Critical flow and choked flow are often used interchangeably, but they mean slightly different things.

In this video, we’re going to give a simple explanation of critical flow as it relates to control valves and the Kimray sizing calculator. Our goal is to clarify what it means when you enter “critical flow” while sizing a valve.

What is Critical Flow?

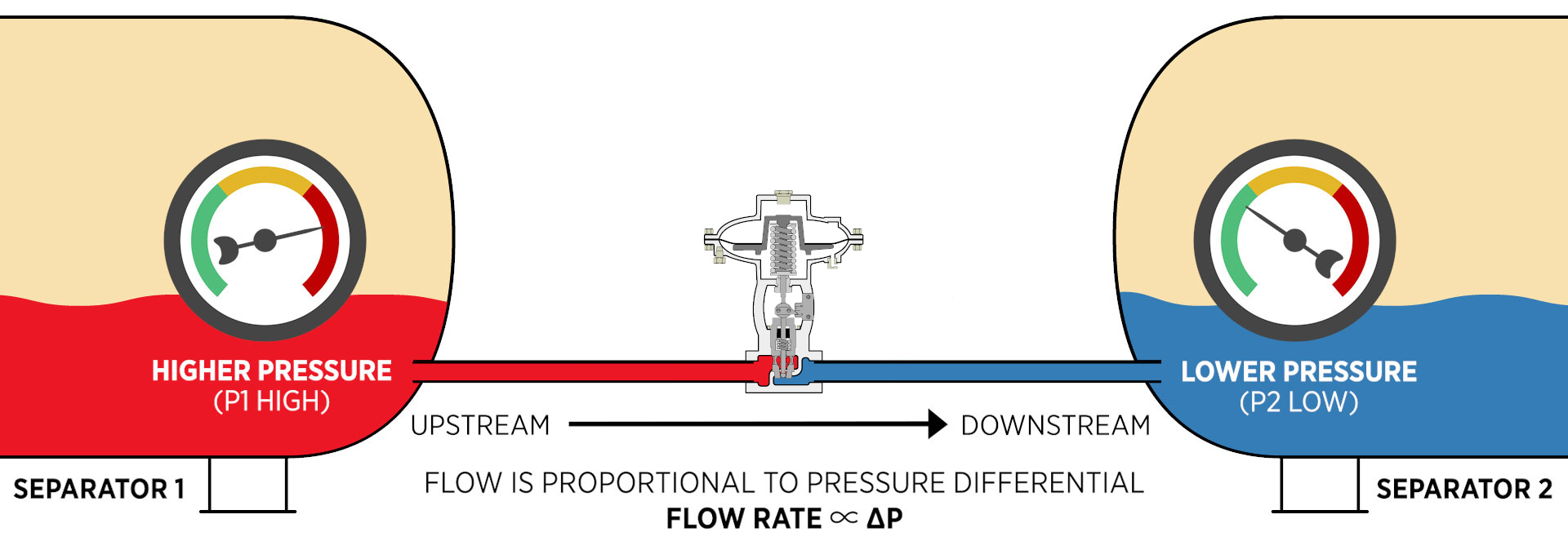

Flow always moves from higher pressure to lower pressure. If the pressure is the same on both sides of a valve, there is no flow. Without a pressure difference, nothing moves.

When pressures differ across a valve, the flow rate depends on that pressure difference. The greater the difference, the higher the flow rate. You can raise flow by either increasing upstream pressure or lowering downstream pressure.

To a certain point.

Critical flow is the maximum flow rate a valve can pass under given conditions. Once this limit is reached, lowering the downstream pressure further will not increase the flow.

When Does a Valve Reach Critical Flow?

Critical flow occurs when downstream pressure is about half or less of upstream pressure.

For example, if a valve has 1000 PSI upstream and 500 PSI downstream, the valve has reached critical flow. Reducing downstream pressure further won’t change the flow rate.

How is Critical Flow Different from Choked Flow?

The terms are often used interchangeably, but here’s the distinction:

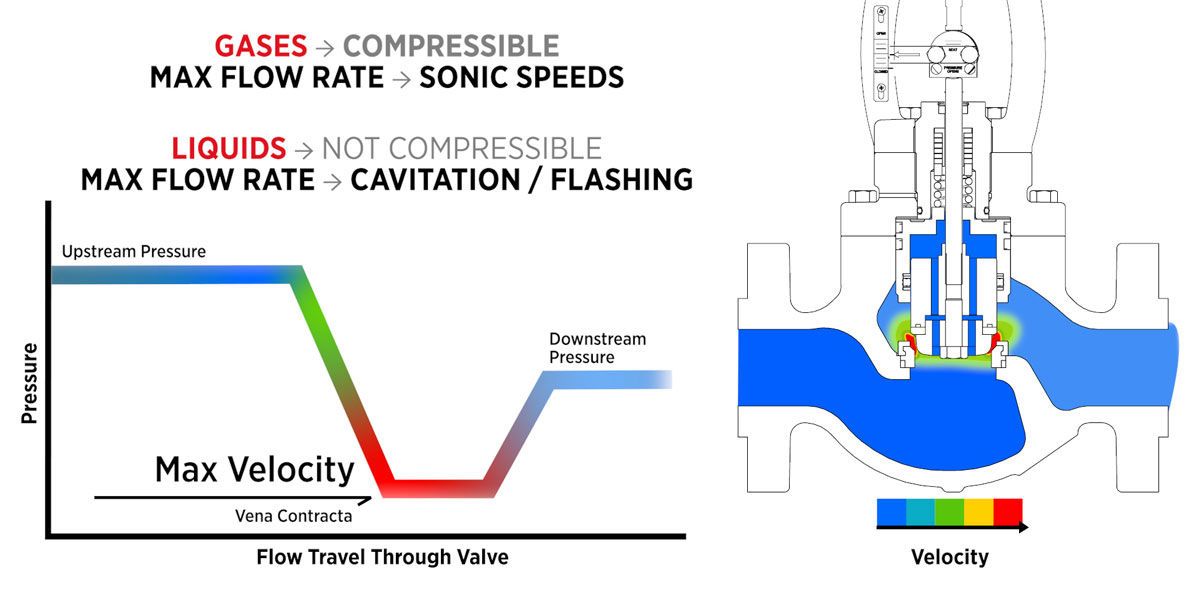

- Critical flow is the general idea of a maximum flow limit. It applies to both gases and liquids.

- Choked flow is the specific case for gases, where velocity at the narrowest point reaches Mach 1 (the speed of sound).

Since gases are compressible, they can reach sonic speeds at a restriction. Liquids don’t normally do this, so true choked flow doesn’t occur. Instead, liquids reach a maximum flow rate due to cavitation or flashing, not Mach 1 speeds.

For more on cavitation and flashing, check out our blog:

Gas Pressure Drop: 6 Things Producers Need to Know

Critical Flow Concerns for Gas & Liquid Applications

While not technically identical, in valve sizing, the terms are usually used interchangeably, and both have concerns to be aware of.

- In gas applications, the main concern is cooling from the Joule–Thomson (JT) effect. For example, a 100 PSI drop causes about a 6–8 °F temperature drop.

- In liquid applications, the main concern is cavitation. This can damage valve internals and increase the chance of water hammer. Temperature loss is also a concern with liquids because they could freeze and block flow.

Why It Matters in Oil and Gas Production

Let’s look at how this shows up in the Kimray sizing calculator.

With certain inputs, you may see a warning for critical flow. This does not mean the valve is sized incorrectly. It’s simply a warning that choked flow may occur based on the combination of flow rate, Cv, and pressure differential.

- Decreasing downstream pressure will not increase flow once you’re at critical flow.

- Increasing upstream pressure, however, can allow for greater flow rates.

Critical Flow vs. Critical Flow Factor

One last note: critical flow is not the same as critical flow factor (Cf).

- Critical flow is the flow limit condition.

- Critical flow factor is a value that describes how pressure recovers after its lowest point in a control valve. Cf is used in flow calculations and is listed on each product’s details page.

For more on Cf, check out our video and blog: