A flow control valve regulates the flow of liquid or gas.

Flow control valves are used in a variety of industries. In this article, we’ll explain the operation of two common types for oil and gas producers: a High Pressure Control Valve and a Liquid Dump Valve.

What is function of a flow control valve?

In oil and gas production, flow control valves are used to move oil, gas and water through piping and downstream for separation, transportation, or storage.

Where are flow control valves used?

Oil and gas producers use flow control valves on separation equipment like free water knockouts, separators, heater treaters and GPUs.

What are the different types of flow control valve?

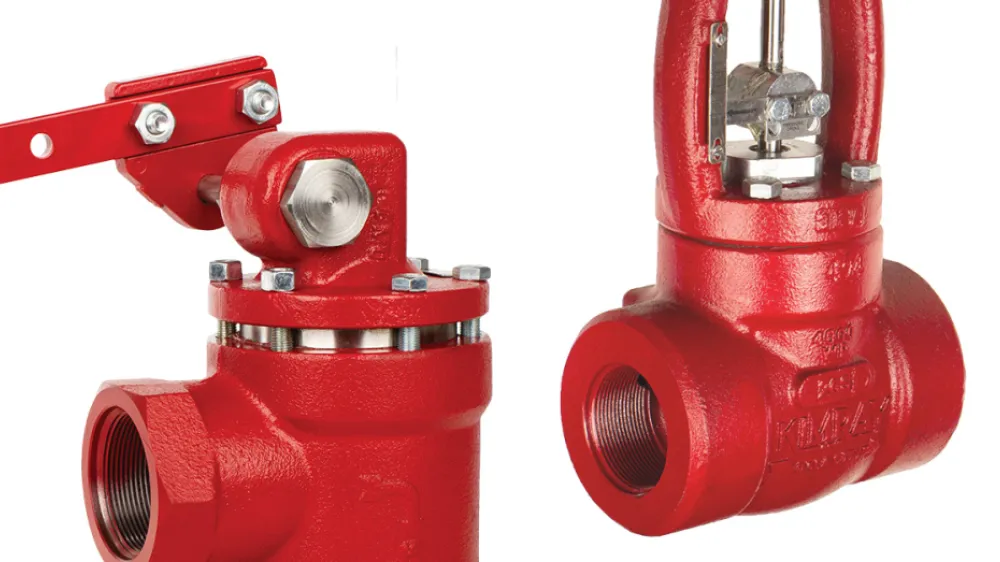

Two common types of flow control valves used in upstream oil and gas production are high pressure control valves and lever-operated liquid dump valves.

High Pressure Control Valve

A High Pressure Control Valve is a versatile product that can be used in both flow control and pressure control applications.

In flow control it is typically used as a liquid dump valve on a separation vessel.

Here's how it works:

The valve will remain in its fail position until it’s told to do otherwise by a pilot.

In a liquid dump application, the pilot will receive a signal from a liquid level controller to open the valve and dump the liquid.

The flow through the stem-guided high pressure control valve comes from on top of the seat. This type of valve offers precise control with the small Cv trim options.

Kimray’s High Pressure Control Valve can also be field converted to fail open or close with simple hand tools.

Lever Operated Liquid Dump Valve

Another common type of flow control valve is the Lever Operated Liquid Dump Valve.

A Liquid Dump Valve is a component of a liquid level control system used to maintain and control the liquid level in production vessels.

A mechanical liquid level control system is made up of five primary parts:

- Trunnion Assembly

- Float Arm

- Float

- Linkage Rod

- Liquid Dump Valve

Here's how it works:

The dump valve is connected to downstream piping.

When the float in the separation vessel rises to the desired level, the linkage rod rises, lifting the arm on the dump valve. This opens the valve and “dumps” the liquid from the vessel downstream to be further processed or sold.

To speak with an expert about your flow control needs, contact your local Kimray store or authorized distributor.