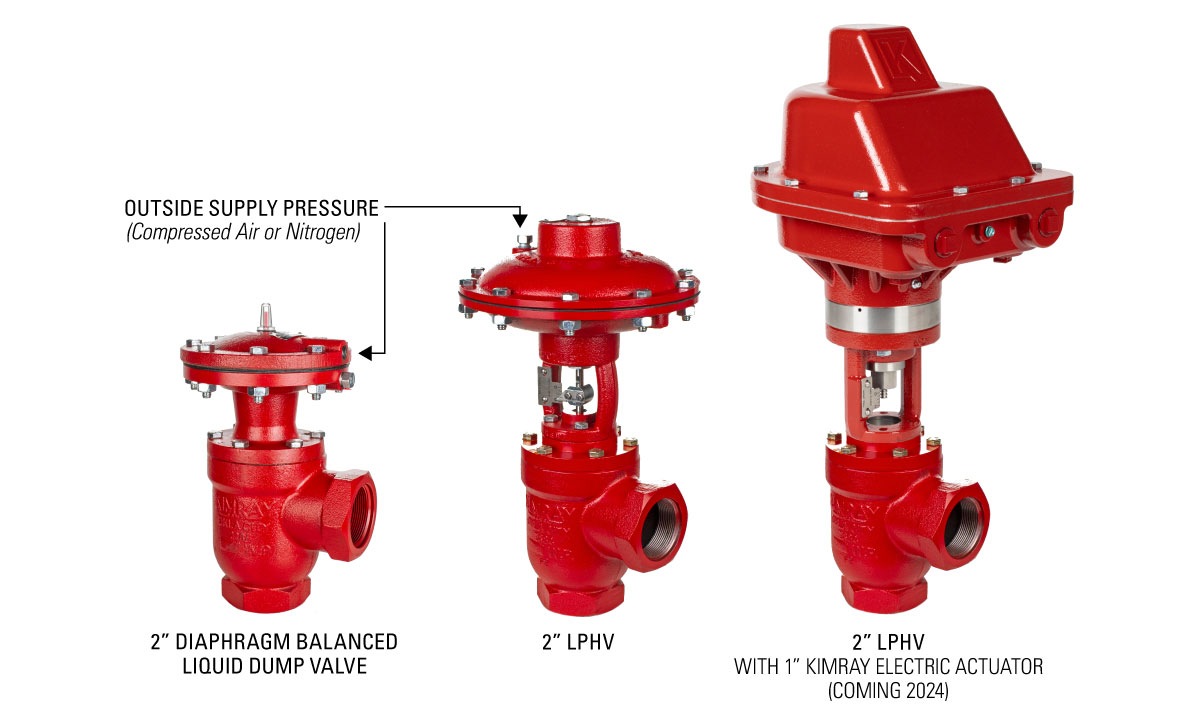

There are two main types of pneumatically operated liquid dump valves:

- Diaphragm Balanced

- Low Pressure High Volume

Let's take a look at some of the features and troubleshooting tips for each.

The Low Pressure High Volume Valve has replaced the Piston Balanced Throttling version of the pneumatically operated dump valve.

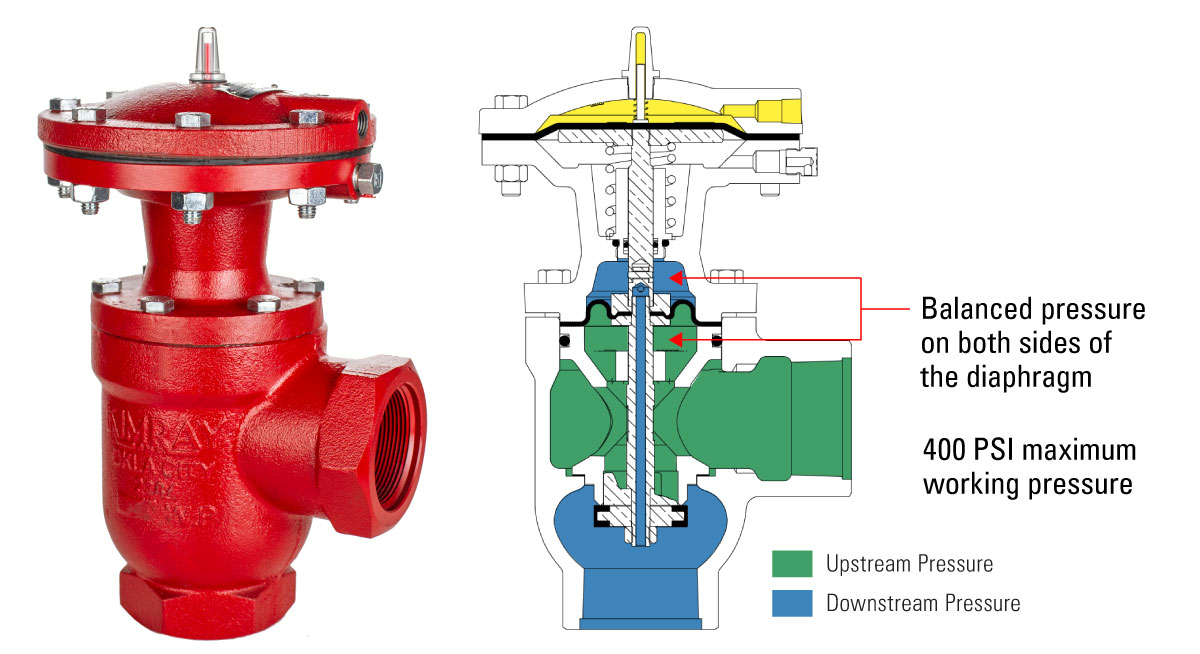

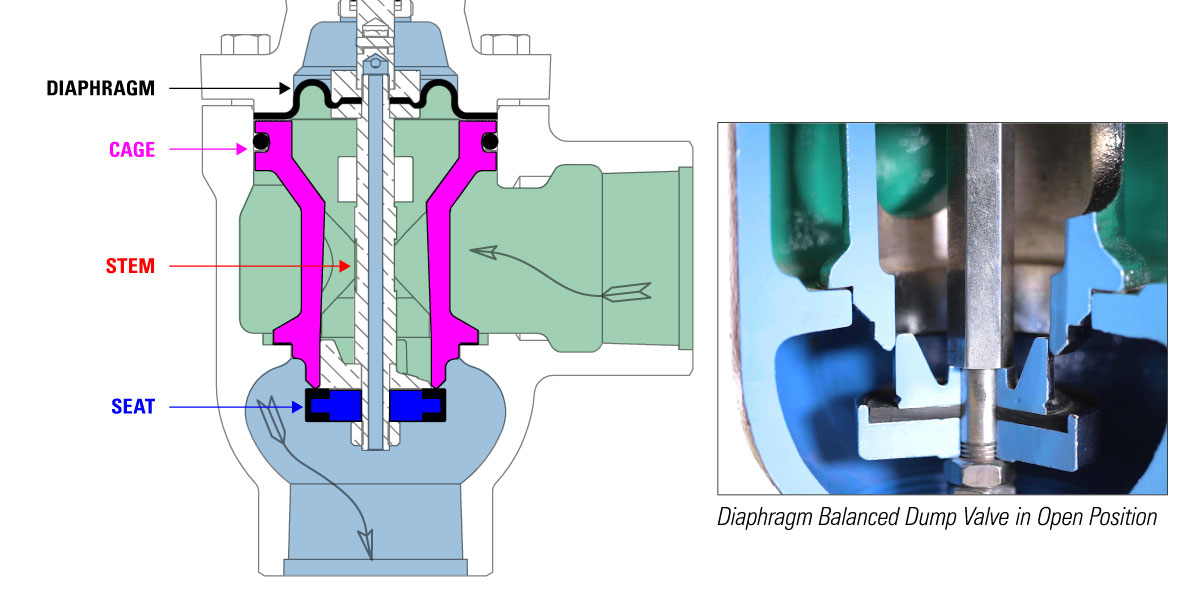

Diaphragm Balanced

The Diaphragm Balanced Liquid Dump Valve is named because the upstream and downstream pressure are balanced, above and below a diaphragm.

Features

- The maximum operating pressure for this dump valve is 400 PSI.

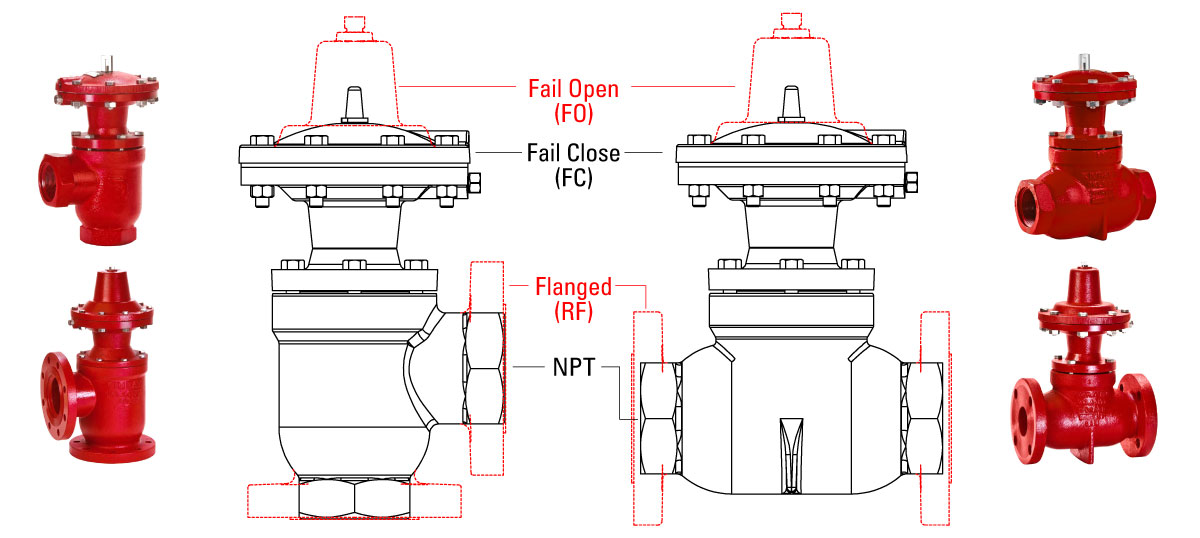

- The fail-open model has a travel indicator. This clear plastic piece with a red indicator will move in and out, letting you know when the dump valve is open or closed.

Flow Path / When Not to Use this Valve

This is not the ideal valve for erosive conditions due to the flow path through the valve itself, which can cause premature wear on the valve seat, the cage, and the valve body. The seat opens down into the flow path, directing the fluid out to the edge of the valve body, which can cause washout around the valve body and the seat.

For standard liquid dump applications in non-erosive environments, as long as the flow requirements match the rated flow rate of the valve, the diaphragm balanced valve will work just fine.

Tips

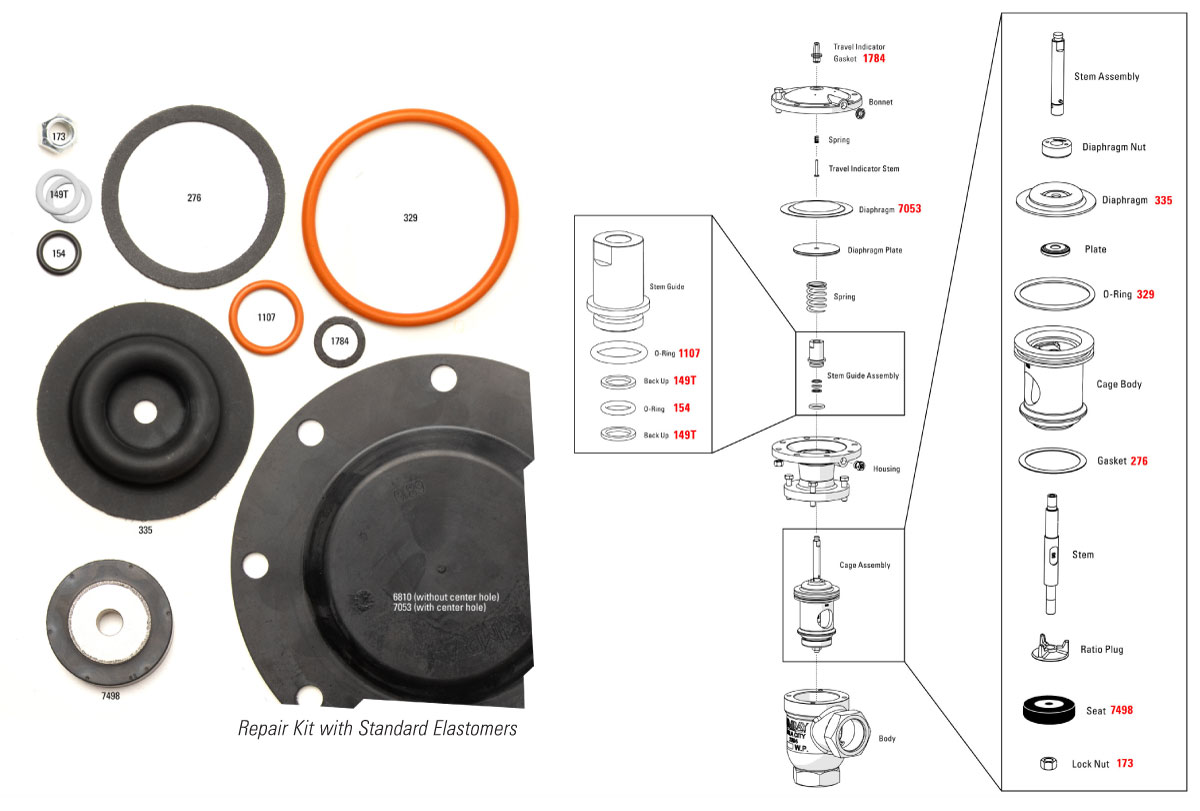

- Careful material and elastomer selection ensure that both materials are suitable for the temperature and the makeup of the fluid passing through the valve.

- In sour gas areas, make sure you have the appropriate elastomer to ensure durability.

- When repairing the diaphragm balanced dump valve or the older model PBTs, you'll need a unique repair tool: the spring compression tool. It's essential for compressing the spring to install the diaphragm plate.

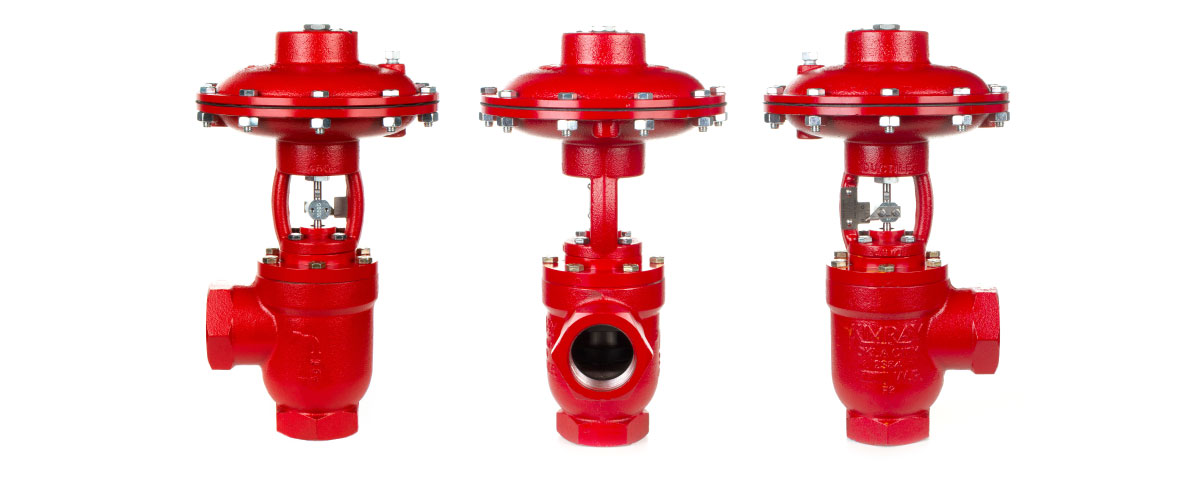

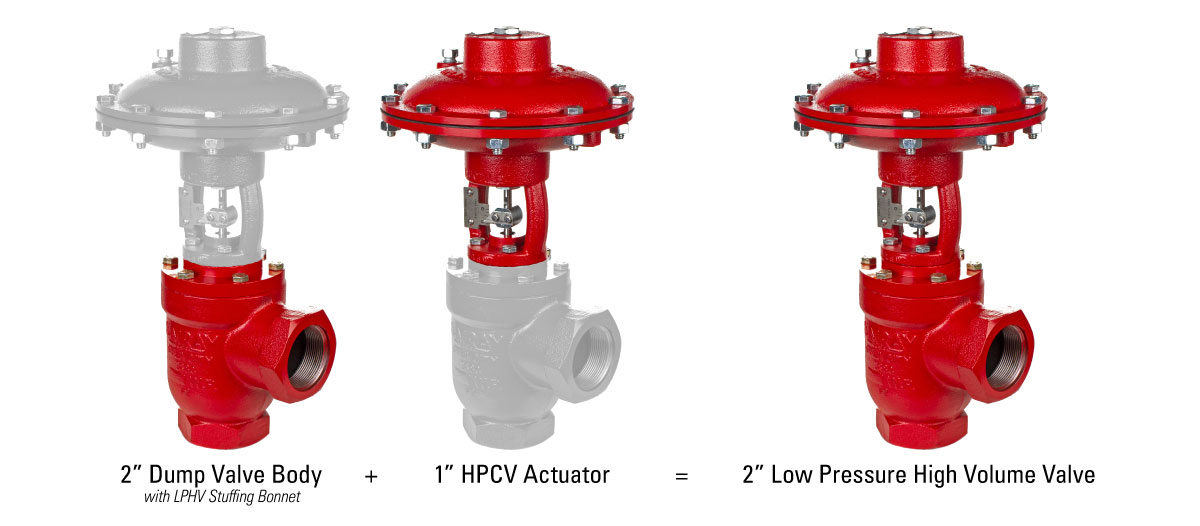

Low Pressure High Volume (LPHV)

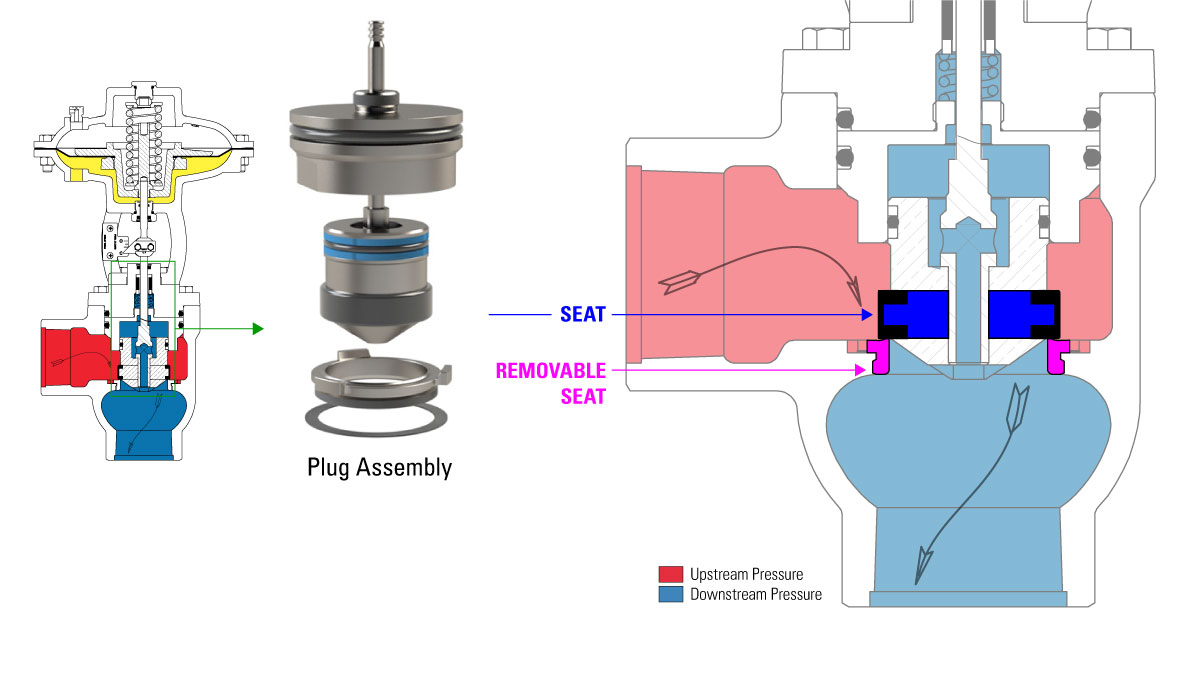

The flow rate of the Low Pressure High Volume Valve (LPHV) is much higher than that of the diaphragm balanced dump valve due to the flow path through the valve.

Upstream pressure flows down through the seat, and when the valve opens, the entire plug assembly moves up and out of the flow path. This design increases flow capacity and reduces wear on the valve body. This makes it ideal for erosive applications, such as when there is sand in the production fluid.

Features

The LPHV is a throttling dump valve. The actuator from our 1" high-pressure control valve, which has a larger surface area, allows for smoother operation and finer control. The ratio plug and flow characteristics of the valve also help with throttling action, allowing a larger volume of fluid to pass through the same 2" connection.

- Available in 2", 3" and 4" end connections, with a maximum operating pressure of 500 PSI.

- A distinct advantage of this actuator is the open yoke, which allows you to see stem travel position and check for packing leaks visually.

- This valve also allows for field-reversible fail positions (open or closed) without extra parts.

- The balanced design ensures smooth and consistent action regardless of pressure drop, aiding in finer control of liquids on both the oil and water sides of your vessel.

- The valve is balanced above and below the piston assembly. Downstream pressure is communicated through the center part of the piston, so no matter the pressure drop, you'll get a smooth, consistent action form the valve. This insures finer control of liquids on both the oil and water sides of your vessel.

Zero Emission Options

Both the Diaphragm Balanced and the LPHV Liquid Dump Valves can accept an outside pneumatic supply. If you are transitioning from natural gas to compressed air or nitrogen for pneumatic supply to reduce your emissions, these are compatible products.