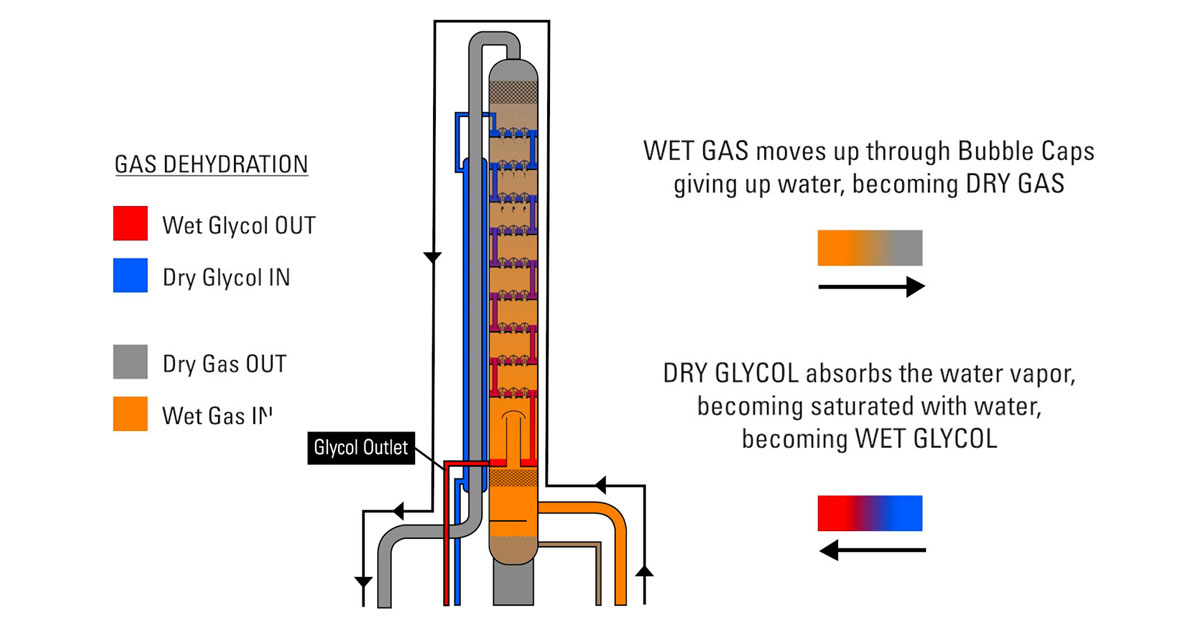

Natural gas dehydration is a process that producers use to remove water vapor from natural gas in order to sell it to a midstream or downstream customer. The producer and the purchaser will have a contractual agreement specifying the maximum dew point allowed in the gas.

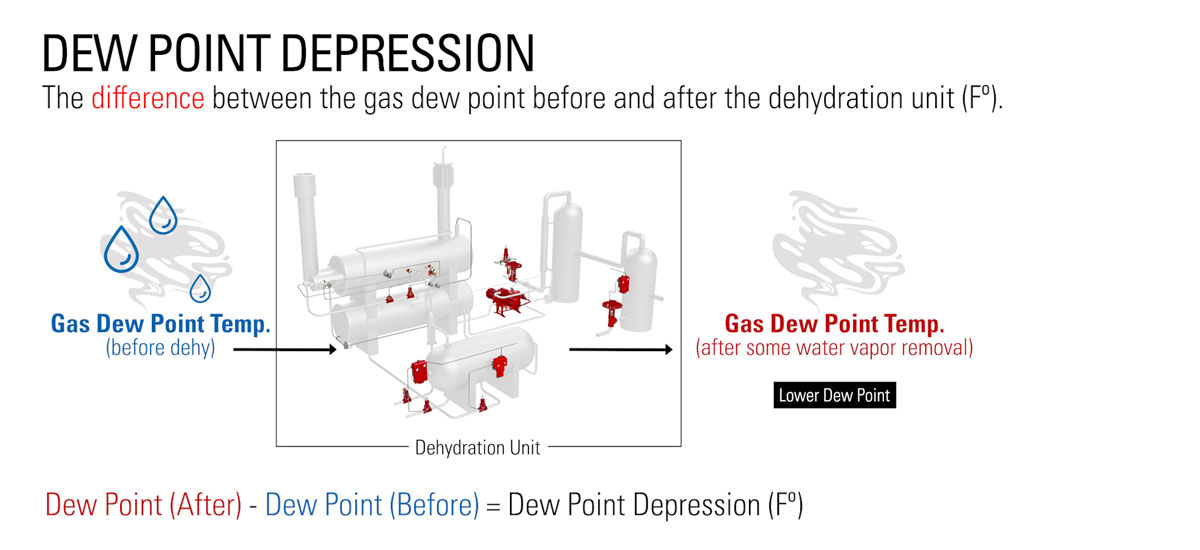

Dew point is when water vapor will start to condense in the gas at certain pressures and temperatures. The gas will be monitored to ensure the maximum dew point is not exceeded.

If dew point exceeds the agreed-upon level, a shut-in valve will close, and you will need to diagnose and fix what’s going wrong in your dehy system so you can continue production.

When you are not meeting dew point, here are 5 things to check:

1. Glycol Circulation Rate

Generally, a triethylene glycol circulation rate of 3-5 gallons per pound of water to be removed is sufficient to adequately dehydrate the gas. However, if the glycol flow rate is excessive, it can overwhelm the reboiler and you will lose efficiency.

Learn How To Calculate Glycol Circulation Rate

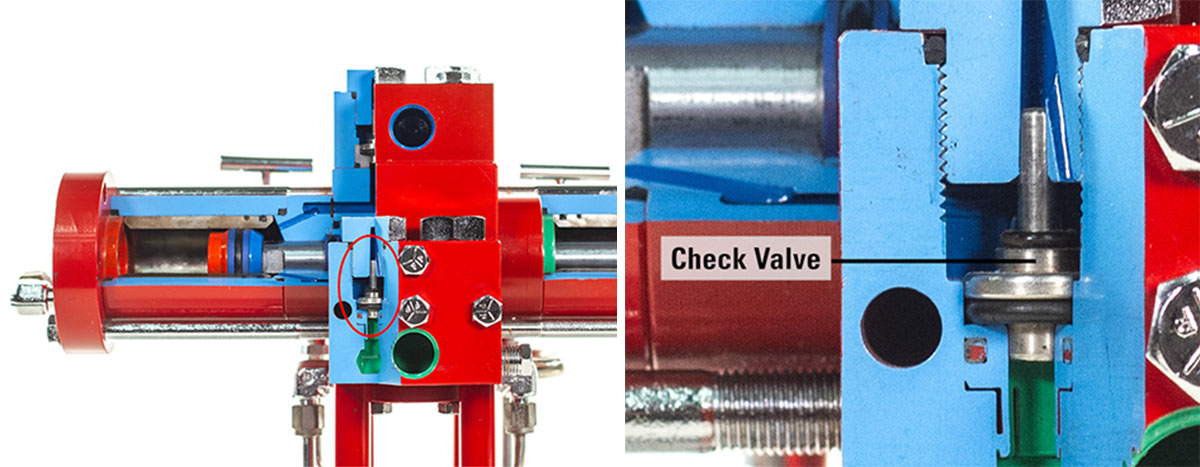

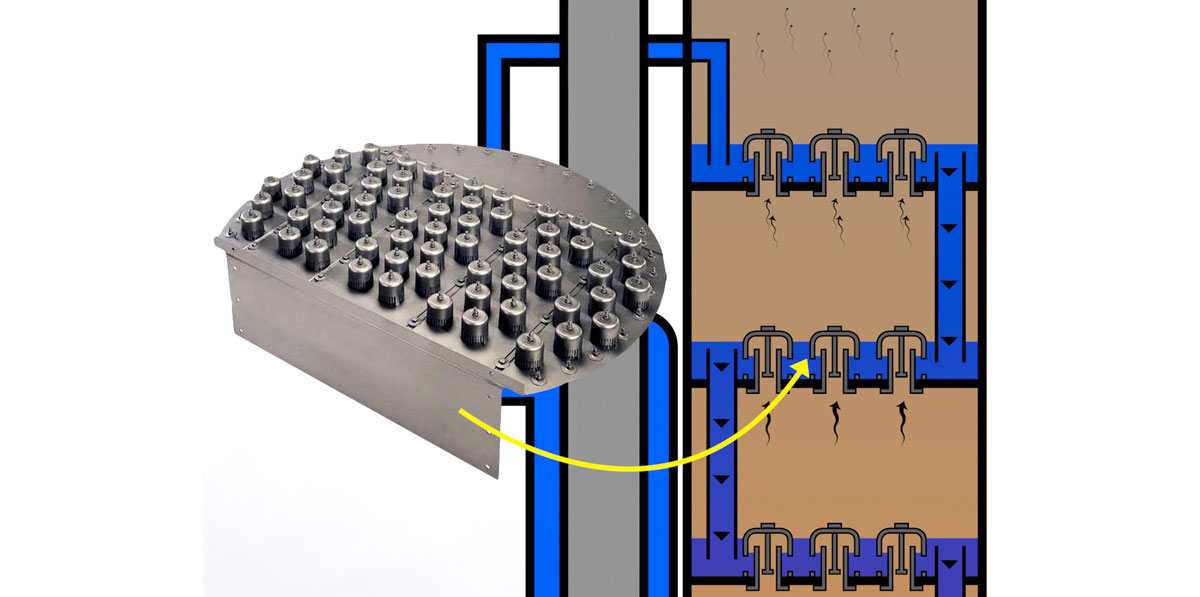

2. Glycol Pump Check Valves

Another thing to check if you are not meeting dew point is your glycol pump check valves. If these valves are clogged or worn, the glycol pump may operate as normal but will not be moving enough glycol to the contact tower.

Even with a pressure gauge indicating a pump cycle, the only evidence of this type of failure is little-to-no dew point depression.

Dew point depression of natural gas is the difference between the gas dew point before and after the dehydration unit, expressed in °F. The outlet of the dehydration unit will always have a lower dew point because of the water removed from the gas.

One sure way to find if the proper amount of glycol is being circulated is to close the valve on the glycol outlet piping of the contact tower and observe through the site glass if the level in the tower is rising compared to what’s normally circulated.

3. Glycol Levels

Low glycol levels can cause a spike in the water content. There will always be some amount of glycol loss in the dehydration system but making sure that the surge tank has enough glycol to circulate will help prevent these issues.

Some common reasons for glycol loss are high pH levels and high temperature differentials which can both cause glycol foaming.

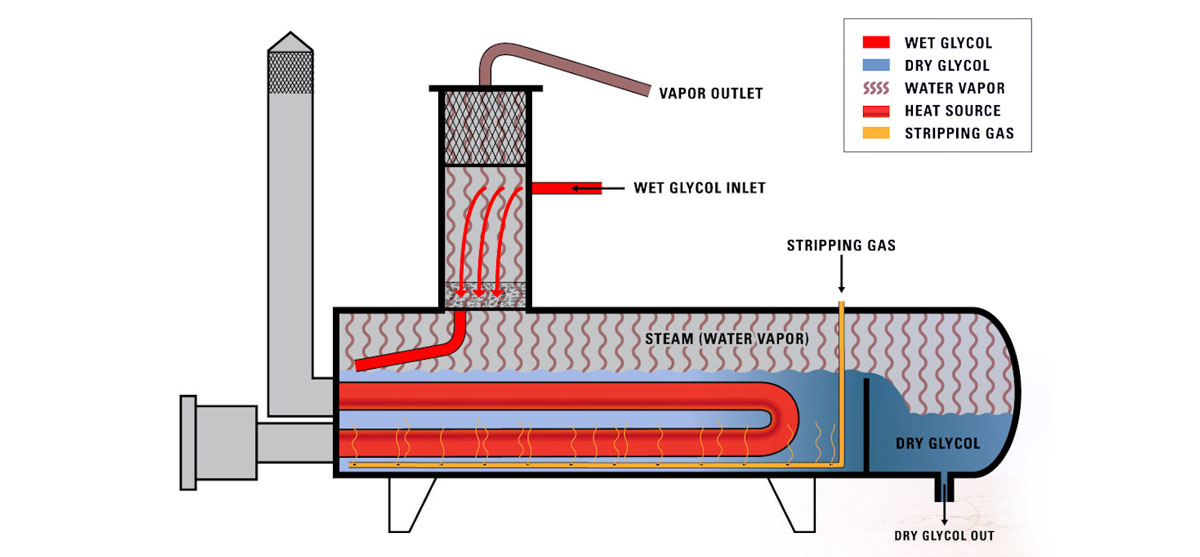

4. Glycol reconcentration rate

Insufficient reconcentration of the glycol will also cause the dew point to increase. If you are not removing enough water from the glycol, it may not be able to absorb enough water from the natural gas to make dew point.

Increasing the reboiler temperature or adding stripping gas will increase the removal rate of water from the glycol.

5. Plugged or blocked piping or equipment

Plugged or blocked piping or equipment, such as the trays in the contact tower, can prevent proper circulation of glycol through the system.

Regular inspections of equipment, good filtration and well-maintained glycol will help prevent blockages from occurring.

To speak with someone about your gas dehydration challenges, contact your local Kimray store or authorized distributor.