Where to listen online:

Looking for an easy way to ruin your day?

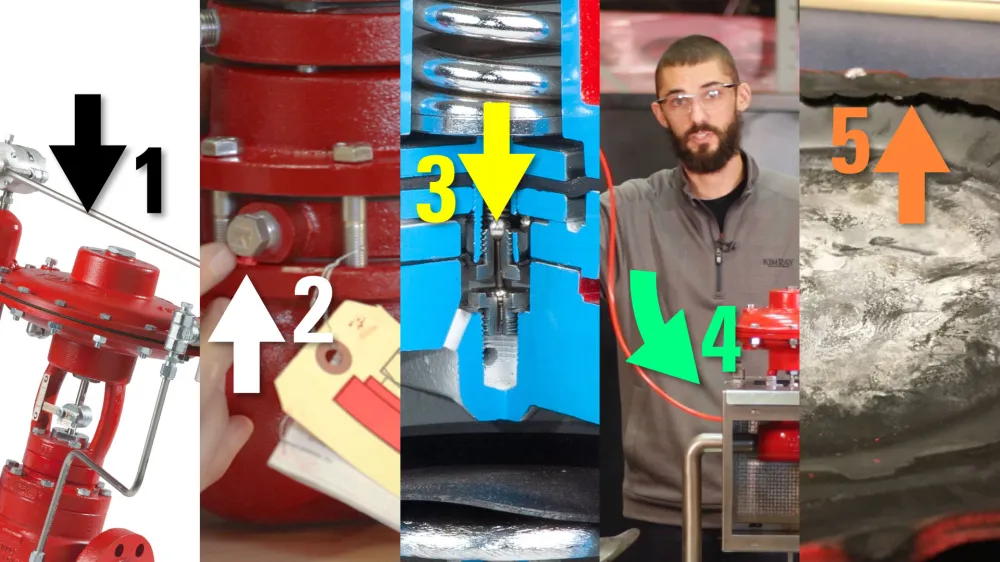

Damaging your control valve can do that and more! So if you are in the the mood for some frustrating downtime, follow these 5 ways to damage your valve:

1. Grab Your valve by the tubing

One easy way to damage your control valve is to grab it by the tubing.

Tubing often looks like the perfect handle to lift a valve, especially a high pressure control valve package.

Lifting the valve by this method can quickly bend the tubing itself or the connection point where the nut and ferrule are. If you bend it too much it can break that seal to the valve.

If you want your valve or regulator to work correctly—the best way to lift it is by the valve body itself, the topworks, or the lifting hooks on the top.

2. Don’t remove stopper in the oil bowl (regulator)

A great way to make sure your regulator doesn't work is to leave the small red stopper in the breather plug.

If your regulator appears to be stuck in the ON position, it's likely that this stopper was not removed during installation.

We put this stopper in the breather plug so oil doesn’t spill out during transportation.

If you want your regulator to work correctly—make sure to remove this plug for proper operation.

3. Use wet gas in your regulator

If you really want to gum up your regulator or high pressure control valve, use wet or dirty gas.

If you want your regulator or valve to work correctly—bring in clean supply gas from a high and dry location.

If your regulator is venting continuously, you either have a blown diaphragm or your pilot plug can’t seat properly due to wet or dirty gas in your pipeline. To fix this, you can remove the bonnet and pilot housing to access the pilot plug. Then remove, clean, and dry the pilot plug, then re-install it.

*Note that Back Pressure Regulators are typically meant for gas, though we do offer options for liquid.

4. Leave Droops in your gas Supply Tubing

If you want to freeze your supply gas and disrupt production, leave droops in your tubing.

Extra slack creates low spots in the line, where liquids can and will collect. If you operate in warmer climates or only in the summertime, this may not be an issue. But in cold weather or in conditions where you have a large pressure drop, these liquids will freeze.

This means your valve will fail because it’s not receiving the appropriate level of supply gas.

If you want your regulator or valve to work correctly—make sure all tubing is running downhill and no parts of the line are sloped at ninety degrees or more.

5. Don’t specify the correct internals for your conditions

If you want to damage the internals of your valve, don't identify which type of trim and material you need.

We offer different types of control valve trim (both in operation and material composition) and a variety of elastomers for your diaphragms and o-rings.

If you want your regulator or valve to work correctly—consult your local Kimray store or authorized distributor and they can help you make an informed decision about which internals will operate best in your specific operational conditions.