INTRODUCTION

The Gen 3 Liquid Level Controller was created to help oil and gas producers maintain accurate liquid level control on their separation equipment even in harsh environments, featuring durable components, easy on-site adjustments, and snap or throttle operating modes with one pilot.

Paired with a pneumatic dump valve, it provides long-lasting, precise liquid level control in separation equipment to keep wells operating at optimal production levels.

In this field study, we’ll show how the level controller performed at a well site in Central Oklahoma.

PROBLEM

An upstream producer in Central Oklahoma needed to maintain accurate level control in their 3-phase separators. They were using a competitor’s level controllers, which were acting erratically, not holding the level consistently. The producer often had to adjust the level settings or change out the pilots to get them to work correctly.

In addition, these controllers bled continuously, allowing the compressed instrument air to escape and causing the compressors to start up more often, draining the compressor motor battery at a faster rate.

In the competitor’s level controller design, vent gas bleeds into the case out of a small orifice, not a threaded port. While this was not an emissions issue in this application with compressed air supply, in other locations where this producer was using supply gas from the vessel, vent gas couldn’t be captured to help reduce emissions.

Production Details

- Production Type: Gas Injection Artificial Lift

- Oil Volume: 600 Bbl/D

- Water Volume: 800 Bbl/D

- Gas Volume: 10 MMCFD

- Solids in Fluid: moderate in flowback phase, low in production phase

- Corrosiveness: low

- H2S: low

- Vessel Pressure: 300 PSI

- Vessel Type: 3-Phase Separator

- Level Controller Supply Pressure Type: Compressed Air

SOLUTION

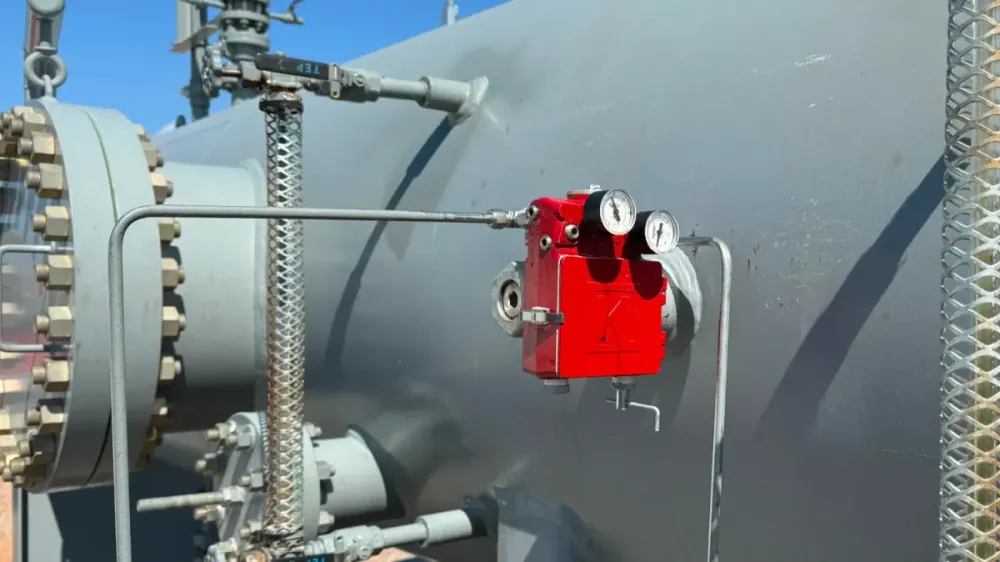

The producers installed a 2” NPT Gen 3 Liquid Level Controller on their separators.

With the Gen 3 installed, the producer no longer had to frequently adjust the level settings or change out the pilot to hold a consistent liquid level, and since the Gen 3 doesn’t continuously vent, the compressor would start up less often.

- Date of Installation: March 6, 2023

RESULTS

After 7 months of operation, the producer reported that the Gen 3 has been reliable, simple to set, and easy for their field hands to learn to operate.

In the words of the field operator to his superintendent:

“When can we replace all of our (current level controllers) with Gen 3s?”

– Field Operator, Central Oklahoma

Based on these results, they have decided to standardize Gen 3s on all liquid level control applications, utilizing them on new installs and on replacing existing units as they fail or wear out.