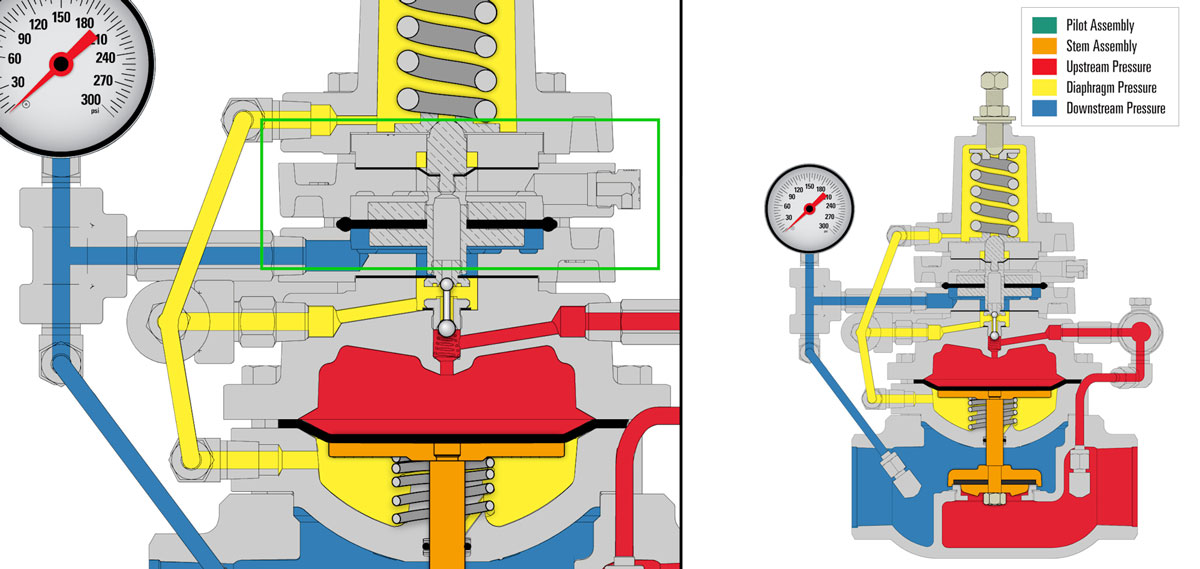

A Pressure Reducing Regulator monitors and controls downstream pressure. It is an integrated valve because the pilot and the valve body are one piece.

With the adjusting screw unthreaded, there is no tension on the pilot assembly to move the valve to an open position.

Upstream pressure flows into the inlet and is blocked by the closed seat in the valve body. Upstream pressure also travels through the tubing into a filter housing where debris and trash are caught to prevent malfunction.

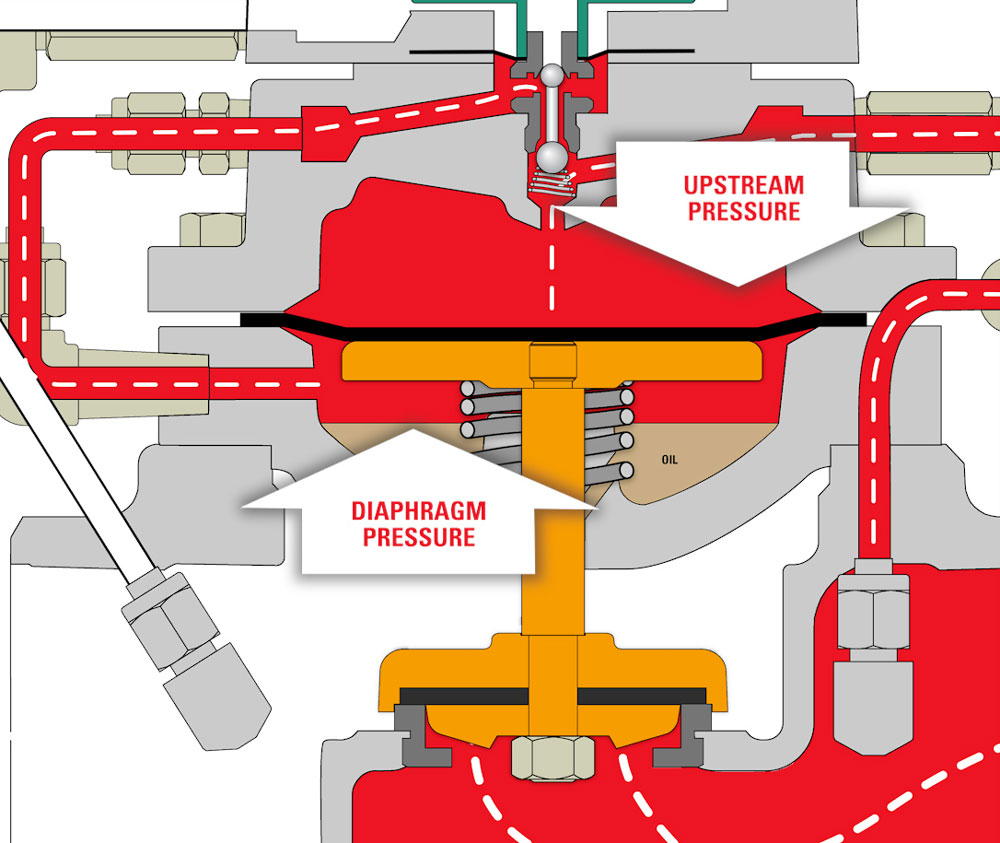

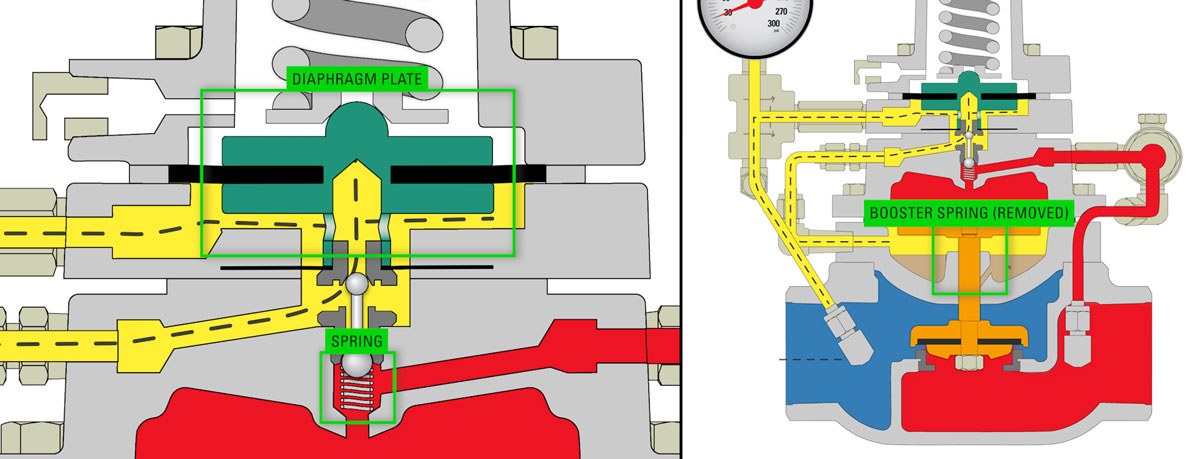

The flow continues underneath the pilot plug and fills the cavity of the motor valve diaphragm. This pushes down on the diaphragm, diaphragm plate, stem, and seat, keeping the valve in the closed position. Because the motor valve diaphragm area is twice that of the seat, the regulator can be held in a closed position with equal pressure on both surfaces.

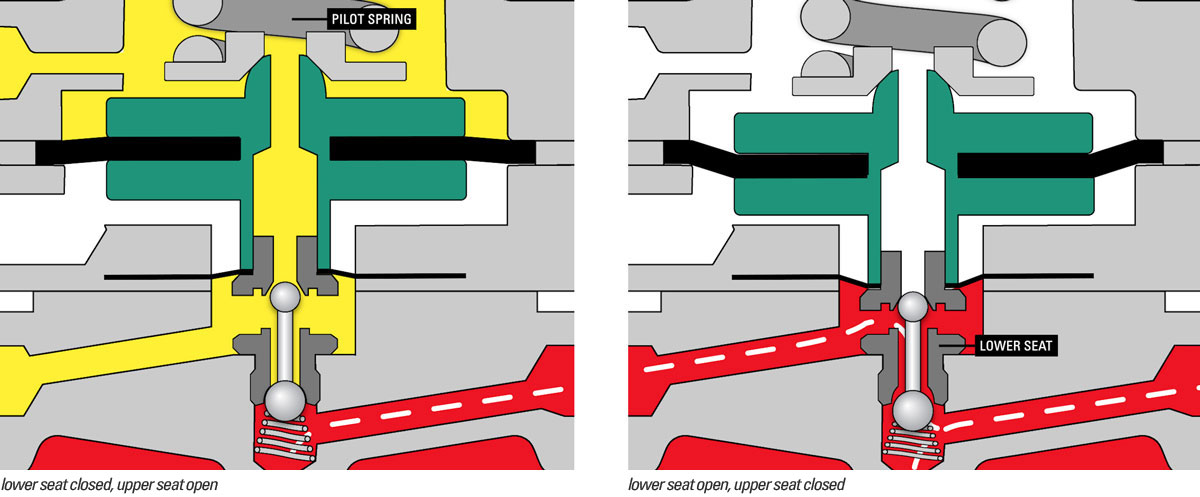

The pilot plug lower seat is closed, blocking upstream pressure. The pilot plug upper seat, which is the pressure vent, is open, allowing diaphragm pressure to vent from underneath the motor valve diaphragm and the valve seat to be in the closed position.

When the adjusting screw is tightened and the pilot spring tension is greater than the downstream pressure, it forces the pilot assembly to move down.

This positions the pilot plug to open the lower seat and allows full upstream pressure to now flow into the cavity of the motor valve diaphragm.

Now the pressures are equalized on both sides of the diaphragm and the upstream pressure can push open the valve seat.

The booster spring aids in the regulator's opening by pushing up on the diaphragm plate, helping raise the valve seat.

The pilot plug movement adjusts the amount of pressure in this cavity, repositioning the stem and seat assembly to control the downstream setpoint. If downstream pressure exceeds the pilot spring tension, which is your set point, it pushes against the pilot spring assembly, closing off the lower seat and unseating the upper seat, which is the pressure vent.

Gas that has been holding the valve open then vents from underneath the motor valve diaphragm to atmosphere, allowing the valve to close and the downstream pressure to be regulated.

With the downstream pressure neither above nor below the set point, the pilot assembly assumes a position in which both seats of the pilot plug are closed. The regulator will maintain and control a constant downstream pressure set point.

Non-Vent Pressure Reducing Regulator

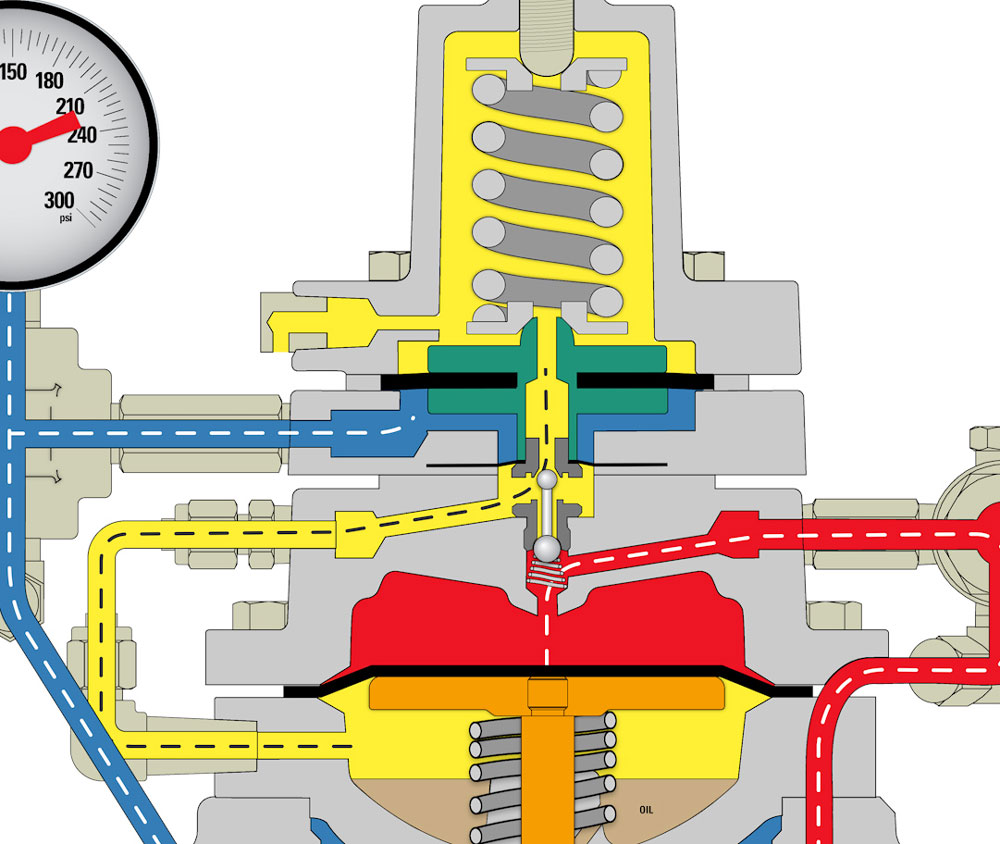

In the non-vent model, the flow path to atmosphere is blocked and redirected downstream. You can convert from a standard PR to a non-vent PR by changing just the diaphragm plate.

Balanced Pressure Reducing Regulator

In the pressure reducing balanced (PRB) model, the diaphragm pressure is communicated to the motor valve diaphragm cavity and to the regulator's pilot housing. There is an extra housing, pivot screw, spacer and a balancing diaphragm that give this regulator a 100:1 set point drift ratio.