Liquid level is a critical parameter in oil and gas production vessels like separators, free water knockouts, and gas scrubbers.

Kimray has three types of float-operated liquid level controllers:

- The Gen 3, which uses a displacer to control an adjustable span of liquid level

- Trunnion assemblies, which use hollow floats and work in conjunction with lever operated dump valves

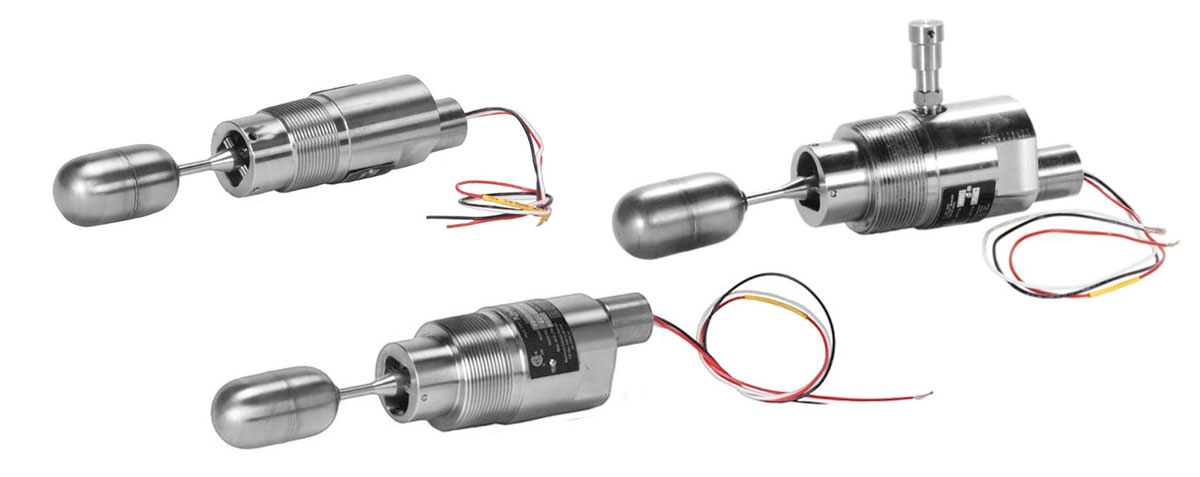

- Level switches, which use small floats for on/off control

In this video, we'll review the Level Switch and look at the features that make it so useful to producers worldwide.

Applications

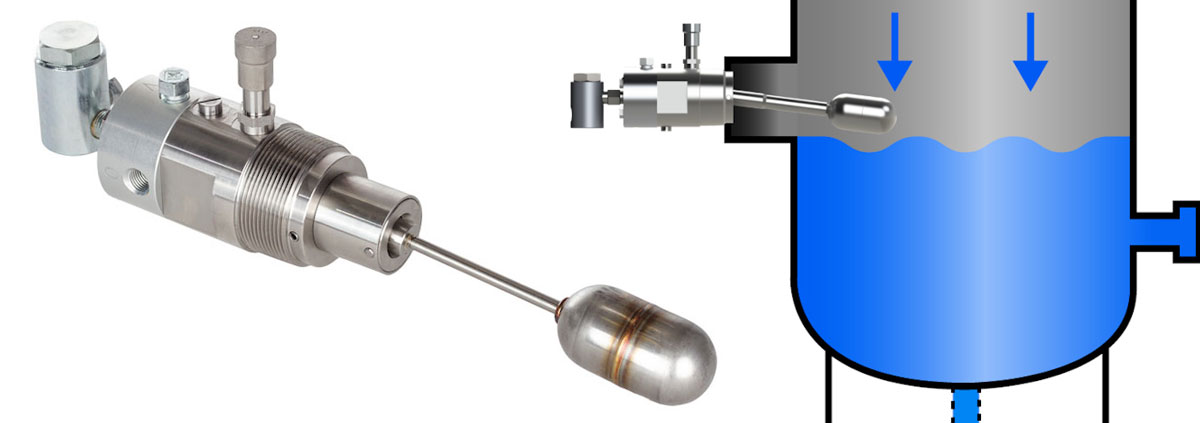

The level switch is a simple, on/off switch ideal for high pressure applications requiring high- or low-level shutdown.

It can also be used in place of a level controller with a displacer, for on/off service in tight spaces such as a 12” diameter vertical separator or any other liquid level control application where a span is not needed.

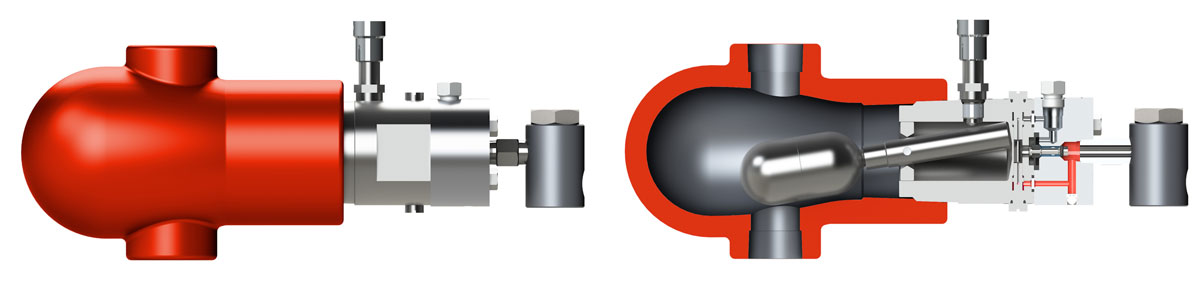

External Float Cages

A Kimray external float cage can be used to separate the float from the turbulence that occurs inside the vessel.

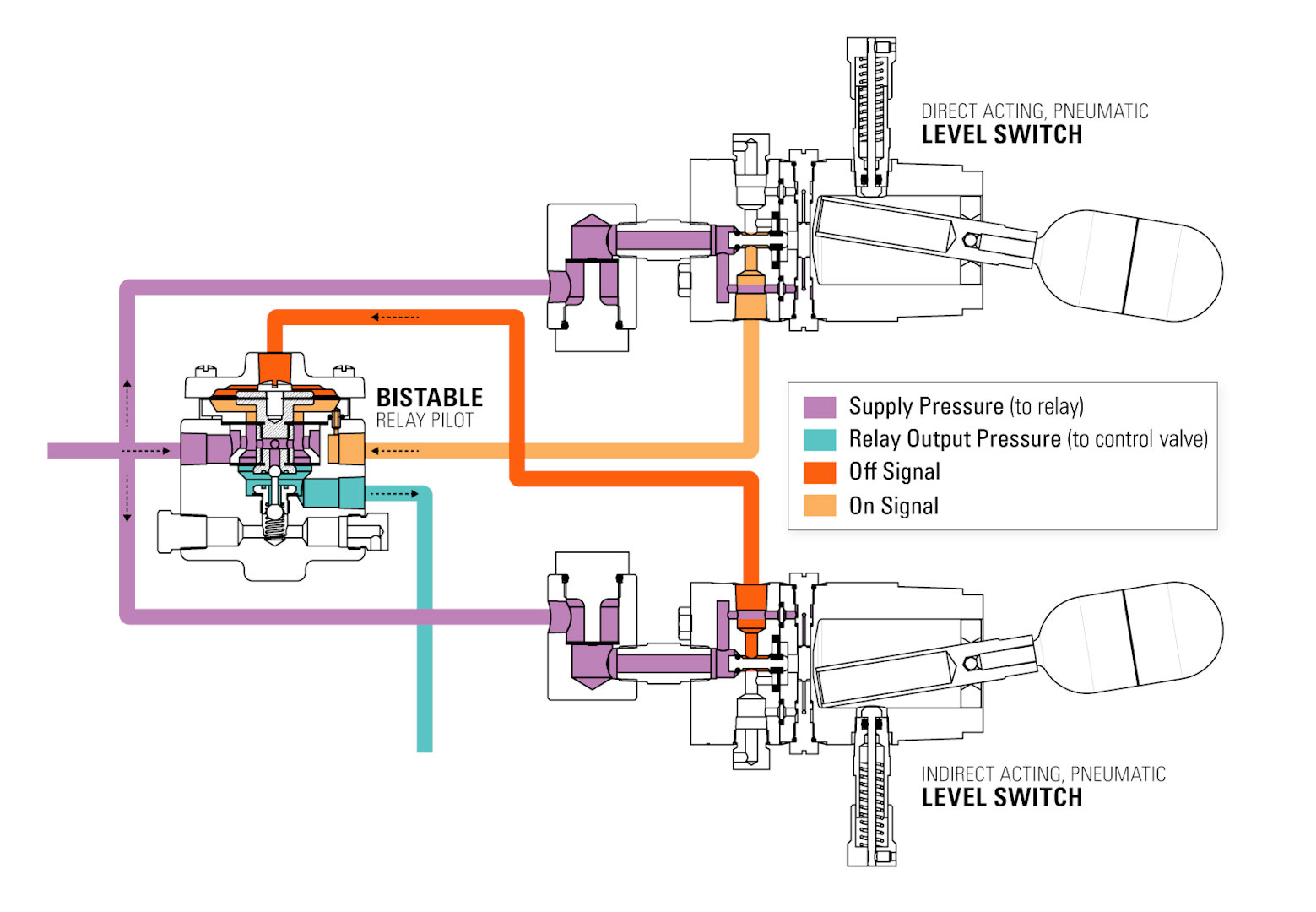

For liquid gap control, you can use two external float cages, two level switches and a relay. The level switches work in tandem and the liquid level oscillates between both level switches.

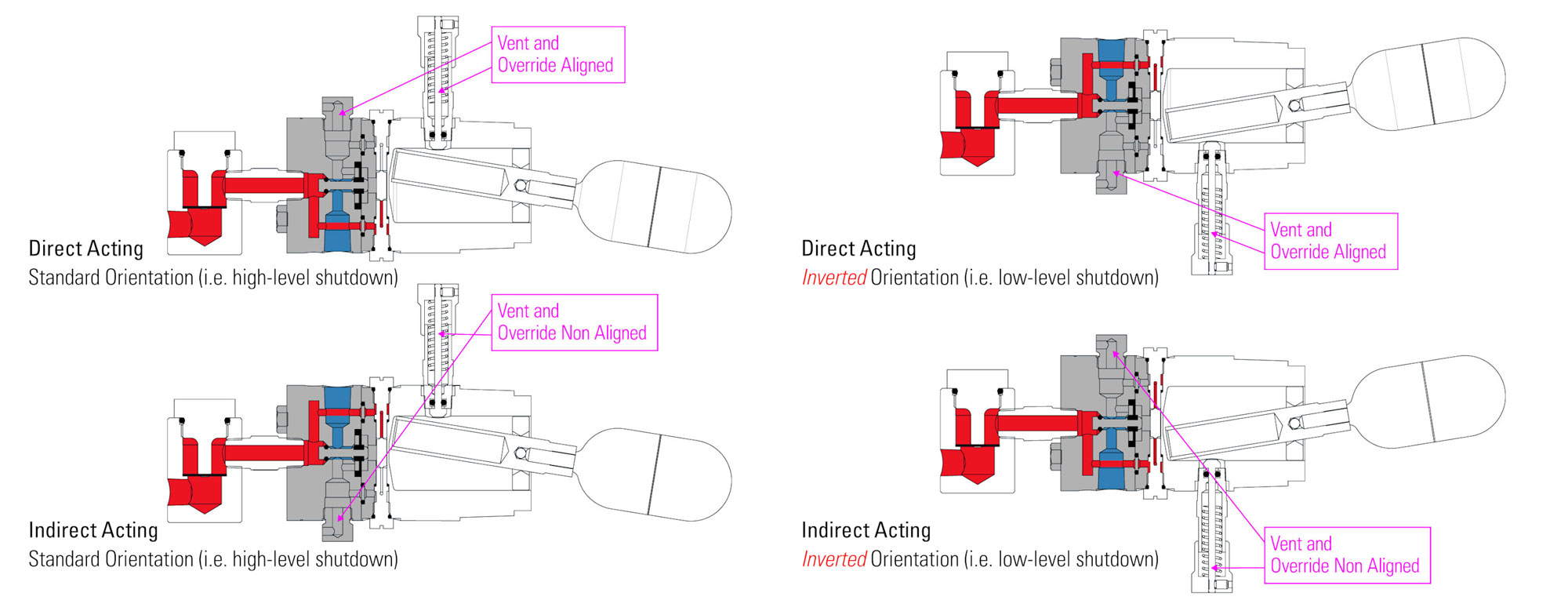

Direct- or Indirect-Acting

The level switch is field-reversible from direct acting to indirect acting, so it can be used in conjunction with a fail-open or fail-closed control valve.

You can easily convert the pneumatic switch from direct to indirect by rotating the pilot body 180º.

The electric level switch can also be converted by changing the wiring from “normally open” to “normally closed” or vice versa.

Manual Override

A convenient manual override button can be used to test the function of the level switch attached to a vessel. Using the override manually actuates the float.

This allows you to check if a dump valve is operating correctly and you're getting supply gas or air through the whole system.

Options

If you need an extension to give the float more clearance, we offer a 3” extended version of the pneumatic level switch.

Low-temperature options are also available, capable of handling much lower temperatures where needed.

Easy to Repair

Operators can easily install simple product repair kits to ensure accurate level control for years to come. It can also be repaired without being removed from the piping.

3 Options for Emissions-Free Operation

There are three options for operating a level switch while releasing zero emissions.

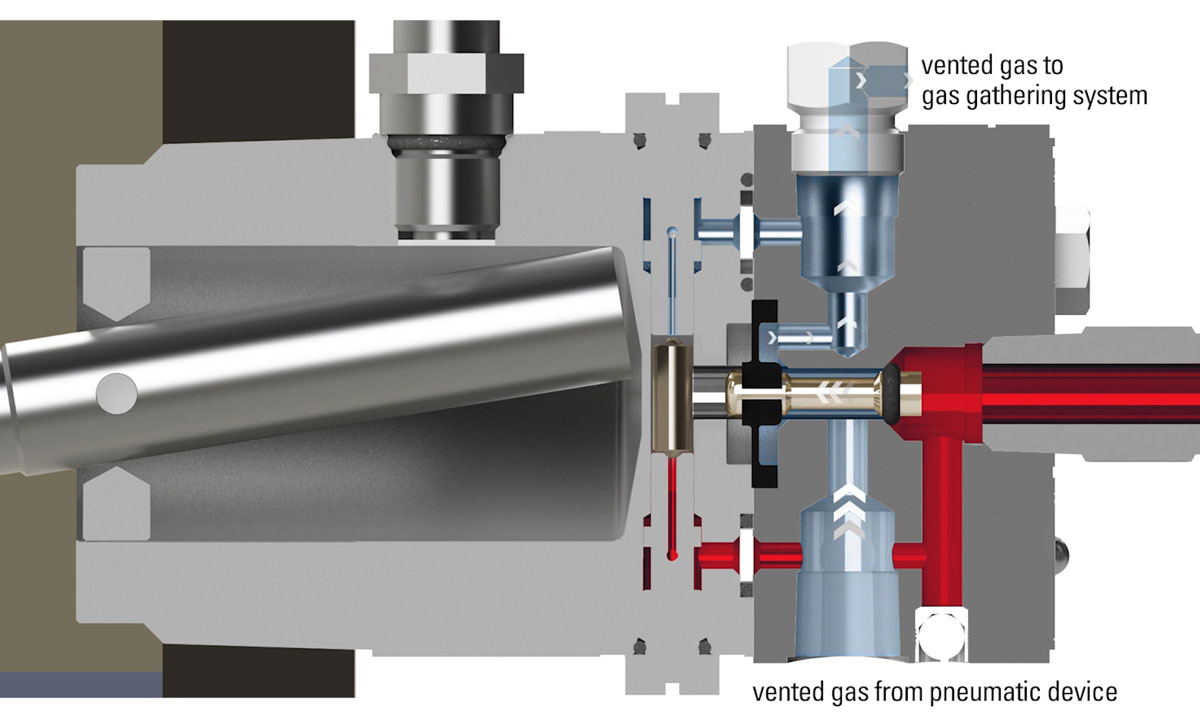

Capture the Gas

The vent port on the level switch is threaded and can be connected to capture vented gas into a gas gathering system.

Outside Supply

Use an outside pneumatic supply such as nitrogen or compressed air.

Electric Level Switch

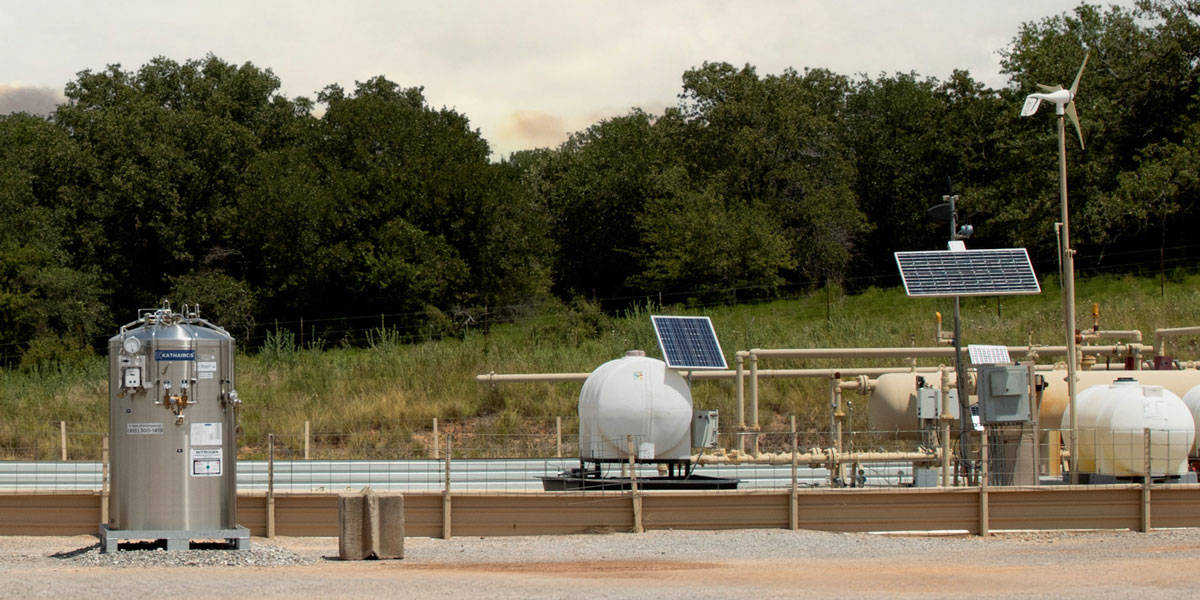

In an industry moving towards automation and process monitoring, there is a need to operate with PLCs, RTUs, and other systems.

An electric level switch operates just like the pneumatic version, except the output signal is electric rather than pneumatic. The low-power electric switch covers the range of 0-25W of power, pairing well with modern automation equipment.

Certifications

Manufactured and assembled in the USA, our liquid level switches are certified for use in North and South America and most areas around the world.

Both the pneumatic and electric models are built with NACE MR0175 compliant wetted parts and can be certified with documentation upon request.

We have 25 distribution centers in the U.S. and international distribution partners globally. Kimray is also an ISO 9001-certified manufacturer.

Reach out to your local Kimray representative today to explore how we can help solve your control challenges.