A control valve is a vital piece of equipment for controlling oil and gas operations. But today we’re going to talk about a small component that may be even more important: a pressure pilot.

Below we'll cover what a pressure pilot does and take a brief look at four common types of pressure pilots.

What is a Pressure Pilot?

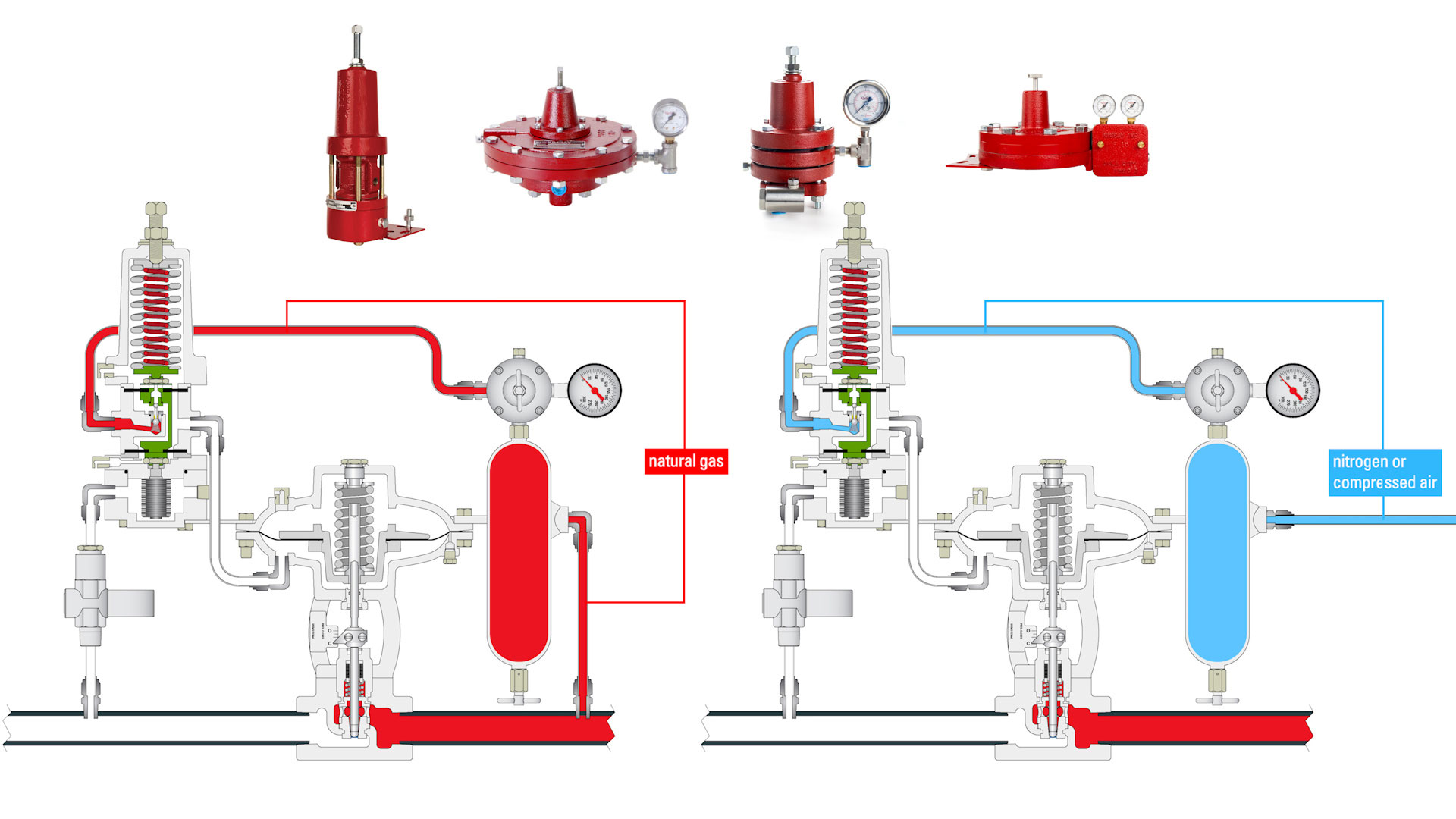

A pressure pilot is used to monitor and control pressure upstream or downstream of a control valve. It does this by pneumatically positioning the valve to achieve your desired set point.

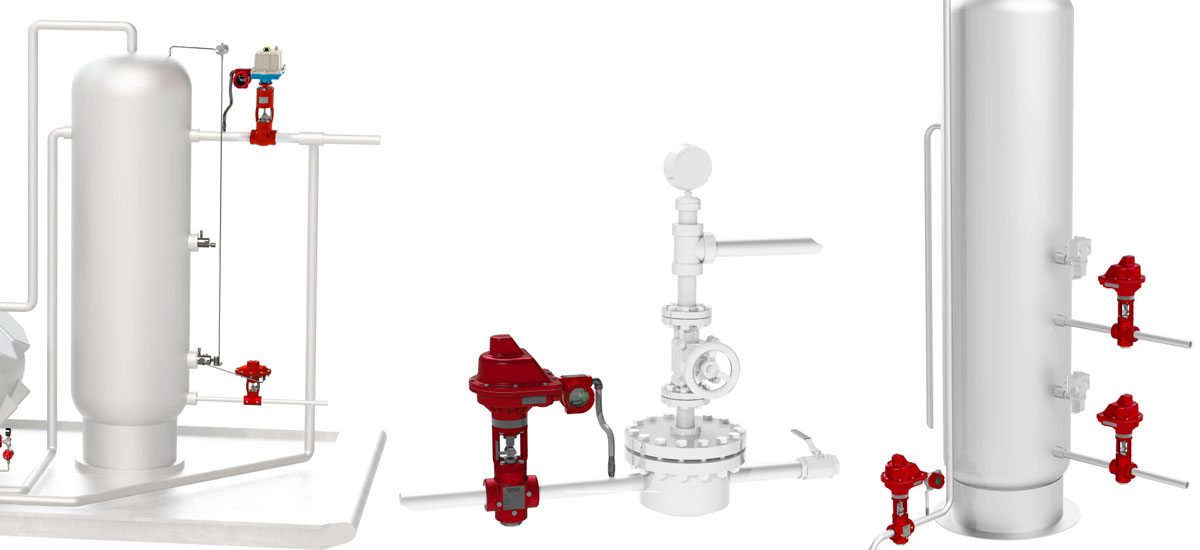

Control Valve Package Animations

A pressure pilot is almost always used on a high pressure control valve package. Valve packages like these allow producers to effectively control their oil and gas separation equipment.

Advantages of Kimray Pilots

Here are a few of the reasons energy producers rely on Kimray pressure pilots:

Durability

The first is the durability that is synonymous with the Kimray name.

The pressure pilot was one of Kimray’s first innovations, and there’s a reason that energy producers have trusted it for decades. We use only the highest quality materials, and our products are manufactured at our headquarters in Oklahoma City, USA.

Modular Design

Another reason producers like to use our pilots is because of their modular design.

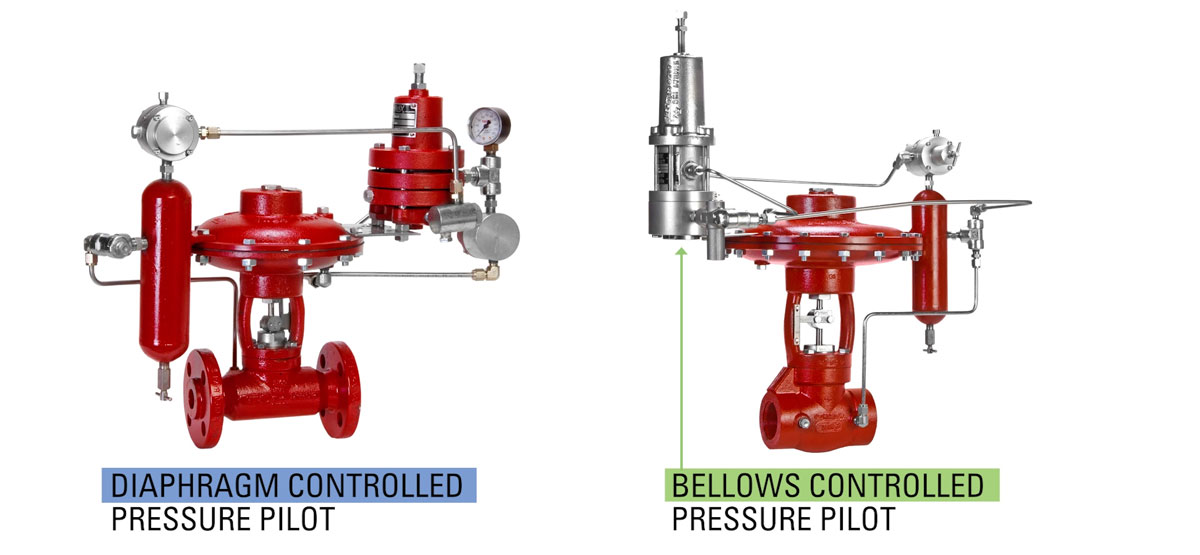

We provide packages for pressure regulation that can be customized to your needs, whether you are holding back pressure on separation equipment or reducing pressure for your compressor.

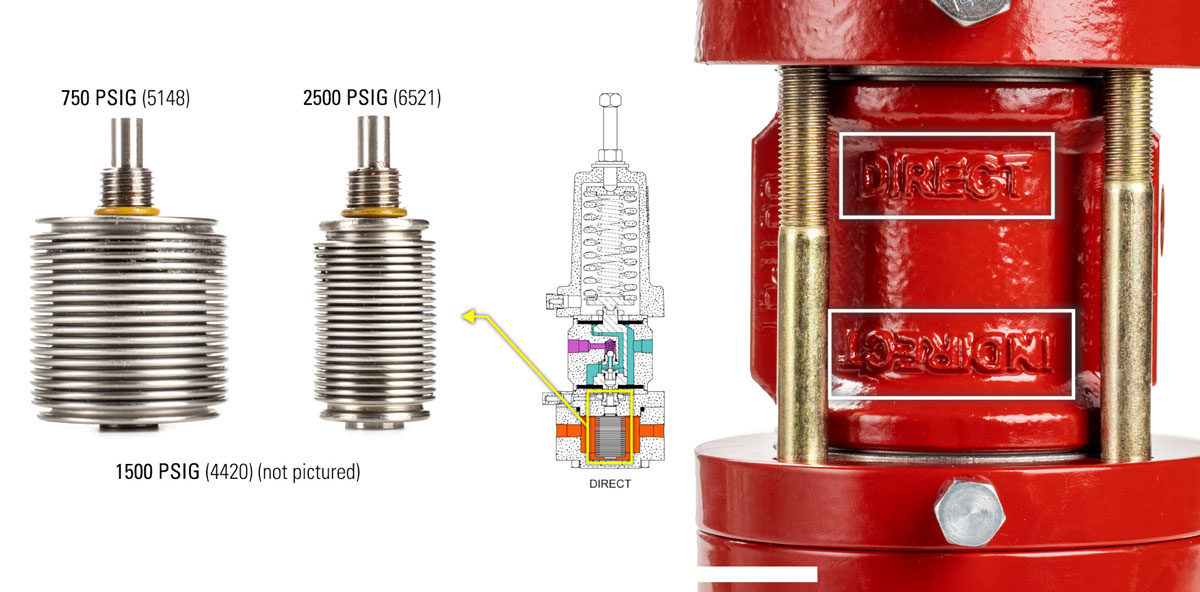

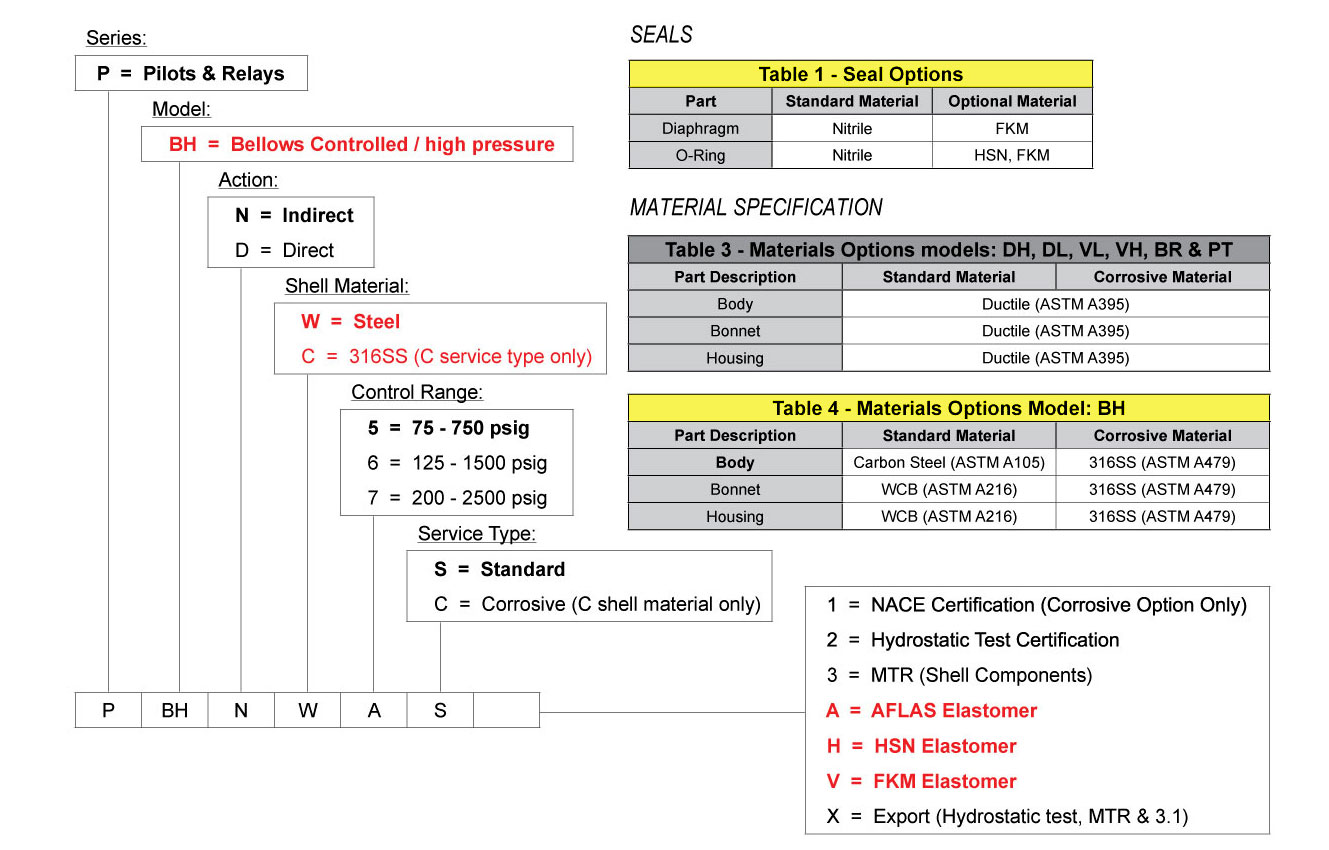

Components in the pilot can also be changed out to adapt to various operating pressures or different modes of action, like

indirect or direct.

Versatility

Finally, we provide material options like steel components and various types of elastomers to help keep your operation running regardless of your production conditions.

4 Types of Pneumatic Pressure Pilots

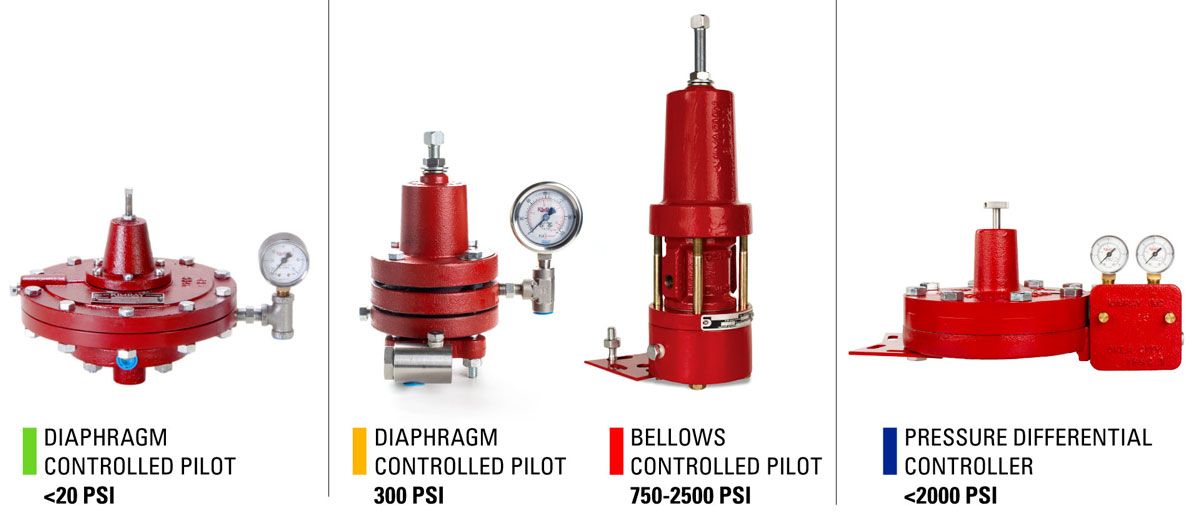

These four popular pneumatic pilots monitor the upstream or downstream pressure of a control valve and can be used in both back pressure and pressure reducing applications.

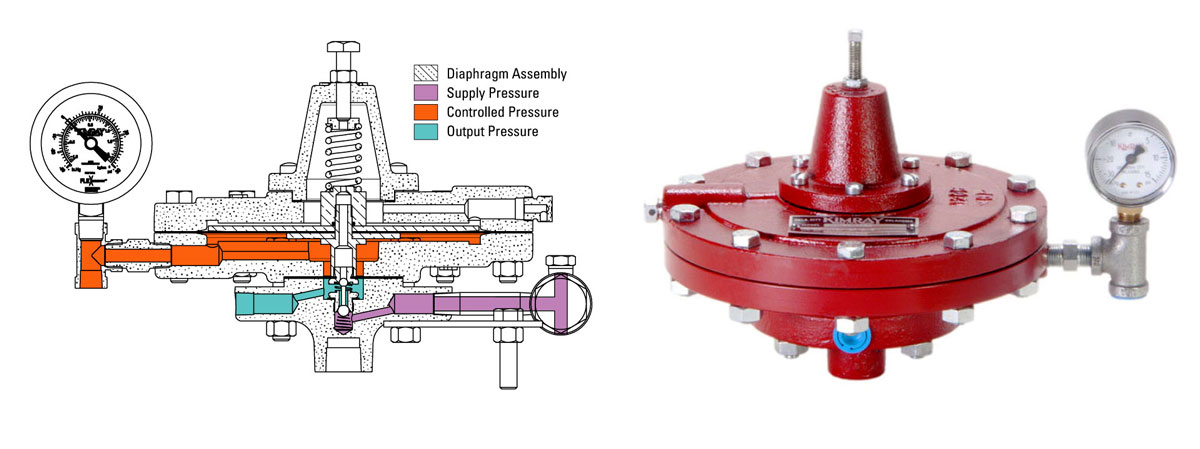

Diaphragm Controlled Low Pressure Pilot

Designed for lower pressures, the Diaphragm Controlled Low Pressure Pilot will work in any application between half an ounce to 20 PSI.

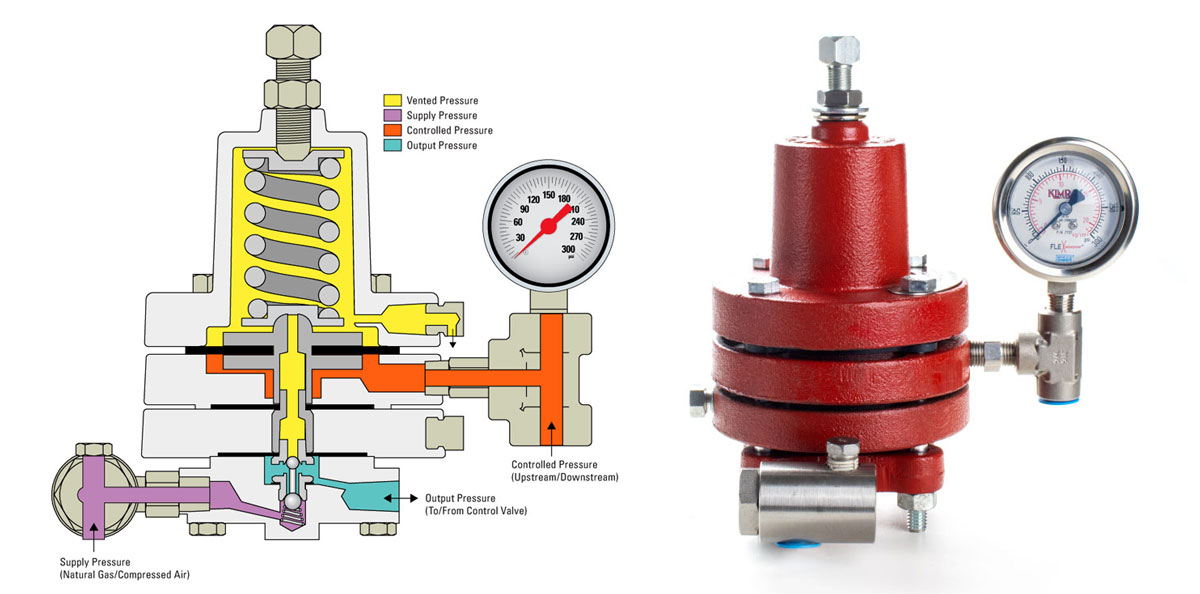

Diaphragm Controlled High Pressure Pilot

The Diaphragm Controlled High Pressure Pilot will work in any application between 10 and 300 PSI.

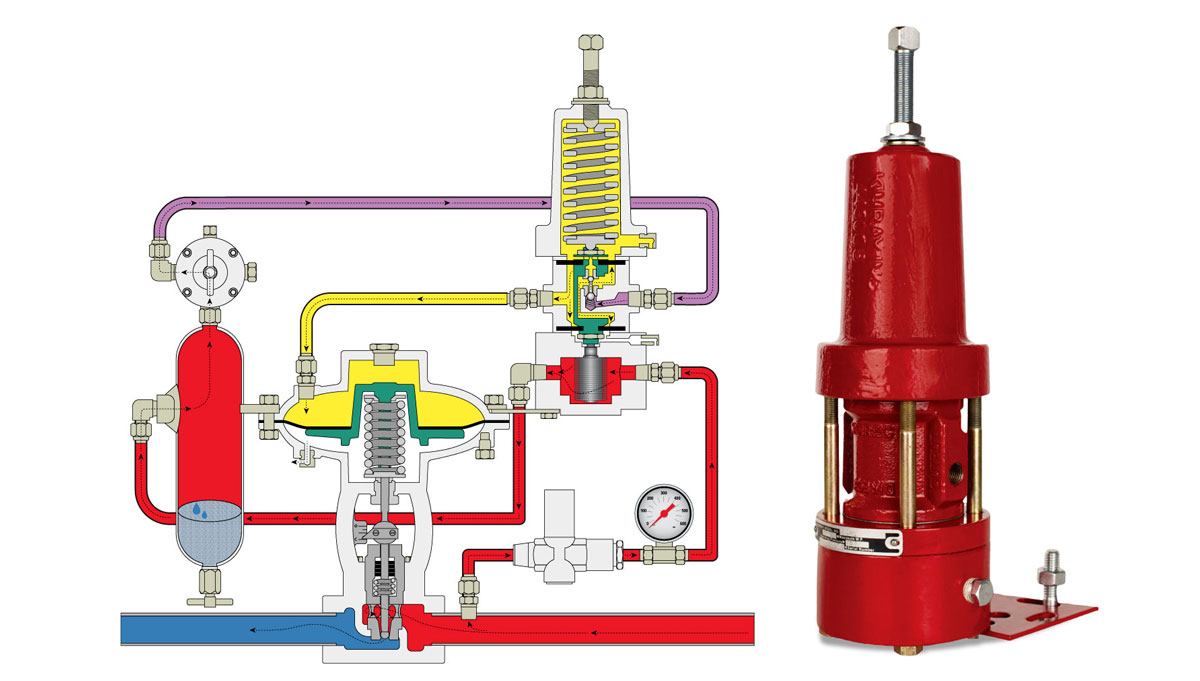

Bellows-Controlled High Pressure Pilot

The Kimray Bellows Controlled Pressure Pilot is versatile and easy to use in several applications. Part of its value is that it can act in either direct or indirect mode and can be converted to operate at a vast span of different pressures—from 75 to 2500 PSI.

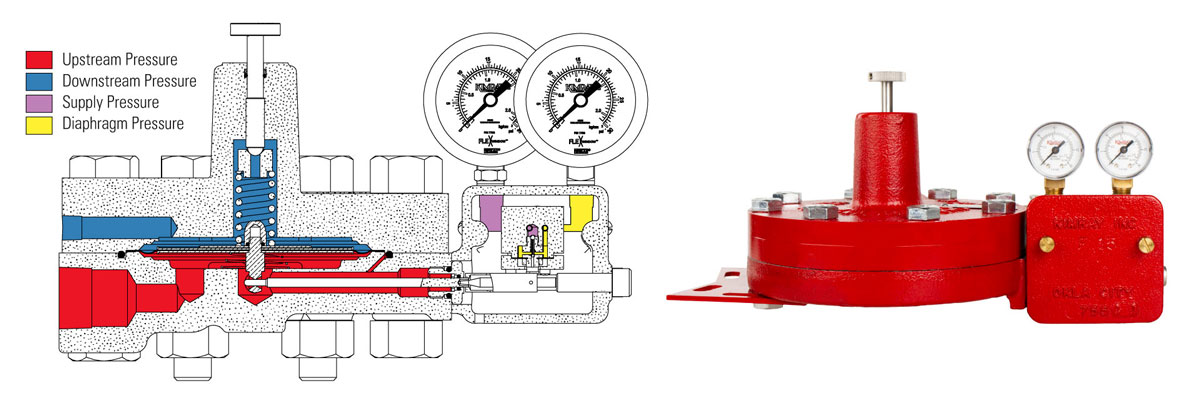

Pressure Differential Controller

A Pressure Differential Controller is used in applications where you need to control a difference in pressure across an orifice plate. This controller has inputs for both upstream and downstream pressure. Those two pressures work against each other with a spring in the pilot, which controls the difference between the pressures.

Note: All our pneumatic pilots can be operated emission-free, when you use nitrogen or compressed air as the supply source.

Electric Pilot

If you are ready to incorporate automation into your operation, you can also check out our Electric Pilot.

The Electric Pilot can be used with any electric actuator to automate a control valve. The pilot takes an input signal—like a pressure or timer—and outputs a signal to an electric actuator.

It offers a ton of versatility, and can be used in back pressure, pressure reduction, pressure differential, gap control, suction control, or as a timer.

Certifications

Manufactured and assembled in the USA, Kimray Pressure Pilots are certified for use in North and South America and most areas around the world.

We have 25 distribution centers in the U.S. and international distribution partners globally. Kimray is also an ISO 9001-certified manufacturer.

Reach out to your local Kimray representative today to explore how we can help solve your control challenges.