Product Applications

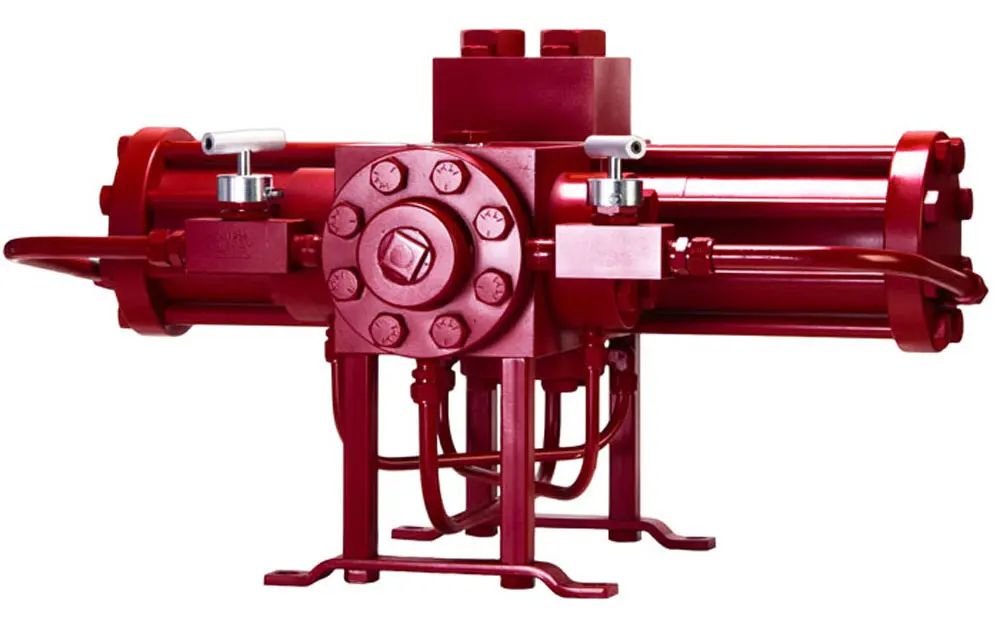

GAJV

Build & Save a Quote

We'll get you options, pricing, and anything else you need.

Anything we can do to help?

Talk to a specialist at (405) 525-4264 or fill out a quick product message form.

Tech Specs

| Type | Value |

|---|---|

| Body Material: | Steel |

| Max Working Pressure: | 2000 psig |

| Min Operating Pressure: | 400 psig |

| Operation: | Pneumatic |

| Catalog Page: | 10:10.1 |

| Min Glycol Flow Rate: | 166 gph |

| Max Glycol Flow Rate: | 450 gph |

| Elastomer: | FKM |

| Additional Info: | Pressure to Volume - Standard Cylinder |

| Weight: | 505 lbs |

Product Videos

Compatible Kits and Tools

| Type | Product Code | |

|---|---|---|

| Repair Kit: | RJL1-V |

Downloads & Updates

Frequently Asked Questions

The absorber must be vertical to insure the proper flow of glycol in the vessel and adequate contact of gas and glycol. Sometimes the trays and bubble caps do not seal properly after erection and should be inspected if very high glycol losses exist. Inspection ports at the trays can be very useful when inspecting or cleaning the vessel

Close gas outlet from contactor. Then the fuel to the reboiler should be shut off. The pump should run until the reboiler temperature is lowered to approximately 200°F. This will prevent glycol decomposition caused by overheating. The plant should be depressurized slowly to prevent a loss of glycol. The absorber should always be depressured from the downstream (gas outlet) side.

The degree of dehydration which can be attained with glycol primarily depends upon the amount of water removed in the reboiler. The leaner the glycol going to the absorber, the more efficient its dehydrating power will be. For example, when the contact temperature in the absorber is 95°F, a lean glycol concentration of 99 percent will provide a sales gas dewpoint of -2°F while a 95% concentration will yield a 43°F dewpoint, if equilibrium conditions are reached.

Most pumps do not have liquid flow recorders. For Kimray pumps, the glycol rate can be determined by counting the number of strokes per minute and then use the pump chart supplied by the manufacturer. It is necessary to know the model of the pump in service to use the chart. For electric pumps, the rate can be calculated by shutting off the manual valve on the absorber glycol discharge line and measuring the height of the buildup per unit time.

This height multiplied by the inside cross-sectional area of the absorber will give the volume of glycol pumped after converting the volume of the absorber to gallons. Or a flow meter could be installed.

The glycol can overload the reboiler and prevent good glycol regeneration. It can also prevent inadequate glycol-gas contact in the absorber and increase pump maintenance problems. The end result may be poor dehydration, high glycol losses, and excessive fuel consumption in reboiler

Still have a question? Send us a quick product message to get help from our team.

Quick Links

Kimray has a team of experts that can help you identify the right products to meet your product and emissions goals.

Talk to a specialist Mon - Fri, 7 AM - 5 PM CST at (405) 525-4264.