What is Natural Gas Flaring?

Combustors and flares are equipment used in energy production to eliminate natural gas and harmful volatile organic compounds, called VOCs.

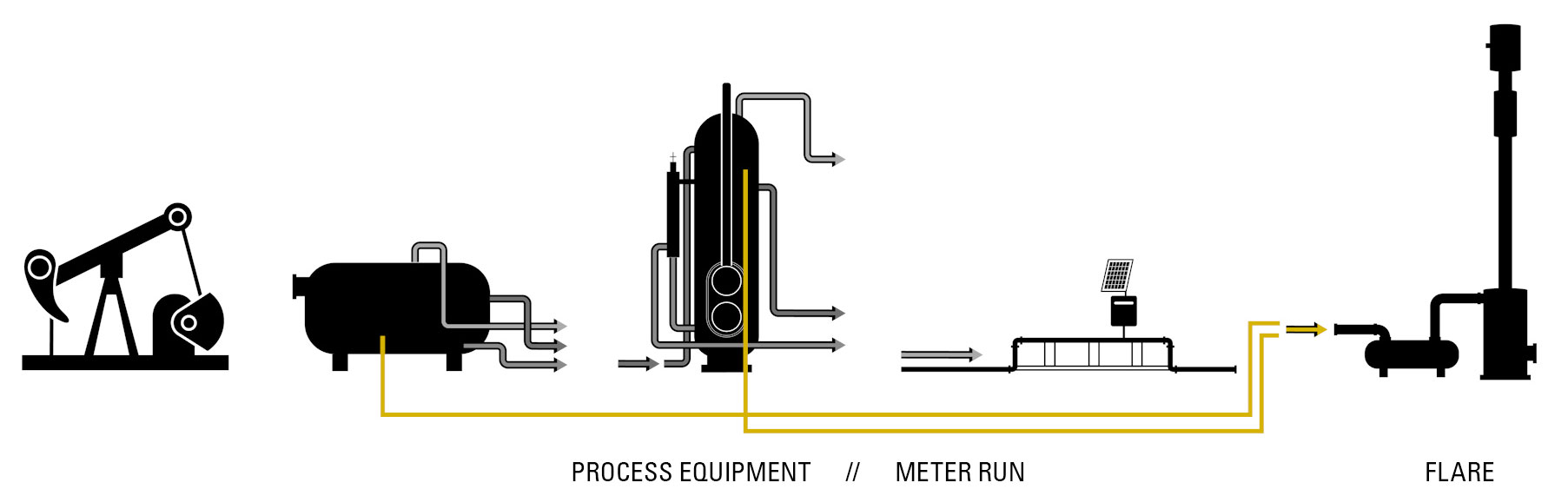

After an oil and gas well is drilled and completed, it will produce three primary elements: water, crude oil, and natural gas.

Companies dispose of or recycle the water. They process and sell the oil.

They then have 3 options for the natural gas:

- Sell it downstream

- Inject it back downhole in a method of artificial lift called gas injection

- Eliminate it with a flare or combustor

4 Reasons Producers eliminate Natural Gas

There are four primary circumstances where companies may eliminate a resource like natural gas rather than sell it.

- Insufficient infrastructure

One reason is that there may not be sufficient infrastructure. The only economical way to transport natural gas is through pipelines, so where that infrastructure does not exist, the gas is often deemed unusable. - Relieving excess pressure

A second circumstance for flaring is when a pipeline is having maintenance performed on it or cannot accept additional volumes of gas. The extra gas is eliminated by flare or combustor instead of causing equipment damage or being released into the atmosphere.

- Startup & shutdown possesses

Some startup processes require gas to be flared before transitioning into production or an operational state. Also, if separation vessels and equipment must be depressurized or a gas plant shut down, the gas in the system will travel to a flare or combustor.

- Avoiding venting gas into the atmosphere

Another common reason for eliminating natural gas is to avoid venting gas emissions it into the atmosphere. This is regulated through the EPA or local regulations for air quality.

How Does a Flare Work?

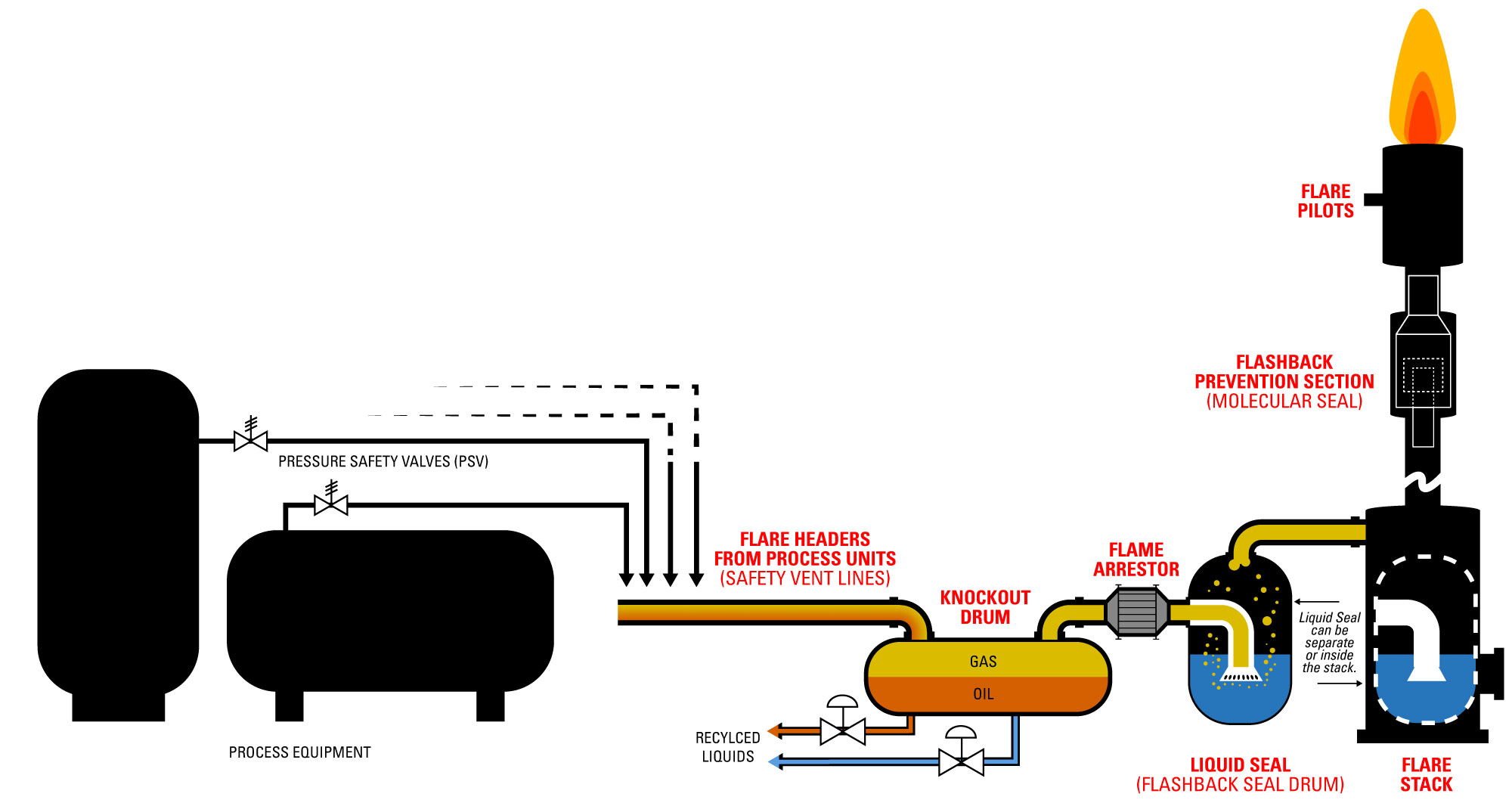

First, a knockout drum gives any condensed liquid a place to collect before the gas travels to the flare. Producers want to capture these liquids because they are a valuable resource, and they may cause a safety hazard if they travel to the flare.

Liquid level controls, pressure control valves, and other instrumentation can be used on this equipment.

After exiting the knockout drum, the gas is routed through a piping system called the flare header. Safety equipment prevents the flames from propagating back through the system and causing damage. This can include flame arrestors, flashback preventors, or liquid seals on larger systems.

A pilot flame burning at the tip of the stack ensures that when the flare needs to be operated, the gases are ignited.

At the tip of the stack is an air-assist mixer which helps combine air with the gases being burned to improve combustion efficiency and lower the overall impact on the environment.

4 Kimray Controls used in Flares and Combustors

There are 4 Kimray controls that can be used on both flares and combustors:

- Burner valve—A Low Pressure or High Pressure Control Valve can be used as a burner valve to throttle the flare gas on and off

- Pilot Guard—Pilot Guards can be used to monitor the pilot flame and shutdown the system if it is extinguished

- Level Controllers—Liquid Level Controllers or Level Switches can be used to control levels in the liquid knockout drum

- Dump Valves—Low Pressure Liquid Dump valves can be used alongside the level controls for the liquid knockout drum

How Do we Capture Natural Gas?

Flaring or combusting gas eliminates several volatile organic compounds “VOCs” from the gas stream. While they is effective at this, these processes does not eliminate all emissions.

Because of this, many companies are exploring gas vapor recovery systems.

Producers can use two primary methods of vapor recovery—Vapor Recovery Towers and Vapor Recovery Units—to capture natural gas off of their production fluid.

What is a Vapor Recovery Tower?

A Vapor Recovery Tower—abbreviated “VRT”—is a vertical pressure vessel designed to capture the vapor off of oil.

Producers typically install vapor recovery towers between production separators and liquid storage tanks. A VRT is typically a very low-pressure, low-differential vessel with high flow rates.

What is a Vapor Recovery Unit?

A Vapor Recovery Unit—abbreviated “VRU”—is a specialized compression package that captures low pressure, wet gas streams from oil and condensate storage tanks.

For more information about these vessels and how we can help you control emissions, contact your local Kimray store or authorized distributor.