Energy producers use products like Kimray's Electric Actuator to provide accurate, emissions-free control of their production processes. In this video, we'll learn how to wire it in and install it for operation in oil and gas applications.

How to Install an Electric Actuator on a Control Valve

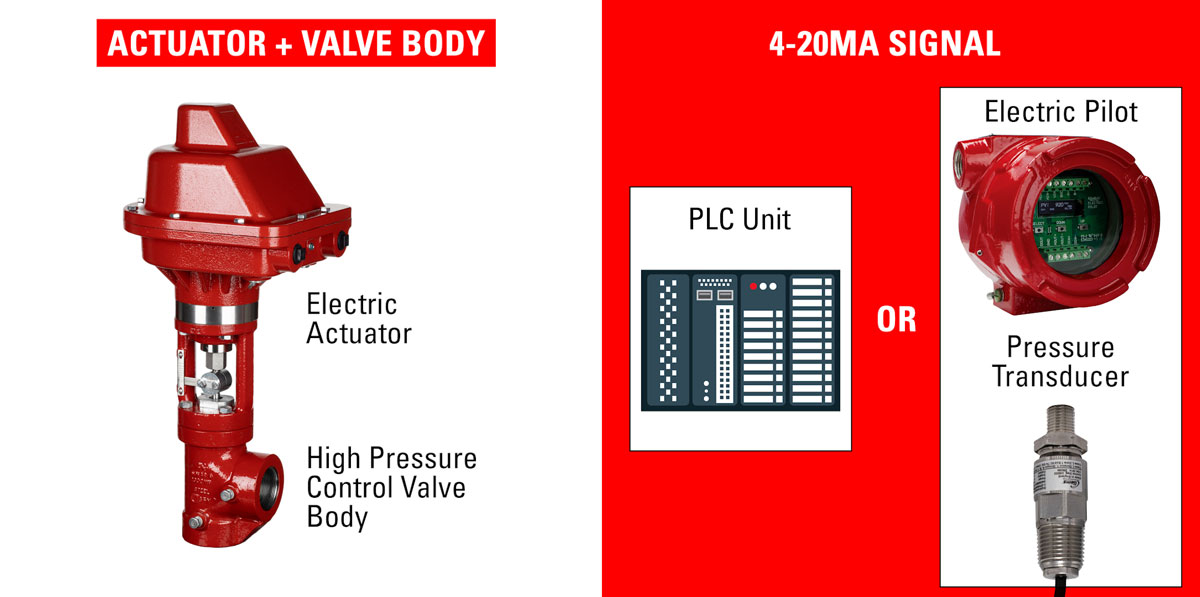

To install and operate your Electric Actuator, you’ll need two things:

- High Pressure Control Valve Body

- 4-20ma signal provided by either a PLC or an Electric Pilot with a Pressure Transducer

For this example, we are using an Electric Pilot and a Pressure Transducer. If you are using a transducer, make sure you are using the correct size for your conditions.

- Connect Your Wires. For this process, you will need wire strippers, a 7/64" Allen wrench, and a termination screwdriver.

- Thread the Pilot onto the Actuator using a Nipple. Depending on your site, you may need to mount it closer to the transducer.

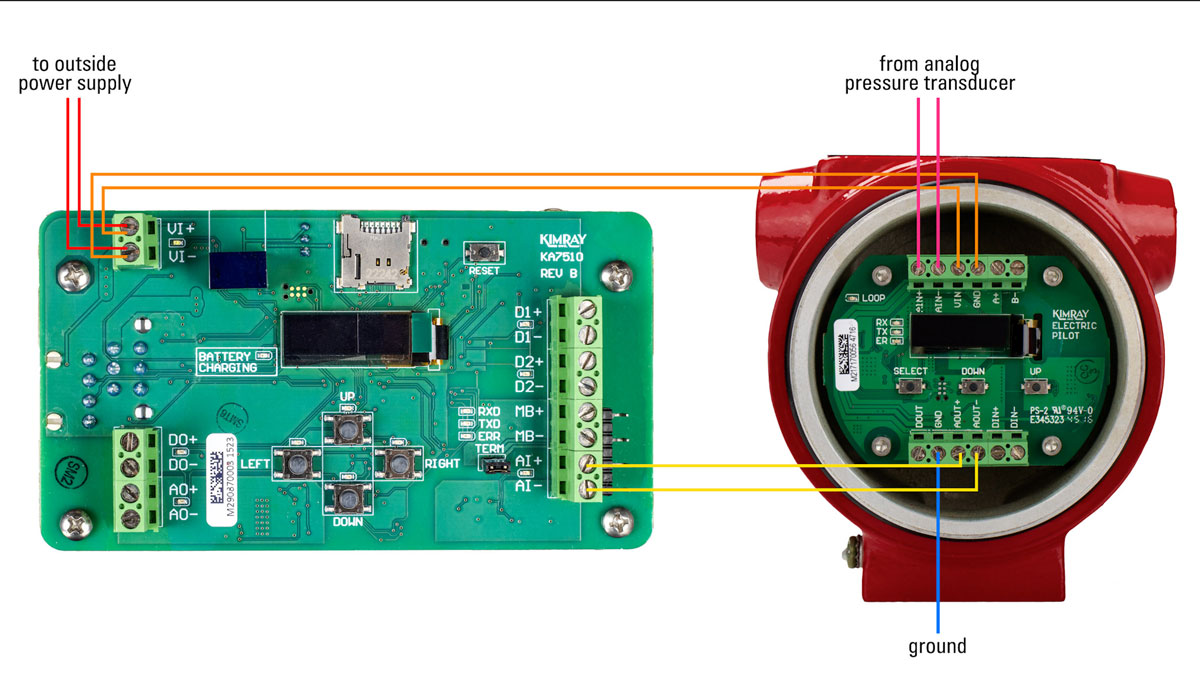

- Pilot Analog In. Take the wires coming from your analog pressure transducer and terminate them to the Pilot in the Analog IN positive and Analog IN negative terminals.

- Pilot Analog Out. Connect another set of wires to the Analog OUT positive and Analog OUT negative terminals.

- Actuator Analog In/Out. Run these wires to the Analog positive and Analog negative terminals on the actuator.

- Actuator Voltage In. Connect the power wires to the actuator in terminals Voltage In Positive and Voltage In Negative. For this installation, we are using 24 Volts DC. The Electric Pilot can share power with the Actuator.

- Pilot Voltage In. Run these wires to the Pilot and terminate them alongside the incoming power on the Voltage IN and Ground terminals.

How to Setup an Electric Actuator for Back Pressure Regulation with an Electric Pilot

Now that wiring is completed, we can select our set points. This will be done with either your PLC and a laptop or an Electric Pilot.

For this example, we will be setting it up for back pressure regulation. The set up for pressure reducing regulation is very similar.

Step 1. Select Sensor Type

- Press the Select button until you reach Sensor Type.

Step 2. Set Pressure

- Press the Up button.

- Press the Up button again until you reach Pressure.

- Press the Select button.

- Press the Up button until you reach your units of pressure.

- We will be using PSI.

- Press Select.

- Now use the Up and Down buttons to set the maximum and minimum working pressures of your pressure transducer. For this example, we’ll say the transducer maximum is 2000 PSI and minimum is 0 PSI.

- Press Select.

Step 3. Select Application

- Now it will display control settings. Press Up to get to the Application menu.

- Use the Up or Down buttons to cycle through and select your application.

- We will be using Back Pressure.

- Press Select.

Step 4. Enter Set Value

- The next menu is for Set Value.

- Use the Up and Down buttons to scroll to your desired set point. In this example, we’ll use 650 PSI.

- Press Select to enter that value.

Step 5. Select Mode

- Now press select until you get to the Mode Menu.

- Use the Up or Down buttons to cycle through and select Manual mode.

- Move the Controller Output to 50%. This will open the valve approximately halfway and allow pressure to flow through.

- Press Select.

- Press Select until you get back to Mode Menu.

- Press the Up button and select Autotune.

- The Pilot will now send varying signals to the valve to see how it reacts. This should take 10-15 seconds.

- Once it has completed Autotune, it will automatically move to Run Mode and begin controlling your set value.

Now your pilot, actuator, and valve are set up for back pressure regulation. You can leave the pilot on this screen, and it will move to standby mode after approximately four minutes.

If you ever need to change your Set Value, you won’t need to run autotune again. You will only need to do that if you change your valve or trim size.

The setup process with the electric pilot is similar for other applications.

If you have any questions about how to set up your Electric Actuator or the components you will need on your specific site, contact our Product Support team.