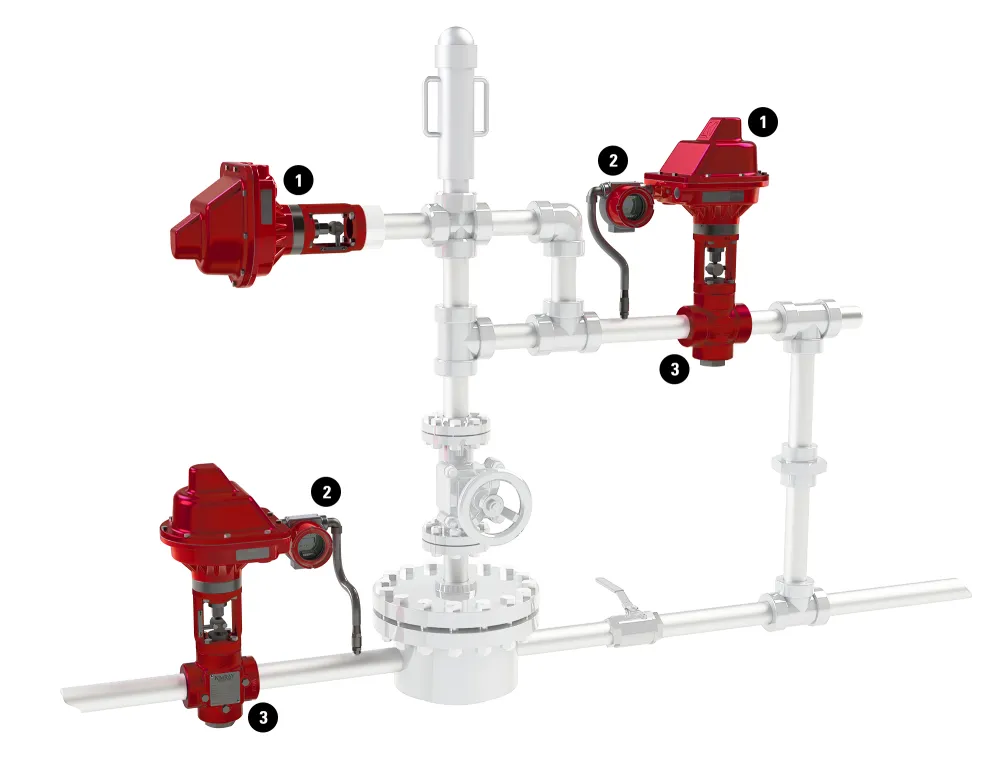

Gas assisted plunger lift can be used to create a pressure differential and draw liquid up the tubing to production equipment. Plunger lift systems use a piston between formation gas and produced liquids. When the control valve is open, the well is flowing and the plunger rests in the lubricator at the surface. As liquids accumulate the well begins to load. When the control valve closes, this stops the flow and the plunger drops through emulsion to the bottom of the well. With the well shut in, the pressure builds until a controller tells the valve to open, allowing the plunger to return while pushing the liquid that’s above it to the surface. A key component of plunger lift is the control valve. The valve must operate unmanned. An electric actuator is ideal in this situation because pneumatics will often fail due to moisture in the gas causing deterioration or freezing.

Related Trainings & Demos

Training that Makes These Diagrams Come to Life

We do in-person trainings at our facilities or in your field to help you make these applications work in the real world.

Learn easy installation techniques

Discover maintenance and preventative care plans to preserve the life of all your equipment

Connect with Kimray engineers and technicians

Find more products to improve your entire system

Domestic and international trainings - Kimray covers the globe

Contact your business development representative to visit us at our OKC campus or have someone come to you. We can't wait to see you.

Monthly Videos, Tips, & Insights

The Kimray Chronicle is your source for news within the Kimray community.

Each monthly newsletter includes information on product improvements, tips on how to better optimize your site, videos and articles on how to complete your own repairs, as well as news about training and events.

© 2026 Kimray, Inc. All Rights Reserved.