The Kimray Energy Exchange Glycol Pump serves the critical function of circulating triethelyne glycol around natural gas dehydration sites.

Let’s take a quick look at what makes the glycol pump so effective for energy producers.

1. Durable

As the industry standard for gas dehydration systems in the U.S. since 1957, the glycol pump is trusted by energy producers to provide reliable, consistent operation. With proper system filtration and preventative maintenance, the pumps will serve for decades.

2. Self Sustaining

The pump is also self sustaining. The pump exchanges energy from contact tower gas pressure with the volume flow of the glycol. This means it requires no external energy source outside of the closed loop dehydration system to operate.

3. Zero Emission

It’s also a zero-emission product. While the pump uses the pressure of the dehydration system gas for power, it is completely sealed and does not vent gas.

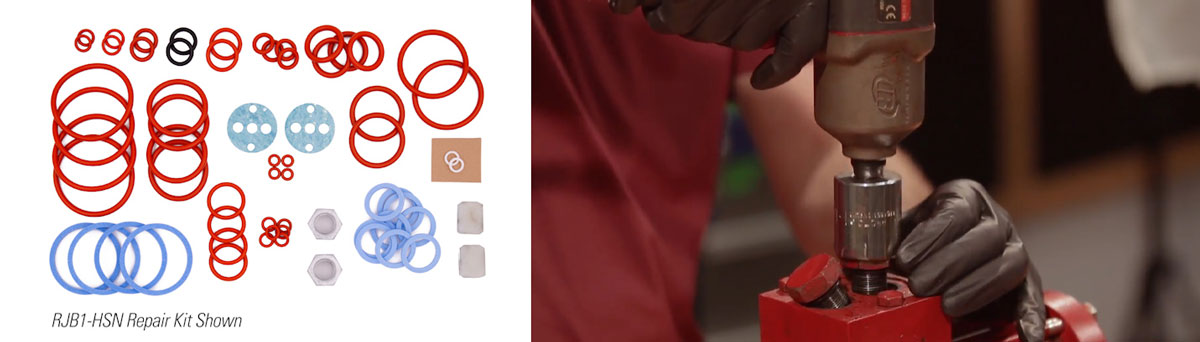

4. Repairable

Adding to its durability, the pump is repairable. Operators can perform preventative maintenance and repair the pump with common hand tools.

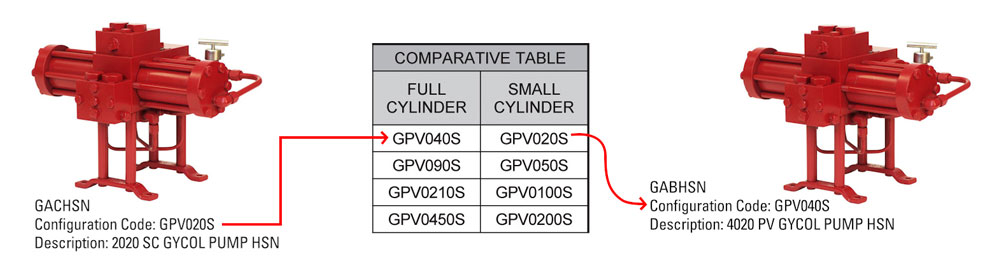

5. Field Convertible

Finally, it’s field convertible. As system pressures change, operators can install a smaller or larger cylinder and conversion kit to adapt to the new conditions.

Specifications

With a variety of sizes, operating pressures, and material options, the pump can be specified to meet your operational conditions.

- The pump comes in eight sizes, with flow rates ranging from 12 to 450 gallons per hour.

- Depending on size, the operating pressures for the pump range from 100 to 2,000 PSI.

- We offer multiple elastomer material options—including HSN, FKM, and Aflas.

Certifications

Manufactured and assembled in the USA, our energy exchange glycol pump is certified for use in North and South America and most areas around the world.

We have 25 distribution centers in the U.S. and international distribution partners globally. Kimray is also an ISO 9001-certified manufacturer.