In many industries, engineers will create a blueprint for equipment and control layout, called a Piping and Instrumentation Diagram, or P&ID. In this video, we’ll walk through codes and symbols specifically for oil and gas production equipment so you can read and understand P&IDs in the industry.

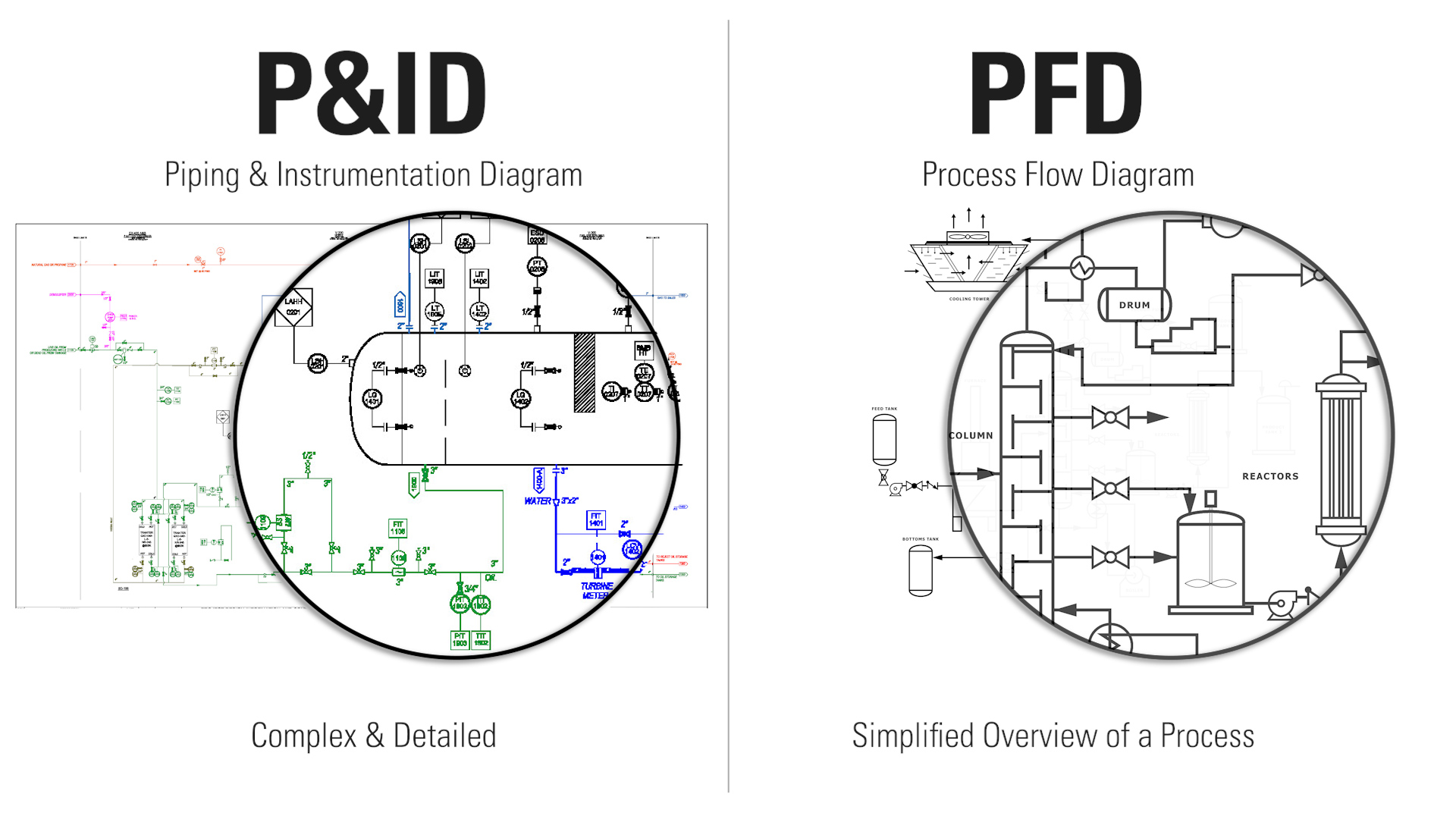

P&ID vs PFD

Process diagrams can be broken down into two major categories:

- Process and Instrument Diagrams (P&IDs)

- Process Flow Diagrams (PFDs).

A P&ID is complex while a PFD is more of an overview of a process.

A flow diagram is a simple illustration that uses process symbols to describe the primary flow path through the production equipment. It provides a quick snapshot of the operating unit and includes all primary equipment and piping symbols that can be used to trace the flow of the well stream through the equipment. Secondary flows, complex control loops and instrumentation are not included. These PFDs are more helpful for visitor information and new employee training.

Field technicians, engineers, and operators use P&IDs to better understand the process and how the instrumentation is interconnected.

Sales personnel and OEMs (original equipment manufacturers) use P&IDs to spec equipment and build the vessels.

Not all P&ID elements are standardized, but the instrumentation symbols follow a standard set by the International Society of Automation (ISA). The ANSI/ISA’s S5.1 standards are what this guide will be using to communicate consistently.

After some practice, you’ll become familiar with many of these codes and symbols, but if you’re just starting out or need a visual resource to reference, make sure to download our P&ID Reference Guide, which features a full list of symbols.

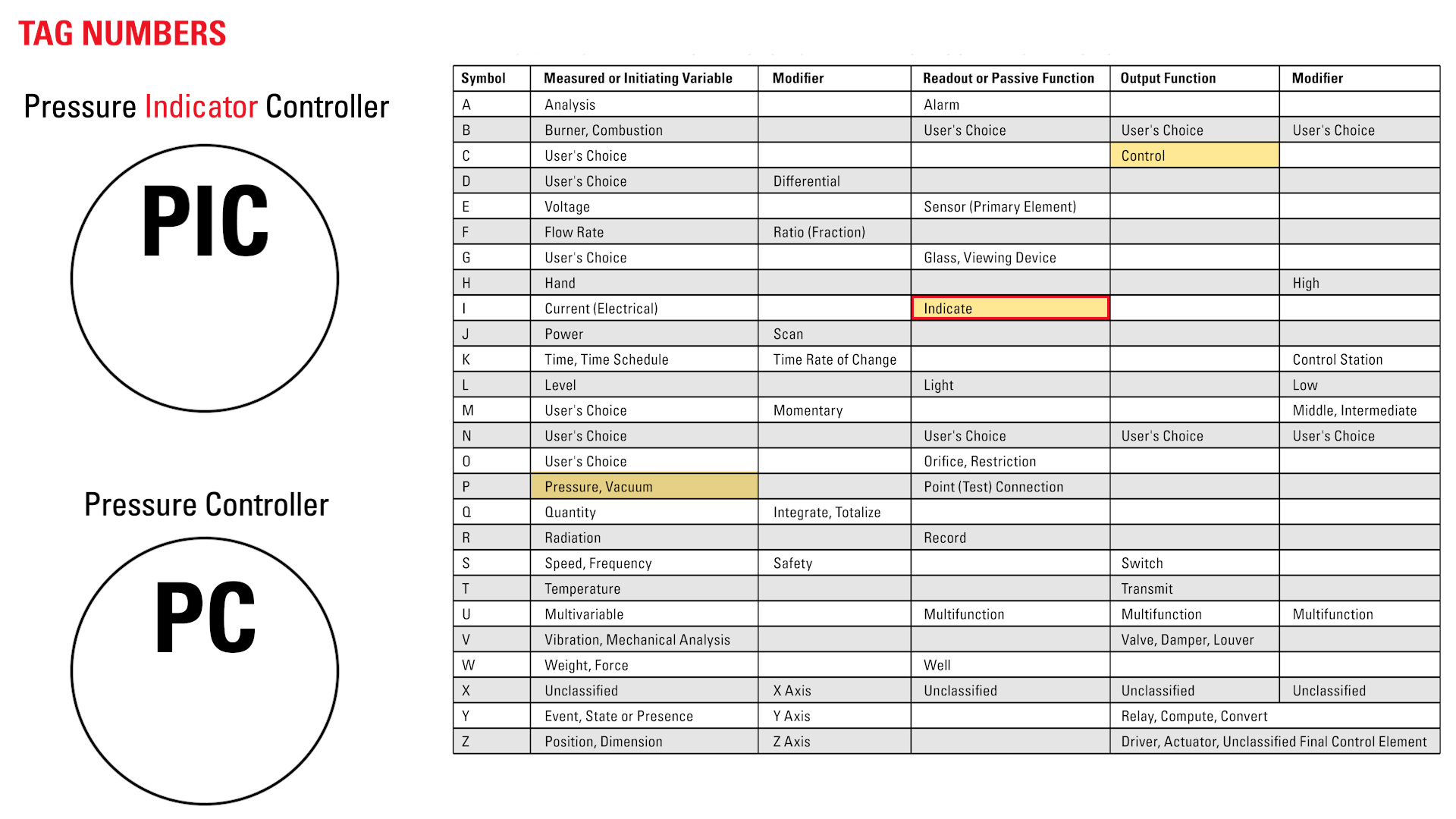

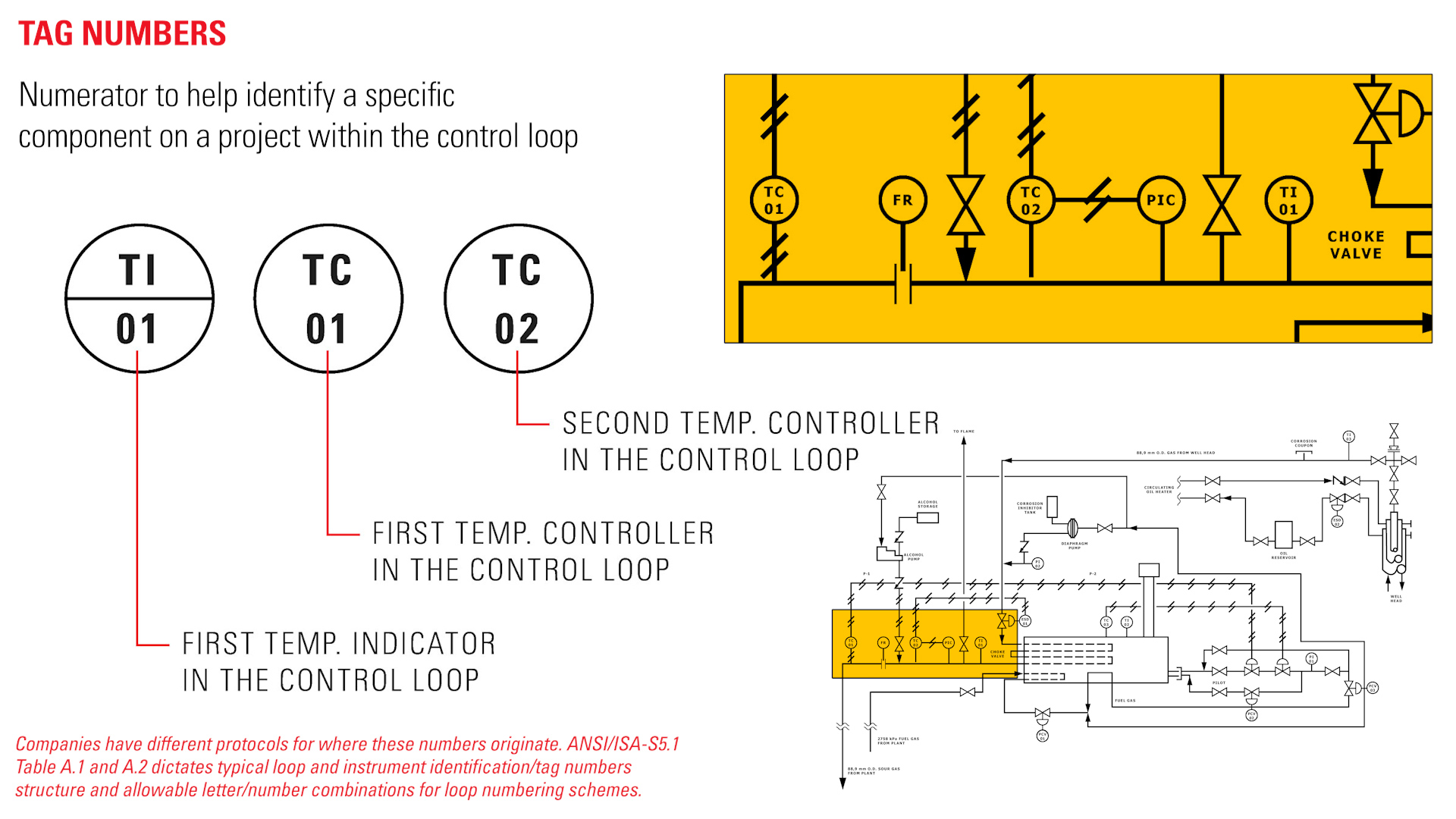

Tag Numbers

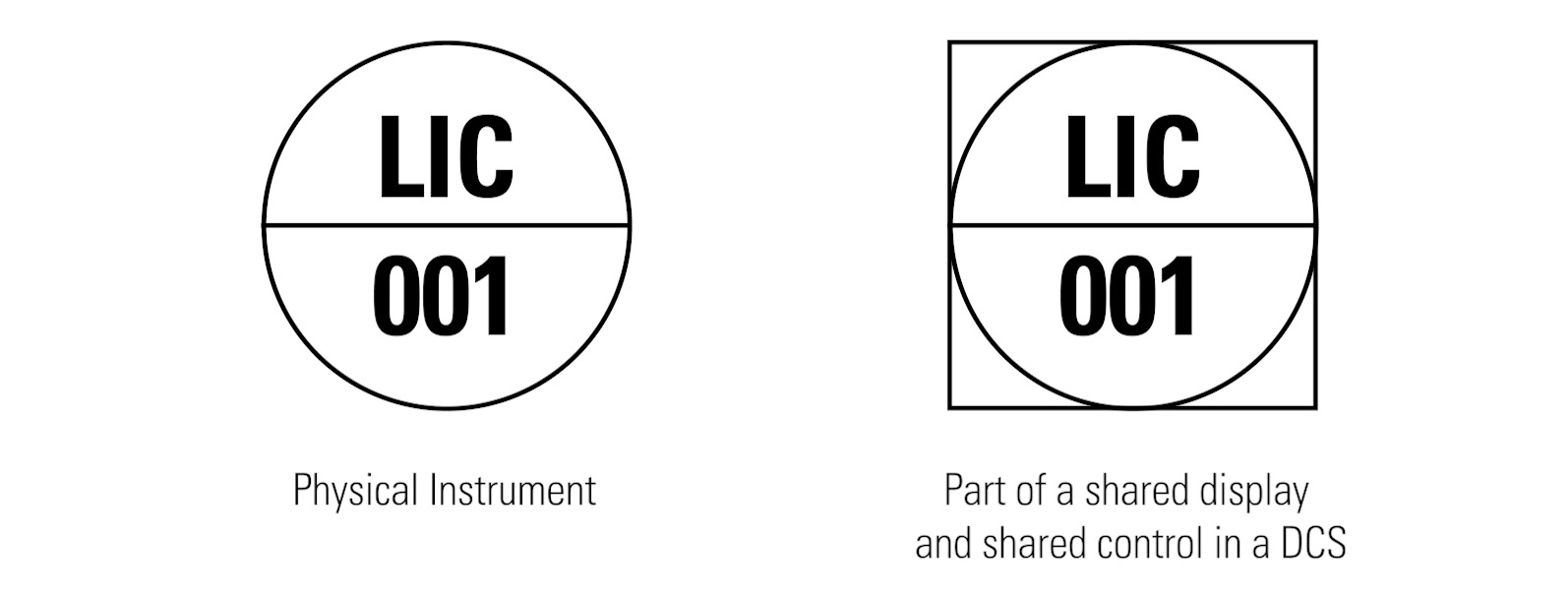

Stand alone, physical instruments are indicated by a tag number with a circle around it.

Tag numbers are a series of letters and numbers that identify a device as what it is controlling, the type of device being used, and the number assigned to it on the P&ID.

- The first letter indicates the parameters being controlled, monitored, or measured.

- The second letter tells the type of device being used.

- The third, fourth, and fifth letters further designate the function of the component and modify the meaning of the preceding letters.

For example, “PC” is a Pressure Controller, while “PIC” is a Pressure Indicator Controller.

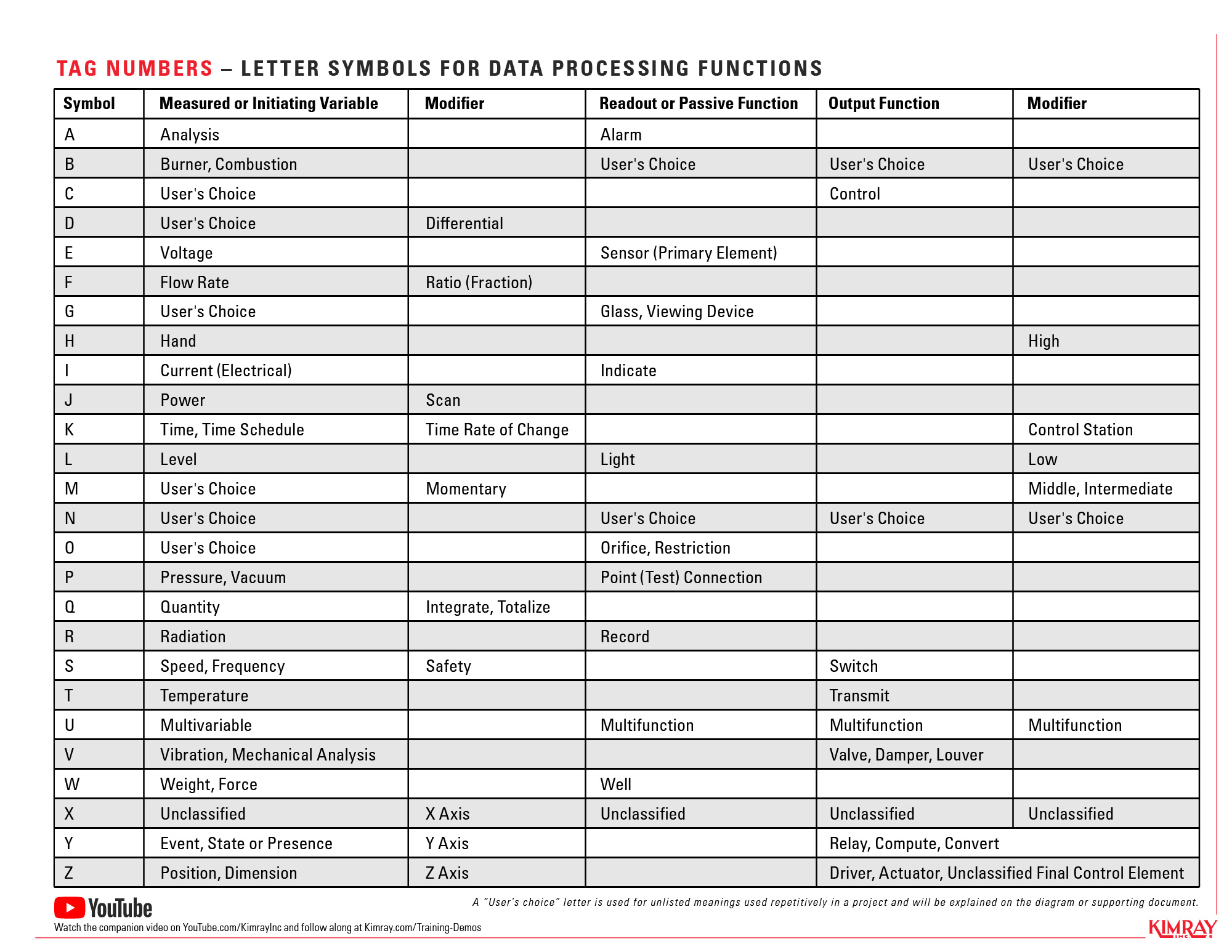

This chart shows common abbreviations for what you would see and how it would be written on a P&ID. However, there are many other abbreviations that you will see such as this more comprehensive industry list.

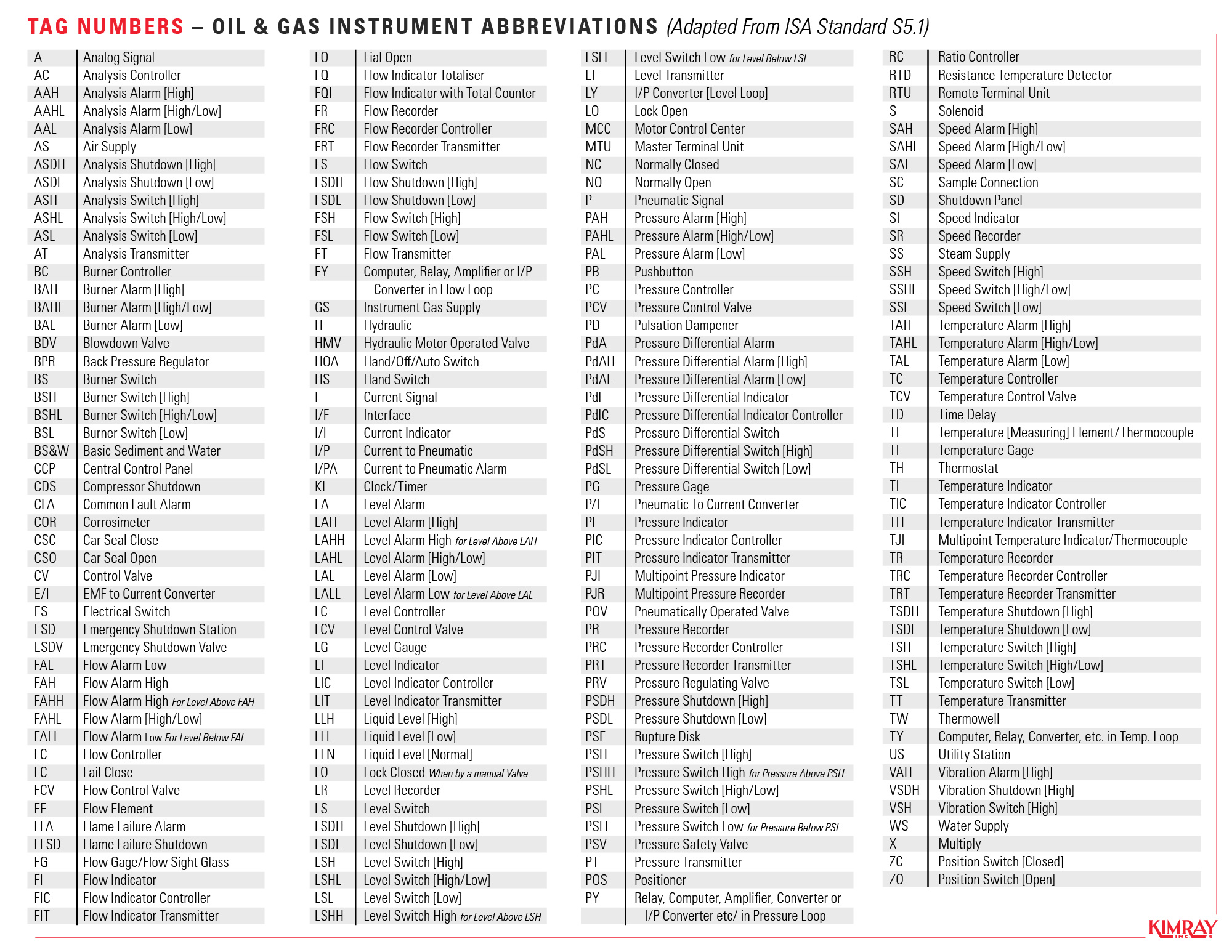

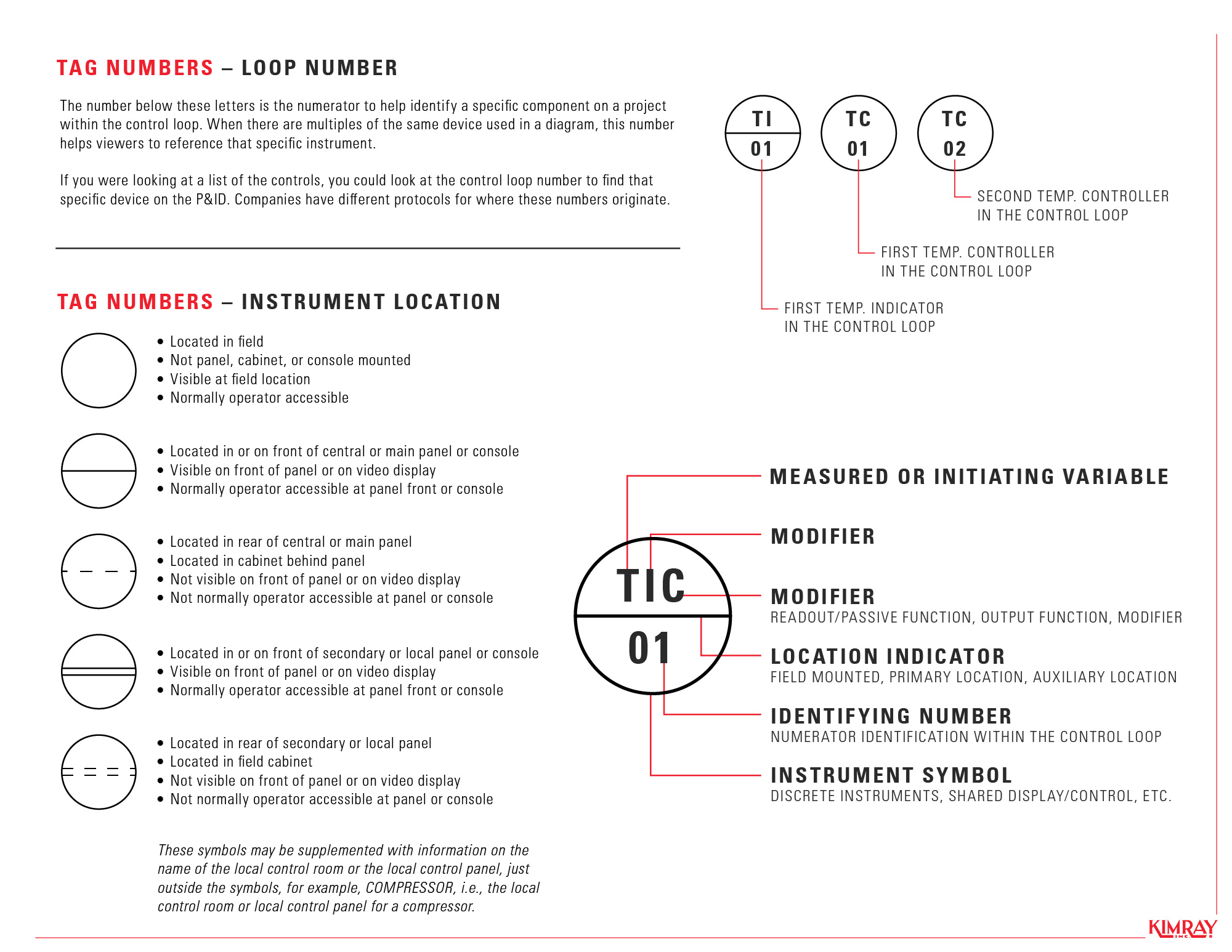

The number below these letters is the numerator to help identify a specific component on a project within the control loop. When there are multiples of the same device used in a diagram, this number helps viewers to reference that specific instrument.

If you were looking at a list of the controls, you could look at the control loop number to find that specific device on the P&ID.

Companies have different protocols for where these numbers originate. ANSI/ISA-S5.1 Table A.1 and A.2 dictates typical loop and instrument identification/tag numbers structure and allowable letter/number combinations for loop numbering schemes.

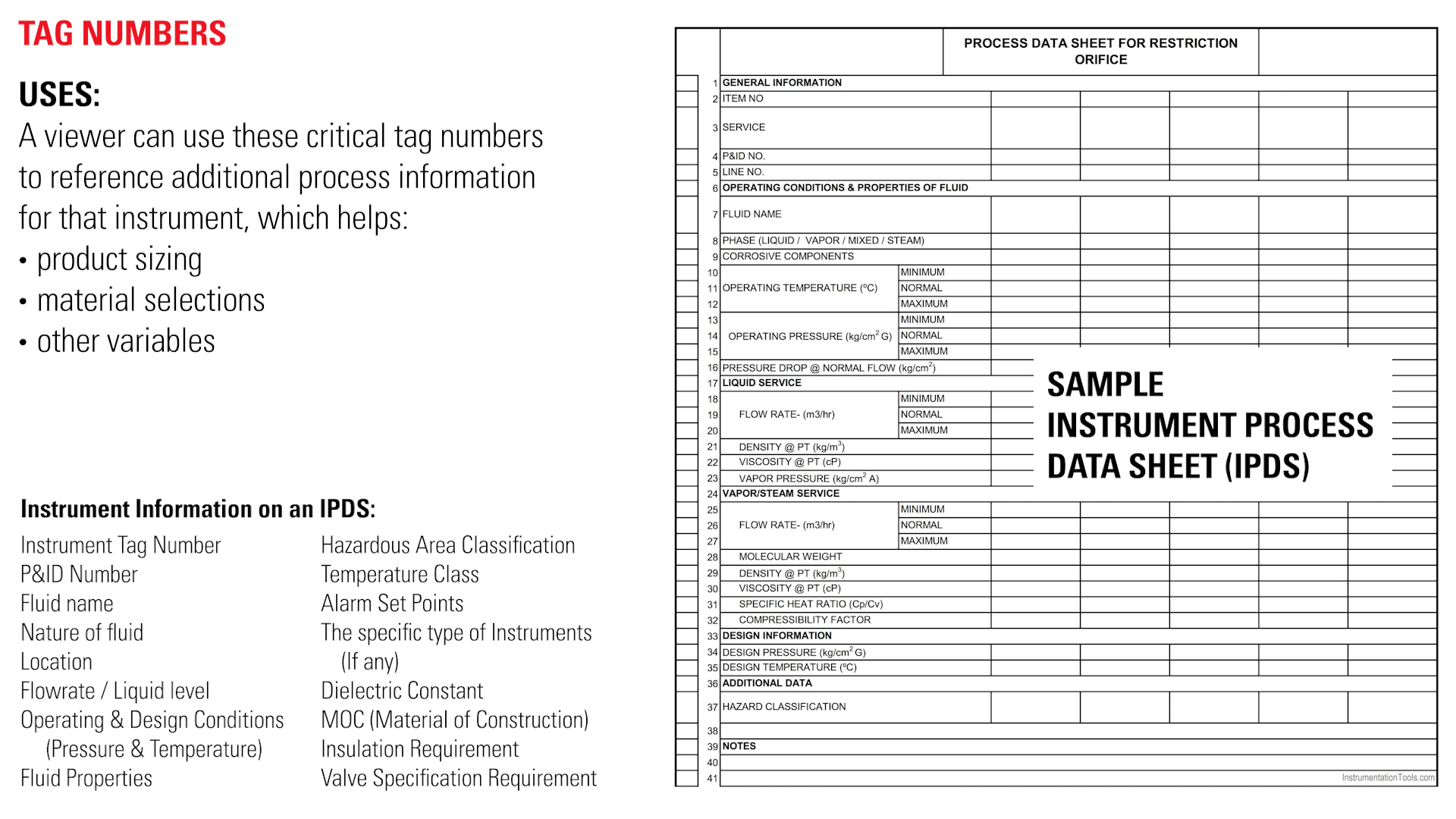

A viewer can use these critical tag numbers to reference additional process information for that instrument, which helps product sizing, material selections and other variables.

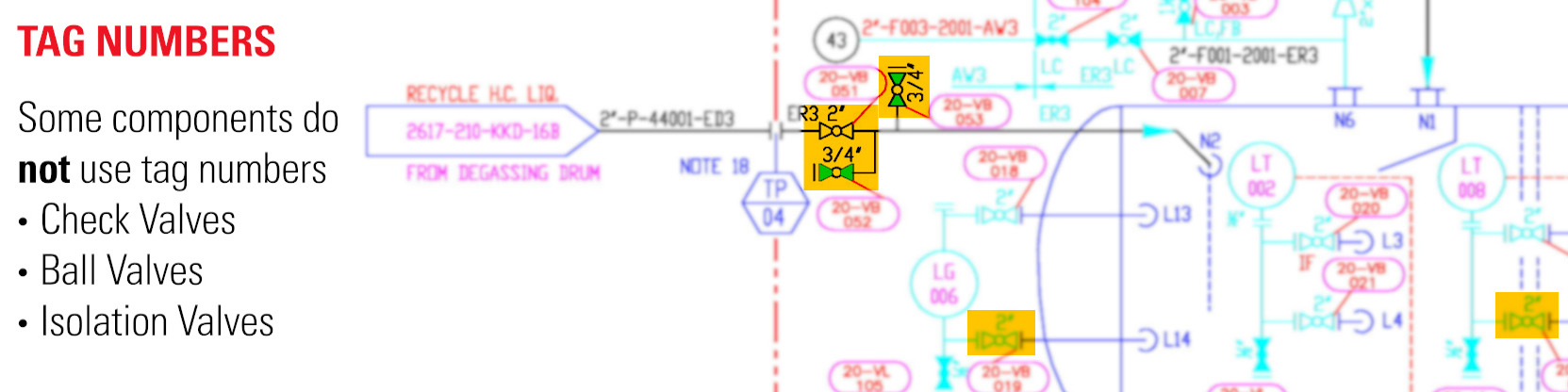

You'll notice that some components such as check valves, ball valves and isolation valves do not use tag numbers. Typically, the information given with these will be limited to their symbol and the line size.

Instrument Location

The circle combined with the presence or absence of a line determines the location of the physical device.

No line means the instrument is installed in the field near the process.

- Located in field

- Not panel, cabinet, or console mounted

- Visible at field location

- Normally operator accessible

A solid line means the instrument is in a primary location in a central control room (accessible to the operator).

- Located in or on front of central or main panel or console

- Visible on front of panel or on video display

- Normally operator accessible at panel front or console

A dashed line tells us that the instrument is in an auxiliary location in a central control room (not accessible to the operator).

- Located in rear of central or main panel

- Located in cabinet behind panel

- Not visible on front of panel or on video display

- Not normally operator accessible at panel or console

A double solid line means that it is in a local control room or on a local control panel

Located in or on front of secondary or local panel or console

Visible on front of panel or on video display

Normally operator accessible at panel front or console

A double dashed line means it’s in an auxiliary location in a local control room or local control panel.

- Located in rear of secondary or local panel

- Located in field cabinet

- Not visible on front of panel or on video display

- Not normally operator accessible at panel or console

These symbols may be supplemented with information on the name of the local control room or the local control panel, just outside the symbols, for example, COMPRESSOR, i.e., the local control room or local control panel for a compressor.

Shared Display & Shared Control

Shared display means you can see the same information in several locations across a network and it can be accessed anywhere. Shared control means you can change the parameters of that device remotely.

Some instruments are part of a Distributed Control System, or DCS, where a user can select a specific controller or indicator and see it in one location, such as on a terminal screen.

With today’s computerized systems using virtual controllers like in PLCs and DCSs, new P&ID symbols had to be developed. If you take the same tag number symbol for a physical instrument and add a square around it, it now means that it is part of a shared display and shared control in a DCS.

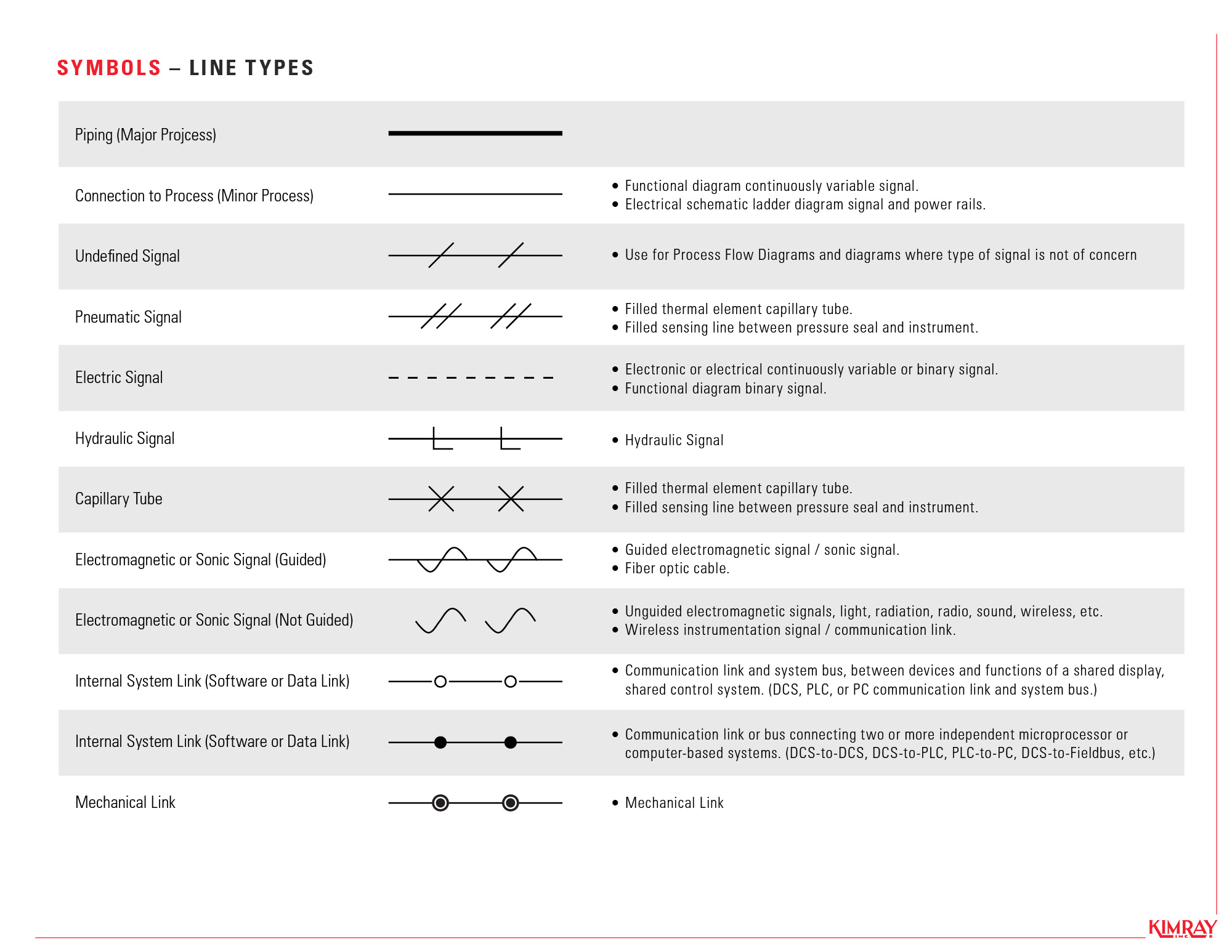

Line Types

Different symbols for line types tell us about the instrument. Users can identify how instruments connect to each other and what type of signal is being used.

For example, a solid line indicates piping, while a dashed line tells us that there is an electrical signal. Familiarize yourself with these different connection symbols by downloading our reference chart.

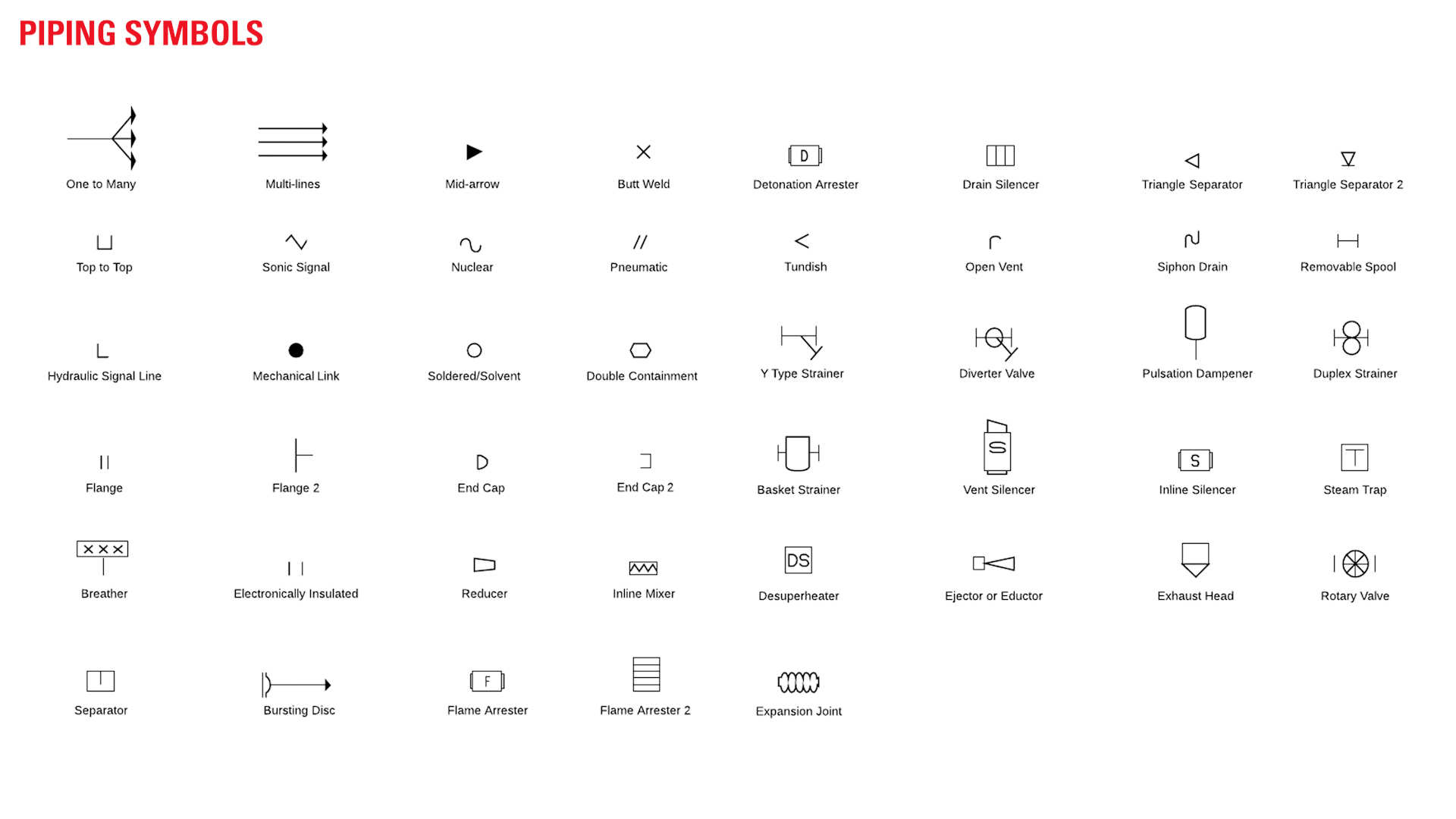

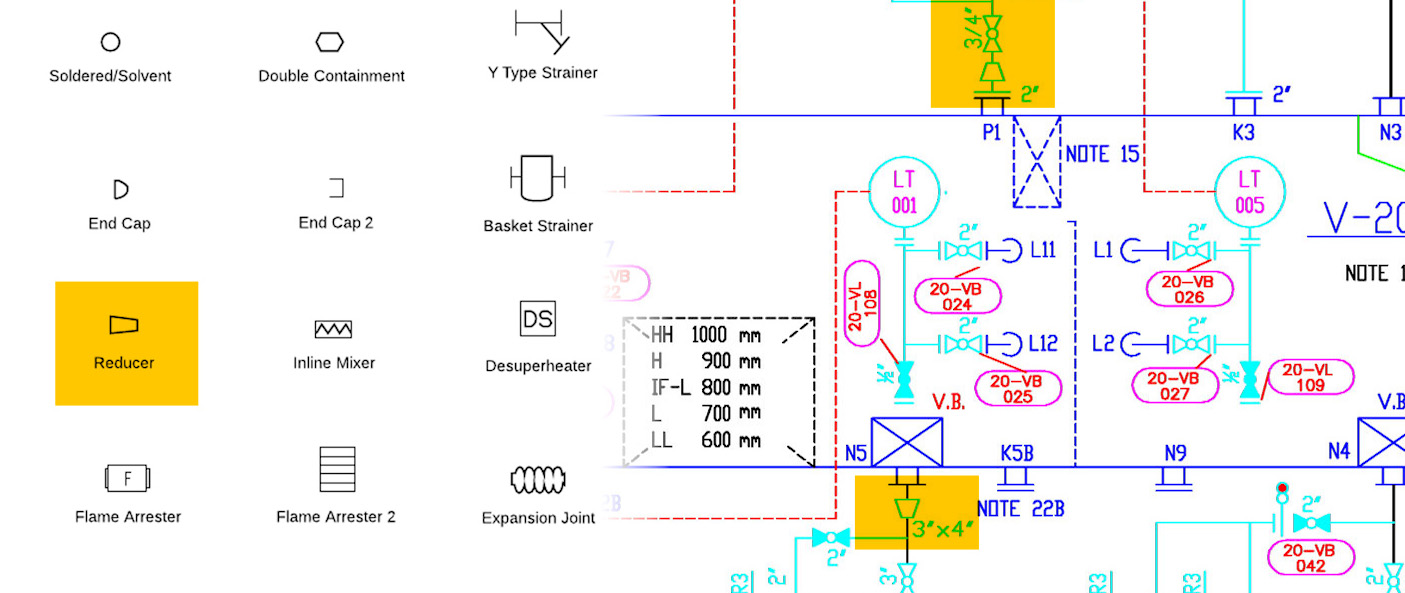

Piping Symbols

Piping symbols have various important uses you’ll want to be familiar with. For example, one important symbol to note here would be the concentric and eccentric reducers. This will help you identify when piping changes sizes. You’ll see these sometimes immediately upstream or downstream of a control device. This information is helpful for understanding flow capacity and sizing.

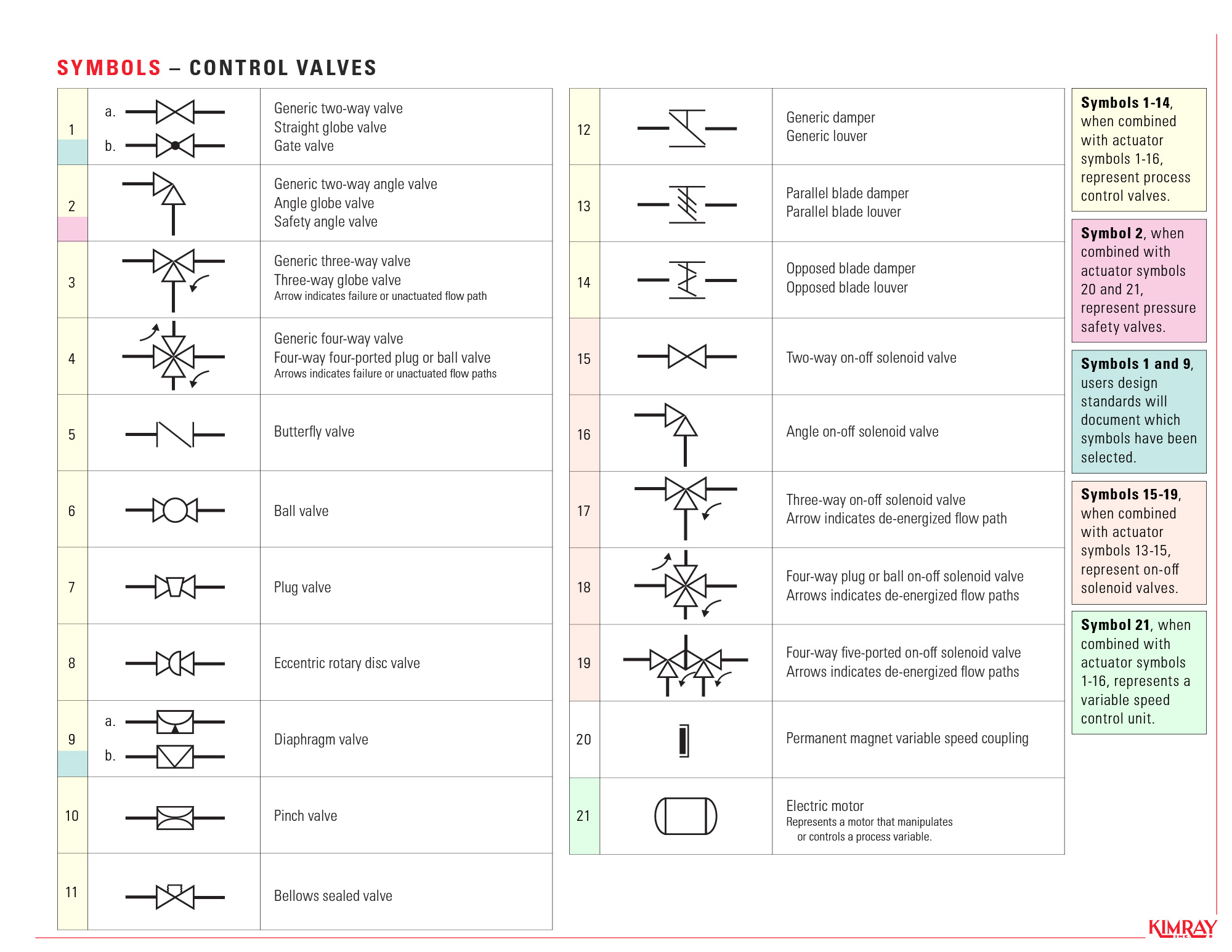

Control Valve Symbols

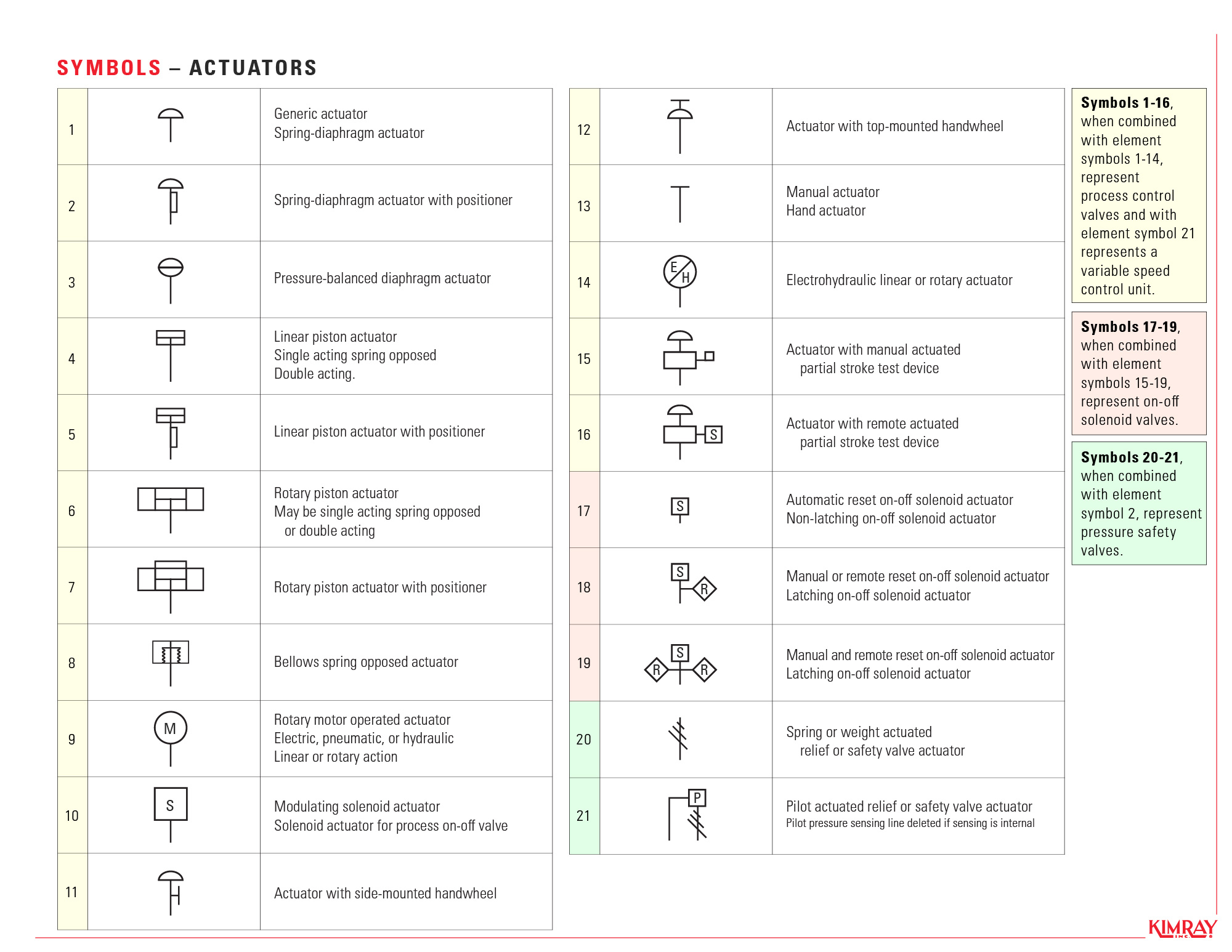

P&ID symbols can sometimes change from company to company. This is especially true with control valve symbols. This chart of common control valve symbols can be downloaded for reference but always consult the P&ID legend if available.

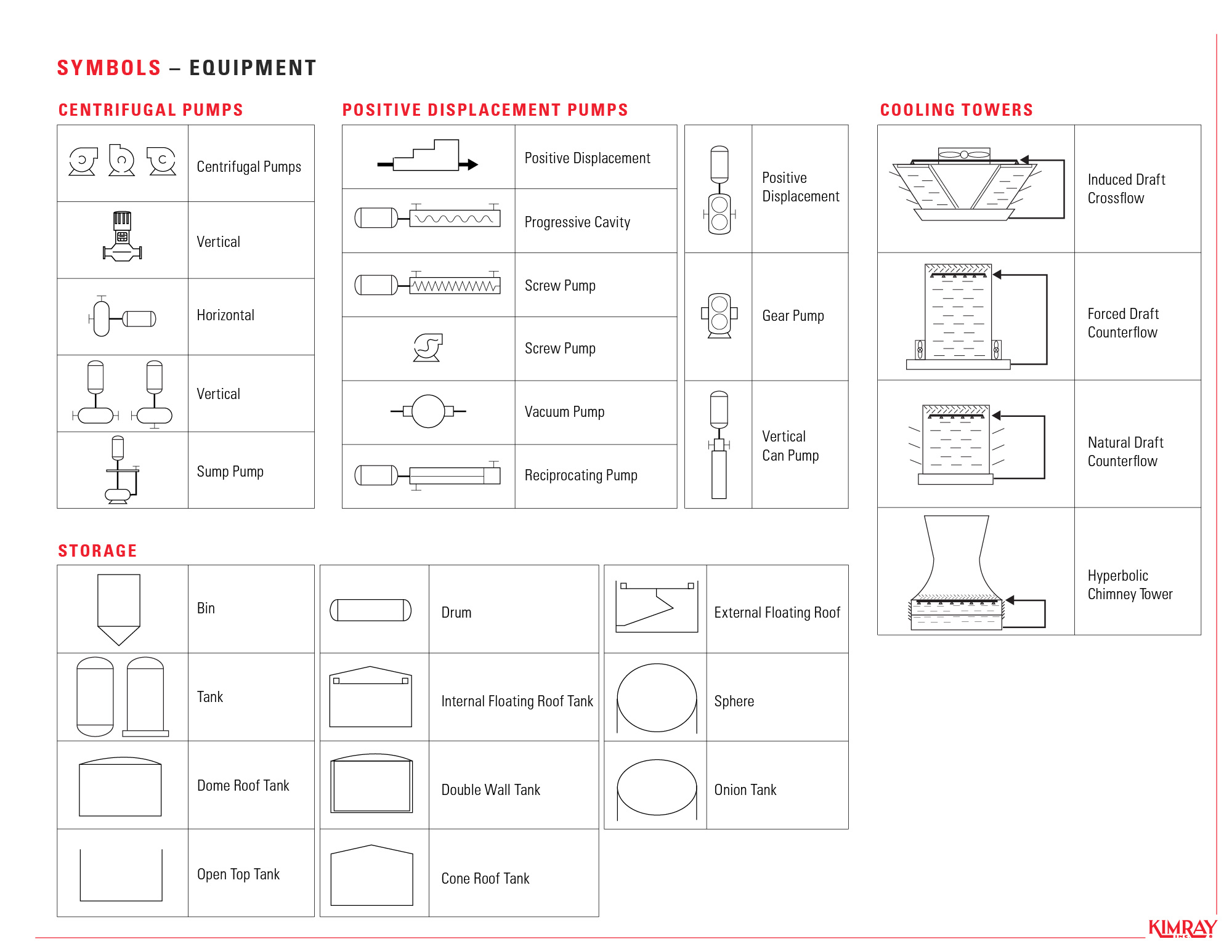

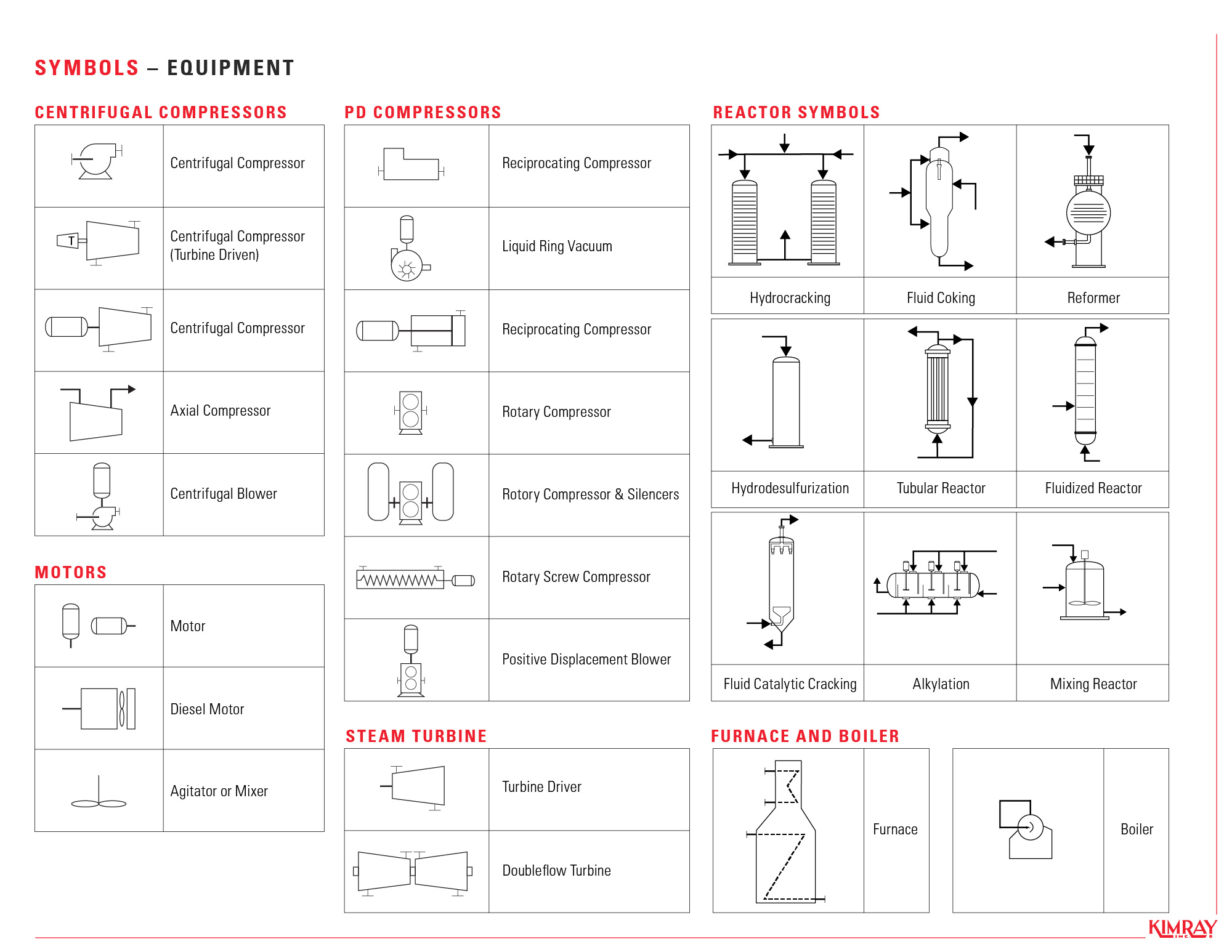

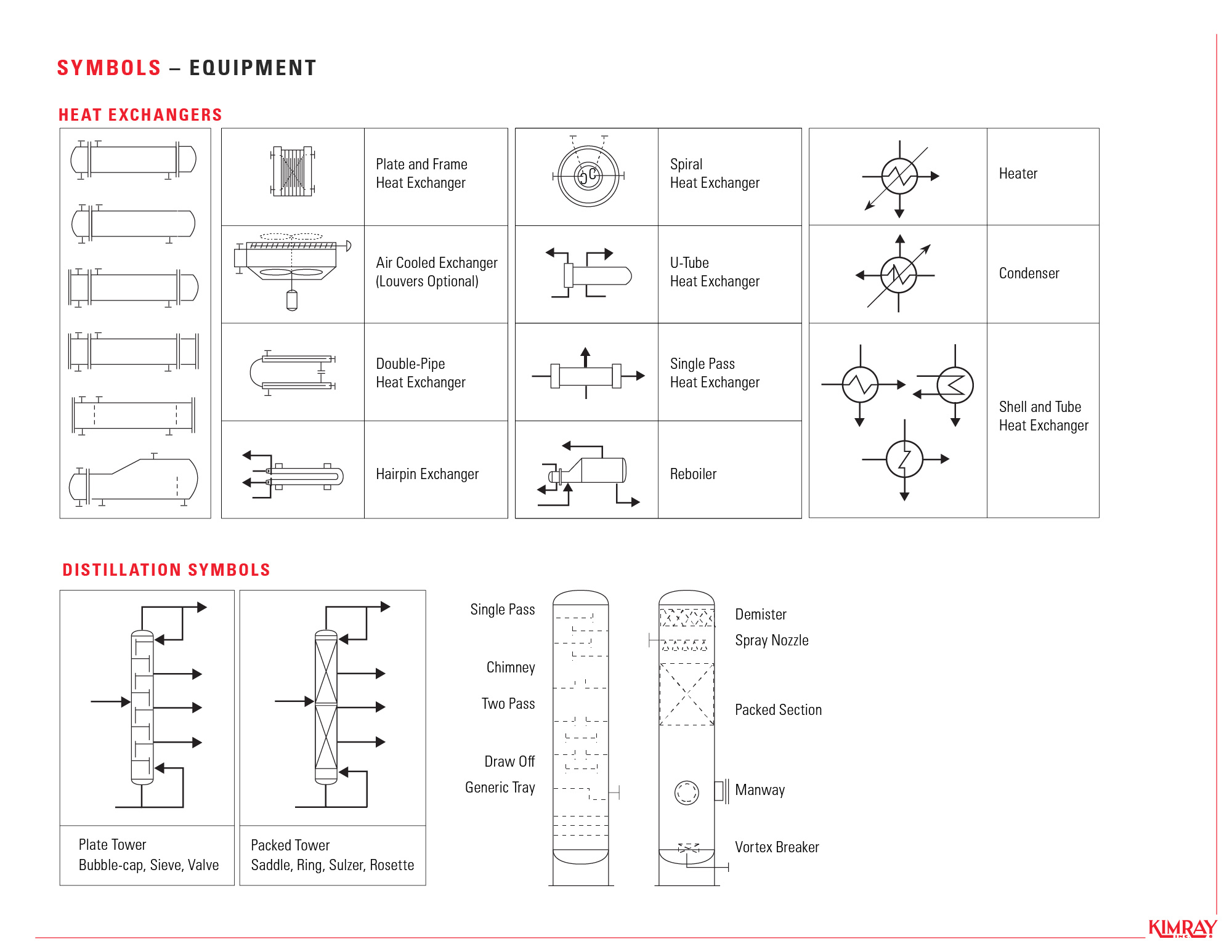

Pumps, Tanks and Other Types of Equipment Symbols

Here are the symbols for pumps, tanks, and other types of equipment. The most common pumps used in oil and gas industry are screw, progressive cavity, and reciprocating pumps. The most common tanks are dome roof tanks.