In this video, we look at gas flow through a High Pressure Back Pressure Package controlled by a Diaphragm Controlled High Pressure Pilot and then with a Bellows Controlled High Pressure Pilot.

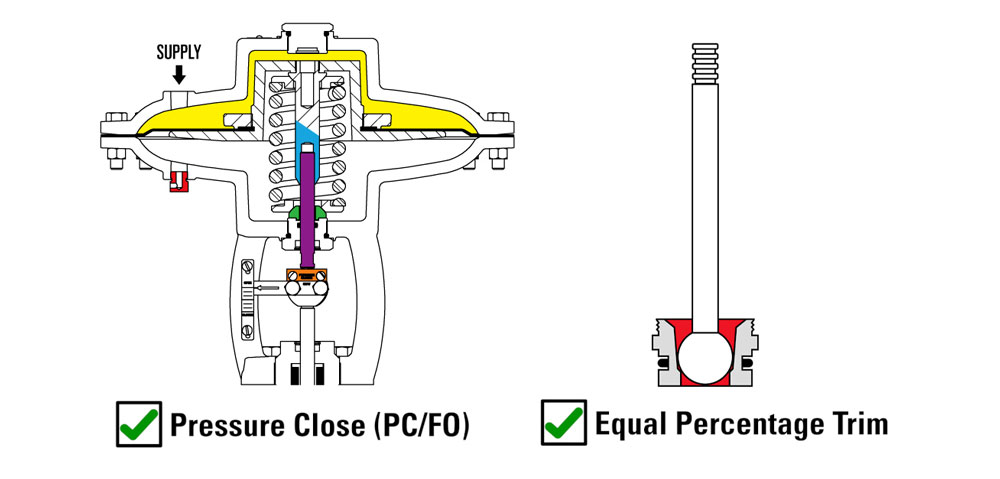

Both are in the standard configuration as pressure-to-close (also called fail-open) and with equal percentage trim.

Note: The amount of movement shown in this animation is exaggerated to demonstrate the working concept.

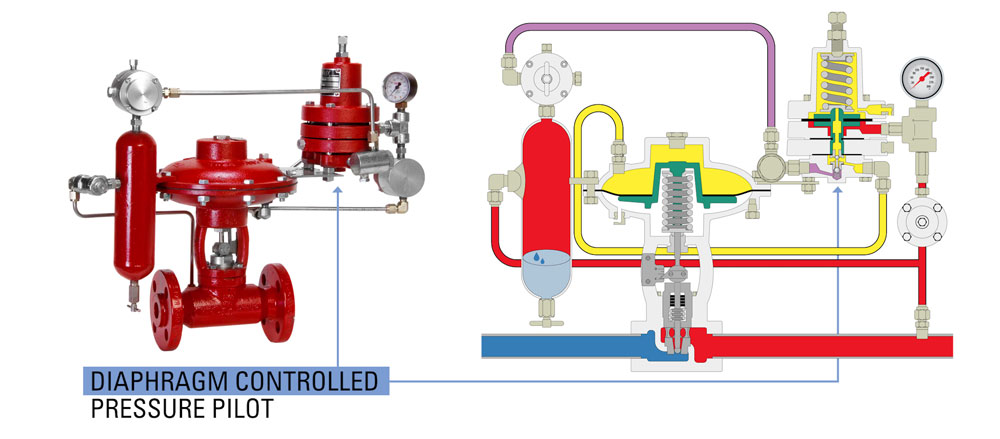

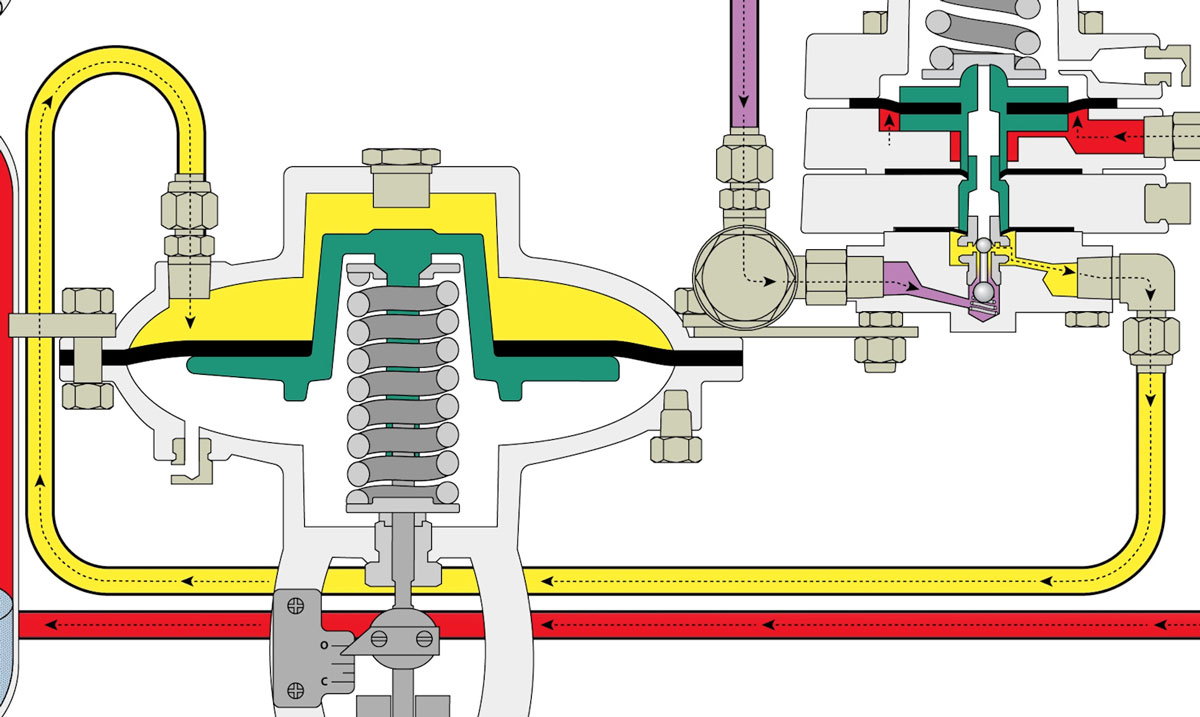

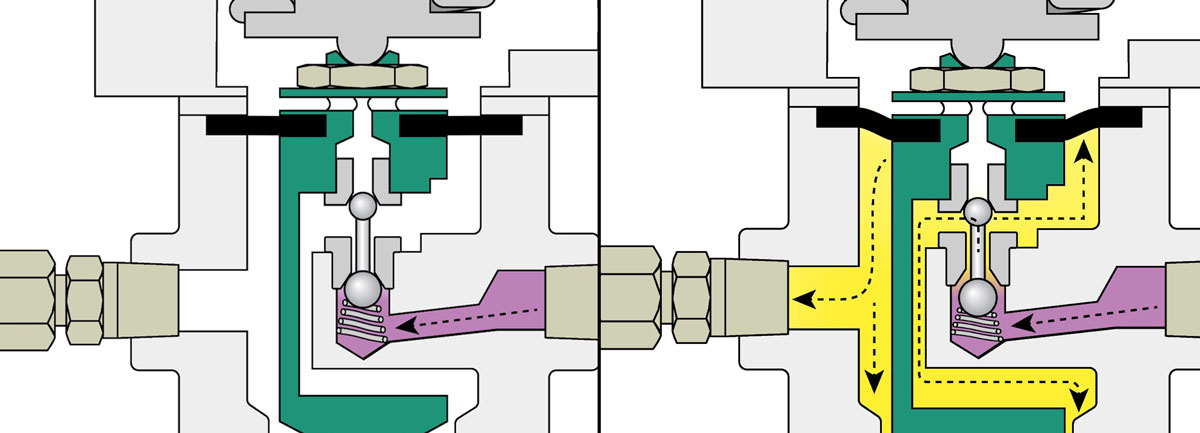

How a Diaphragm Controlled Back Pressure Package Works

First, we’ll look at a High Pressure Back Pressure Package with a Diaphragm Controlled High Pressure Pilot. This pressure pilot controls between 10 and 300 PSI.

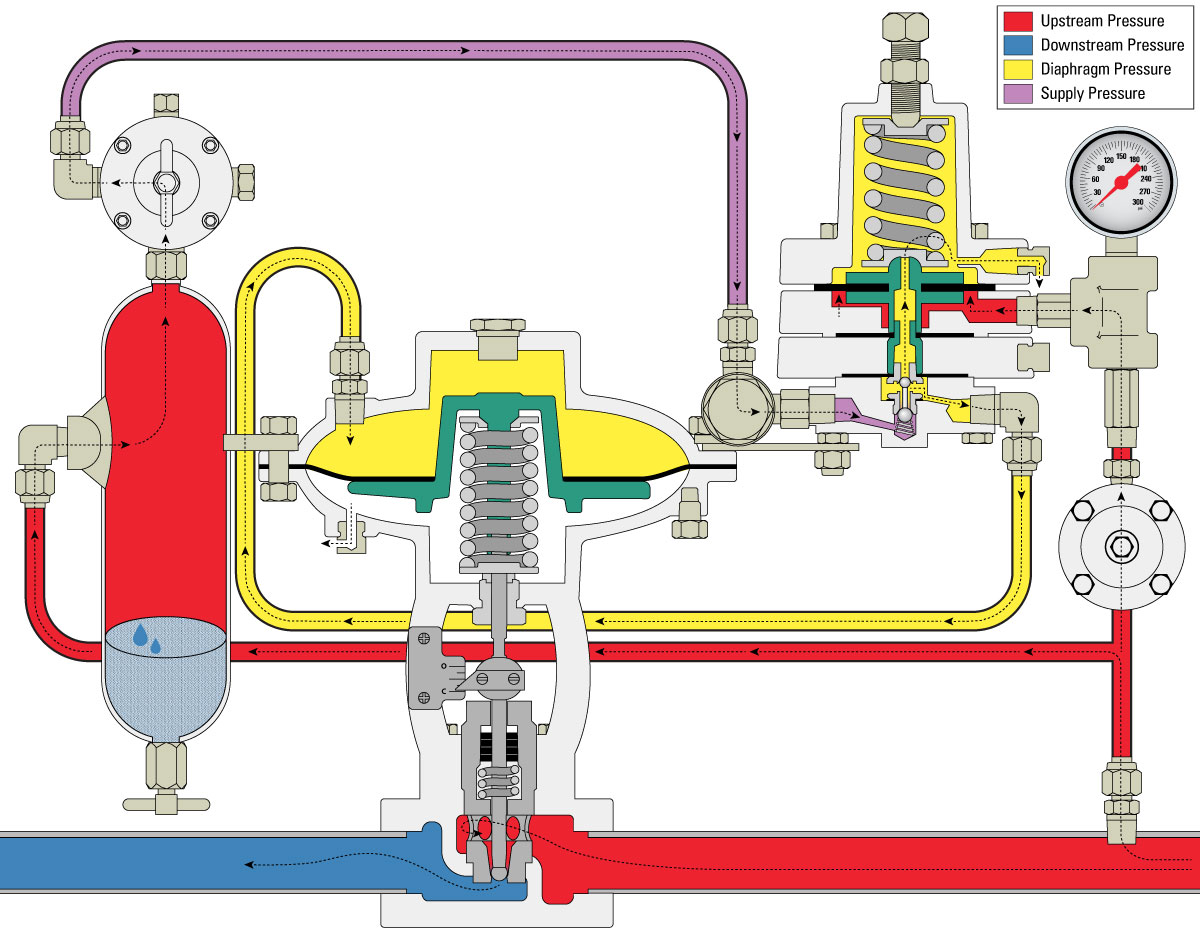

The valve begins in an open position and the adjusting screw unthreaded. Zero pressure is maintained on the upstream side. The upstream pressure begins to flow—in this example, up to 50 PSI. No supply pressure is available yet to close the valve.

Upstream pressure flows into the drip pot and the sense line protector at the same time.

The sense line protector blocks pressure to the pilot when it exceeds the working pressure, which is 300 PSI. When upstream pressure is below 300 PSI, it enters under the pilot diaphragm assembly.

Meanwhile, the drip pot knocks out liquid from the supply gas, which could be detrimental to other instruments. Over time, liquids accumulate in the drip pot and will need to be drained regularly.

Next, the dry gas flows into the supply gas regulator. The upstream pressure is reduced to 30 PSI, which is the required supply pressure for the pilot. Before entering the pilot, it moves through a filter to remove debris.

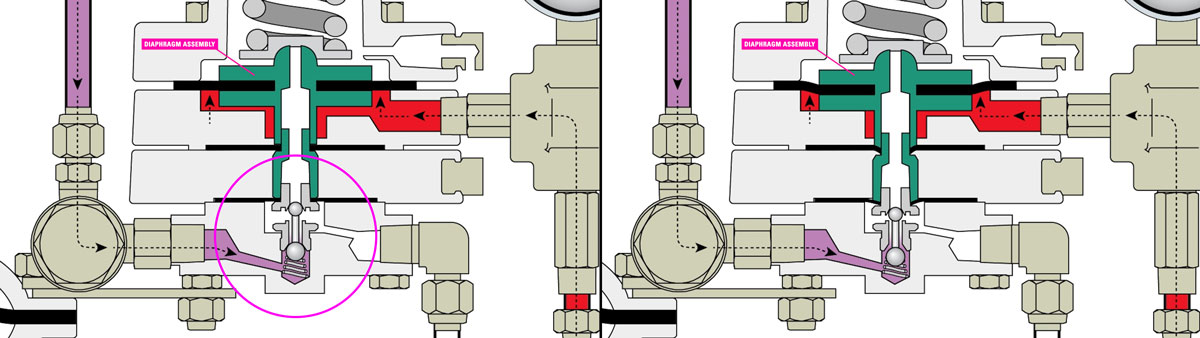

The supply pressure is blocked by the pilot plug. When the adjusting screw is threaded into the bonnet, the spring puts pressure on the diaphragm assembly.

When this assembly is pushed down, it unseats the pilot plug and allows the flow of supply pressure to continue into the control valve actuator.

This supply pressure pushes down on the diaphragm assembly. This closes the valve and allows upstream pressure to increase.

With the set point at 150 PSI, this pilot will keep the valve closed until 150 PSI is reached. As the set point is approached, there is enough pressure pushing up the pilot diaphragm assembly to move it up and reposition the pilot plug.

Supply pressure is now blocked from entering the control valve actuator and is instead rerouted and vented out through the pilot.

Without pressure pushing down on the actuator diaphragm, the valve returns to its fail-safe position, which is open.

Once there is no longer enough upstream pressure to overcome the pilot spring tension, the pilot diaphragm assembly will move back down.

This will seat the top of the pilot plug and unseat the bottom, allowing supply pressure back into the control valve actuator, closing the valve.

If flow conditions are consistent, the valve will throttle open and closed by only a small percentage to maintain the set point. This is achievable because of the equal percentage trim.

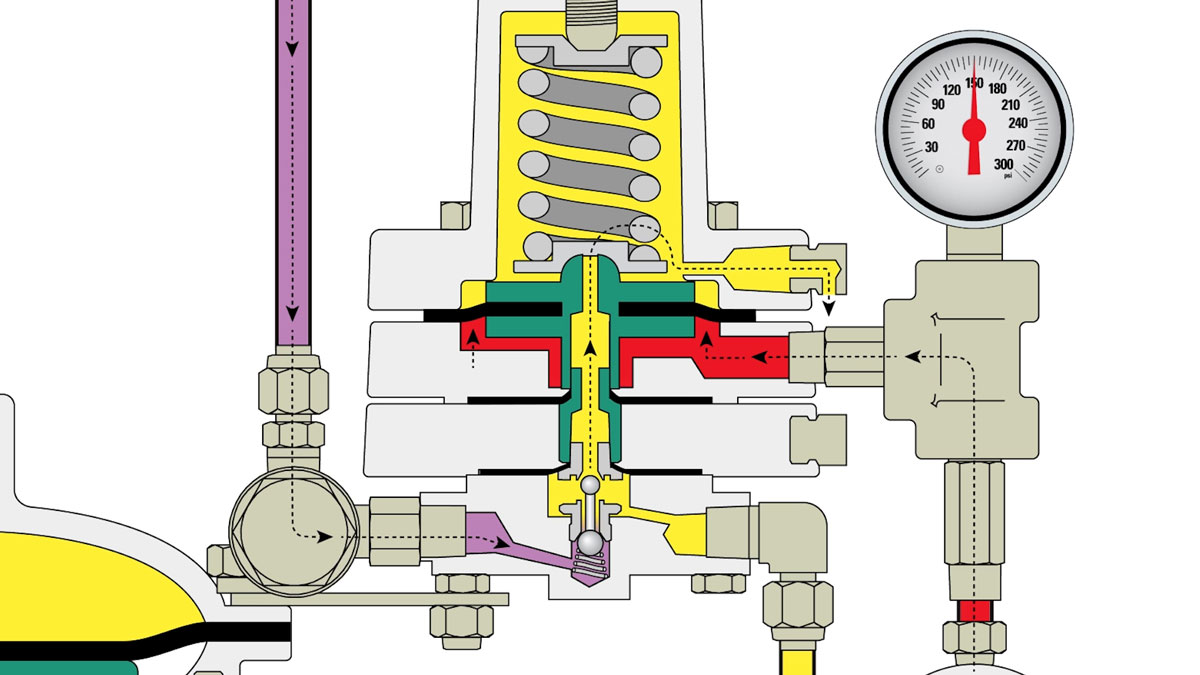

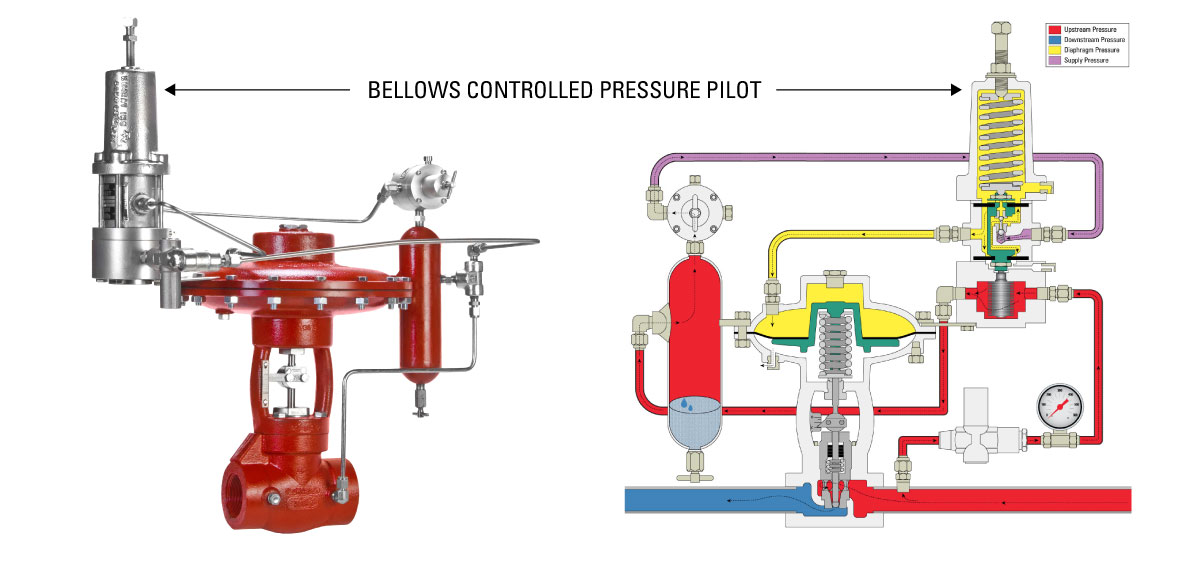

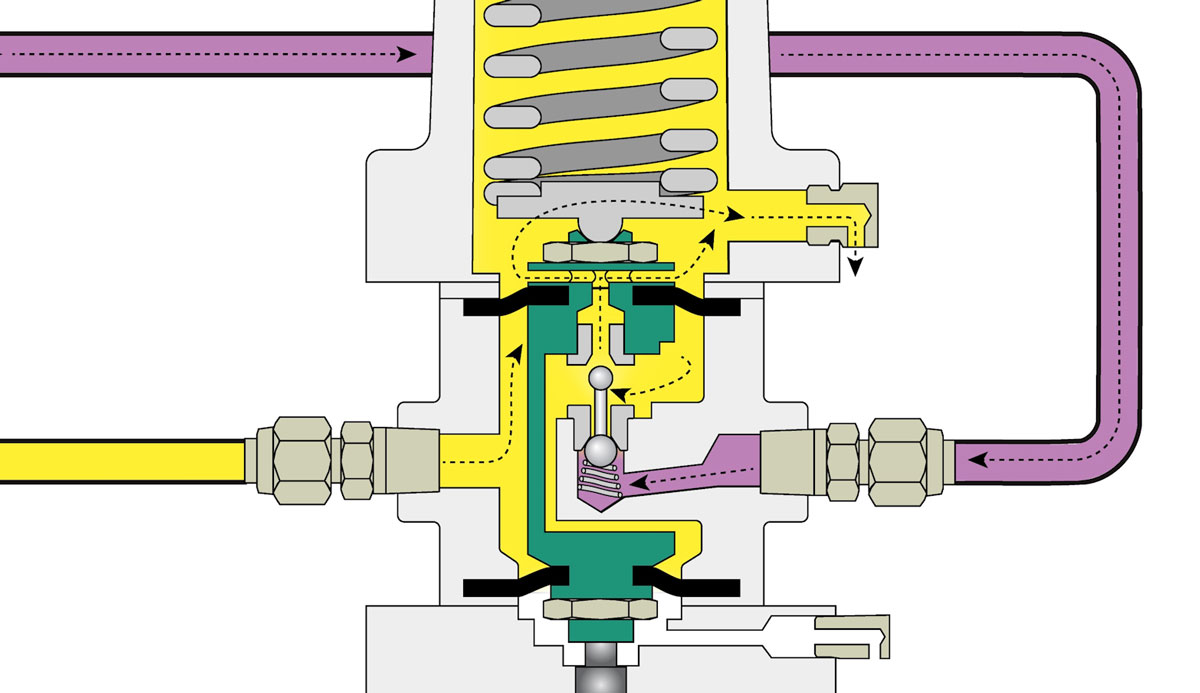

How a Bellows Controlled Back Pressure Package Works

Now, we’ll look at the gas flow through a High Pressure Back Pressure Package configured with a Bellows Controlled High Pressure Pilot. This pressure pilot controls between 75 and 2,500 PSI, depending on the model.

The valve begins in an open position and the adjusting screw completely unthreaded. Zero pressure is maintained on the upstream side. The upstream pressure begins to flow – in this example, up to 75 PSI.

No supply pressure is available yet to close the valve.

Upstream pressure flows into the sense line protector. This device allows pressure below the maximum set point to pass through.

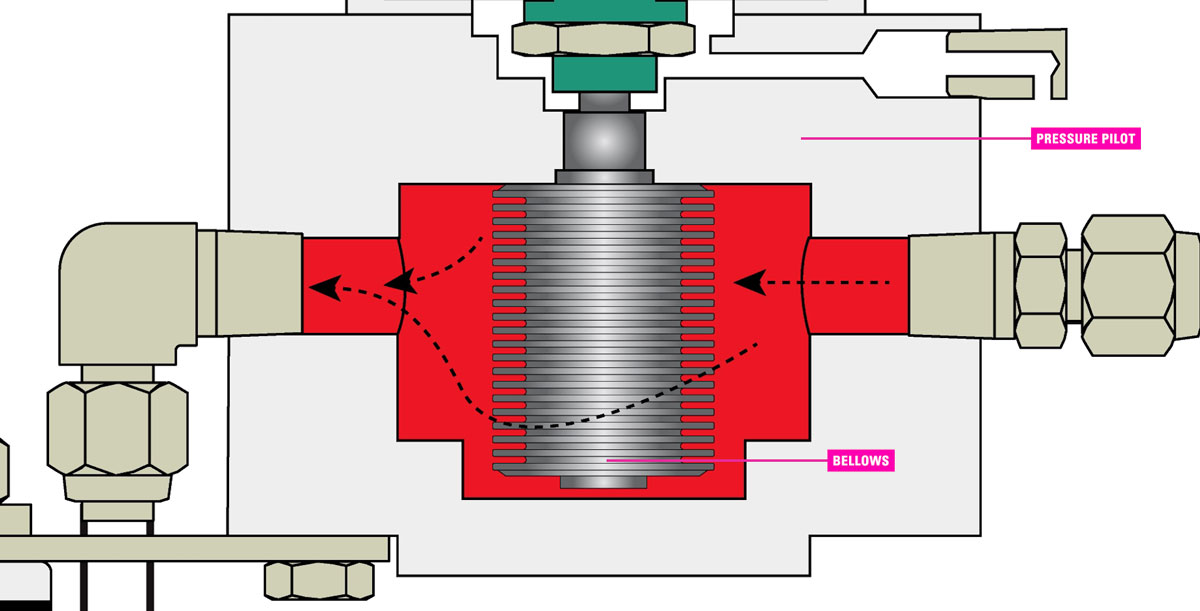

It then flows into the pressure pilot where it encounters the bellows. The bellows is the pressure sensing element of the pilot.

Upstream pressure then flows into the drip pot, which knocks out liquid from the supply gas that could be detrimental to other instruments. Over time, liquids accumulate in the drip pot and will need to be drained regularly.

Next, the dry gas flows into the supply gas regulator. The upstream pressure is reduced to 30 PSI, which is the required supply pressure for the pilot.

This supply pressure moves into the pilot where the flow is blocked by the pilot plug.

When the adjusting screw is unthreaded, there is no downward pressure on the pilot diaphragm assembly. Once the adjusting screw is threaded into the bonnet, the spring puts pressure on the assembly, which positions the pilot plug to open the flow of supply pressure into the control valve actuator.

This supply pressure pushes down on the control valve diaphragm working against the tension of the spring. This closes the valve and allows upstream pressure to increase towards the set point.

With the set point at 400 PSI, this pilot will keep the valve closed until 400 PSI is reached.

As the upstream pressure (sense pressure) increases above the set point, it compresses the bellows, actuating the bellows stem to move the diaphragm assembly up.

Supply pressure is now blocked from entering the control valve actuator and is instead rerouted and vented out through the pilot.

Without pressure pushing down on the actuator diaphragm, the valve returns to its fail-safe position, which is open.

As upstream pressure (sense pressure) decreases below the set point, the bellows uncompresses. This allows the pilot spring tension to reposition the diaphragm assembly and unseat the lower pilot plug.

Supply pressure can now enter the actuator to close the control valve.

If flow conditions are consistent, the valve will throttle open and closed by only a small percentage to maintain the set point. This is achievable because of the equal percentage trim.

To speak with an expert about High Pressure Back Pressure Packages or the pilots that control them, contact your local Kimray store or authorized distributor.