Where to listen online:

What is a pump jack?

A pump jack is a widely recognized piece of equipment used to pump crude oil from underground reservoirs.

How Does a pump jack work?

Producers use pump jacks as part of a method of artificial lift called rod lift. You'll also hear this called sucker-rod lift or a beam-pumping system.

Why Is Rod Lift Used?

Of all the forms of artificial lift, rod lift is the most common.

If it wasn't already the first form of artificial lift installed, rod lift is usually the last system used on a well before production is stopped. A rod lift set up can operate at low reservoir pressures and continue to produce oil for many years with little operating cost and low maintenance.

Because it can operate at low reservoir pressures, sucker-rod pumps are used in most stripper wells. A stripper well is an oil or gas well near the end of its economical production time, typically making less than 10 barrels of oil per day (bbld).

What Equipment is needed for Rod Lift?

Most surface units are beam pumps, which include a prime mover and gear reducer. This system is called a beam-pump installation. The generic name of “sucker-rod lift” refers to all types of reciprocating rod-lift methods including the lesser used hydraulically actuated units or tall-tower systems.

This is why you’ll hear the terms rod lift, beam pump, sucker-rod and pump jack all used to mean generally the same form of artificial lift.

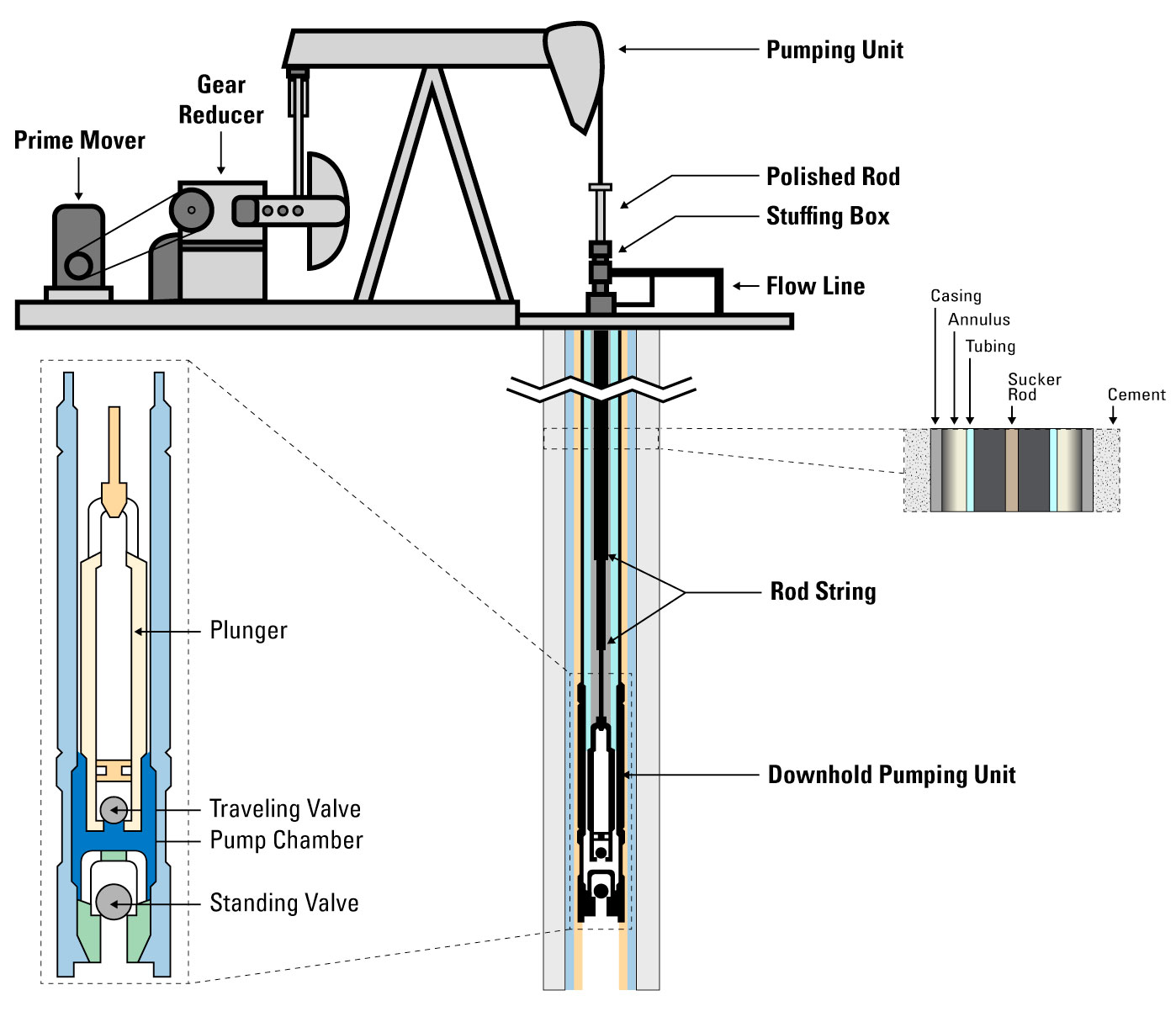

A common rod lift system can be simplified to three broad components: the surface pumping unit, the rod string and the downhole pumping unit. Let’s go over each of these components.

Surface Pumping Unit

The surface pumping unit includes several key components such as the prime mover, gear reducer (or gear box), pump jack and stuffing box.

Prime Mover

A rod lift system is powered by an electric motor or combustion engine called a prime mover. It delivers high-speed, low-torque power to a gear reducer.

Gear Reducer / Gear Box

The gear reducer, also called a gear box, converts that energy into a high-torque output for the pump jack. It allows the torque and speed between a motor and a load to be modified as needed.

This high-torque output is required for the pumping unit to move the counterweights and rod strings, as well as the column of oil from thousands of feet underground to the surface.

Pump Jack

The pump jack, or pumping unit, uses the rotating motion of the prime mover and reciprocates a vertical motion on the rod strings which are connected to the downhole pump.

The pump jack is the main visible element that has acquired many creative names over the years like the nodding donkey, rocking horse, dinosaur, and thirsty bird.

Stuffing Box

The stuffing box forms a tight seal with the polished rod and allows it to move up and down without oil leaking out. It diverts the produced fluids out of the pumping tee and into the flow line.

Rod String

Polished Rod

The polished rod is the top-most rod in a rod string.

Sucker Rod String

The polished rod is connected to the long string of sucker rods or rod strings, which connect the surface unit to the downhole pump. Each time the rods and pumps are stroked, a volume of produced fluid is lifted to the surface.

Pump Assembly

Downhole Pump Assembly

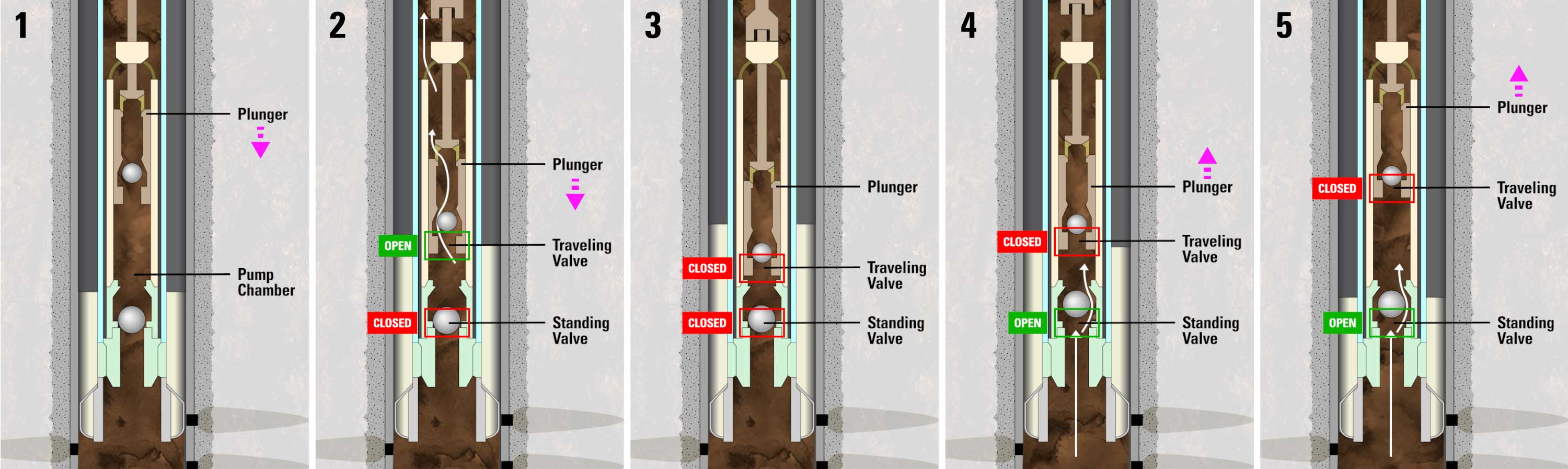

The downhole pump is the component that moves the fluid up the tubing. It consists of a pump chamber, a plunger with a traveling valve (riding valve) and a standing valve.

As the plunger travels down the pump chamber, the traveling valve is open while the standing valve is closed, allowing fluid to flow above the plunger.

When the plunger is traveling back up the pump chamber, the standing valve opens, and the traveling valve closes, drawing in more fluid from the reservoir.

The pump assembly acts like a check valve. It allows fluid to flow up through ball checks but not back into the reservoir.

Multi-Plunger Pumps

Pumping units can also be designed with multiple plungers. Some applications where a double-plunger could be used include production with high viscosity oil or low gas-to-oil ratios.

CHALLENGES WITH PUMP JACKS

Volume Limitations

One challenge with pump jacks is the volume limitations. If you are operating with increased volumes, you may have to change out the pump to a larger size to accommodate the changing conditions, which requires downtime for a work over rig to pull the rods and pump from the well.

Gas Interference

If the well is producing enough oil, the pumping unit may operate 24/7, but as production declines the operator may slow down the speed of the unit or operate it intermittently. If the pump is being operated too quickly, gas may be produced through the same perforations as the oil.

If gas enters the pump it leads to insufficient pressure building up in the pump. Under these conditions, the pump cannot open the standing or traveling valves due to compression of the gas.

With little or nothing brought to the surface, this issue is known as gas interference. This can become “Gas Lock" where neither valve in the pump opens during the stroke cycle.