In this video, Mike explains the operation and applications of the Kimray Pneumatic Liquid Dump Valve.

Two types of pneumatic liquid dump valves

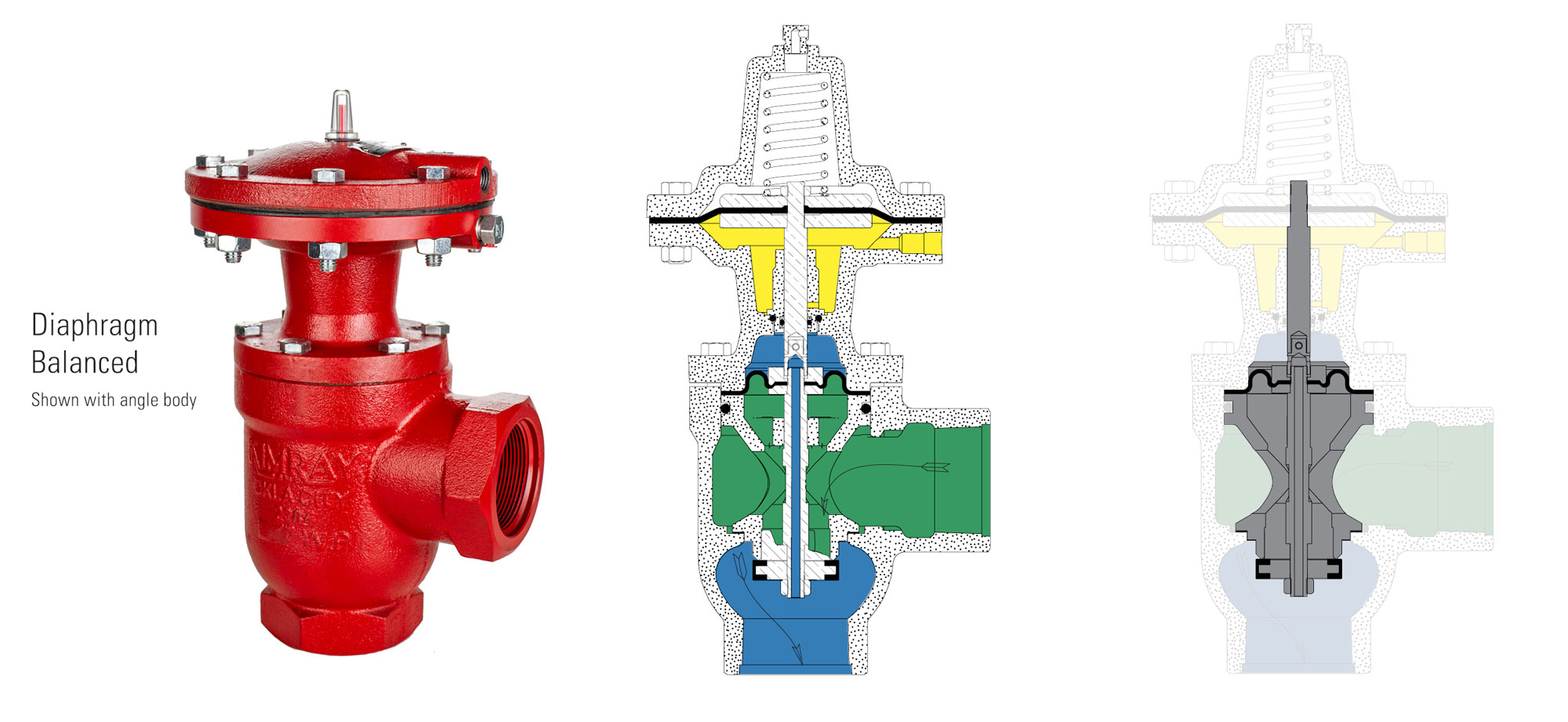

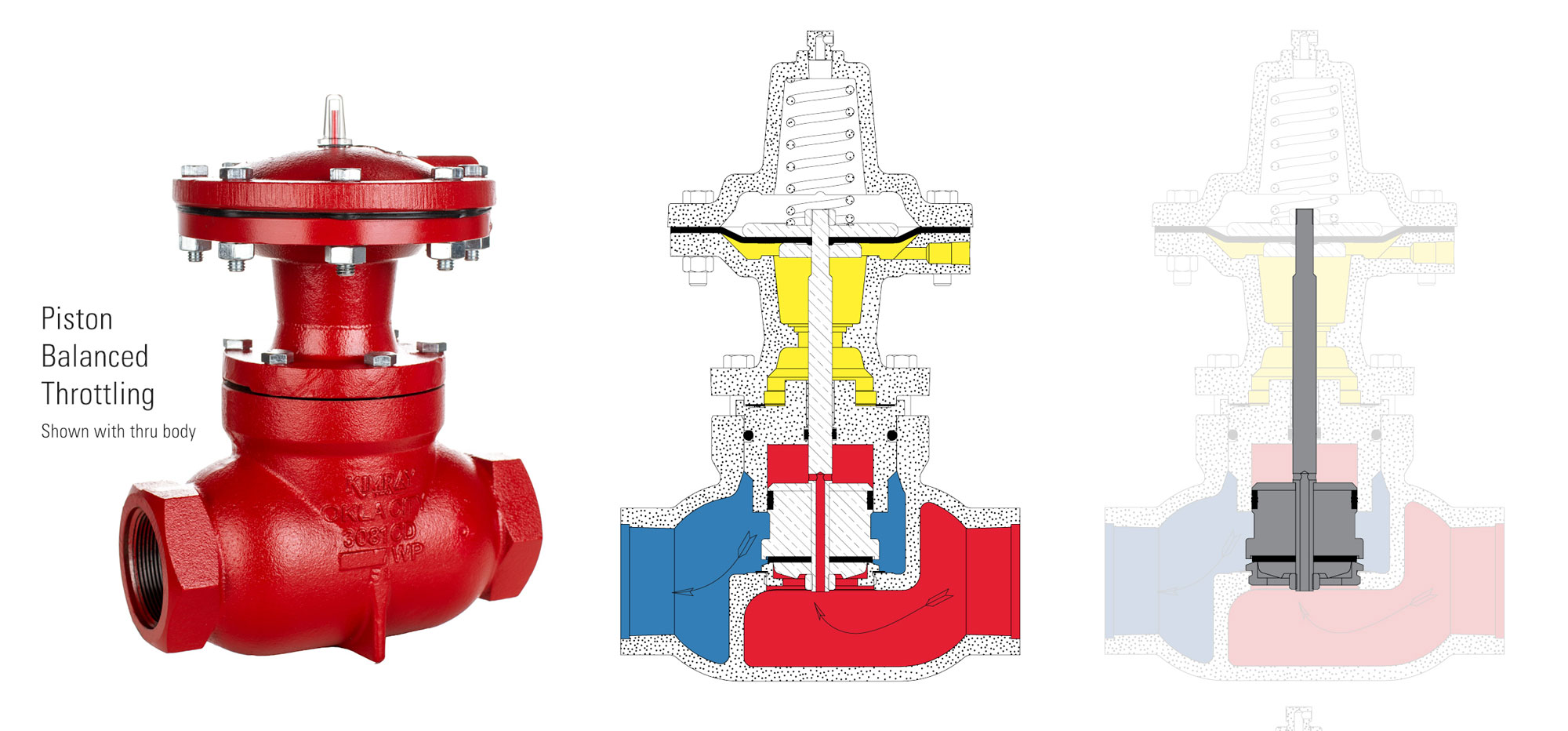

Kimray Pneumatic Liquid Dump Valves, also referred to as balanced low pressure control valves, are available in two primary models—diaphragm balanced or piston balanced throttling.

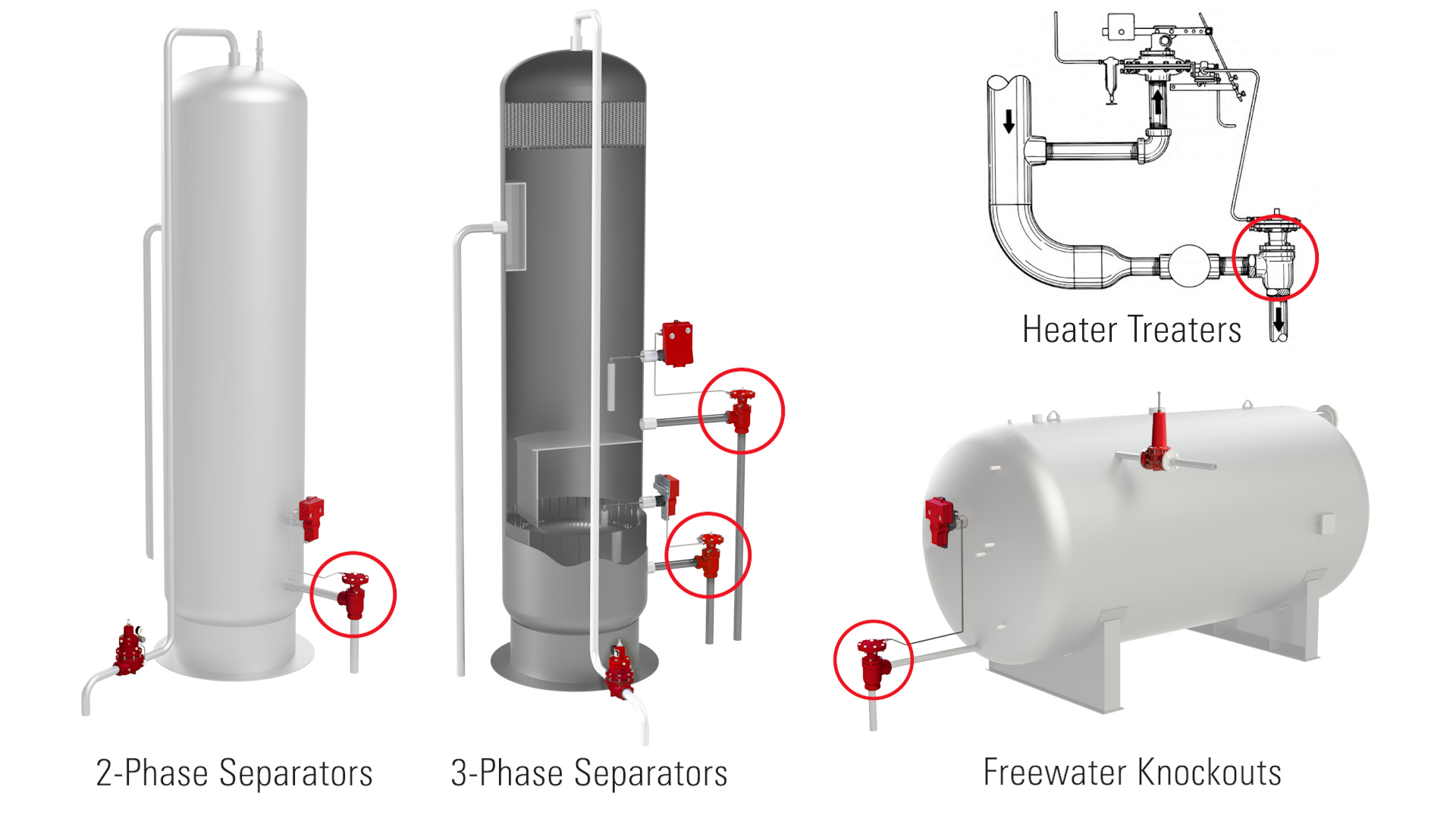

These valves are used to dump liquid from separation vessels such as 2- and 3- phase separators, heater treaters and free water knockouts.

If you’re metering off the fluid, the snap action controls will give you the most accurate meter readings.

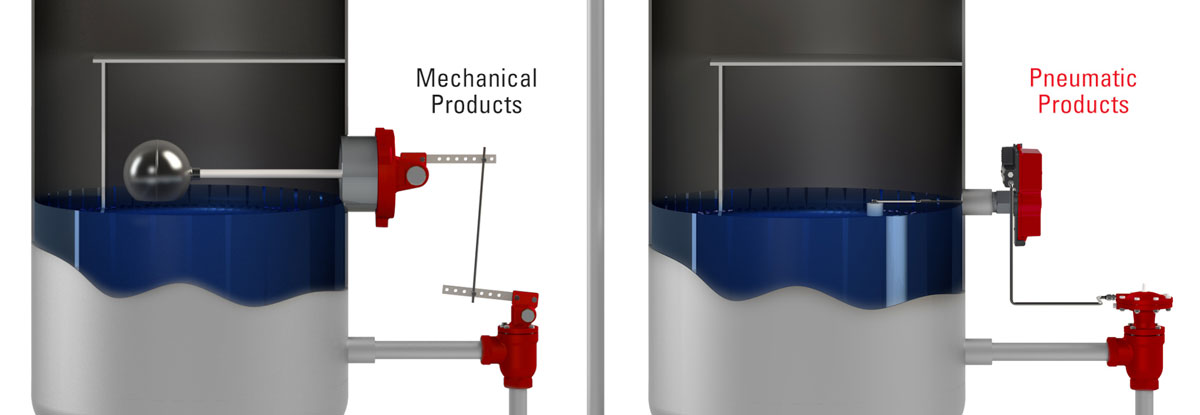

Another benefit to pneumatic controls is the ease of adjustment for fluid gravity changes, meaning that you won’t have to weight the float or adjust the lever arm and weights for any changes in the vessel.

Here’s how it works.

How a Liquid Dump Valve Works

This valve operates in conjunction with a pneumatic liquid level controller, such as the new Gen 3,* or a pneumatic liquid level switch, which senses the level of liquid inside the vessel.

Note that the Gen II is shown in the video. Check out the all-new Gen 3 here: https://kimray.com/gen3

When the liquid reaches a desired level, the controller sends a pneumatic signal to the valve.

The diaphragm balanced valve is a cost-effective version, good for normal conditions.

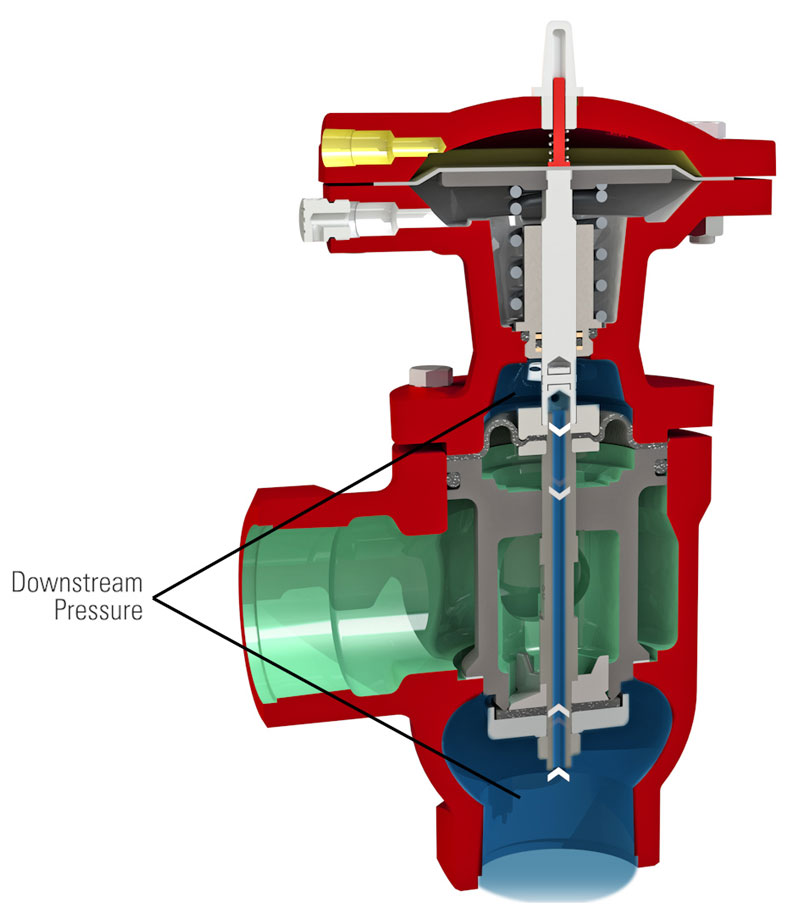

The signal enters the actuator of the valve. An increase in the diaphragm pressure overcomes the spring force and moves the diaphragm assembly down. This opens the valve, allowing the liquid to be dumped downstream.

The signal enters the actuator of the valve. An increase in the diaphragm pressure overcomes the spring force and moves the diaphragm assembly down. This opens the valve, allowing the liquid to be dumped downstream.

This valve is balanced, which means the downstream pressure creates a force from both the top and bottom to eliminate the effect of higher differential pressures.

When the liquid level recedes, the pneumatic signal is vented out through the level controller. This removes the pressure from the actuator, allowing the valve to close.

For erosive conditions, we recommend the piston balanced throttling version. In this valve, the trim raises up out of the flow path to mitigate erosion.

In order to meet their emissions goals, many producers are choosing to use compressed air for their pneumatic control valves and equipment. Head over here to learn more about using compressed air to reduce emissions.

For further information, contact your local Kimray store or authorized distributor.