Separator vessel design is a crucial consideration for oil and gas producers trying to separate valuable resources from disposable ones.

Produced well fluid consists of different ratios of oil, water, natural gas, and sediment. Horizontal and vertical three-phase separators split that emulsion into three individual components.

In this video, we review 4 types of three-phase separator vessel design:

- Horizontal with Overflow Weir

- Horizontal with Oil Bucket and Water Weir

- Vertical with Interface Control

- Vertical with a Downcomer and Spreader

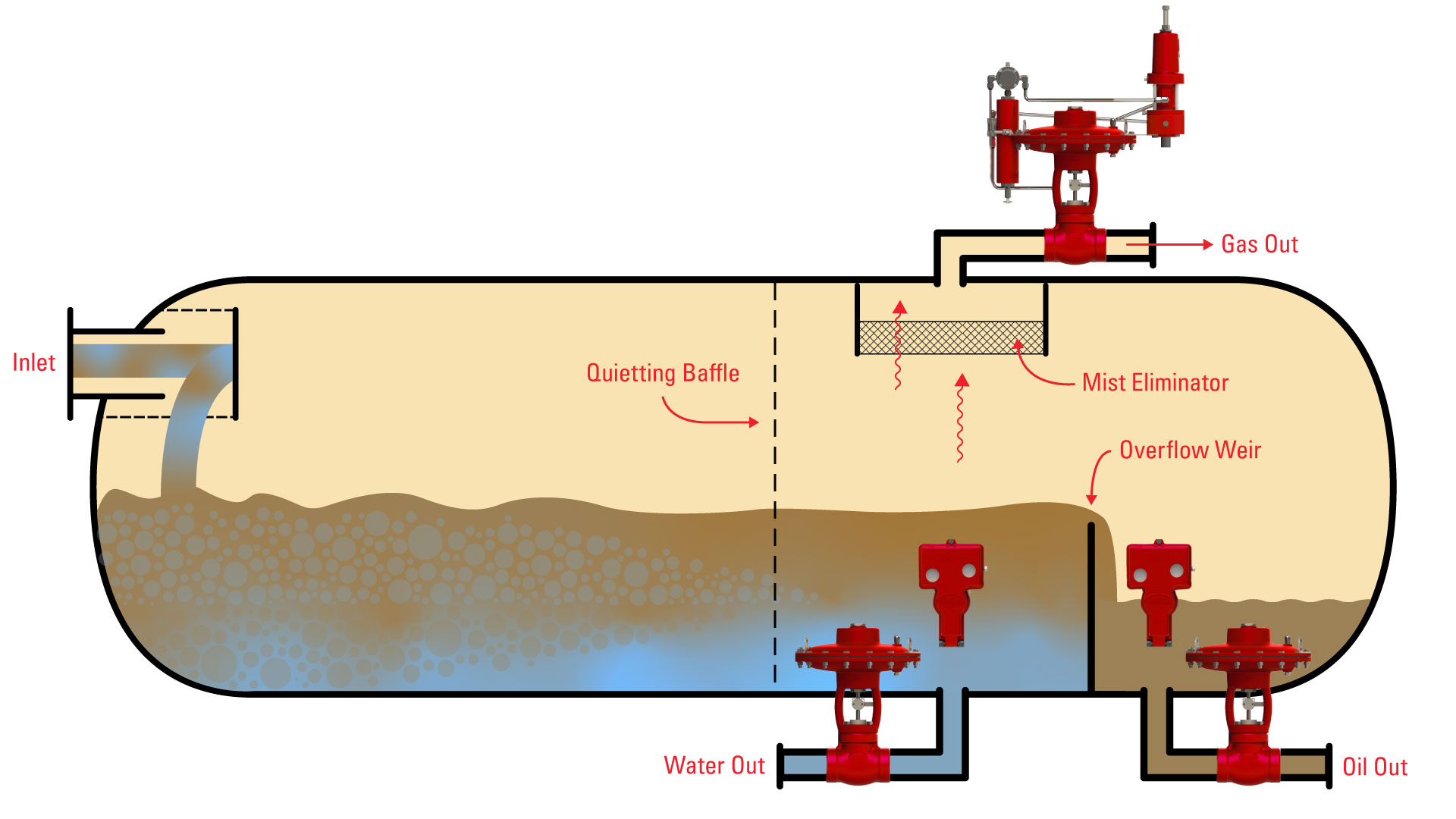

1. Horizontal Three-Phase Separator with Overflow Weir

In a horizontal three-phase separator with an overflow weir, fluid enters the vessel through an inlet and immediately hits an inlet diverter. The sudden impact and change of direction helps to release the gas by breaking the surface tension of the liquid.

In the liquid collection section of the vessel, the oil separates and forms a layer above the water. An interface level controller maintains the oil-water level. This controller signals a dump valve to release water from the vessel as needed to maintain the oil-water interface height.

The oil spills over the top of the overflow weir and a level controller operates a dump valve to maintain the oil level in the oil bucket.

Gas rises to the top of the separator and exits through a mist extractor, or demister, to a back pressure control valve which maintains constant vessel pressure.

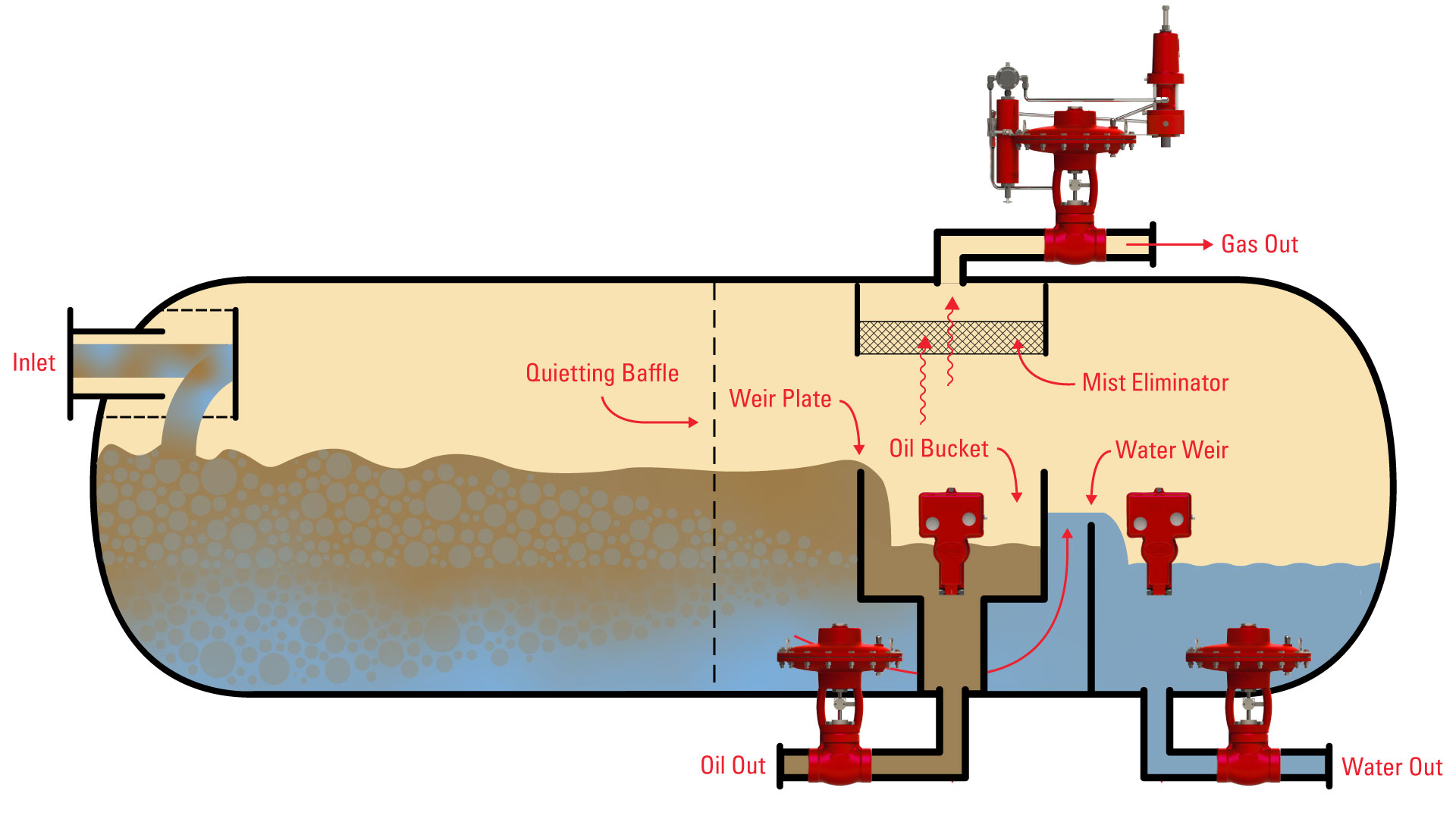

2. Horizontal Three-Phase Separator with Oil Bucket and Water Weir

In a horizontal three-phase separator with an oil bucket and water weir, the vessel does not require an active interface controller.

As the oil separates on top of the water it spills over the weir plate and into the oil bucket. The oil level in the bucket is controlled by a level controller sending a signal to the oil dump valve.

The water flows under the oil bucket and over the water weir where it is controlled by the water level controller and dump valve.

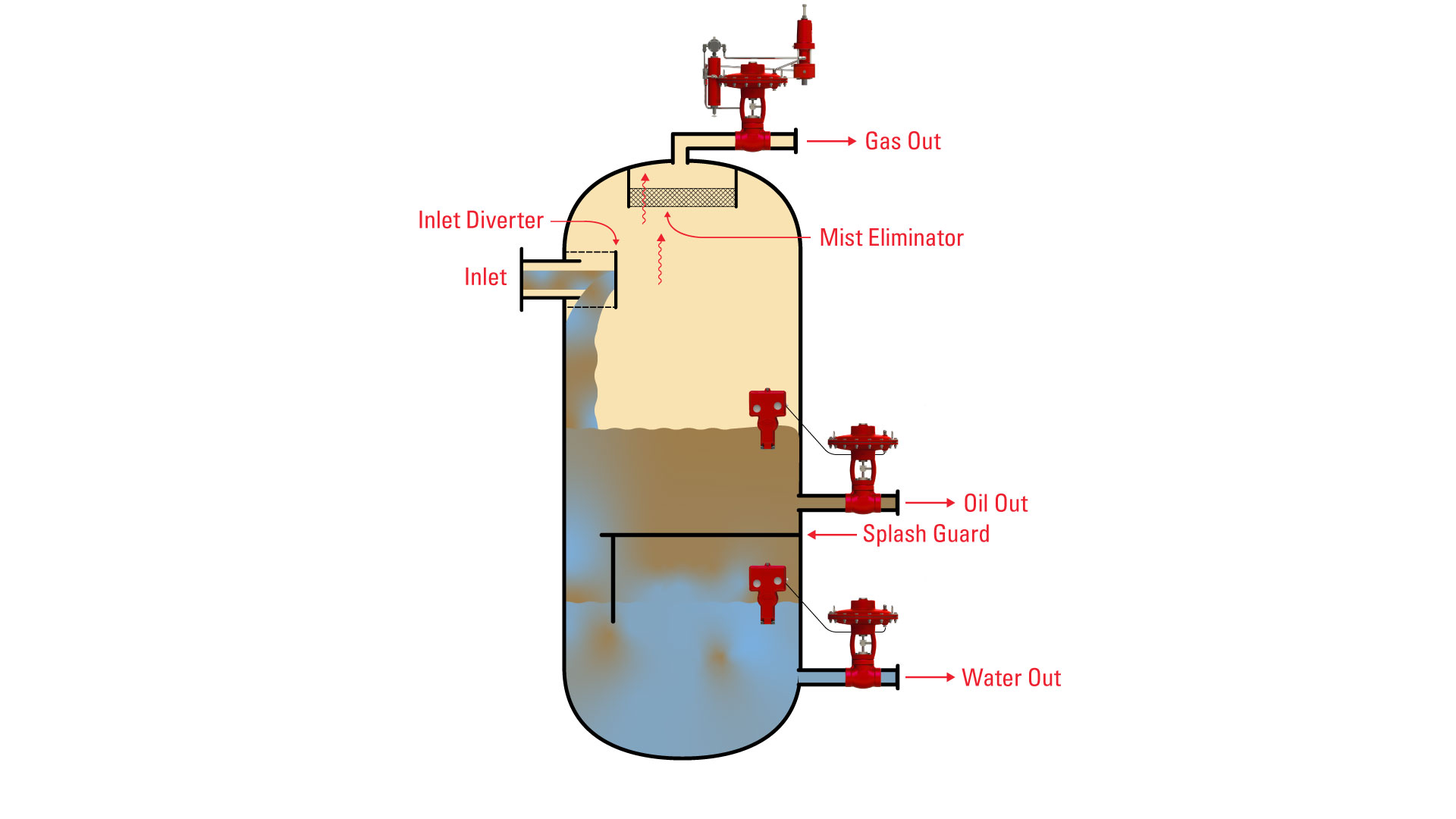

3. Vertical Three-Phase Separator with Interface Control

In a vertical three-phase separator with interface control, the emulsion enters the vessel and immediately hits the inlet diverter plate, separating the bulk of the gas upon entry.

The inlet divertor also helps to control the emulsion flowing into the vessel by directing it down along the side wall, minimizing disturbances to the fluid.

Lower in the vessel, the emulsion encounters a splash guard to further minimize agitation. This baffle is open and allows the emulsion to flow downward while protecting direct interaction with the interface level controller to prevent a false reading of the fluid level.

As the oil separates, the interface level is determined. The interface level controller will open the water dump valve when the interface level rises.

This oil level is also controlled by a liquid level controller, which will open the oil dump valve when the oil level rises.

The gas travels to the top of the vessel through a mist extractor and a back pressure control valve, which maintains constant vessel pressure.

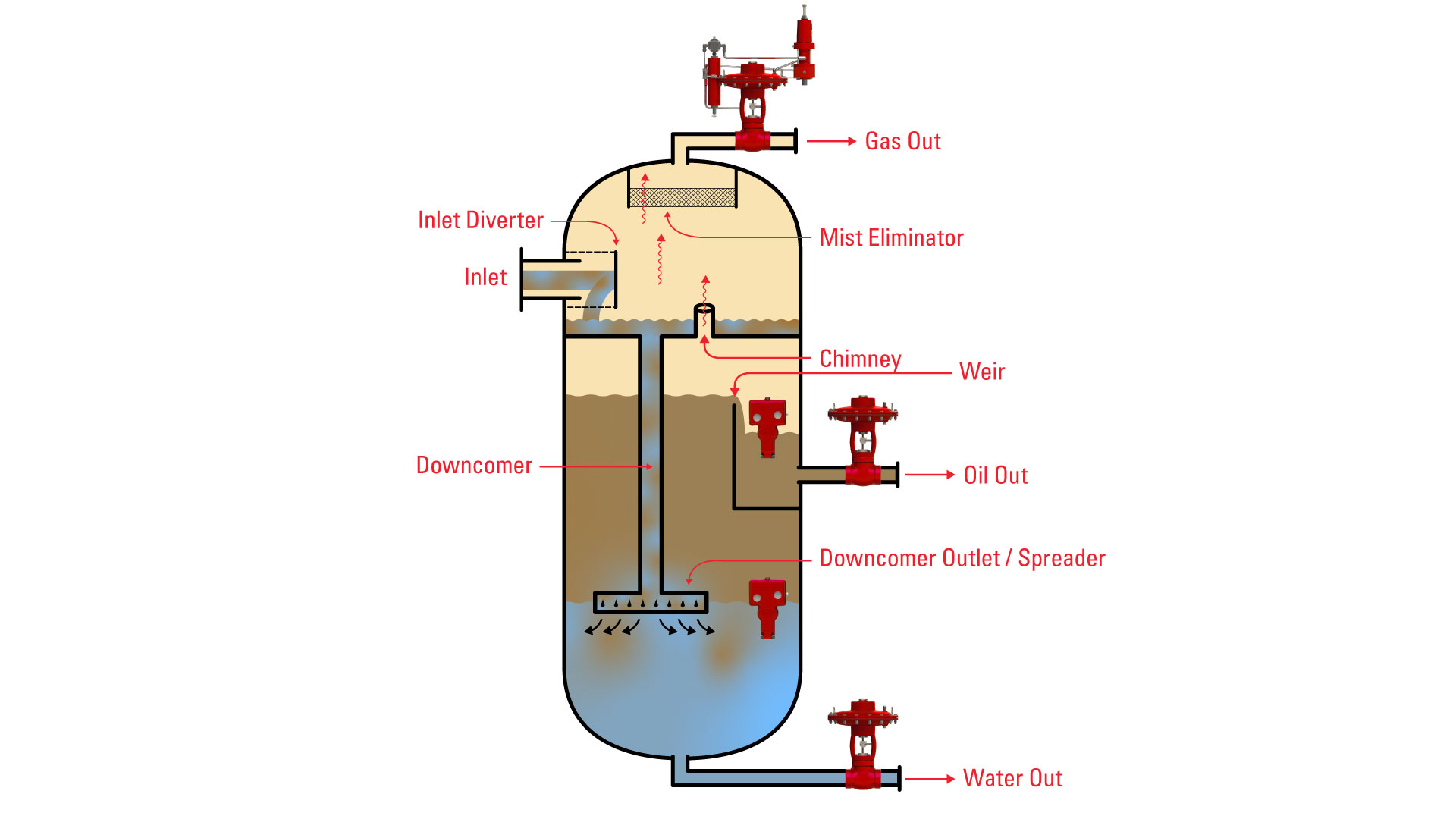

4. Vertical Three-Phase Separator with a Downcomer and Spreader

In a vertical three-phase separator with a downcomer and spreader, flow enters the vessel through the inlet and is immediately met by an inlet diverter to help separate the bulk of the gas.

A downcomer sends the liquid through the oil-water interface to keep from disturbing the fluid in the vessel.

The downcomer outlet, or spreader, is located at the oil-water interface.

Water, being heavier than oil, will separate and settle to the bottom of the vessel. The interface level controller will open the water dump valve when the interface level rises.

The lighter oil will separate out and rest on top of the water. The weir height determines the oil level. Oil flows over the weir and into the oil bucket. This oil level in the bucket is then controlled by a level controller, which opens the oil dump valve when the level increases.

A chimney equalizes gas pressure between the lower section of the vessel (the liquid-liquid separation zone) and the gas section (the gas-liquid separation zone).

The gas exits through a mist extractor to a back pressure control valve, which maintains constant vessel pressure.