The Kimray Metering Valve is a precision piece of control equipment used and trusted around the world to meter and control flow for oil and gas applications.

In this video, we’ll go through the various applications, options and configurations of the Kimray Metering Valve. We’ll also review how to read and set the indicator label.

Applications

Metering

As the name implies, metering valves were designed to meter or control the flow on meter runs and flow lines. They feature opening increments of sixty-fourths of an inch, making them useful for this kind of precision control. Over time, more sophisticated designs have come into use with digital readouts gathering much more information and working together with remote terminal units and PLCS to read data.

Now, they’re rarely used for metering lines and instead have a few other useful applications, especially globally.

Gas Lift

The number one use of Kimray Metering Valves is actually for production in Middle and South America. They’re typically used on gas lift applications to control the amount of gas injected into the well. It's been proven so successful that each gas injection well now requires one, making the Metering Valve one of Kimray’s highest volume selling products in these regions.

Choke

They can also be used as a choke under low-pressure-drop conditions where freezing is not an issue due to the JT Effect.

Metering valves are designed for both liquid and gas control applications.

For gas pressure reduction, a High Pressure Control Valve package would typically be used for size and versatility, but not in a liquid application. You could also use a Pressure Reducing Regulator, which keeps a consistent set point; however, as a choke, you want it to stay constant and not move. Therefore, the metering valve can be used.

Sand Drain

As an alternative use, the Kimray Metering Valve can be used for sand drains on separation vessels. When sand is separated from the flow stream and settles to the bottom of the vessel, the metering valve can be used to offload the sand from that vessel manually thanks to the large, easy-to-use adjusting knob.

If used in an erosive application like this, the appropriate trim material and valve body must be used.

COmponent Overview

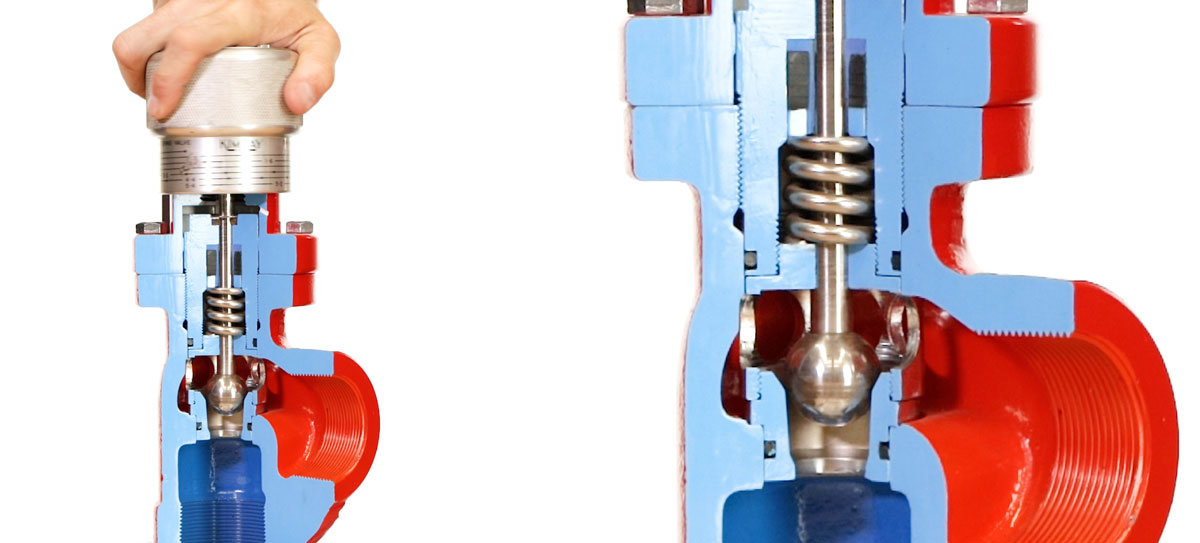

Metering valves have either a Stem Guided or Cage Guided valve body and a manual actuator.

Stem Guided

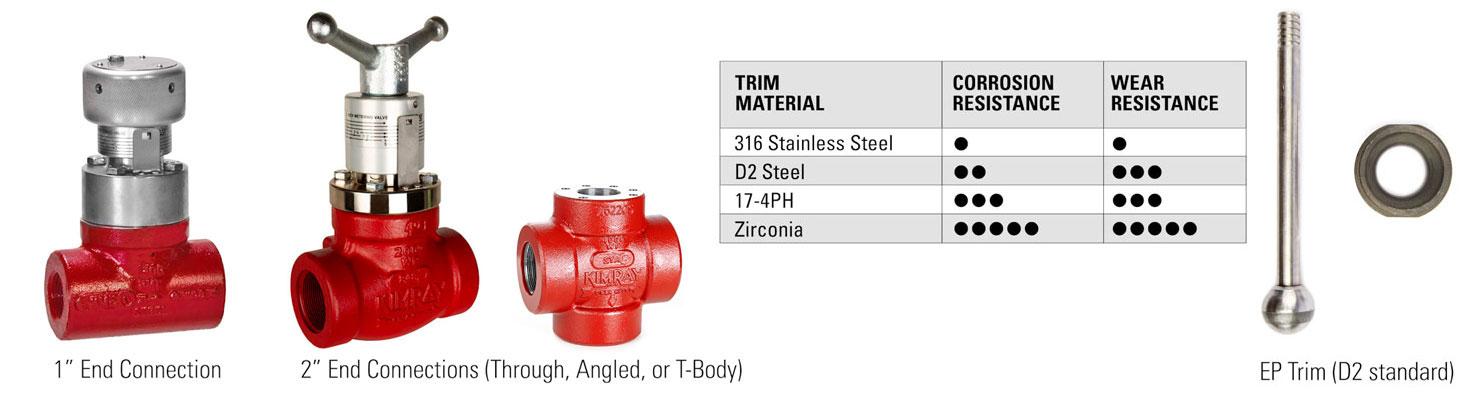

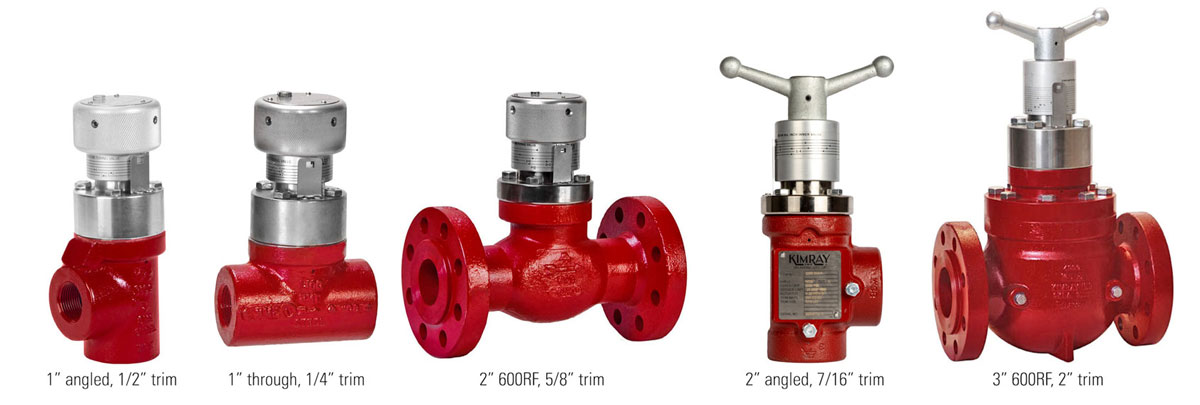

Stem Guided Metering Valves are available in 1” and 2” end connections and come with Equal Percentage trim in a variety of sizes depending on your specific flow requirements.

Equal Percentage Trim is available in D2, 316 SS, Zirconia, and 17-4PH depending on your production needs and is replaceable so you can adapt to changing conditions.

A 2” Stem Guided T-Body can also be used when combined with a metering actuator. For example, if you have a T-Body available, you can simply order and attach a Metering Actuator.

Cage Guided

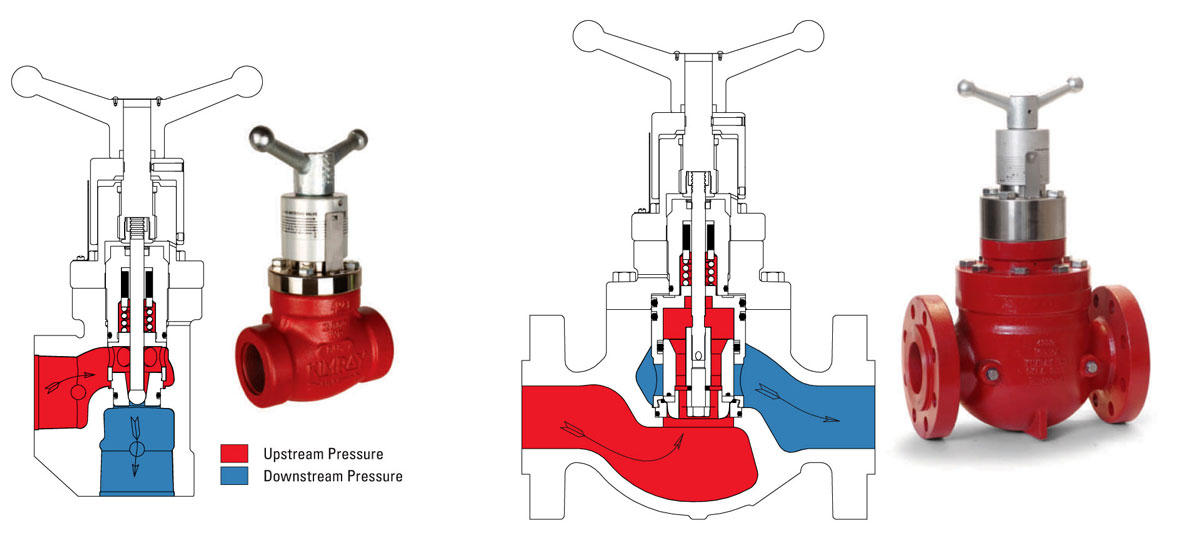

Cage Guided Metering Valves have a balanced trim set. This means that downstream pressure is balanced below and above the internal valve trim, allowing the valve to open and close even under high differential pressures.

Cage Guided Metering Valves are available in 2” and 3” end connections and standard Equal Percentage trim.

Cage guided metering valves are used to flow larger volumes, even under low-pressure differentials.

Actuator Options

Attached to the top of the body is one of two actuator options. The adjusting knob actuator is used on all 1” metering valves and is optional for some 2” and 3”.

The handle actuator is standard for 2” and 3” sizes. This large handle makes it even easier to adjust for precisely setting the indicator.

Setting the Indicator

Indicator Labels

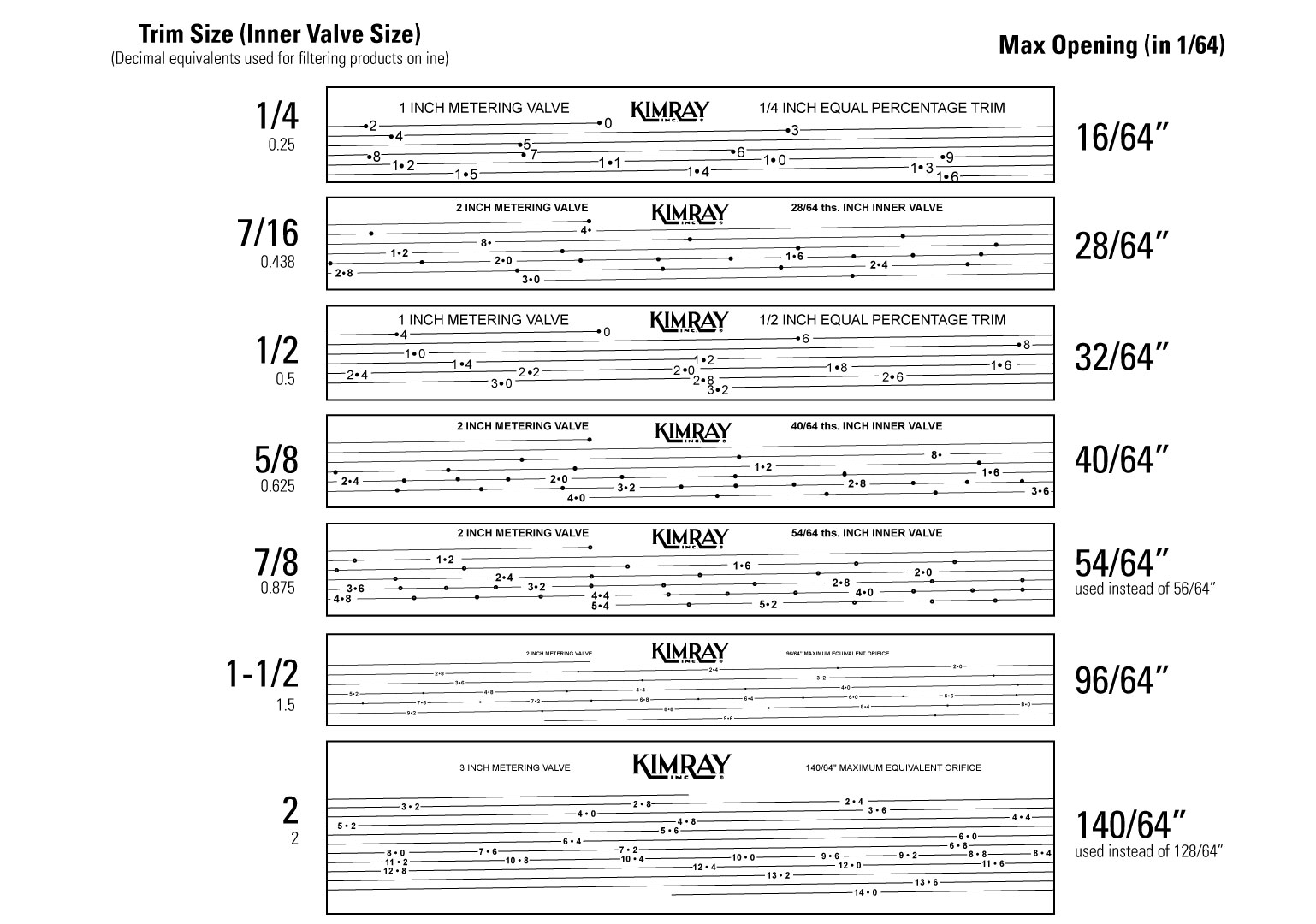

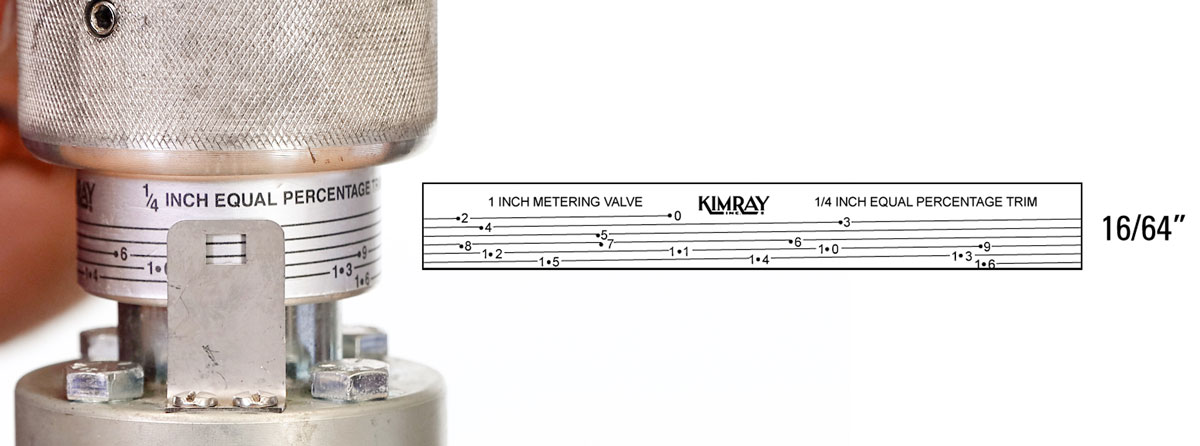

Each Metering Valve has an indicator label correlating to the trim size used. There are seven in all, so your label may vary from our examples.

Each mark indicates a relative position of the stem in relation to the seat. Full closed is determined by the first, or lowest, indicator mark at the starting point. Full open is determined by the last, top-most, indicator mark. The numbers next to the indicator marks are in sixty-fourth inches.

Calibrate the Indicator Label

To set the Metering Valve for the first time, you’ll need to first make sure the indicator label is calibrated to the fully closed position of the valve. This is only necessary with the handle design, as the knob and indicator label are connected on adjusting knob models.

With a 1/8" hex wrench, loosen the set screw on the indicator label, then rotate the adjusting knob until you reach a hard stop, fully closing the valve.

Next, rotate the indicator label so that the last number can be read through the indicator window. Tighten the set screw and now adjustments to the trim position can be made.

Setting the Valve Position

To set the Metering Valve trim position, align the top dot on the indicator label to be visible in the indicator window. This represents the fully closed position.

As you turn the knob, the indicator window follows the line. Each dot along the path indicates the amount the valve is open. Your specific indicator label correlates to the valve trim size.

For example, this Metering Valve has 1/4" trim. In 1/64" increments, that’s 16/64th. That means that on this label, there are 16 indicators, starting with “16” at the bottom, meaning fully open.

Turn the adjusting knob to an indicator mark until the desired set point is reached. Once set, the trim is in a fixed position until adjusted.

Limiting The Valve Position

The Metering Valve with the knob-style actuator has a Plug on top covering a set screw which can be tightened once your position is set. This will create a stop as to how far closed the valve can be set. When fully tightened, adjustments can be made to open the valve more, but cannot be closed any further.

The handle style actuator has a set screw on the lower part of the indicator label. This locks it into position to avoid unwanted adjustments.

To speak with an expert about which valves would be best for your operation, contact your local Kimray store or authorized distributor.