Gas Dehydration and Glycol Regeneration process

Triethelyne glycol (TEG) is a critical component in the process of natural gas dehydration.

Once the glycol is in circulation, however, it quickly becomes saturated with water and must be regenerated before it’s recirculated through the system.

Glycol is “hydroscopic,” meaning it attracts water to itself.

Its high boiling point allows the absorbed water to be boiled off from the glycol without degrading it.

Once the glycol is saturated or “rich” with water vapor, that water needs to be removed before the glycol can be used again.

Higher glycol purity levels mean you can circulate less glycol through the dehydration system to remove the same amount of water. In the long run, this will lessen the wear and tear on your glycol regneration process and equipment and save money on filters and fuel costs for the burner.

Ideally, you want your glycol to be 98% or higher in purity. If your glycol is not reaching that level, here are 5 things we recommend trying:

1. Increase Glycol reboiler temperature

Typical reboiler temperatures are 350°F to 400°F. Some glycol regeneration systems systems can increase glycol purity levels to 98% or more just by raising the temperature.

Glycol boiling point is 546°F, but the degradation temperature of glycol is 404°F, so do not operate the reboiler over that temperature.

2. Replace glycol

If the temperature of the glycol has ever risen above 404°F, it may be damaged or “cooked” and will not be as effective at absorbing water vapor from the gas.

Depending on the glycol damage, some or all the glycol will need to be replaced.

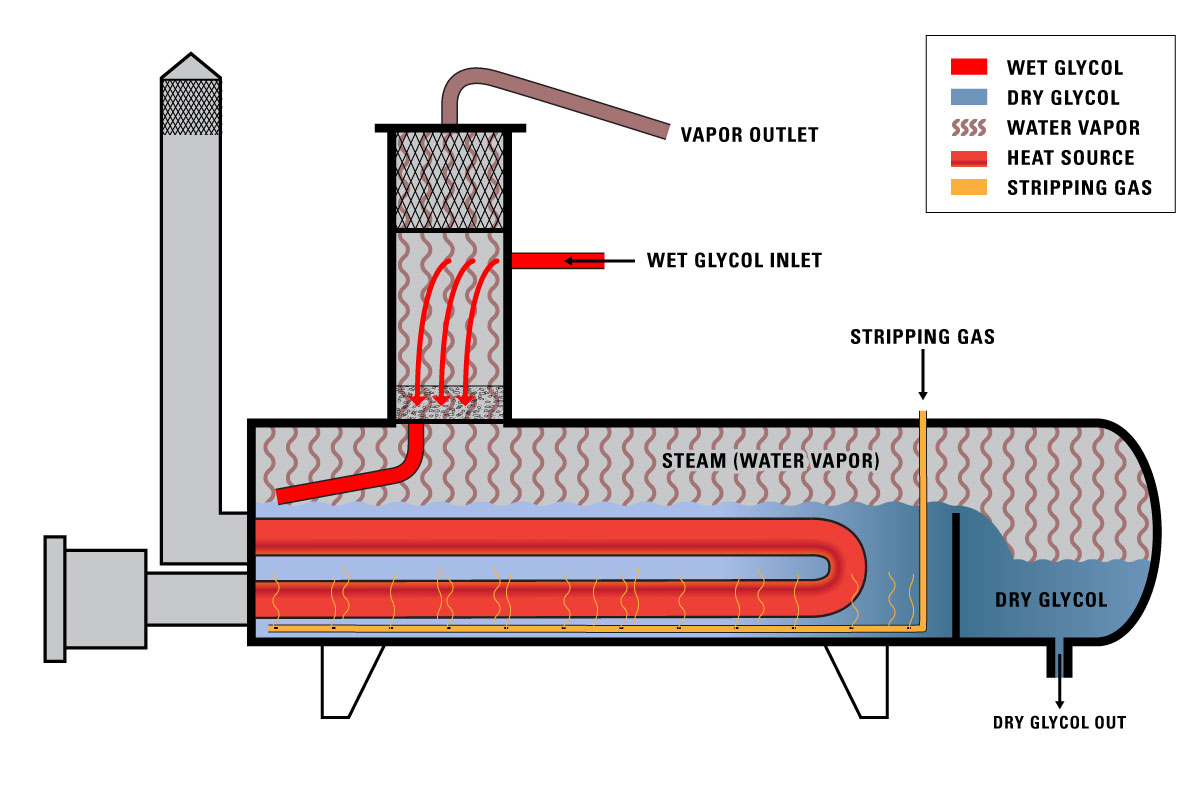

3. Use stripping gas in reboiler

Stripping gas is low pressure, high temperature gas that attracts the water entrained within the glycol.

This gas is used in reboilers to further separate the water that is not distilled from the glycol.

Before entering the reboiler, the stripping gas is pre-heated through a heat exchanger in the surge tank or reboiler. The elevated temperatures of the striping gas increase its hygroscopic properties to the point that it grabs onto the remaining water molecules in the glycol and carries it out through the still column.

By using gas to strip the glycol of even more water you can reach glycol purity levels of almost 100%.

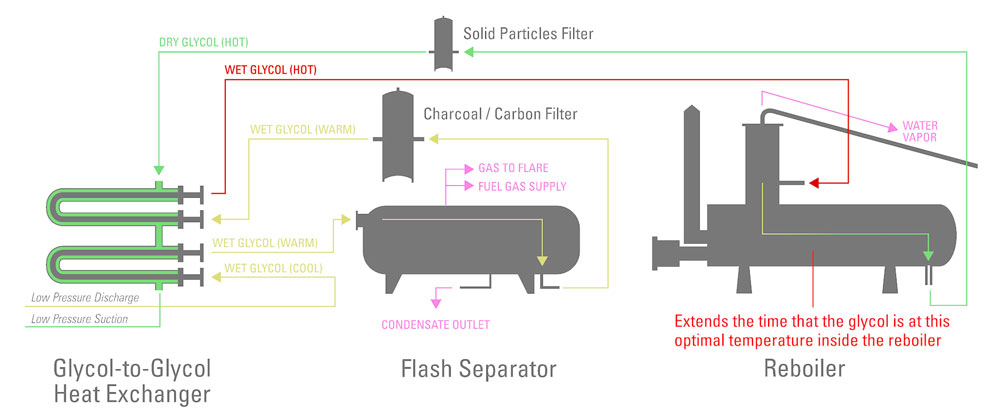

4. Increase the use of heat exchangers

Heat exchangers can be utilized to preheat the glycol before it enters the reboiler. This will increase the efficiency of the reboiler so that it does not have to expend more energy to heat the glycol to the optimal temperature for water removal.

Preheating the glycol also extends the time that the glycol is at this optimal temperature inside the reboiler, resulting in greater distillation and purity levels.

5. Remove impurities through good glycol filtration

Removing impurities such as hydrocarbons, lube oil and solid contaminants from the glycol will not only increase the removal rate of water from the gas but it will also protect the reboiler and heat exchangers from contamination buildup and loss of efficiency. Learn more about filtration.

Following these steps can help you increase the removal rate of water by increasing your glycol purity level.

To learn more about natural gas dehydration, watch our other videos on this subject. To speak with an expert about your gas dehy system challenges, contact your local Kimray store or authorized distributor.