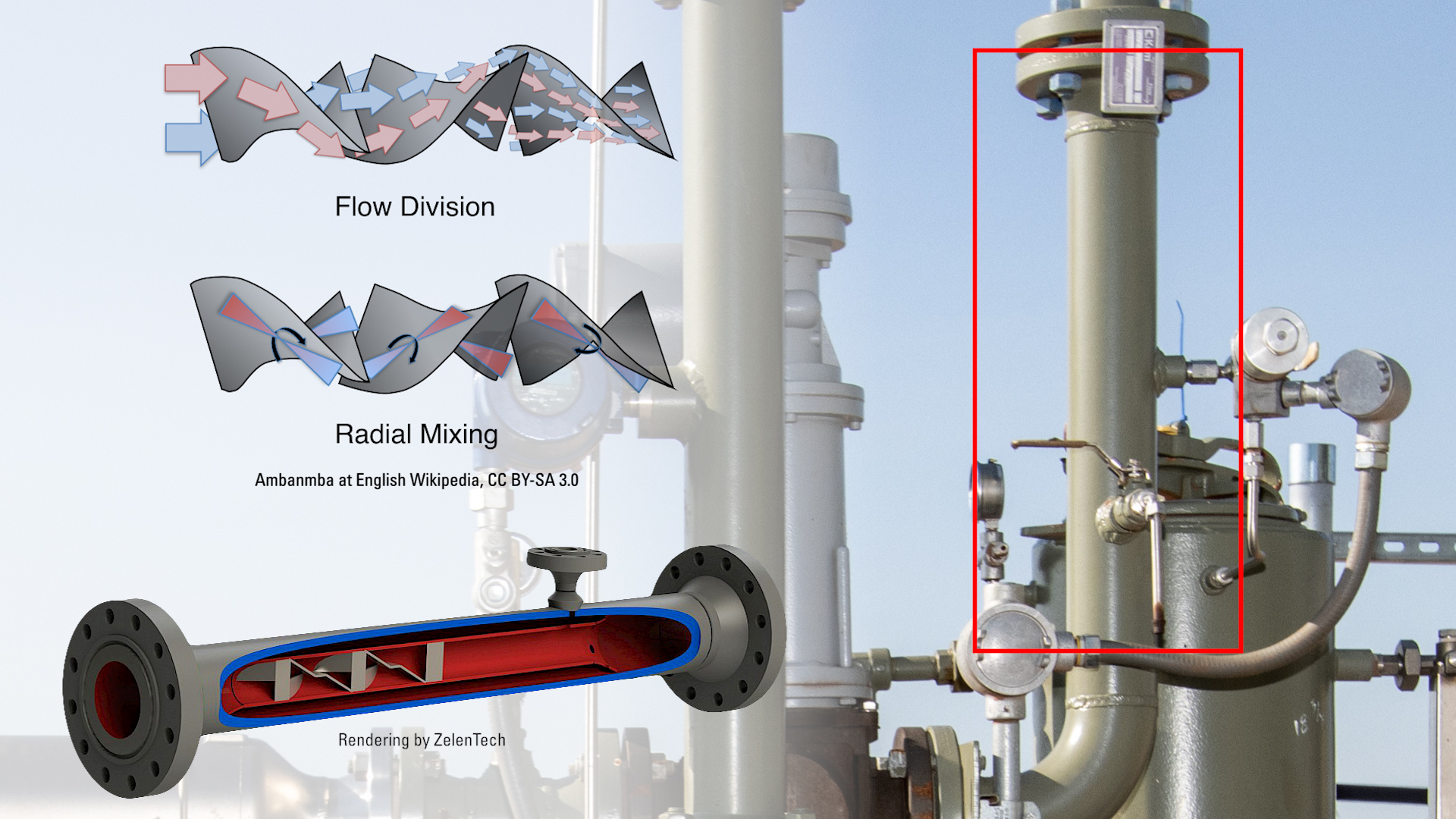

Inlet Static Mixer

An inlet static mixer emulsifies the liquid so that an accurate volume measurement can be taken. There is natural separation when the fluid is flowing through a straight pipe which can lead to certain kinds of meters reading only one of the fluid phases and not both.

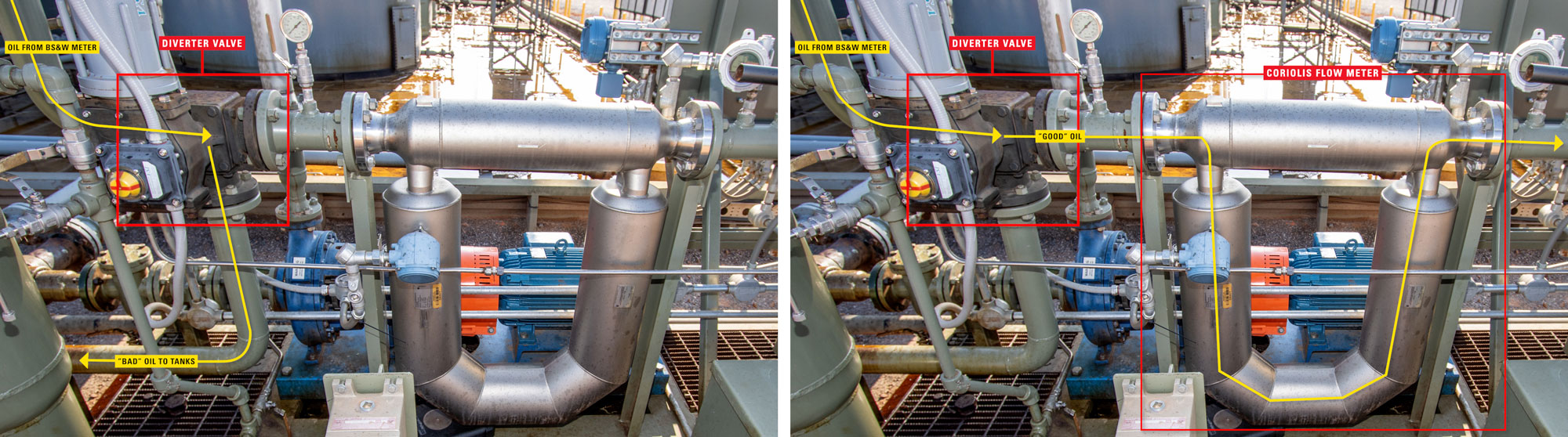

3-Way Diverter Valve

The BS&W monitor also controls a 3-way valve to direct the oil to its appropriate destination.

If the sediment and water amounts are too high, the diverter valve will route the oil to a separate "bad oil" tank to allow natural separation to occur before it is re-routed to the LACT unit again. Bypass lines can direct the oil to the beginning of the separation process or a stand-alone heated vessel to remove high levels of BS&W.

If the sediment and water amounts are acceptable the 3-way diverter valve will open and send the oil to a flow meter to have the volume measured.

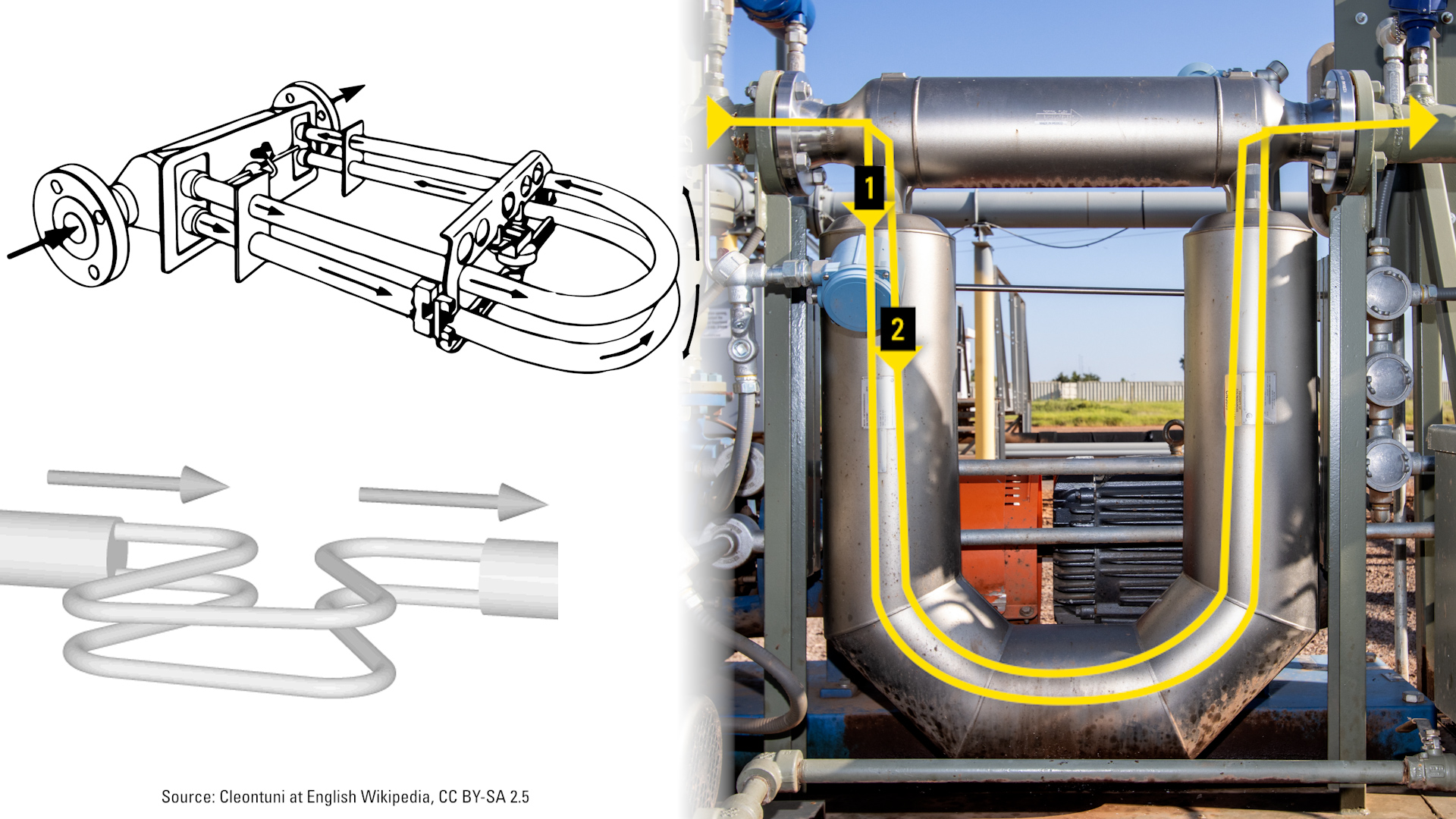

Coriolis Flow Meter

The type of meter is determined by the maximum mass and volumetric flow rate. On this location, a Coriolis meter is being used. Using motion mechanics, the meter splits the process fluid into two coils oscillating in opposite directions. Voltage is generated, sine waves are created, and the time delay in motion is proportional to the mass flow rate.

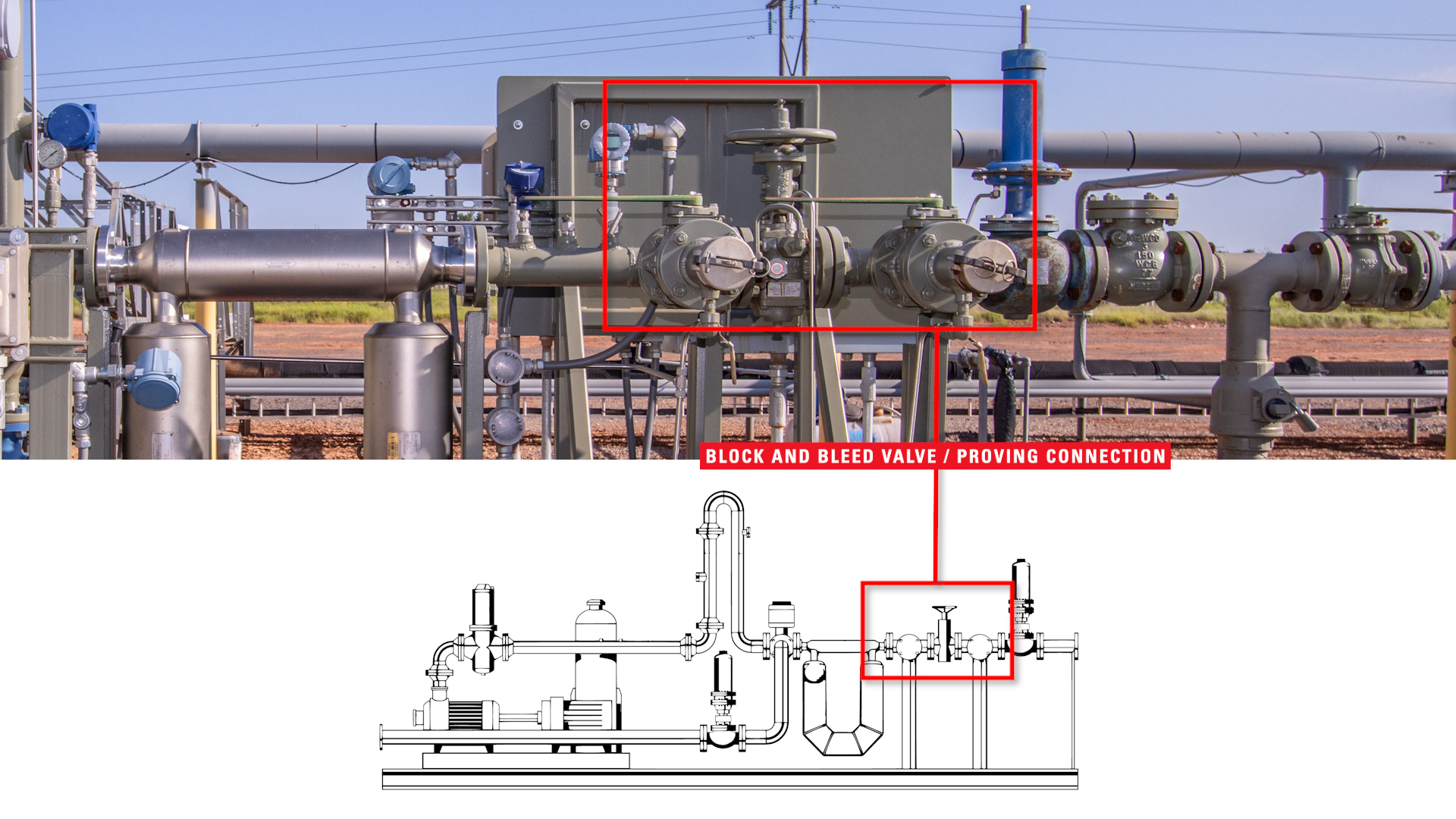

Block & Bleed Valves / Proving Connections

Located after the flow meter are block and bleed valves and proving connections. This is where a proving meter can be connected to periodically test the accuracy of the metering system.

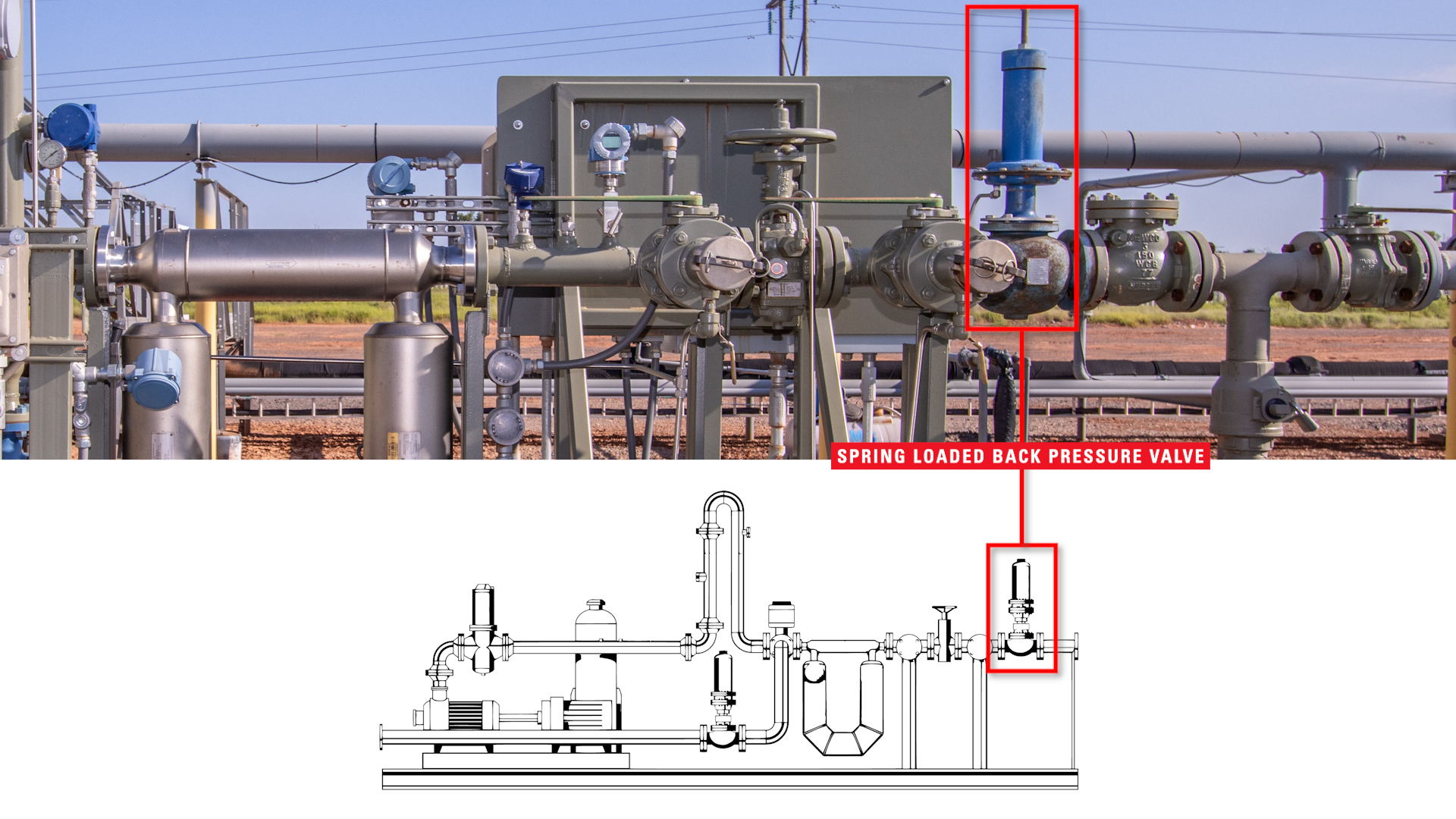

Spring Loaded Back Pressure Regulator

The oil moves through a back pressure valve which holds pressure against the LACT unit. This is typically a spring loaded back pressure regulator because it requires no supply gas to operate.

Check Valve

A check valve prevents the backflow of metered fluid from the pipeline back to the LACT unit.

Where Does the Oil Go?

The "good" oil runs through the primary LACT unit into an external midstream pipeline. On this location, it is discharged at 45 PSI. It is then directed to a progressive cavity pump (PCP) which will increase the pressure to over 600 PSI. This will provide enough pressure for the oil to continue through the pipeline to other booster stations and destinations.

.jpg)

This is a secondary LACT unit on location. From this unit, the good oil moves to a flex hose for connection to a truck to pull oil off the tanks. Bypass valves allow operators to direct oil through this unit when a truck is prepared.

How are LACT Units Automated?

Almost all of what makes the LACT unit automatic/automated is the controller or PLC (Programmable Logic Controller) which is a very important component of the whole system. With this controller in place, all the oil processing through the LACT can be automated.

The BS&W monitor, flow meter, tank level controls, fluid pump, diverter valve and any other equipment all communicate with the PLC, which determines outputs to the other components based on the parameters set by the user.

Why are LACT Units Important?

Some people refer to the LACT as the "cash register" of the oilfield, because producers use it to meter and calculate payments when selling the oil.

But it's important to remember LACT units not only measure the quantity of the product being transferred but also its quality—the amount of sediment and water in the oil. The allowable amount of BS&W will be determined by the seller and purchaser's agreement.