Upstream oil and gas producers around the globe use High Pressure Control Valves to control processes like separation, gas back pressure, and pressure reduction.

Let's explore what producers find so useful about this valve and explore a few of the most popular product options.

5 key Benefits of a high Pressure control valve

All Kimray High Pressure Control Valves are designed with 5 user-friendly features.

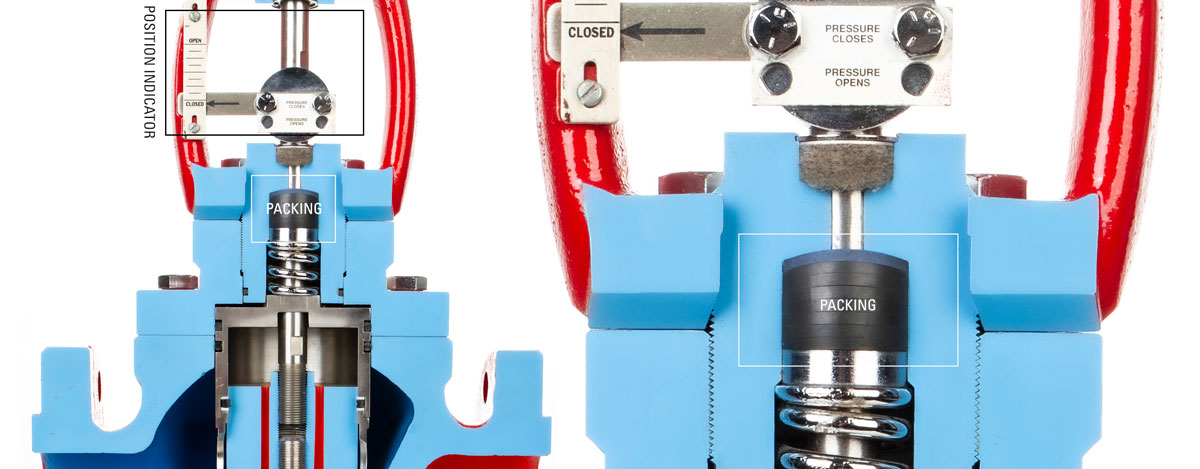

1. Open Yoke Design

Operators can check the valve’s position at any time by looking at the position indicator in the open yoke. This design also enables early detection of packing wear.

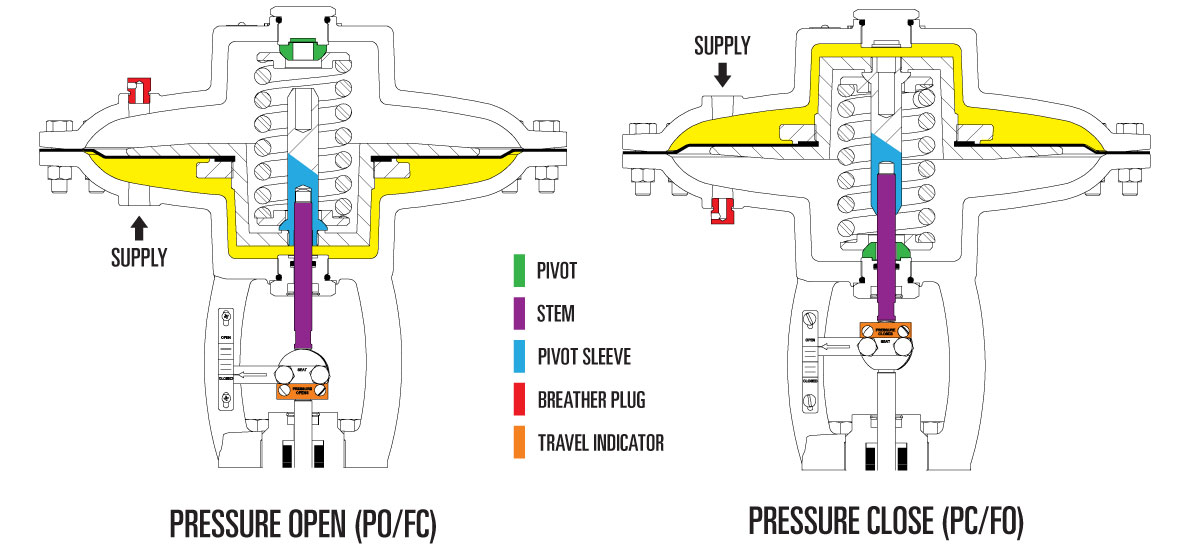

2. Field-Convertible Topworks

Operators can convert the topworks to fail-open or fail-closed operation with simple hand tools.

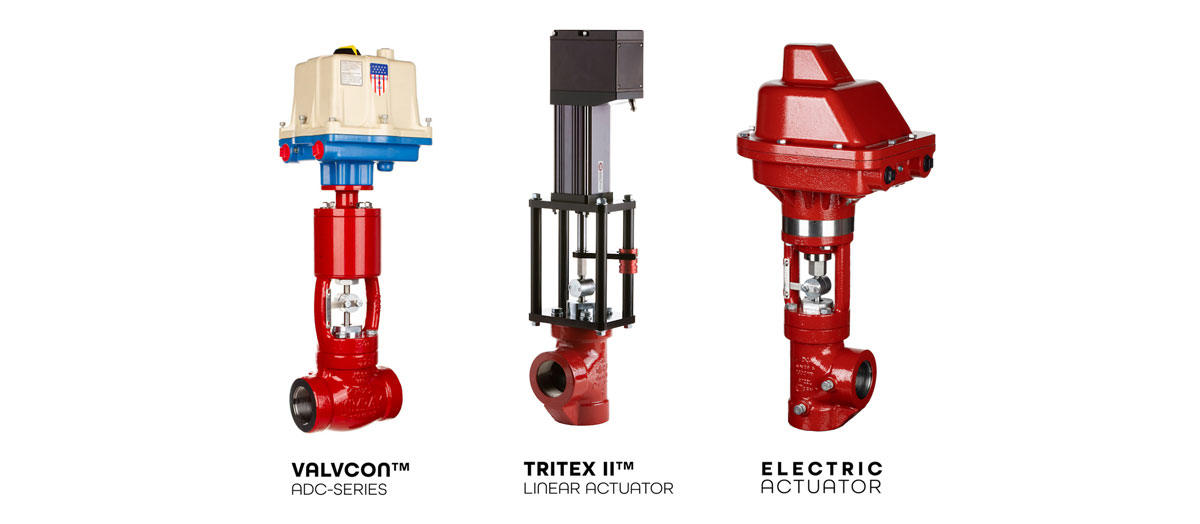

3. Zero Emission Options

Producers can operate the HPCV while releasing zero emissions by powering the valve with an air compressor and pressure pilot or an electric actuator.

4. Ease of Repair

Operators can install our simple product repair kits without the need for scheduled downtime or specialized repair teams.

5. Application-Specific Packages

Rather than ordering multiple parts to assemble themselves, producers can order application-specific valve packages, which include accessory items like pilots, drip pots, and supply gas regulators.

What are the Different Types of High Pressure Control Valves?

Now let’s dive into a few specifics about four of our High Pressure Control Valves:

- Cage Guided

- Stem Guided

- Stem Guided T-Body

- Metering

Cage Guided

- The cage Guided control valve can flow large volumes even under low-pressure differentials. Cage Guided valves have a balanced trim, which means that downstream pressure is balanced below and above the internal valve trim. This balanced trim allows the valve to open/close even under high differential pressures.

- They are available in 2”-10” and ideal for large CVs (28.6 - 1091).

- Cage Guided valves are available in full port or reduced port trims, which can be replaced if your production conditions change without replacing the entire valve.

Stem Guided

- Stem Guided valves provide tight control for low flow or high differential, gas regulation, and liquid dump valve applications.

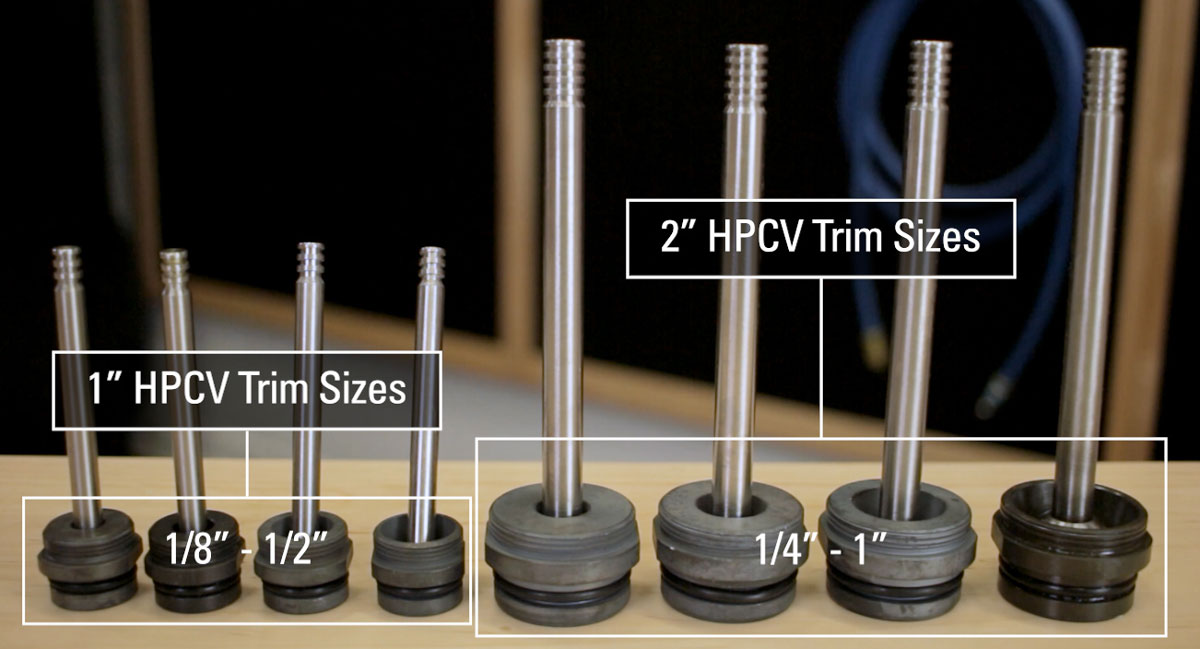

- They are available in 1”-2” and used for smaller CVs ranging from 0.34 to 21.

- There are more valve trim options for stem-guided valves, with sizes from 1/8” - 1”. Trim sets are replaceable to adapt to changing production conditions.

3 Types of Trim Design for Stem-Guided Valves

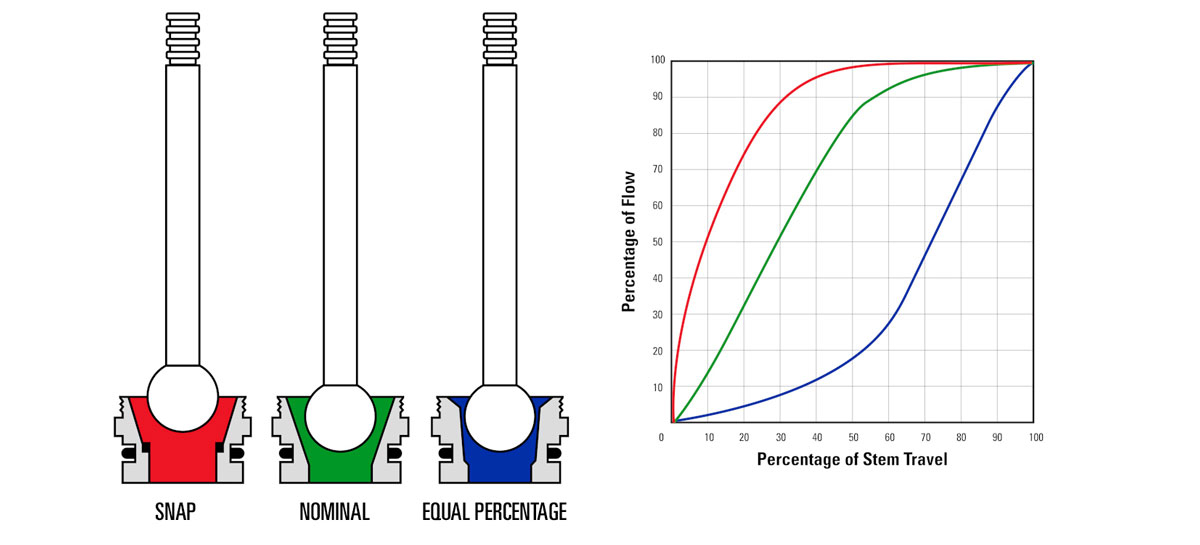

There are 3 trim designs for use in different applications to open at different rates.

- Snap trim applications include liquid dump in erosive conditions and liquid dump when metering liquids.

- Nominal trim is used for standard dump valve applications or for holding interface.

- Equal percentage trim is used for precise gas regulation or applications where a smaller Cv is required.

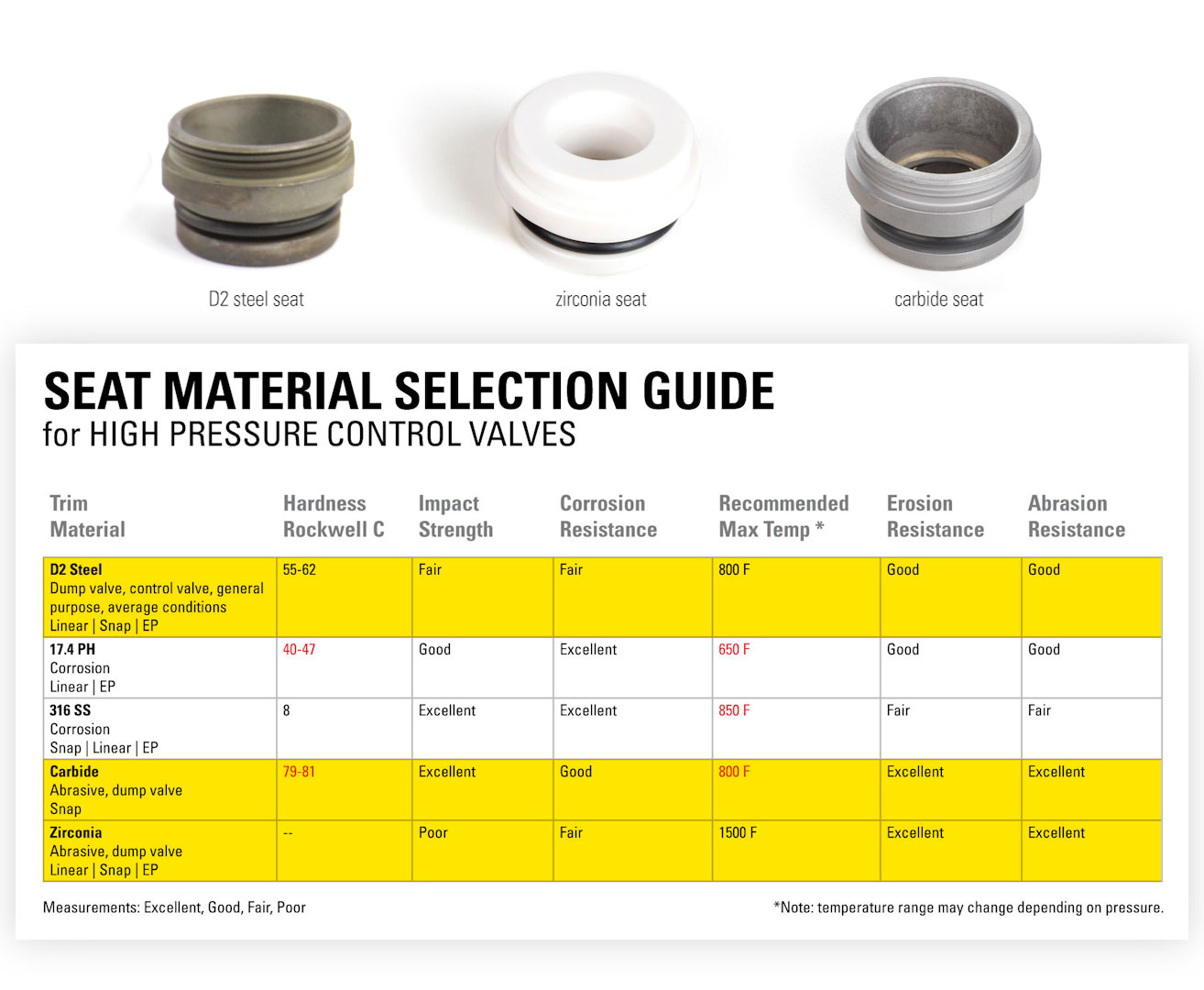

3 Material Options for Stem-Guided Valves

There are also 3 primary material options for valve trim:

- Standard D2 Steel Trim. D2 steel is our standard valve trim material, which is good for average conditions with little sand or erosion.

- Carbide Trim. For sandy or erosive conditions, we recommend carbide trim, which is 2.5x harder than D2 steel trim.

- Zirconia Trim. For extremely abrasive conditions, we recommend Zirconia trim, which performed up to 16x better than D2 steel trim in an ASTM G65 Sand Abrasion Test.

Stem Guided Body Types

Both Cage and Stem Guided High Pressure Control Valves are available in angled- and through-body, but the stem guided is also available in the versatile T-Body configuration.

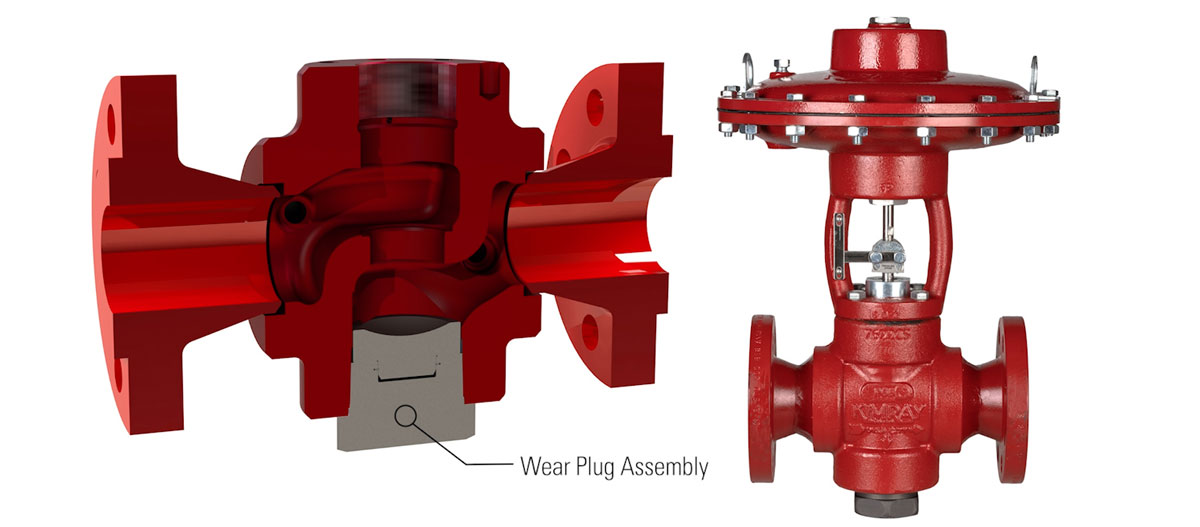

Stem Guided T-Body

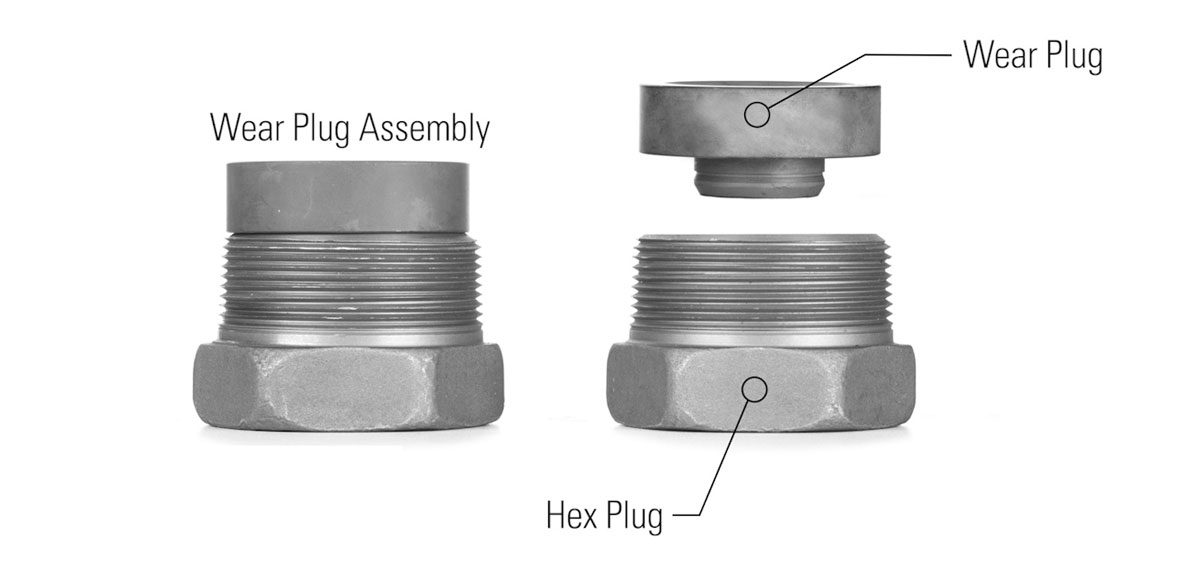

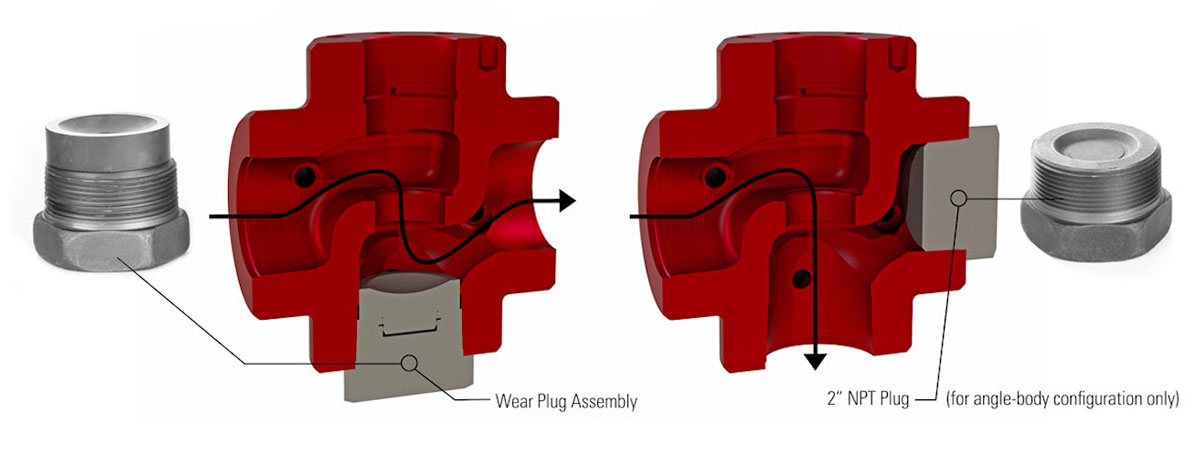

The Stem Guided T-Body valve features a replaceable wear plug assembly. This piece absorbs the force of erosive materials, and it can be easily examined and replaced as needed rather than replacing an entire valve body, saving producers both time and money.

The NPT end connection option can be converted from through-body to angle-body configuration. This means you can easily repurpose your valves for different applications and purchase one valve rather than two to reduce the overall amount of inventory needed for your operation.

The flanged options include flanges on the side ports and retain the 2” NPT port on the bottom for the wear plug assembly.

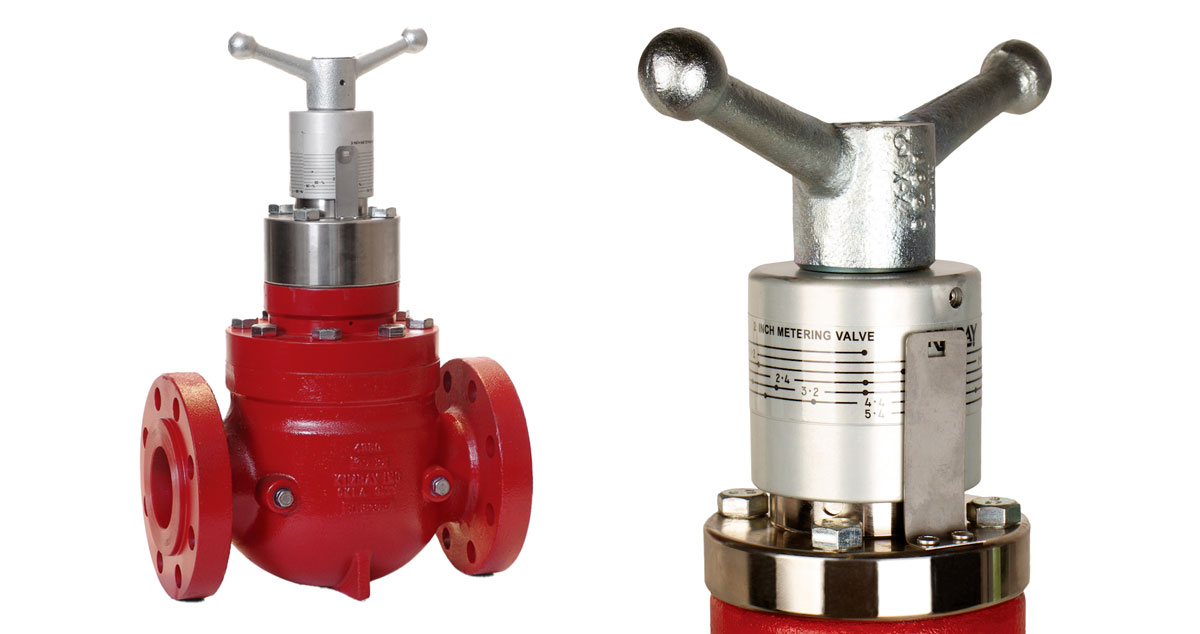

Metering Valves

Metering control valves are used any time a control point is required in 64ths of an inch opening to control the flow of liquids or gases on meter runs or flow lines.

These valves feature a large adjusting knob that makes it easy to adjust.

Where can High Pressure Control Valves be Used?

High Pressure Control Valves can be used for gas or liquid applications.

Gas Back Pressure and Pressure Reduction

For gas applications they’re ideal for pressures greater than 300 PSI or for pressures below 300 PSI if where the Cv is also low and required tighter control than a standard gas regulator.

What accessory parts are required?

Note that for gas back pressure and pressure reducing applications, a package is required. Packages include the control valve, pressure pilot, drip pot and supply gas regulator.

Liquid Dump Applications

For liquid applications, the High Pressure Control Valve is ideal for pressures greater than 500 PSI.

What accessory parts are required?

In liquid dump applications, the control valve will be operated by a liquid level controller or level switch. The pneumatic output of the level controller will apply a pressurized signal to the actuator of the dump valve to open or close it.

Electric actuation is also an option.

Certifications

Manufactured and assembled in the USA, our high pressure control valves are certified for use in North and South America, and most areas around the world. Visit our certifications page to see if our HPCVs are certified for your area.

Kimray has been helping energy producers solve their biggest control challenges since 1948. Reach out to your local Kimray representative today to explore how we can help improve your operation.