The Kimray High Pressure Control Valve is a versatile solution for all your oil and gas production needs.

It can be used as a dump valve, pressure regulator, suction controller, recirculation valve, as well as in plunger lift applications.

Choosing Your High Pressure Control Valve

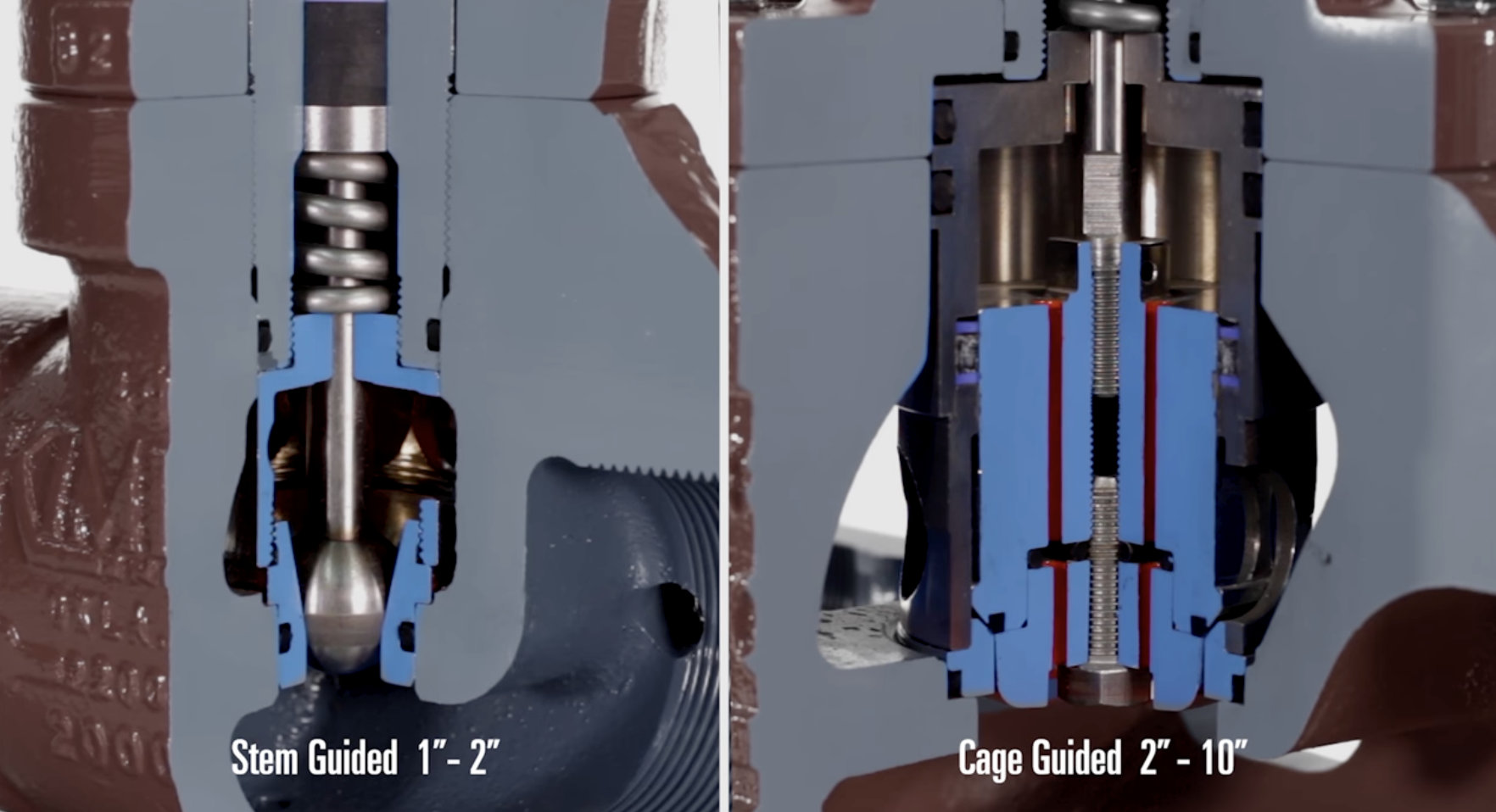

There are two options to choose from: Stem Guided or Cage Guided.

- Stem Guided connection sizes range from 1-2”

- Cage Guided connection sizes range from 2-10”

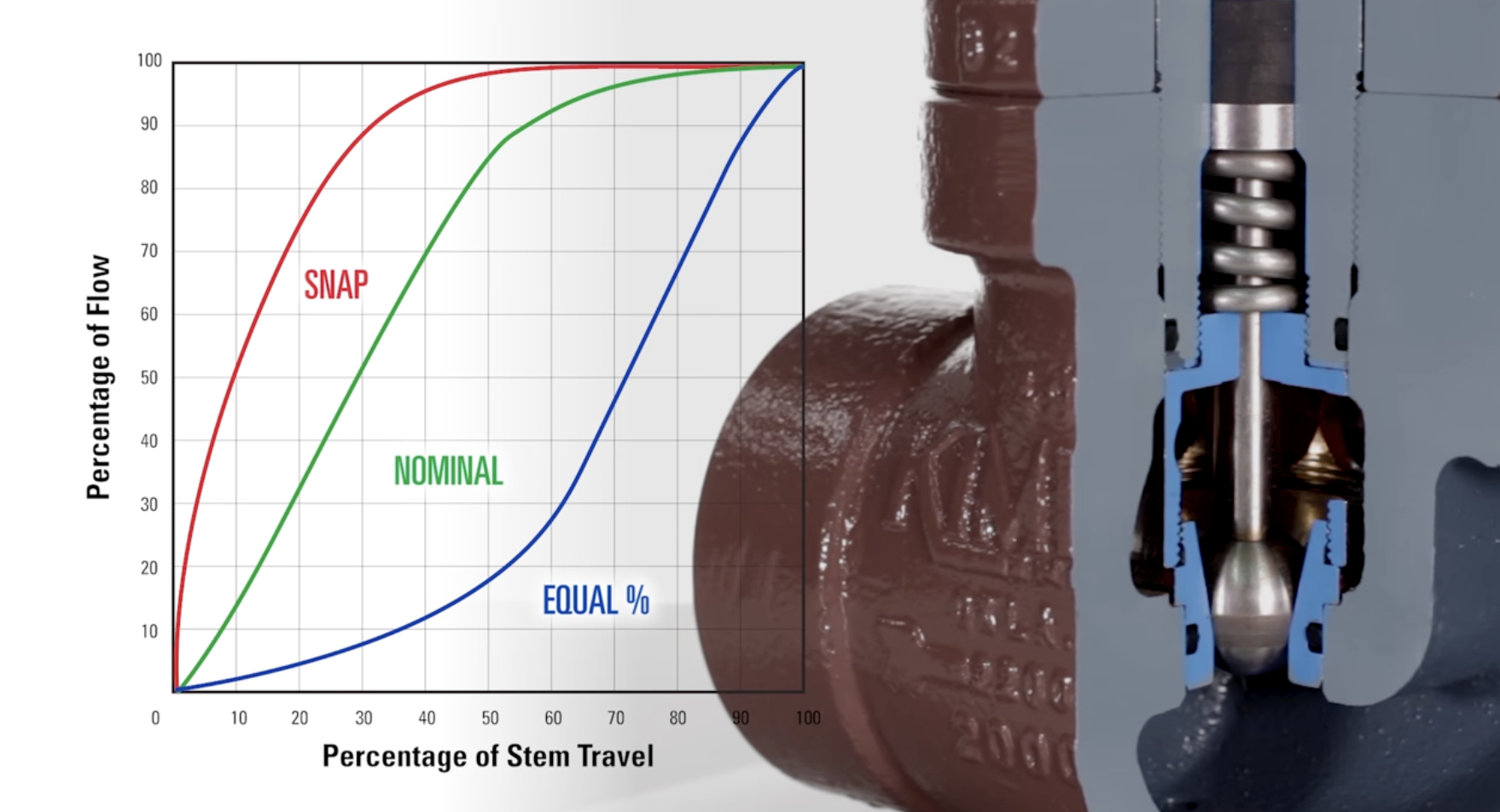

The stem-guided valve can be configured with either snap, nominal or equal percentage trim. This allows you to use it for a liquid dump or gas control application. If your conditions change, these trim sets can also be swapped out in the field without taking the body out of line.

How It Works

The valve will remain in its fail position until it’s told to do otherwise by a pilot or liquid level controller.

In a liquid dump application, it will receive a pneumatic signal from a liquid level controller to open and dump the liquid.

In a pressure regulating application, one of our pressure pilots will be monitoring either upstream or downstream pressure, and when it needs to make an adjustment, it will send a pneumatic signal to the valve actuator to open or close it.

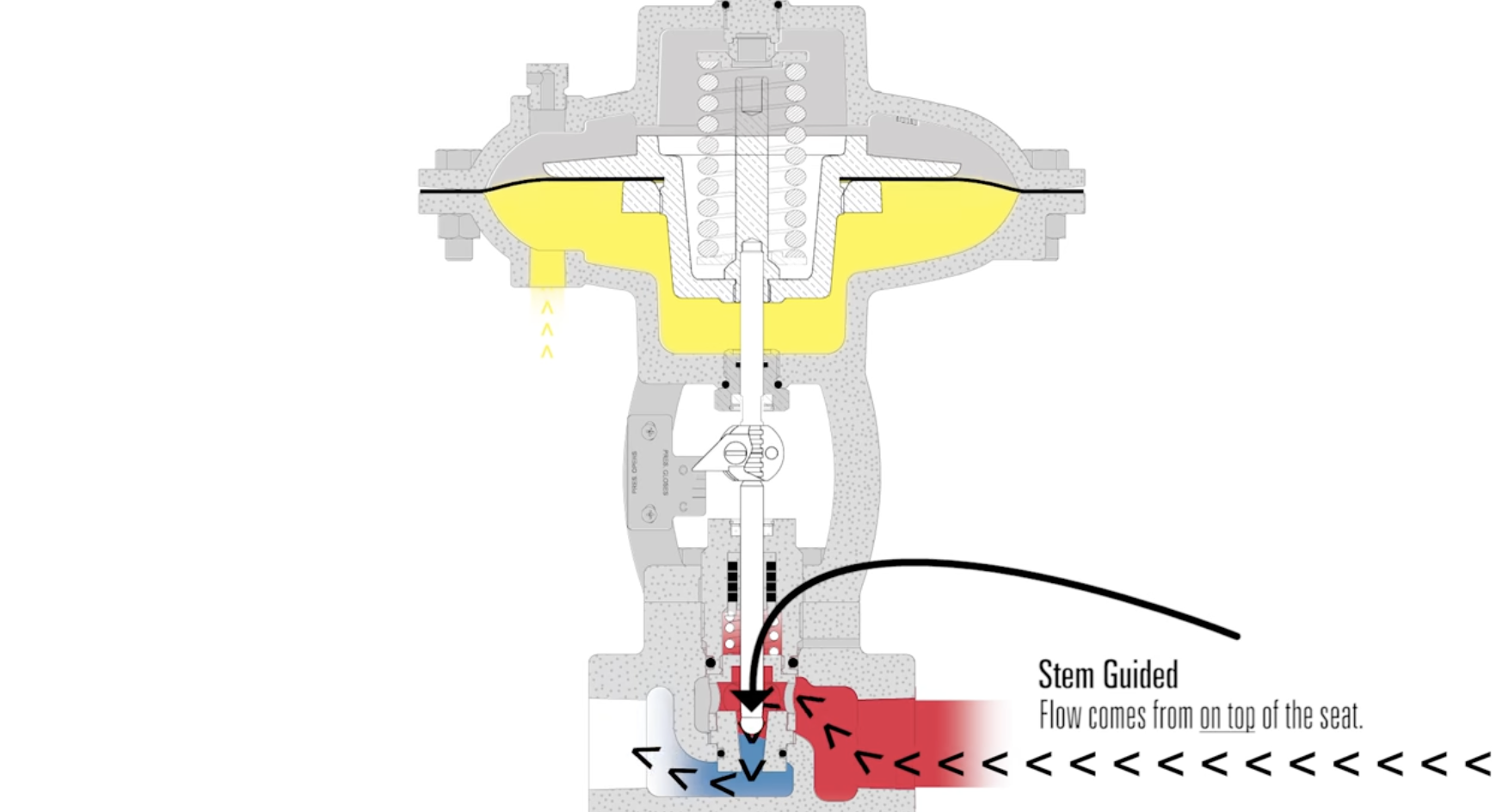

Flow Path: Stem Guided

The flow through the Stem-Guided High Pressure Control Valve comes from on top of the seat. This valve offers precise control with the small Cv trim options.

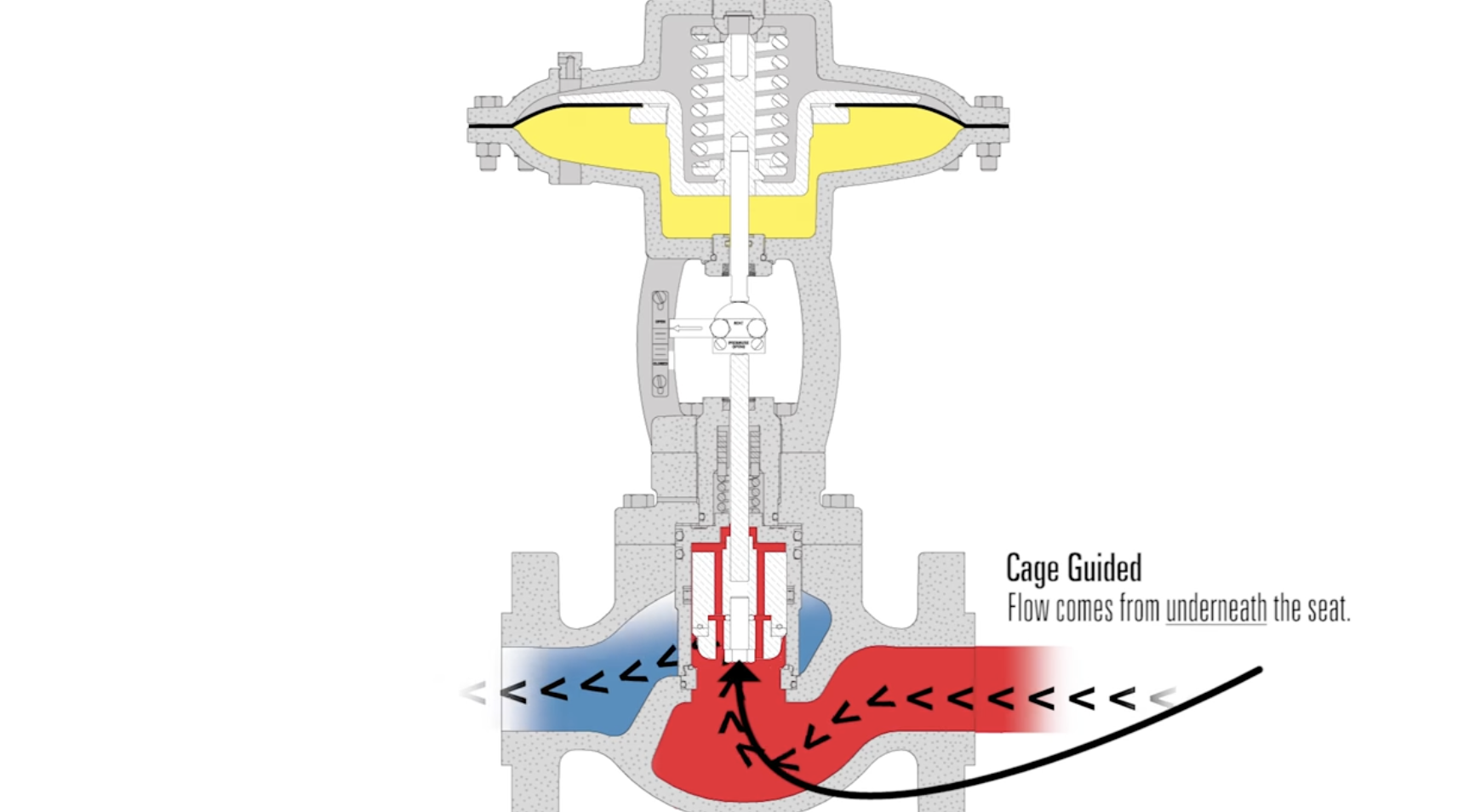

Flow Path: Cage Guided

The flow through the Cage-Guided High Pressure Control Valve comes from underneath the seat. The upstream pressure moves through the two communication holes inside the piston. This equalizes the pressure on the top and bottom of the piston.

This means that the valve is balanced, so regardless of how large your pressure drop is, the valve can be opened or closed by a standard pressure of supply gas from the pilot.

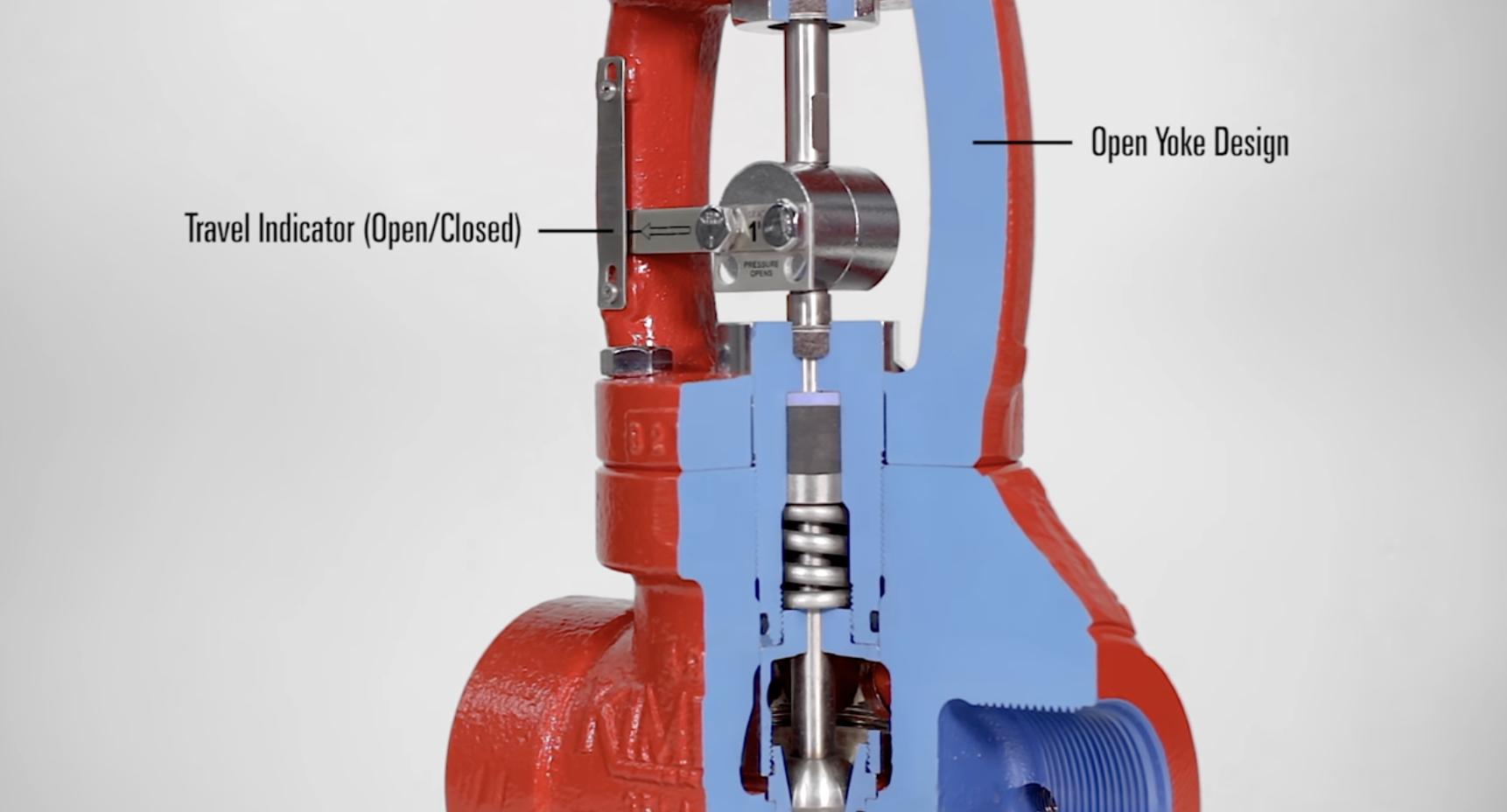

Position Indication and Conversion

The open-yoke design on both of these valves gives us an indication of valve travel. This also allows early detection of packing wear to indicate whether you need to change the packing.

High Pressure Control Valves can be field converted to fail open or close with simple hand tools, and there’s no need to purchase any additional parts.

These valves are also compatible with electric actuators for zero-emission, automated control.