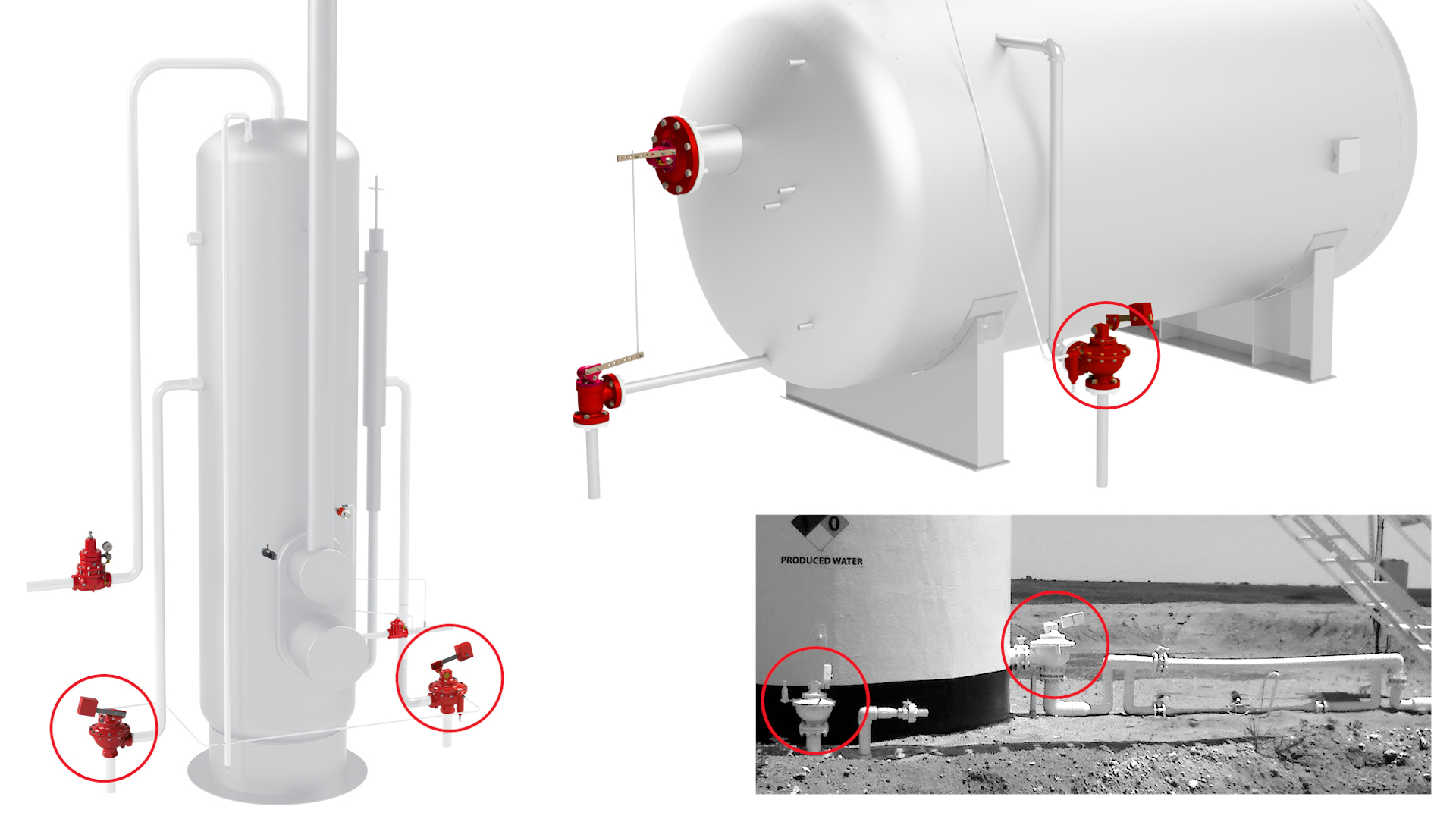

The Weight Operated Dump Valve (formerly known as a Treater Valve) is a weight-operated throttling valve designed to hold liquid level in production vessels such as heater treaters, free water knockouts, and saltwater disposal systems.

The Weight Operated Dump Valve actuates based on hydrostatic pressure. Production vessels like heater treaters create a column of liquid in the discharge piping, which generates hydrostatic pressure.

Liquid Level Control Process

Here's how the Weight Operated Dump Valve works:

- First, a weight and lever push down on the diaphragm assembly. This closes the seat.

- When the liquid rises above the set level, it overcomes the force of the weight.

- The force of the weight lifts the diaphragm assembly against the weight load. This opens the valve.

- Liquid discharges and the column of liquid lowers.

- Lastly, the weight closes the valve.

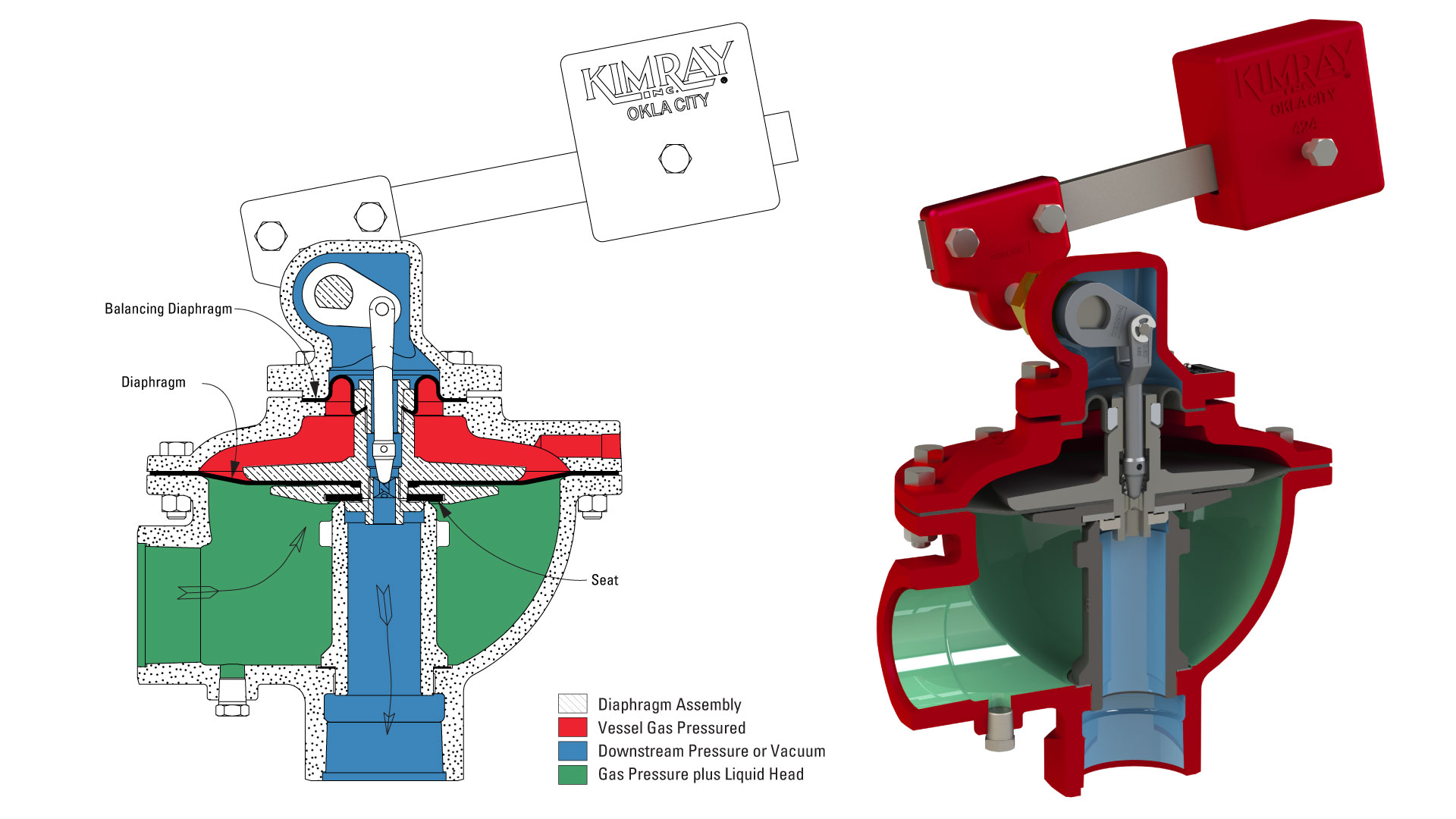

One of the most beneficial features of the Weight Operated Dump Valve is the balanced upstream/downstream pressure. This provides security for instances where pressure comes backwards from a tank up into the downstream outlet of the valve.

Inside the Weight Operated Dump Valve

Here's what's happening inside the valve as it operates:

- The Vessel Gas Pressure (Red) inside the Upper Housing acts upwardly on the Balancing Diaphragm to cancel the downward pressure on the Seat.

- Downstream Pressure (Blue) acting on the Seat communicates to the top side of the Balancing Diaphragm. This cancels any downstream pressure or vacuum effect on the valve operation.

- A Weight and Lever—through a rotary Teflon-packed stuffing box to a Pivot Stem—is the force that holds the seat close. The Pivot Stem pushes down on the Diaphragm Assembly.

- When the liquid rises in the discharge piping of the vessel above the set level, it lifts the Diaphragm Assembly against the Weight load to open the valve.

- As liquid discharges to lower the level, the Weight closes the valve.

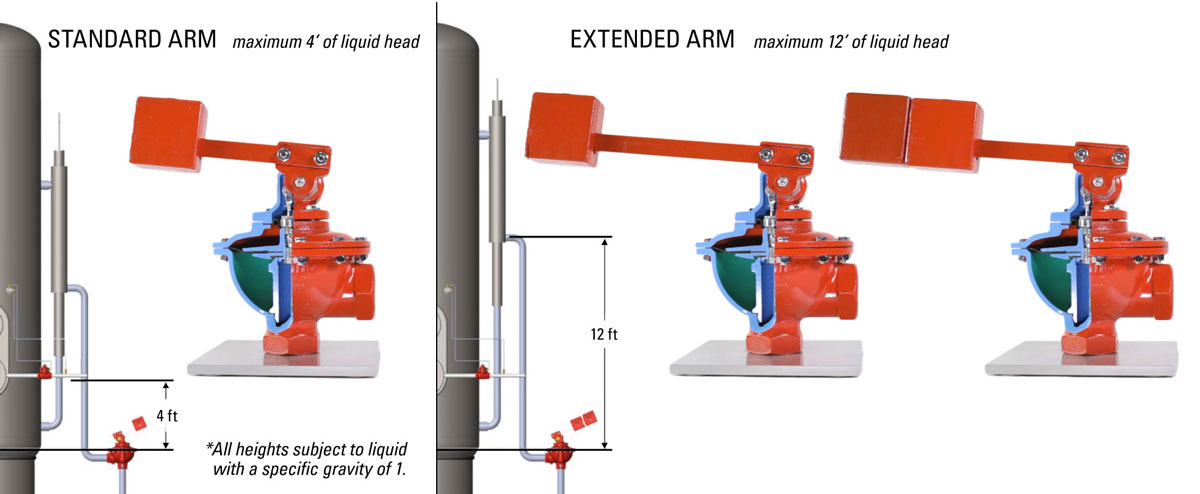

How to Adjust a Weight Operated Dump Valve

You can adjust the height of the water column by moving the weight on the attached lever in or out. The standard lever is designed to 2-4 feet of liquid.

You can hold higher liquid levels by using an optional longer lever and adding an additional weight.

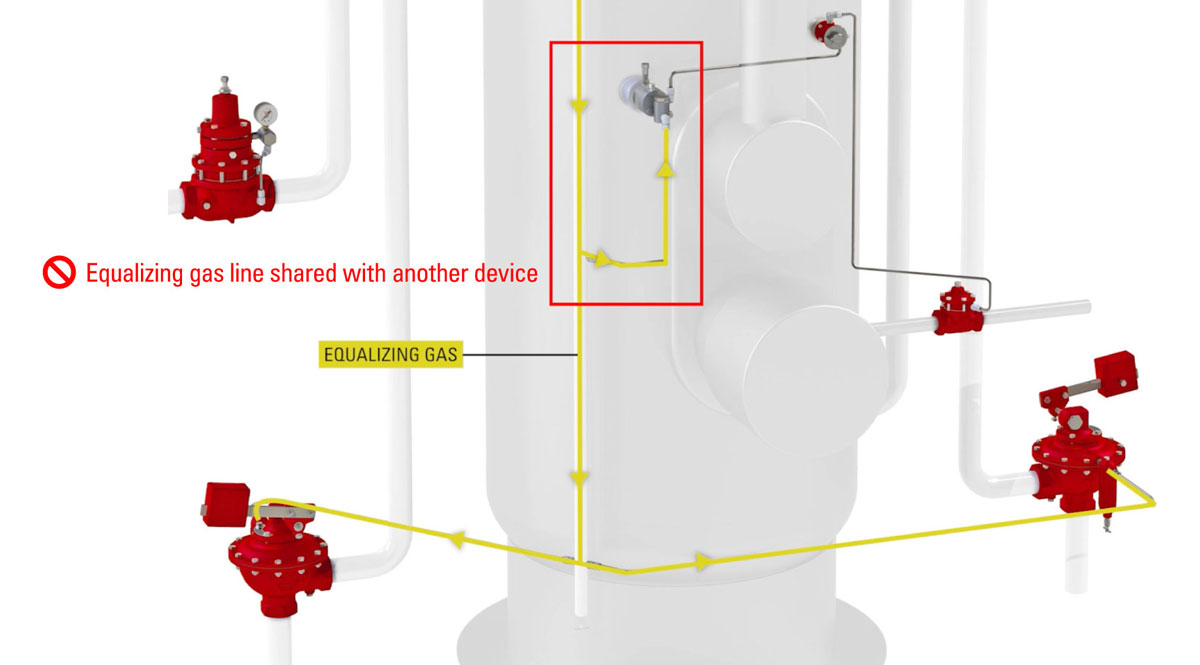

The Critical Importance of the Equalizing Line

To work correctly, this valve requires a gas equalizing line from pressurized vessels such as treaters and free water knockouts. This line equalizes the vessel pressure and valve pressure, ensuring proper operation of the valve.

The gas equalizing line must be taken directly from the vessel. If it is not pulled from the vessel but from a volume pot used for other controllers, the Weight Operated Dump Valve will not hold a steady pressure and operation will be negatively affected.

Likewise, if the equalizing line is shared with any other components, like a pilot, operation will be affected, and the valve may not open or close at the set liquid height.

It is also critical to make sure there are no sags in horizontal runs of the equalizing line, as these sags can fill with condensate or water and adversely affect the valve's operation.

For further questions about the Weight Operated Dump Valve or any other Kimray product, contact your local Kimray store or authorized distributor.