Once oil has been produced and separated, it is piped to what is often its final stop on an upstream production site: a storage tank.

While they don’t require the same types of valves used in the separation process, they do require pressure relief to compensate for the ongoing filling and emptying that happens.

In this video and blog, we highlight two key devices needed for pressure compensation:

- Pressure/Vacuum Relief Valves

- Emergency Pressure Relief Valves

Pressure/Vacuum Relief Valves (PVRVs)

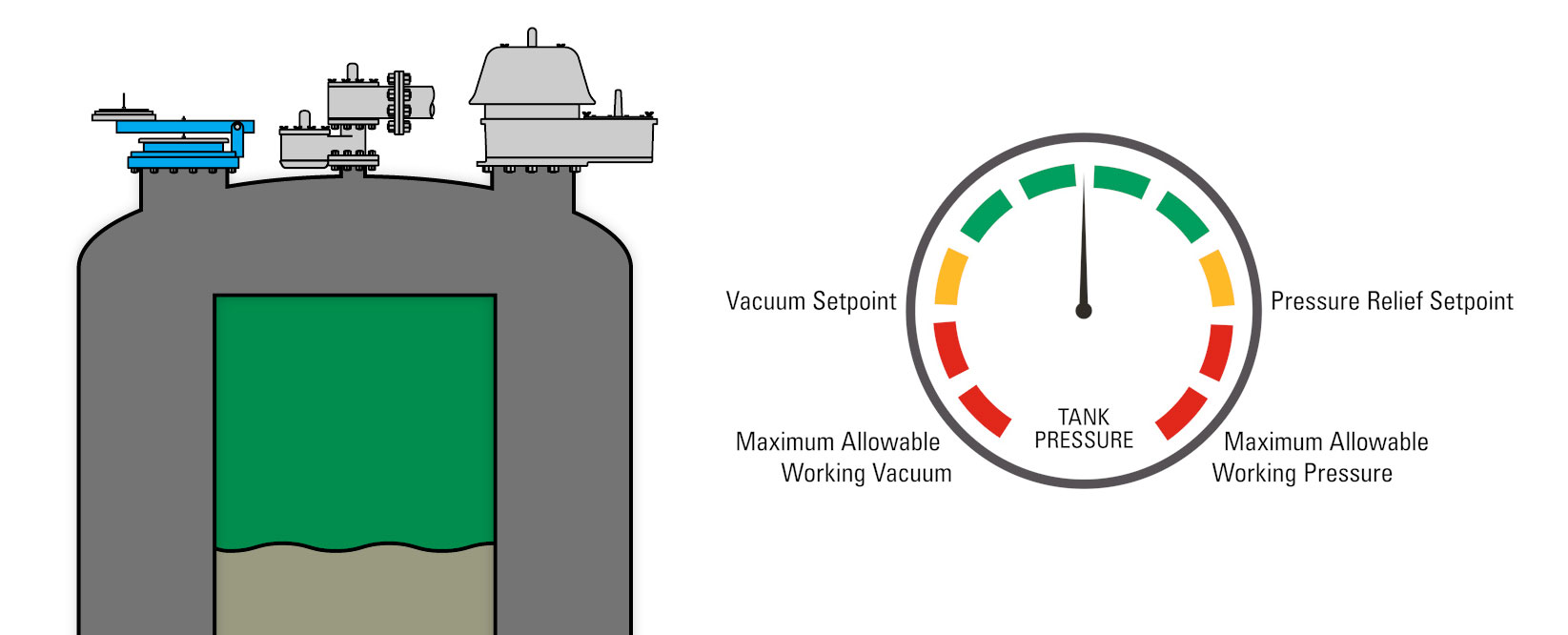

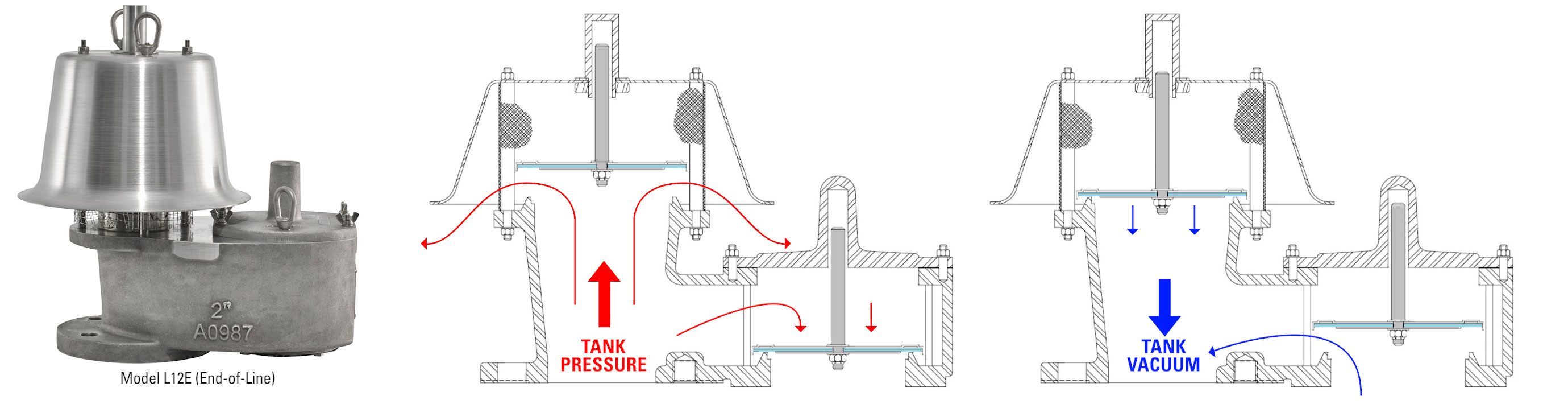

Pressure/vacuum Relief Valves, or PVRVs, are used during normal operation to allow storage tanks to compensate for the increase of pressure when the tank is filling as well as the vacuum condition when the tank is emptying.

Pressure/vacuum Relief Valves, or PVRVs, are used during normal operation to allow storage tanks to compensate for the increase of pressure when the tank is filling as well as the vacuum condition when the tank is emptying.

The pressure and vacuum relief function is similar to that of the thief hatch, providing a higher level of venting capacity suitable for some storage tanks, though the combined efforts of both the thief hatch and PVRV may be necessary.

Pressure/Vacuum Relief Valves with high flow capacities can also allow for multiple tanks to be tied into a common vent line and central header.

The type of PVRV used depends on emissions considerations, pressure requirements, and site design.

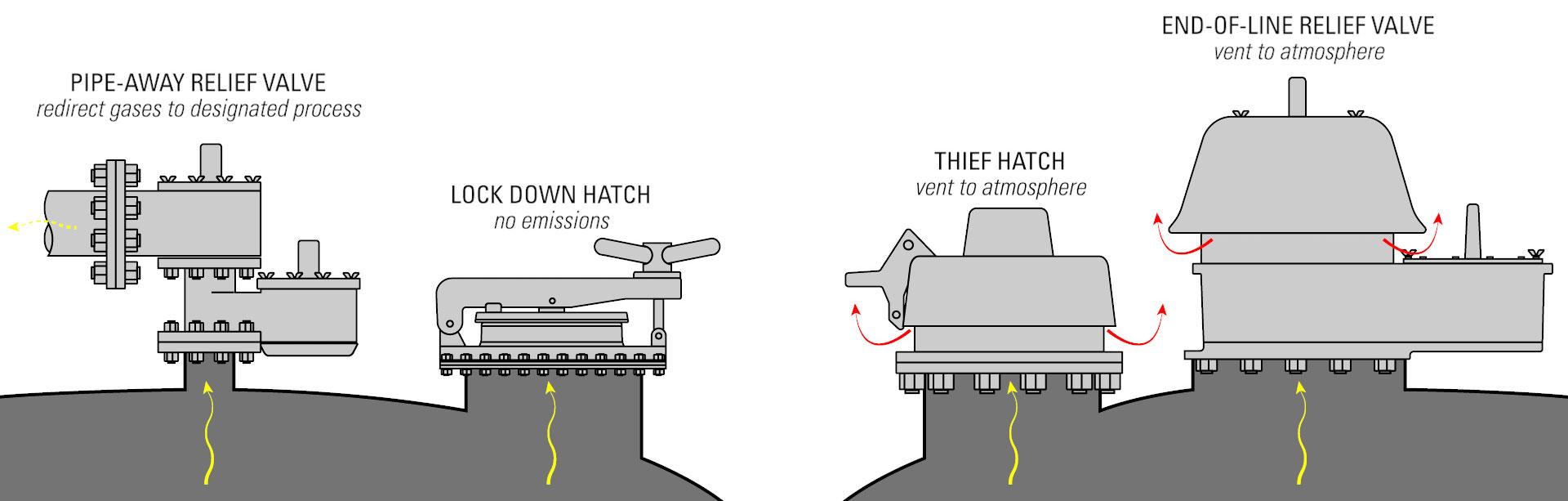

End-of-Line vs Pipe-Away Relief Valves

End-of-Line Relief Valves relieve excess tank pressure directly into the atmosphere. This option is typically for applications where gas does not contain harmful elements like H2S.

Pipe-Away Relief Valves redirect gases to a designated location or process, such as a VRU or flare.

When limiting emissions while venting is a requirement, lock-down hatches are used instead of thief hatch models, and pipe-away relief valves are used instead of end-of-line.

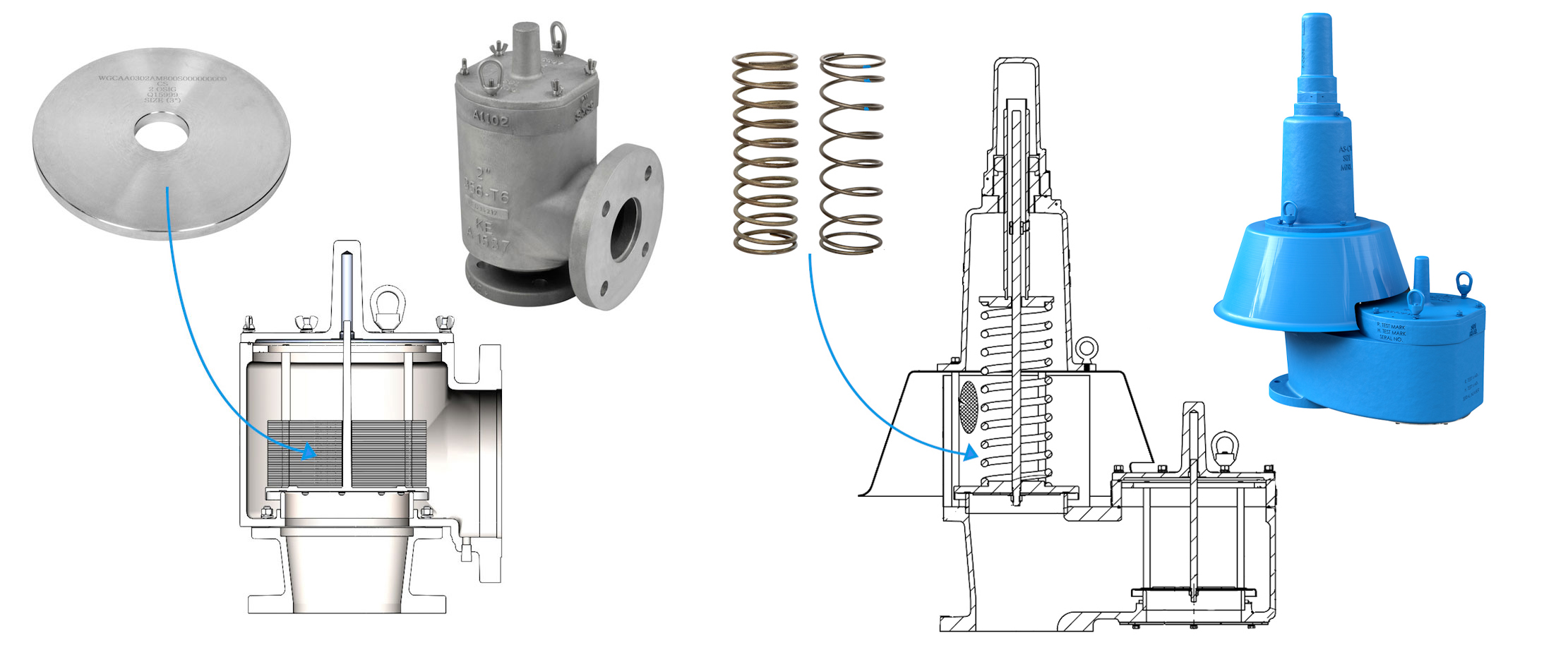

Weight-Loaded vs Spring-Loaded

PVRVs can be weight-loaded, spring-loaded, or a combination of both.

- Weight-loaded PVRV valves are for storage tanks that are designed with pressures less than 24 osig.

Spring-loaded relief valves have higher pressure ratings for storage tanks designed for pressure above 24 osig.

Emergency Relief Vent Valves

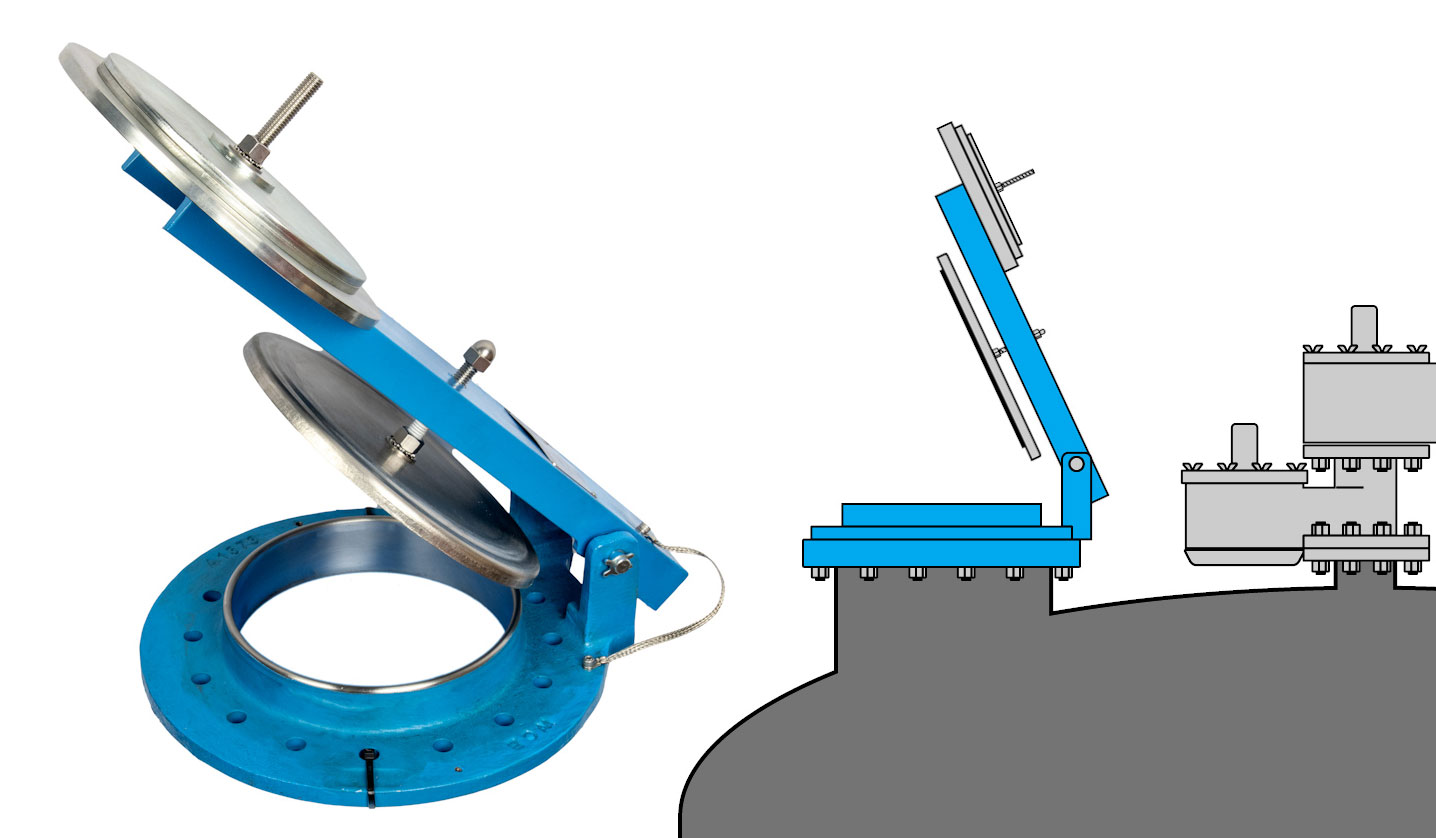

Emergency pressure relief valves are required on most storage tanks. The large opening is designed to provide quick relief if a sudden upset condition causes abnormal pressure inside the tank.

Emergency pressure relief valves are required on most storage tanks. The large opening is designed to provide quick relief if a sudden upset condition causes abnormal pressure inside the tank.

These valve are the last defense to prevent a storage tank from rupturing.

To discuss which type of relief valve is ideal for your operation, reach out to your local Kimray store.