Oil and gas producers have to deal with two types of downtime: planned and unplanned.

Unplanned vs. Planned Downtime

Unplanned downtime happens when a piece of your equipment, like the valve we saw earlier, goes unchecked for a period of time and is compromised. Production equipment is under constant wear, especially control valves, where the tight flow paths can experience abrasive production fluid at its highest velocity.

The reality is your valves and regulators will need to be repaired at some point. With unplanned downtime, you don’t know when that will be. But when it happens, it will be a problem.

- It will probably come at an inconvenient time for your team.

- You may have hazardous material to account for and clean up.

- You may not have the repair components you need on hand, so you’ll have to wait for it to be shipped.

All the while, you are losing valuable production time on your wells.

This is why we strongly recommend a consistent schedule of planned downtime for preventative maintenance.

With scheduled preventative maintenance, you can:

- Ensure the appropriate team members are on site

- Have all parts on hand

- And prevent environmental hazards like spills and fugitive emissions

How Often Should You Perform Preventative Maintenance on an Oil and Gas Well Site?

We’re often asked how often you should check your equipment.

This depends largely on your production conditions. If you are in the early stages of production, it may need to be as often as every two weeks. For legacy operations that are seeing lower production volumes, we recommend preventative maintenance every 1 year at minimum.

What does preventative maintenance look like?

It will differ from company to company.

- One good practice is to have a rotating inventory of valves and regulators. This way when you shut down, you can just switch out equipment.

- Other producers schedule a day to shut down a particular site and complete repairs on their valves and regulators in line.

Either way, we recommend keeping a good stock of Kimray repair kits and valve components on hand.

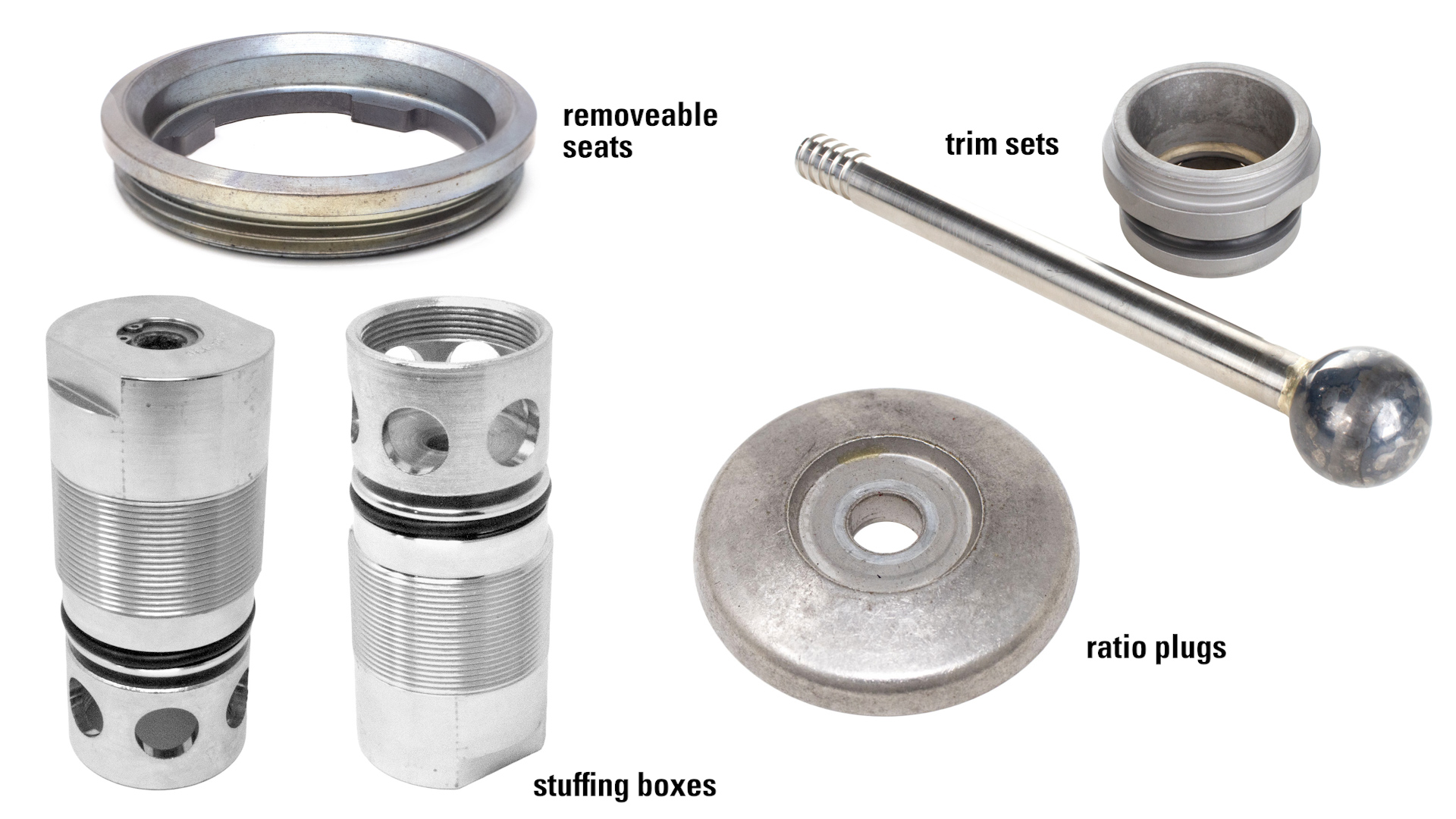

Repair kits are stocked with items like o-rings and diaphragms for your specific valves and regulators.

But we also recommend having components like valve trim sets on hand, which need to be ordered separately from the repair kits. You can find these items in the Technical Specifications document for your product.

Kimray Field Service technicians are now available in some areas to provide preventative maintenance. These product experts can come to your operation and provide maintenance on all your Kimray products.