Cold weather provides unique challenges to maintaining uptime at your oil and gas production site.

Whether you operate in a cold-weather state like Wyoming or North Dakota, farther north in Canada, or you only experience freezing temperatures during the winter months, freezing gas lines and control valves can have damaging effects on your production goals.

Check out these 5 tips on how to protect your team, optimize production, and prevent freezing when the weather gets cold.

1. Cover Exposed Skin

When working on site in the cold, make sure all exposed skin is covered from the elements. Your company may offer cold weather PPE requirements, so be sure to consult those. In addition, we recommend dressing in layers, wearing gloves to protect your fingers, and covering your ears with a winter cap.

Working in the cold leads to increased risks for your hands in particular. Fingers can quickly grow numb in the cold, which means you may cut yourself and not realize it.

Take regular breaks to sit in your truck with the heater on and warm your paws.

2. Point Breather Plugs Down (or Downwind)

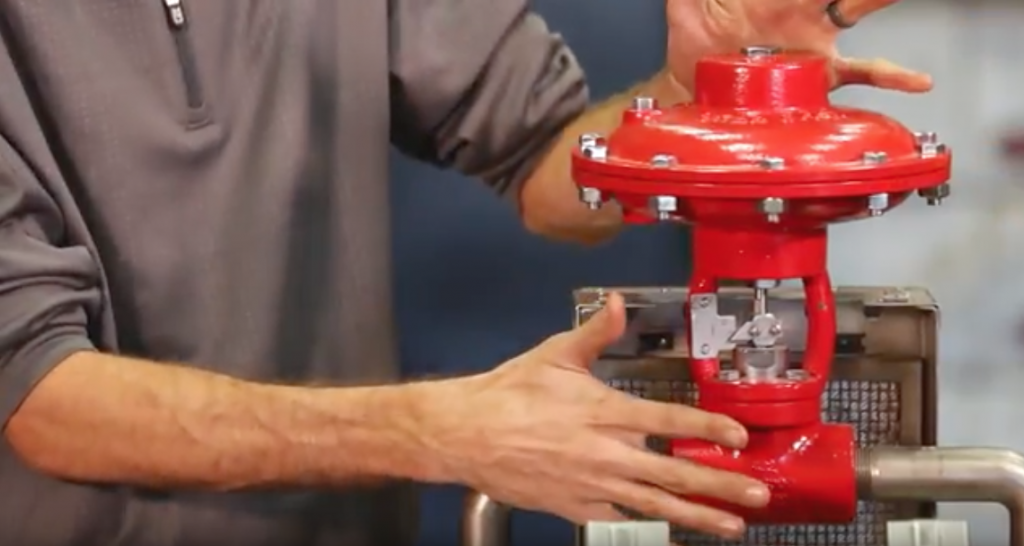

When operating in cold weather, one of the biggest problems you’ll encounter is freezing fluid in your control valves and pressure regulators.

To prevent this, use a wrench and make sure the breather plugs on all of your regulators and any other equipment that uses breather plugs are facing down.

This simple step will prevent moisture from entering and freezing, which can cause the equipment to fail.

If the breather plug is oriented horizontally, like it is on the Kimray High Pressure Control Valve, turn it away from the north wind so wind and rain don’t get in and cause freezing.

3. Specify Elastomers for Methanol Injection

Some producers use a chemical called methanol in oil and gas production. Methanol is injected into the gas stream to prevent freezing in their control valves and other production equipment.

While effective, methanol is also corrosive and can eat away certain types of elastomers. If you choose this route, make sure to specify the appropriate cold weather elastomers that are compatible with methanol gas.

4. Use a CATCO Heater

Another spot vulnerable to freezing is your control valve body.

As an example, say you have a compressed natural gas (CNG) application. You need to take gas from a large storage tank under extremely high pressure—say 4,000 psi—and cut it down to 200 psi in order to be used at a CNG fueling station.

Due to the JT Effect, valves carrying out a pressure cut that large will be susceptible to freezing, especially when it’s cold outside.

To prevent freezing, some operators use heat tape wrapped around insulation. The problem with this method comes when you need to repair the valve.

You have to cut the tape and insulation away to get access to the valve and then replace it when you are finished.

A good alternative to this option is using a Catco Heater.

This heater uses supply gas to provide a flameless heat that keeps the valve warm, and it features a hinge door with two clips on the top to provide easy access for maintenance or repair.

5. Remove Slack in Gas Tubing

One other spot you may encounter freezing is in your tubing lines. If you are setting up a Weight Operated Dump Valve, you may buy a length of tubing, hook it up to the valve, and then run it to the top of your heater treater without regard for slack in the line.

Extra slack creates low spots in the line, where liquids can and will collect. If you operate in warmer climates or only in the summertime, this may not be an issue. But in cold weather these liquids will freeze.

This means your valve will fail because it’s not receiving the appropriate level of supply gas.

To prevent a gas line freeze, make sure all tubing is running downhill and no parts of the line are sloped at ninety degrees or more.

5 Cold Weather Oil and Gas Production Tips I Podcast Ep. #60