Upstream oil and gas automation refers to the growing trend of using electronic and digital tools to control production processes. For some, this is cause for excitement as they see opportunities for efficiency gains and lower emissions. For others, it’s cause for anxiety as they feel intimidated by the seeming complexities of electric power.

In this video, Kimray's Jordan Moore explains 6 key terms in upstream oil and gas automation.

1. PLC

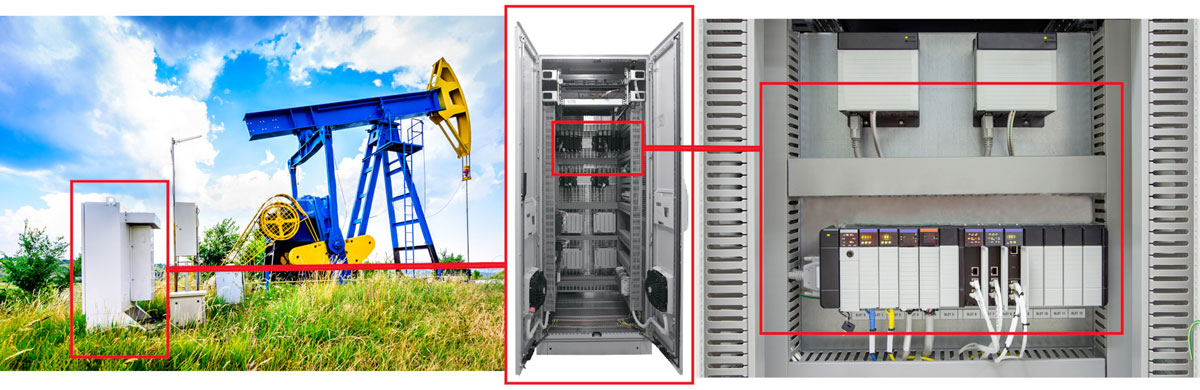

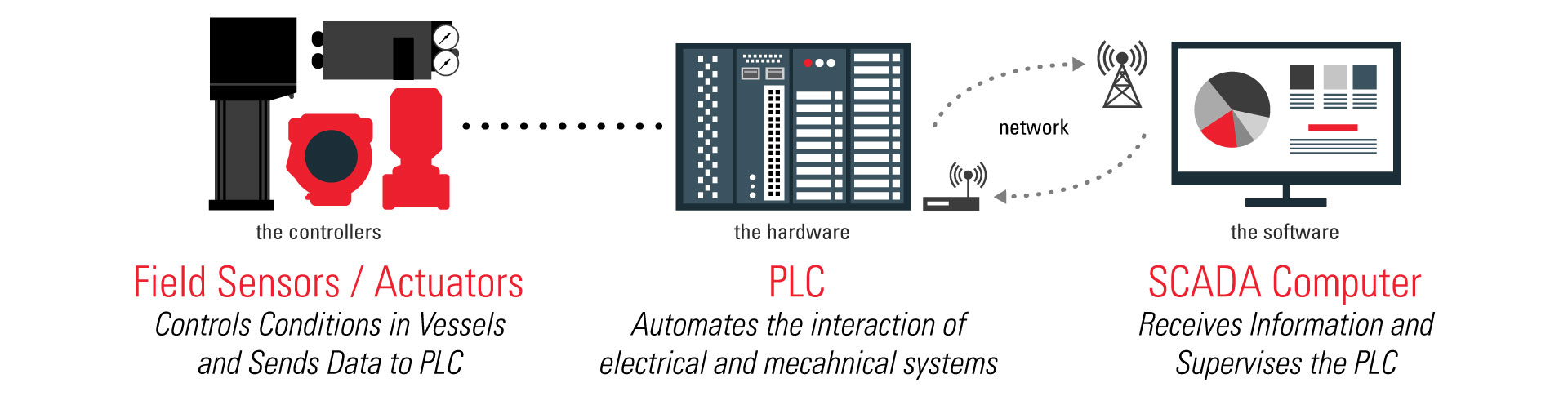

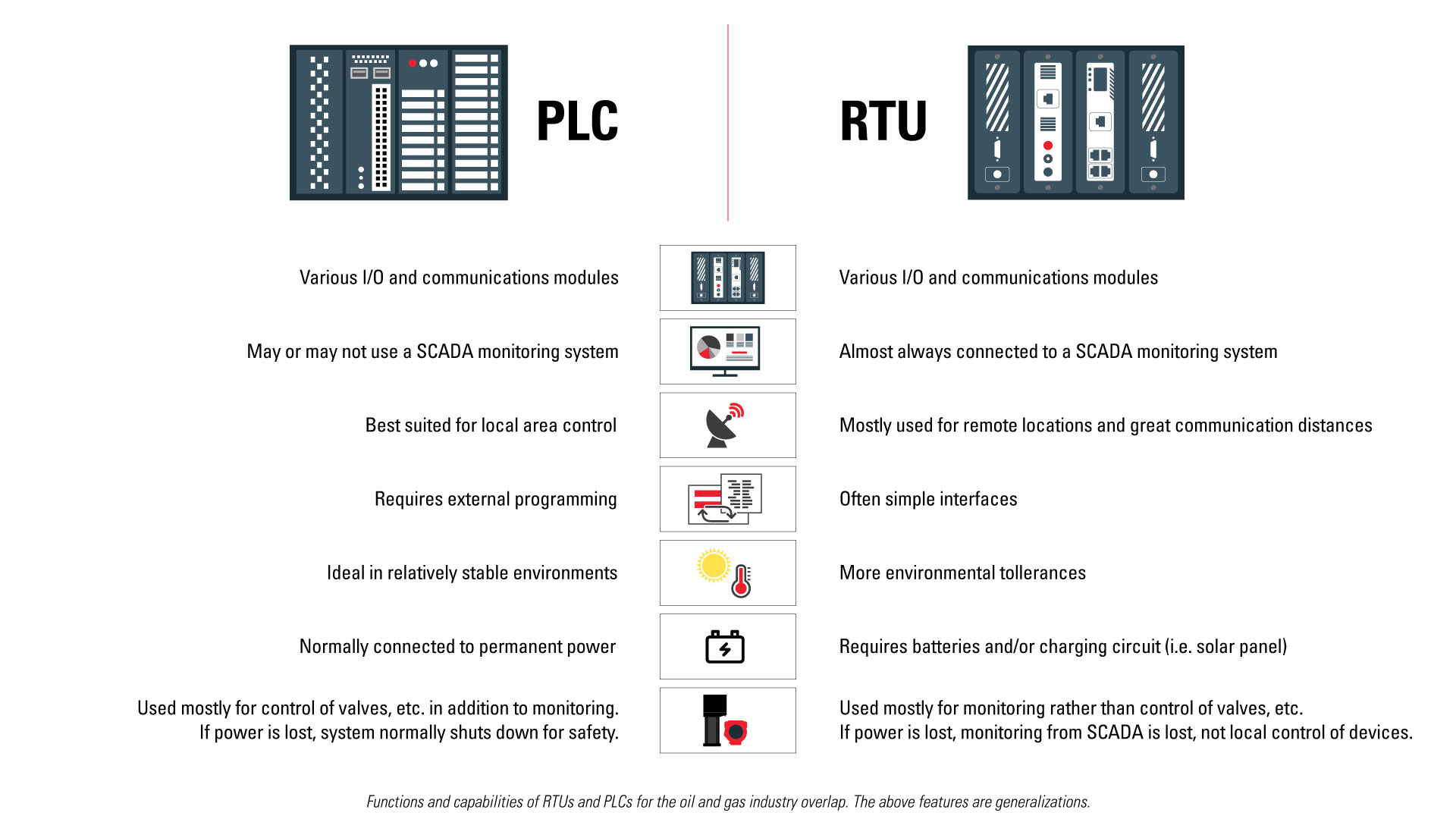

A PLC, which stands for “Programmable Logic Controller,” is a computer that’s been programmed to control a process. A PLC receives information about process conditions and then sends information to devices on a production site in order to control them.

To send and receive this data, a PLC uses a communication system called SCADA.

Here’s one example of how a PLC could work:

An electric temperature controller is digitally reading the temperature in a heater treater. You’ve specified a set point in your PLC and set a protocol so it will react when the temperature gets above or below that point.

If the temperature gets above the set point, the PLC will send a signal to a burner valve to reduce the amount of supply gas going to your burner, which will lower the temperature.

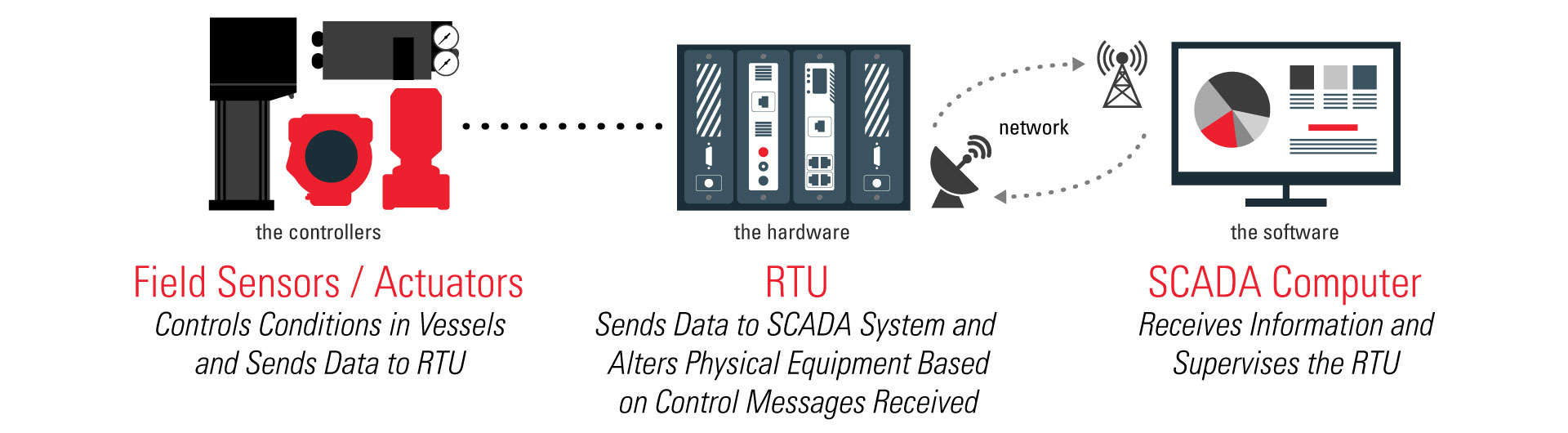

2. RTU

RTU stands for Remote Terminal Unit. An RTU is a basic digital readout box on a well site that receives process conditions from controllers and pilots. These readouts may be temperature or pressure readings among others. Some have touch screens while others have simple digital readouts.

RTUs are controlled by and send process information to a SCADA system, which receives the information and supervises the RTUs.

3. I/P Positioner

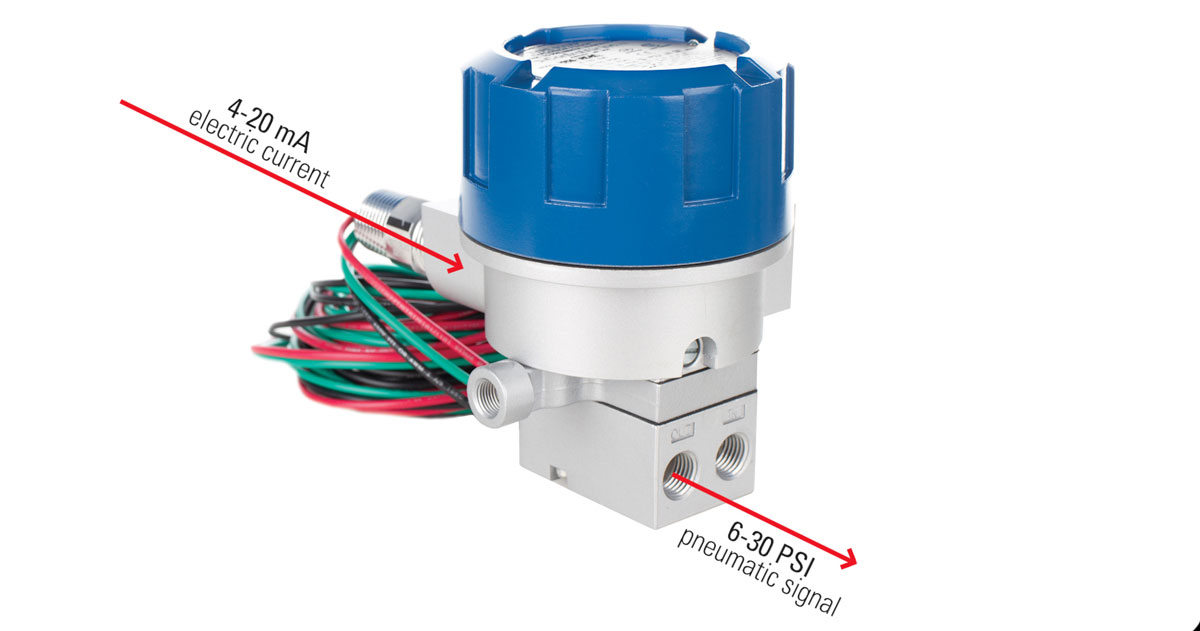

An I/P positioner is a device that receives an electrical current signal, abbreviated “I,” and converts it to a corresponding pneumatic signal, abbreviated “P.” To do this, it also has a supply gas input that provides the pneumatic pressure.

Our YAK2, for example, receives a 4-20 mA signal and converts it to a corresponding 6-30 PSI pneumatic signal, which it sends to the pneumatic actuator of a control valve.

4. Transducer

A transducer receives a pneumatic signal and converts it to a corresponding electric signal.

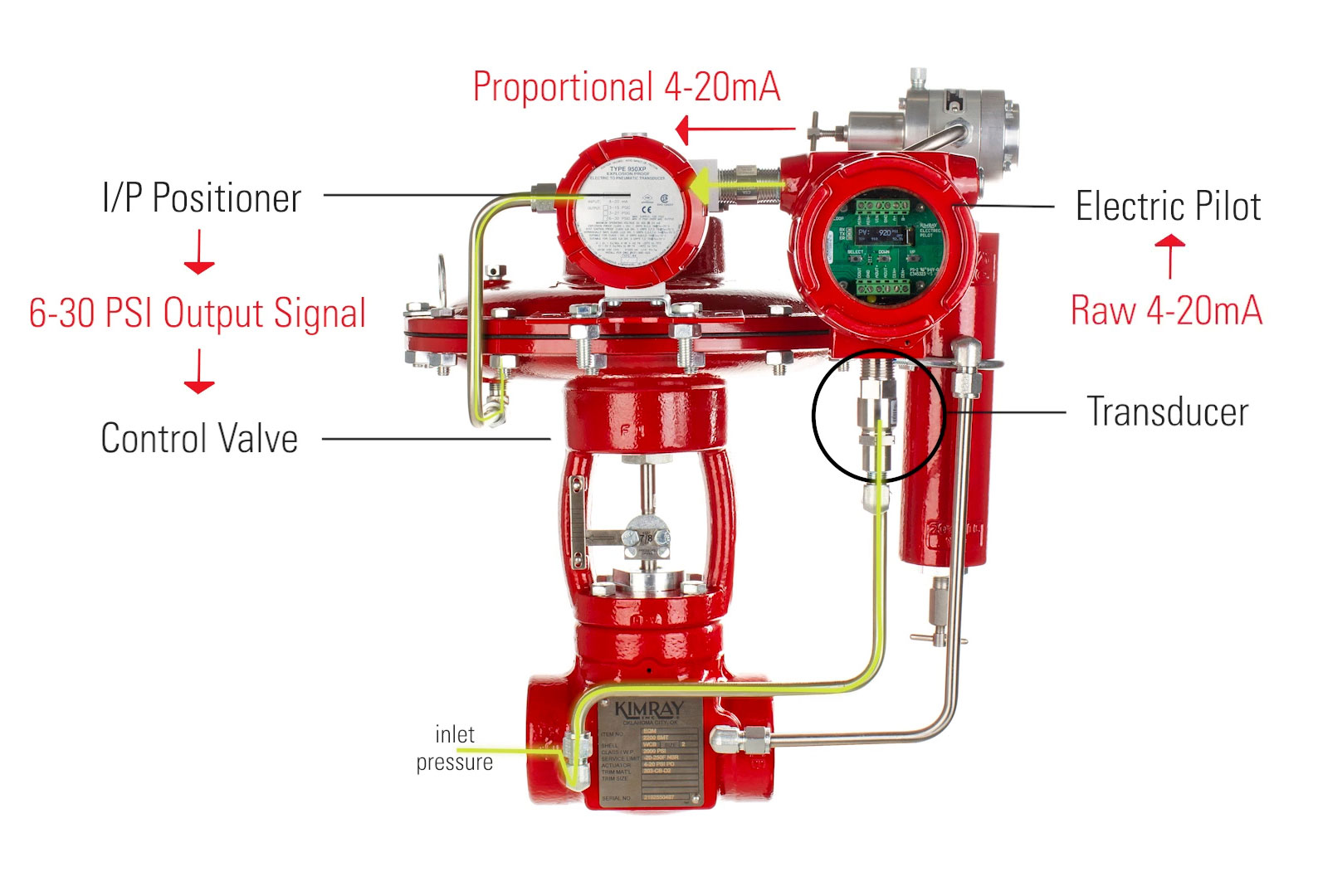

One example of an I/P and Transducer working together is on our Electric Valve Controller. On this package, the Transducer measures process pressure and gives a raw 4-20mA signal to the pilot.

The Electric Pilot then takes that signal and converts it to a proportional 4-20mA signal and sends that to the I/P Positioner.

The I/P positioner converts that electric input signal to a corresponding 6-30 PSI output signal and sends that level of supply gas to the High Pressure Control Valve.

Some people wonder why they need the pilot in this instance. Without the pilot, there is no decision maker. The pilot takes the raw transducer signal and converts it to an accurate corresponding pressure.

5. Solar Panels

A solar panel uses UV light to produce DC electricity, which most electric control equipment can run on.

You may wonder what happens at night or on a cloudy day? The power captured is stored in a battery or bank of batteries.

Solar panels can be used in an array of oil and gas applications and are common in more remote areas. Solar panels allow you to reap the benefits of electric power without the cost of running electric wiring to your site.

Make sure to size the solar panels and batteries to handle your specific application.

6. AC/DC

When most people think of electricity, they think of plugging a device into a wall. That is AC, which stands for Alternating Current. On a well site, AC power can come from wires run to a nearby power pole. One common product that uses AC is an Electric Submersible Pump, which is used for artificial lift.

DC, which stands for Direct Current, is what’s stored in batteries. On a well site, DC is most often generated by solar panels, though it may also derive from an AC-DC converter.

To see how easy it is to take a first step into valve automation, watch this video on our Electric Valve Controller package.

To speak with an expert about incorporating upstream oil and gas automation in your next project, contact your local Kimray store or authorized distributor.