In oil and gas production applications, it can be hard to tell the difference between a back pressure regulator and a pressure reducing regulator.

How To Identify a Back Pressure Regulator

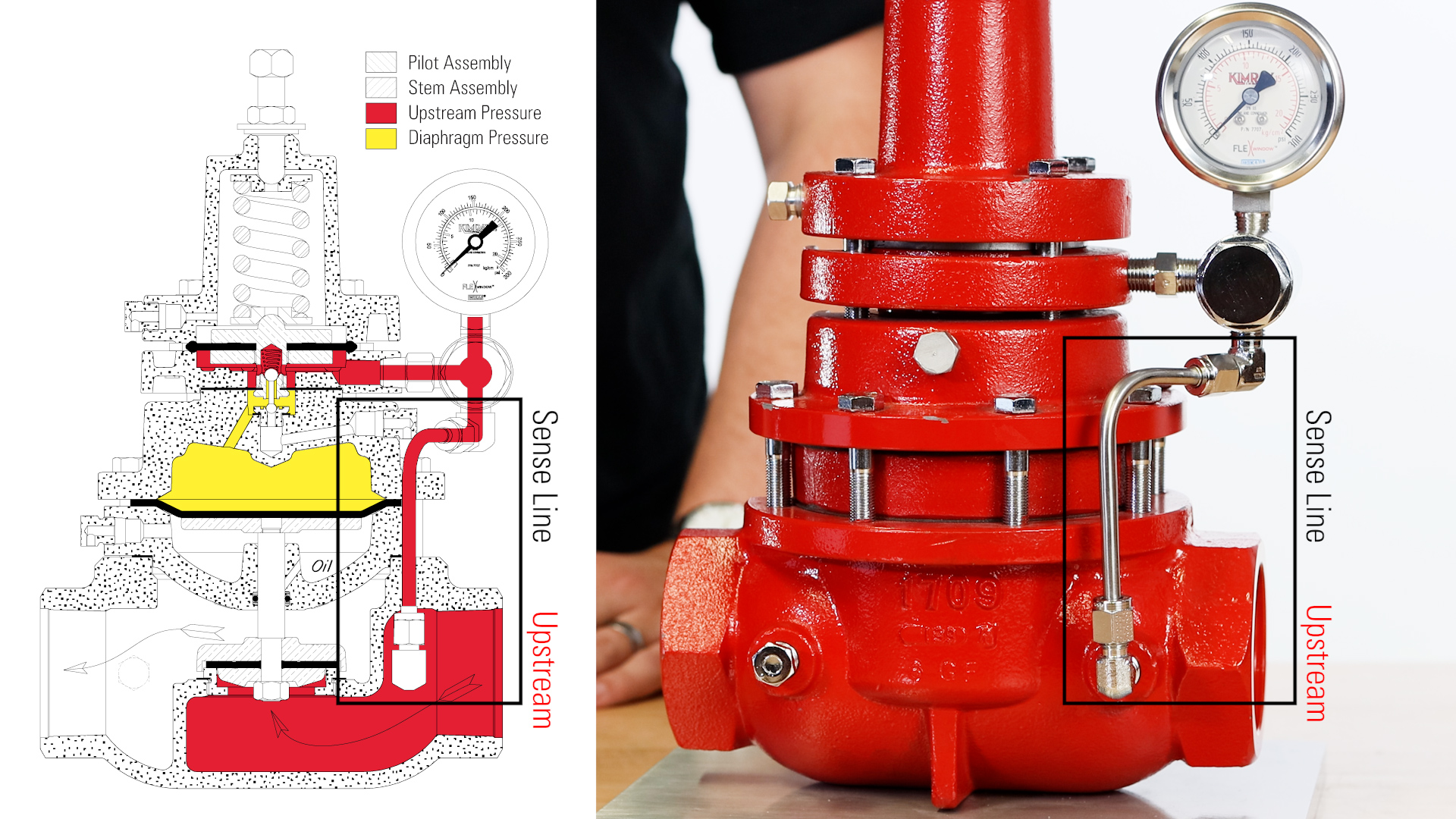

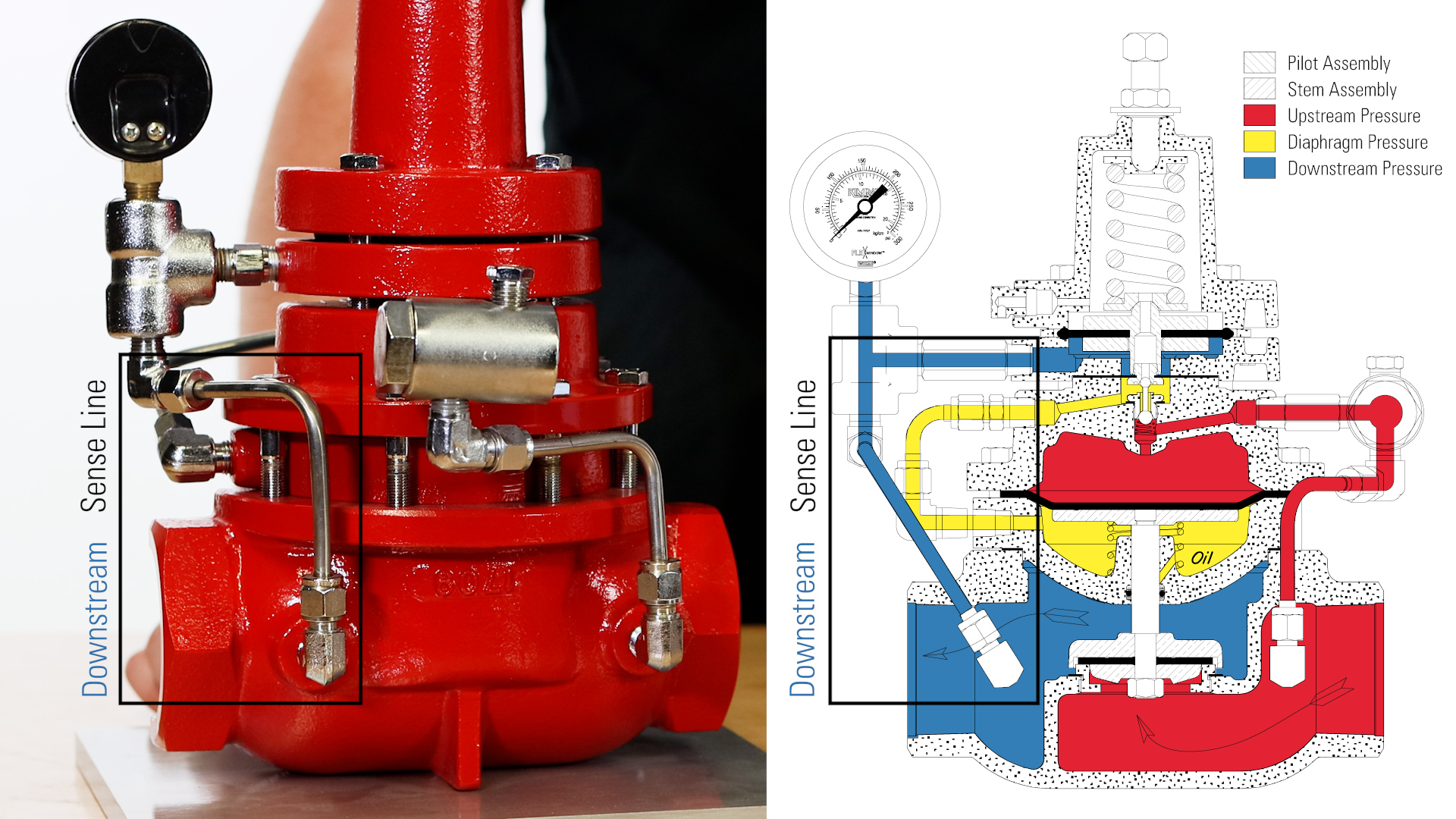

While the bodies of the back pressure regulator and pressure reducing regulator look the same, the key to identifying yours is to locate the sense line.

A Back Pressure Regulator is a type of control valve designed to hold pressure on production vessels and release pressure downstream when a set point is reached.

This pressurizes the vessels so that the opening of a control valve or dump valve creates a pressure differential, causing the fluid to leave the vessel and go on the next destination in the process.

Applications for Back Pressure Regulators include:

- Gas Sales Lines

- Production Vessels (e.g., Separators, Heater Treaters or Free Water Knockouts)

- Vent or Flare Lines

- Sense Line on a Back Pressure Regulator

Whichever type of regulator you have, your sense line will always be running to the pressure gauge. The sense line on a back pressure regulator will be coming from the upstream side of the valve, because you sense upstream pressure on a back pressure regulator.

How to Identify a Pressure Reducing Regulator

While a Back Pressure Regulator holds pressure on a vessel, a Pressure Reducing Regulator is designed to precisely regulate the flow of gas. It creates and holds a downstream set point.

As the name implies, the Pressure Reducing Regulator reduces upstream pressure, but allows it to flow through at a consistent, pre-determined rate.

Applications for Pressure Reducing Regulators include:

- Suction Controllers on a Natural Gas Compressors

- Recirculation Valves on Natural Gas Compressors

- Supply Fuel or Instrument Gas on Production Equipment

- Gas Meter Runs

- Sense Line on a Pressure Reducing Regulator

On a pressure reducing regulator, the sensing line coming into the pressure gauge will come from the downstream side of the valve.